Cellular light weight concrete block CLC technology

-

Upload

nileshajmera -

Category

Technology

-

view

5.370 -

download

9

description

Transcript of Cellular light weight concrete block CLC technology

FABRITE TECHNOLOGIESA SHWETKETU GROUP COMPANY

WELCOMES YOUTO

THE GREEN WORLD OFECO-FRIENDLY

CONSTRUCTION MATERIALSTECHNOLOGIES

FABRITE TECHNOLOGIESA SHWETKETU GROUP COMPANY

THE TURNKEY SOLUTION PROVIDERIN THE FIELD OF PLANT & MACHINERIES

FORCONSTRUCTION MATERIALS, CHEMICALS,

ADHESIVES,FILLING & PACKING MACHINES &

INDUSTRIAL AUTOMATION

ABOUT US

FABRITE TECHNOLOGIES is an High-tech Engineering company in field of Eco friendly Cellular Lightweight Concrete (CLC) Blocks Technology. CLC blocks are also know as Foam concrete blocks. We have over 15 years of experience in the field of CLC blocks.

We manufacture CLC Blocks Manufacturing equipments. The design of the equipments are based on German technology. We provide turnkey solutions for manufacture CLC blocks. With manufacturing CLC block equipments, we are providing installations and training to staff of the clients.

WHAT MAKES CLC BLOCKS POPULAR ?

LIGHT IN WEIGHT – It’s density ranges from 300 to 1800 Kg/m³. It is three times less in weight than clay or fly ash blocks. A 100mm thick CLC wall will be equivalent to dense concrete wall having more than 5 times thickness and almost 10 times in weight.

ECO - FRIENDLY– Foam concrete is an eco-friendly material as fly ash and other industrial wastes used in manufacturing blocks and thus protecting the environment. The production process or its use does not release any harmful effluents to the environment. This is also an alternative to plywood partitions and thus control deforestation.

SOUND INSULATION– Excellent for sound insulation.

WHAT MAKES CLC BLOCKS POPULAR? – CONT’D

LOWER WATER ABSORPTION – It absorbs

almost 50% less water as compared to concrete or clay bricks and helps to reduce cracks in the walls.

EASY TO HANDLE & INSTAL – They are easy and quick to install, thus minimizing construction cost. They require minimal maintenance, which reduces long term cost. Foam concrete blocks are saving in cement , sand, water, labour, energy and time.

WHAT MAKES CLC BLOCKS POPULAR? – CONT’D

THERMAL INSULATION– It keeps house cool in summer and warm in winter, saves energy/electricity for cooling and heating.

FIRE PROTECTION – A 100mm thick wall of density 1000 kg/m³, offers fire endurance by preventing heat transmission for almost 4 hours without releasing any Toxic fumes. Fire rating of cellular concrete are far superior to brickwork or dense concrete.

WHY TO INVEST IN FABRITE CLC PLANT ?

Lowest Initial Investment & Upgradable Quick returns & Highly Profitable Future product for Construction Industries Eco-Friendly Green Product Saves Precious & Fertile Agriculture Saving soil Less competition in market Easy to handle operations of the plant and can be

owned without major engineering expertise Very Low Electrical power required to run a plant Very Small area is required to setup a plant Minimum manpower Reduces masonry time & Construction Material &

Dead weight.

HOW CAN WE SERVE YOU ?

Technical Consultancy

Business Consultancy & Solutions

Supply of equipment for CLC block manufacturing

Supply of Specialise Additive & raw materials

Successful production and after sales services for one year.

HOW CAN WE SERVE YOU ?

Complete Turnkey projects

Time and materials Management consultancy

System Re-engineering

Product development

Facilities Management (technical).

TECHNICAL SPECIFICATIONS

Dimension of CLC blocks

Length : 400, 500 or 600 mm

Height : 200, 250 mm

Width : 100, 150, 200, 250, 300 mm

The average dimensions of the units, when determined as given in Appendix ‘A’ of IS:2185 (Part IV).

TECHNICAL SPECIFICATIONS – CONT’D

CLC blocks confirms to three grades

Grade A : These are used as load bearing units and shall have a block density in the range of 1200 kg/cum to 1800 kg/cum.

Grade B : These are used as non-load bearing units and shall have a block density in the range of 800 to 1000 kg/cum.

Grade C : These are used for providing thermal insulation and shall have a block density in the range of 400 to 600 kg/cum.

TECHNICAL SPECIFICATIONS – CONT’D

Physical Requirements

Type Density Minimum compressive

Strength N/mm³Maximum water

absorption % age

Grade A 1800160014001200

2517.5126.5

7.57.510.010.0

Grade B 1000800

3.52.5

12.512.5

Grade C 600400

1.00.5

15.015.0

COMPARISION BETWEEN BRICKS & BLOCKS

Construction of 100 sq feet 6 inch wall Rate 3400

Material Brick Wall Block Wall

Quantity Prices/unit Cost Quantity Prices/unit Cost

Brick/Block 600.00 8.50 5100.00 56.00 76.51 4284.43

Mortar

Cement (Bag)

3.38 275.00 928.13 1.28 275.00 350.63

Sand (brass) 0.15 5500.00 825.00 0.06 5500.00 330.00

Plaster

Cement (Bag)

4.00 275.00 1100.00 2.00 275.00 550.00

Sand (brass) 0.16 5500.00 880.00 0.08 5500.00 440.00

8833.13

5955.05

Savings (%) 32.6

WHY WE? – CONT’D

Others We, THE FABRITE

9 More man power required for production.

This technology reduces manpower by almost 5 times.

10 More storage space required due to longer curing period.

Less storage space required for steam curing.

11 Initial cost for plant setup is less. Initial cost for plant setup is high.

12 Manual system cause damage to the product.

Semi automatic system avoid damage to the product.

13 Low production capacity does not fulfill time bound project

requirement.

High production capacity fulfill project requirement satisfactorily.

14 ROI more than 7 years ROI within 3 to 4 years depending upon the project size.

WHAT IS THE INVESTMENT REQUIRED ?

Plant Size at 100%

production

Land in Acre

Investment cost in Lakh

Return in years

1 20 m³ 0.5 Rs. 37 lakh 3

2 50 m³ 1 Rs. 95 lakh 4

3 100 m³ 1.5 Rs.161 lakh 3

4 200 m³ 2 Rs.260 lakh 3 Note : 1. Land cost not considered as it would differ from region to region. 2. The above cost is inclusive of Machinery, Shed, Curing Chamber &

miscellaneous Civil work.

OPTIONS FOR GROWTH

Current plant capacity

Upgrading Plan

Investment in Lakh

% Incr ement of Original project

cost

50 m³ 100 m³ 39 24.22

100 m³ 200 m³ 94

36.15

PRODUCTION OF BLOCKS AS PER PLANT SIZE

Calculation for production of block per day as per plant size

Block size

Blocks Per m³

Production for 20m³

Production for 50m³

Production for 100m³

Production for

200m³

600X200X200 mm

44 880 2200 4400 8800

600X200X150 mm

55 1100 2750 5500 11000

600X200X100 mm

88 1760 4400 8800 17600

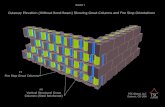

PLANT DESIGN FOR CLC PRODUCTION

PLANT SHED MAIN PLANT

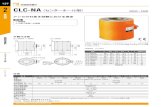

MACHINERIES MANUFACTURED BY FABRITE

FOAM GENERATORHIGH SPEED MIXTURE

MACHINERIES MANUFACTURED BY FABRITE

MOULD AND TROLLY WIRE CUTTING MACHINE

MACHINERIES MANUFACTURED BY FABRITE

PRIMARY MIXTURE COMPUTERISED CONTROL PANEL

MACHINERIES MANUFACTURED BY FABRITE

BATCHING SYSTEM MAIN PLANT

STEAM CURING SYSTEM

CURING CHAMBER CURING CHAMBER

CELLULAR LIGHTWEIGHT CONCRETE BLOCK

FINISHED Product

CLC BRICK & BLOCK SIZE

Popular block sizes are:600x200x200/100mm500x250x200/100mm500x400x100mmor as desired

REFERENCES:

Turnkey Projects and Consultancy

Plant size Place State

Anocrete 100 m³ Sahapur Maharashtra

Sony Associates 100 m³ Nasik Maharashtra

Shree Group Bricks & Block Co. 100 m³ Murbad Maharashtra

G P T Infra Project - 50 m³ Tripura

Global Infrastructure 30 m³ Bhubaneswar Orissa

Consultancy and upgrading of machinery

Plant size Place State

Ultracon 100 m³ Nasik Maharashtra

ECOBLOCK 50 m³ Ranchi Jharkand

Ultracon (Manual) 30 m³ Nasik Maharashtra

Alteck Cement product Pvt. Ltd. (Manual)

30 m³ Kolkata WB.

FABRITE TECHNOLOGIESA SHWETKETU GROUP COMPANY

REGD. OFF:202,MADHUVAN CHS LTD,SHRI KRISHNA COMPLEX,

NEAR SHRIRAM NAGAR, VIVA COLLEGE ROAD,VIRAR (WEST),TAL : VASAI, DIST : THANE

MAHARASHTRA – 401 303.

ADMN OFF:6,JM SHOPPING CENTRE,OPP. RLY.STATION,

VARTAK ROAD, VIRAR (WEST)TAL : VASAI, DIST : THANE, MAHARASHTRA -401 303.

HAND PHONE : +919370003009 EMAIL : [email protected]

THANK YOU