Centralized Lubrication for Construction and Mining Equipment · 2014-10-10 · Centralized...

Transcript of Centralized Lubrication for Construction and Mining Equipment · 2014-10-10 · Centralized...

Centralized Lubrication for Construction andMining EquipmentExperience Productivity

Productivity is key in today’s global economy.Proper lubrication increases uptime andmakes maintenance routines simple.

Application-oriented Lubrication SystemsAlways the Right Answer

2

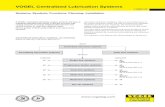

Construction Machines and VehiclesQuicklub Progressive Systems and BDS (Bearing Dosage System)

■ 203 or QLS pumps■ SSV divider valves

Mining EquipmentCentroMatic Single-line Systems■ PowerMaster or

FlowMaster pumps■ SL injectors

Helios Two-line Systems■ PowerMaster or

FlowMaster pumps■ VSG metering devices

Special Applications■ Lincoln hydraulic hammer lubri-

cation systems are characterized by their unique, durable construction with special pump elements for chisel pastes.

■ Lincoln lubrication systemsfor open gears – also as airless system!

■ Lincoln chain lubrication systems are available for all applications

Lincoln provides individual serviceoffers geared to all needs of theconstruction & mining industry. Asyour successful and competentprovider of centralized lubricationsystems, we are represented foryou and your customers in morethan 90 countries worldwide.

Lincoln’s Complete ServiceModules■ Engineering and consulting■ Telephone support ■ pre-assembled kits■ Installation and commissioning■ Training■ Maintenance programs

Contact Lincoln for yourlubrication requirements.Top in know-how, technology and service.

Lincoln’s Complete Service

BDS – Bearing Dosage SystemEfficient and Convenient

3

Hier steht Blindtext fürBildunterschriftHiersteht Blindtext für

Trouble-freeAll lubrication points are con-nected to one or more lubricant metering devices that can be centrally and easily supplied withgrease. Lube points which arenormally difficult to access cannow be serviced quickly andefficiently – guaranteeing the right quantity of lubrication forevery point.

FlexibleDepending on the environmentalconditions, you can choose theproper lubrication interval withouta tedious procedure. Frequent lubrication builds-up a greasecollar protection that inhibits waterand dirt from penetrating the bea-ring, preventing premature wear.

RetrofitPeak performance resulting fromprofessional lubrication is nowavailable at an affordable price.BDS is easy to retrofit. High-pressure Quicklinc plug-in fittings assure an easy and quick installa-tion. Due to its modular design,the BDS can be expanded or re-trofitted with an automatic lubrica-tion pump at any time.

Option

Schematic view of a typical BDS application

4

Quicklub Progressive SystemEconomical & Reliable

Reduce installation expenses with Lincoln’svalue-added, pre-assembled kits – a considerable advantage for OEMs!

Filling of Quicklub Pumps: Fast & Easy

Quicklub systems have been designed to meet the toughest lubrication requirements of con-struction machines and equipment.Their operation is based on thereliable progressive principle inwhich the lubricant is dispensedby a piston pump via progressiveplunger metering devices to thelubrication point. The lubricationoccurs in metered, timed intervalsat a maximum pressure of 350 bar.Thus the lubrication of bearingswith high back-pressures is alsoviable. The pump can serve up to

three independent circuits, eachwith its own pump element, consist-ing of numerous lubrication pointswith lubricant.

The system is easy to monitorand ensures that the right quanti-ty of grease is supplied to the lubrication points.

Quicklub System Benefits■ No corrosion of the light-

weight pump housing which is made of heavy-duty, fiber-reinforced resin.

■ The pump motor is protected against damage and moisture.

■ 2, 4, and 8-liter reservoir (optional with filling from the top and a lockable lid)

■ 5 different pump elements with fixed or variable output

■ Over-pressure valve - also equipped with an indicator and reservoir return

■ Fully-automatic option via integrated circuit board

■ Integrated display with touch pad and data logger function for the storage of important information such as operating time, faults or blockages and low-level.

■ Installation can be performed with threaded or 350 bar rated Quicklinc plug-in type fittings.

■ The high-precision progressive metering device in block-form allows pressure differences of 100 bar and eliminates leaks.

■ Multiple outlets of the pro-gressive metering device can easily be internally combined without the need of external connectors.

The QLS 301 is a completesystem. It comes pre-assembledwith everything a system needs:all kit components and a built-inover-pressure valve. No systemassembly is necessary as isusually required with commonlubrication systems. Lubricationpoints can be supplied with NLGI 2grease (QLS 301) or oil (QLS 311)directly from the pump at an affordable price. The long list ofstandard features is a remarkablecharacteristic of the QLS pump.

Ideal for■ Compact equipment with

few lubrication points■ Loading cranes■ Chain lubrication

It’s compactThe QLS is not only a pump. Itcontains all the components andall the functions needed to lubri-cate at a professional level. Thecompact design makes it easy tofind an installation location even in the most unthinkable places.

It’s sturdyThe QLS may be small, but itsperformance is powerful. It canhandle temperatures ranging from-25oC to +70oC, variable mountingpositions and high pressure wash-downs (IP6K9K, NEMA 4 protection).

It’s multi-taskingThe QLS features multi-tasking.An integrated circuit board op-timally controls pause and opera-ting times, monitors the function toensure lubricant is fed, and allowsadditional lubrication cycles to beinitiated. Settings are always at

your fingertips – all settings areperformed with ease via keypad.Settings and messages are shownon the built-in display window.

Standard Features■ Complete, compact system

ready to use “out of the box”■ Variable mounting position■ Integrated circuit board with

system function monitoring■ Integrated display and keypad■ Standard low-level control■ Built-in over-pressure valve■ Internal lubricant return

possibility■ Available with or without

attached divider block (up to 18 outlets)

■ Optional external fault contact

QLS 301 Power PackageThe Solution for the Supply of few Points

230 mm

191 mm

171 mm

5

6

Lincoln lubrication systems are designed to keep your machineryrunning, and to match your needs.Our systems help reduce yourmaintenance work. Depending onthe application, systems such astwo-line or single-line systems areall part of the Lincoln range.

Experience Productivity■ Decades of experience in

serving our customers■ Ensures process safety■ Quick payback■ Electric, pneumatic, hydraulic

or hand operated pumps■ Choice of reservoir, drum

or container type pumps■ Controllers and monitoring

capabilities that meet your needs.

Dependable Centralized Lubrication SyThe Answer for Large Machinery

The unique, rotary-activated re-ciprocating FlowMaster hydraulicpump offers users almost unlimi-ted opportunities. Its control mani-fold adjusts the amount of lubricantand the pressure required for eachapplication. The more hydraulic in-put available, the more output thepump can generate. The pump’scontrols match a machine’s hy-draulic output to the requirementsof its lubrication system. Extremetemperatures won’t stop the FlowMaster. It has passed rigorous

tests in both arctic and desert typeconditions. The pump works wellwith high-viscosity grease (NLGI 2and higher) at low temperaturesbecause it’s pump tube has a spe-cial pre-charge chamber and areciprocating cylinder designed toallow better priming. An inlet ball

check reciprocates with thepump cylinder allowing better grease flow to the pump chamber.

With its impressive output range,the FlowMaster handles everything from small mobile equipment withlow lubricant requirements to ma-chinery with the highest lubricantdemands.

FlowMaster pumps are designed to work with Quicklub progressivesystems, CentroMatic single-linesystems or Helios two-line systems.

FlowMaster Hydraulic PumpPowerful and Versatile

Container Supply System

FlowMaster with Hose Reel

ystems and Service

CentroMatic single-line systemsare used when the quantity oflubricant per point largely differs.The flexible, and direct operatingCentroMatic injector has a metal-

to-metal fit and spring-loaded metering pistons that can supplylubricant at high pressures (up to240 bar for grease and 68 bar foroil). Thus, oil and grease up toNLGI class 2 may be used.

Each independently operatedinjector serves only one lubricationpoint and may be accurately adjust-ed to deliver the precise amount oflubricant required. Provided thepump capacity is sufficient and thetube dimensions are appropriate,the system may be enlarged at any time.

Features■ Individual metering per

lubrication point■ Visual monitoring■ Lubricant supply at high

pressure■ Simplicity – easy to understand

and install■ Extra lubrication points

may easily be added■ Injectors also available in

stainless steel

The Flexible CentroMatic Single-Line System

Even in severe conditions such ascold or hot temperatures, dirty andwet environments, Helios Two-linesystems provide a reliable of meansof supplying lubricant to lubricationpoints. One centrally located pumpis capable of consistently supplyinga large number of points with lubri-cant. A higher flexibility in the

metering of lubricant is achieved incombination with Quicklub pro-gressive divider valves. Also the cost effective-ness speaks for a combined system. Helios two-line systems may be extended at any time.

Features ■ Perfect for widely dispersed

lubrication points■ A maximum system pressure of

400 bar enables the usage of smaller tube diameter.

■ Visual or electrical monitoring of each outlet pair

■ If one bearing should block-up, all other outlet pairs continue to supply lubricant.

■ Simple and individual metering of the lubricant – each outlet pair can be adjusted separately.

The Classic Helios Two-line System

7

Heinrich-Hertz-Str. 2-8D-69190 WalldorfGermany

Form W-016-A-0301© Copyright 2001 Printed in Germany

Tel. + 49.6227.33.0Fax + 49.6227.33.259www.lincolnindustrial.com

Prin

ted

on 1

00%

rec

yclin

g pa

per.

Automated LubricationThe Path to Cost Reduction

A lack of lubrication can bring yourmachines to a screeching halt. Theincreased cost of lubricants andmaintenance duties, coupled with a higher machine value, drives theneed for automatic, centralizedlubrication systems.

Harsh conditions such as dirt, con-tamination, water, and mechanicalloads cumulatively result in a highwear rate of bearings and frictionpoints.

Lubrication is therefore absolutelynecessary in order to provide theright protection. Lincoln lubricationsystems are a reliable means of regular lubrication.

While the machine is in operation,the lubricant is automatically deli-vered in time-controlled and mete-red quantities to all connectedpoints in the system. Lubrication “in motion” ensures that the lubri-cant is optimally and evenly distri-buted within the bearing, thus redu-cing friction and premature wear.

This is the ultimate form of lubrica-tion applied in a systematic manner.Increased safety is another impor-tant factor. Dangerously located orhard to reach lubrication points nolonger need to be accessed byhand. What’s more, is a reductionin maintenance costs by the elimi-nation of time consuming, tedioustasks and a reduction in lubricantconsumption.

Large Savings = Fast PaybackThe installation of a centralized lubrication system drastically redu-ces repair and maintenance costs.In addition lubricant consumption is cut and the life span of wearcomponents is increased. This automatically reduces downtimeand operation costs.

Automated vs. Manual Lubrication

Optimal

To much lubrication:product contamination

AutomatedLubrication

ManualLubrication

To little lubrication:friction & wear

Advantages of Automated Lubrication ■ Increased profits and

productivity■ Lower costs for repairs,

spare parts and lubricant■ Improved operating times;

less costly downtime■ Longer maintenance intervals■ Dramatic reduction in lubrication-

related bearing failures■ Significant contributions to

safety and the enviroment