CDJ300 & CDJ600 - Trend Direct UK · CDJ300 & CDJ600-1-Dear Customer ... and fine height adjuster...

Transcript of CDJ300 & CDJ600 - Trend Direct UK · CDJ300 & CDJ600-1-Dear Customer ... and fine height adjuster...

CDJ300 &

CDJ600

MANU-CDJ v4.0 20/7/10 10:33 Page 50

CDJ300 & CDJ600

-1-

Dear Customer

Thank you for purchasing this Trend product, wehope you enjoy many years of creative andproductive use.

Please remember to return your guarantee cardwithin 28 days of purchase.

The following symbols are used throughout thismanual:

Denotes risk of personal injury, lossof life or damage to the tool in caseof non-observance of theinstructions in this manual.

Refer to the instruction manual ofyour power tool.

This unit must not be put into service until it hasbeen established that the power tool to beconnected to this unit is in compliance with2006/42/EC (identified by the CE marking on the power tool).

INTENDED USE

This accessory is intended to be used with aportable router with suitable cutter, guide bushand fine height adjuster fitted to cut dovetailjoints in natural timbers.

TECHNICAL DATA

Dovetail size 12.7mm

Max. workpiece width:

CDJ300 300mm

CDJ600 600mm

Workpiece thickness 12-25mm

Max. router base dia. 180mm

Guide bush size 15.8mm

Weight: CDJ300 6.2kg

CDJ600 11.3kg

CONTENTSTECHNICAL DATA _____________________1SAFETY____________________________2-3ITEMS ENCLOSED ____________________4DESCRIPTION OF PARTS_______________5ASSEMBLY– CDJ300 ___________________________6-7– CDJ600 ____________________________8– CDJ600 Sliding Edge Guide Stops _______9– Mounting to Workboard _______________10– Aligning Workpieces__________________10– Clamping Bars & Knobs_______________10– Template Comb Fitting & Adjustment ____11– Setting up the Router_________________12TEMPLATE SPECIFICATION _________14-17TIMBER PREPARATION– Lapped Dovetails ____________________18– Box Joints (Accessory) _______________19– Through Dovetails (Accessory) _________20OPERATION– Routing the Workpiece________________21– Standard 1/2”(12.7mm) Lapped D/tail _22-24– 1/2”(12.7mm) Rebated Lapped D/tail __25-26OPTIONAL ACCESSORIES– 1/4”(6.35mm) Lapped 01 ___________27-28– 1/4”(6.35mm) Rebated Lapped 01_______29– Box Comb 02 & 03 ________________30-31– 32mm Centre Dowel 04 ____________32-35– Through Dovetail 05 & 06___________36-38MAINTENANCE ______________________39ENVIRONMENTAL PROTECTION________39SPARE PARTS– Spare Parts List __________________40-43– Spare Parts Diagram ______________44-46TROUBLE SHOOTING_________________47

�If you require further safety advice,technical information or spare parts,please call our technical supportdepartment or visit www.trend-uk.com

MANU-CDJ v4.0 20/7/10 10:33 Page 1

-2-

CDJ300 & CDJ600

SAFETYWARNING:

Observe the safety regulations in theinstruction manual of the power tool to beused. Please read the followinginstructions carefully. Failure to do socould lead to serious injury. When usingelectric tools, basic safety precautions,including the following should always befollowed to reduce the risk of fire, electricshock and personal injury. Also observeany applicable additional safety rules.Read the following safety instructionsbefore attempting to operate this product.

PLEASE KEEP THESEINSTRUCTIONS IN A SAFE PLACE.

The attention of UK users is drawn to TheProvision and Use of Work EquipmentRegulations 1998, and any subsequentamendments.

Users should also read the HSE/HSCSafe Use of Woodworking MachineryApproved Code of Practice and GuidanceDocument and any amendments.

Users must be competent withwoodworking equipment before using ourproducts.

IMPORTANT NOTE:

Residual Risk. Although the safetyinstructions and operating manuals forour tools contain extensive instructions onsafe working with power tools, everypower tool involves a certain residual riskwhich cannot be completely excluded bysafety mechanisms. Power tools musttherefore always be operated withcaution!

General1. Disconnect power tool and attachment

from power supply when not in use,before servicing, when makingadjustments and when changingaccessories such as cutters. Ensureswitch is in “off” position. Alwaysensure cutter has stopped rotating.

2. Always mount the power tool,accessory or attachment in conformitywith the instructions. Only useattachment and accessories specifiedin the power tool manual. The tool orattachment should not be modified orused for any application other thanthat for which it was designed. Do notforce tool.

3. Keep children and visitors away. Donot let children or visitors touch thetool, accessory or attachment. Keepchildren and visitors away from workarea. Make the workshop child proofwith padlock and master switch.

4. Dress properly. Do not wear looseclothing or jewellry, they can becaught in moving parts. Rubber glovesand non-skid footwear is

recommended when workingoutdoors. Wear protective haircovering to contain long hair.

5. Consider working environment. Do notuse the product in the rain or in adamp environment. Keep work areawell lit. Do not use power tools neargasoline or flammable liquids. Keepworkshop at a comfortabletemperature so your hands are notcold. Connect machines that are usedin the open via a residual currentdevice (RCD) with an actuationcurrent of 30 mA maximum. Use onlyextension cables that are approved foroutdoor use.

6. The accessory or attachment must bekept level and stable at all times.

7. Keep work area clean. Clutteredworkshops and benches can causeinjuries. Ensure there is sufficientroom to work safely.

8. Secure idle tools. When not in use,tools should be stored in a dry andhigh or locked up place, out of reachof children.

9. For best control and safety use bothhands on the power tool andattachment. Keep both hands awayfrom cutting area. Always wait for thespindle and cutter to stop rotatingbefore making any adjustments.

10.Always keep guards in place and ingood working order.

11.Remove any nails, staples and othermetal parts from the workpiece.

12.Maintain tools and cutters with care.Keep cutters sharp and clean forbetter and safer performance. Do notuse damaged cutters. Followinstructions for lubricating andchanging accessories. Keep handlesdry, clean and free from oil andgrease.

13.Maintain accessories. Do not usedamaged accessories. Only useaccessories recommended by themanufacturer.

14.Check damaged parts. Beforeoperation inspect the attachment, thepower tool, the cable, extension cableand the plug carefully for signs ofdamage. Check for alignment ofmoving parts, binding, breakage,mounting and any other conditionsthat may effect its operation. Have anydamage repaired by an AuthorisedService Agent before using the tool oraccessory. Protect tools from impactand shock.

15.Do not use tool if switch does not turnit on or off. Have defective switchesreplaced by an Authorised ServiceAgent

16.Don't over reach. Keep proper footing

and balance at all times. Do not useawkward or uncomfortable handpositions.

17.Don’t abuse the cable. Never carrypower tool or accessory by cord orpull it to disconnect from the socket.Keep cord from heat, oil and sharpedges. Always trail the power cordaway from the work area.

18.Connect dust extraction equipment.If devices are provided for theconnection of dust extraction andcollection facilities, ensure these areconnected and properly used.

19.Check all fixing and fastening nuts,bolts and screws on power tool,attachment and cutting tools beforeuse to ensure they are tight andsecure. Periodically check whenmachining over long periods.

20.Stay alert. Watch what you are doing.Use common sense. Do not operatetools when you are tired, under theinfluence of drugs or alcohol.

21.Personal Protective Equipment (PPE)for eye, ear and respiratory protectionmust be worn. All PPE must meetcurrent UK and EU legislation.

22.Do not leave tools runningunattended. Do not leave tool until itcomes to a complete stop.

23.Always clamp workpiece beingmachined securely.

24.Only use cutting tools forwoodworking that meet EN847-1/2safety standards, and anysubsequent amendments.

25.Vibration levels. Hand held powertools produce different vibrationlevels. You should always refer to thespecifications and relevant Health &Safety Guide.

Routing Safety1. Read and understand instructions

supplied with power tool, attachmentand cutter.

2. Keep hands, hair and clothing clear ofthe cutter.

3. Remove adjusting keys andspanners. Check to see that keys andadjusting spanners are removed fromthe router tool, cutter and attachmentbefore turning router on. Make surecutter can rotate freely.

4. Noise. Take appropriate measures forthe protection of hearing if the soundpressure of 85dB(A) is exceeded.Routing sound pressure may exceed85dB(A), so ear protection must beworn.

5. Eye protection. Always wear eyeprotection in the form of safetygoggles, spectacles or visors toprotect the eyes.

MANU-CDJ v4.0 20/7/10 10:33 Page 2

-3-

CDJ300 & CDJ600

6. Respiratory protection. Wear a face ordust mask, or powered respirator.Dust masks/filters should be changedregularly.

7. Do not switch router on with the cuttertouching the workpiece. At the end ofthe cut, release the router plunge andallow spindle to stop rotating. Neveruse the spindle lock as a brake

8. The direction of routing must alwaysbe opposite to the cutter's direction ofrotation. Do not back-cut or climb-cut.

9. Check before cutting that there are noobstructions in the path of the router.Ensure there are no obstaclesbeneath workpiece when cutting fullthickness, and that a sacrificial worksurface is used.

Router Cutter Safety1. Cutting tools are sharp. Care should

be taken when handling them. Do notdrop cutters or knock them againsthard objects. Handle very smalldiameter cutters with extra care.Always return cutter to its packagingafter use.

2. Always use cutters with a shankdiameter corresponding to the size ofthe collet installed in your tool.

3. The maximum speed (n.max) markedon the tool, or in instructions or onpackaging shall not be exceeded.Where stated the speed range shallbe adhered to. Recommended speedsare shown in the Trend RoutingCatalogue and/or website.

4. Always use router cutters in a router.Drill and boring bits must not be usedin a router. Router cutters must onlybe used for the material cuttingapplication for which they aredesigned. Do not use on metal ormasonry.

5. Never use cutters with a diameterexceeding the maximum diameterindicated in the technical data of thepowertool or attachment used.

6. Before each use check that the cuttingtool is sharp and free from damage.Do not use the cutting tool if it is dull,broken or cracked or if in any otherdamage is noticeable or suspected.

7. Cutters should be kept clean. Resinbuild up should be removed at regularintervals with Resin Cleaner®. Theuse of a PTFE dry lubricant willreduce resin build up. Do not usePTFE spray on plastic parts.

8. When using stacked tooling (multi-blade, block and groover etc.) on aspindle arbor, ensure that the cuttingedges are staggered to each other toreduce the cutting impact.

9. Cutter shanks should be inserted intothe collet all the way to the line

indicated on the shank. This ensuresthat at least 3⁄4 of the shank length isheld in the collet. Ensure clampingsurfaces are cleaned to remove dirt,grease, oil and water.

10.Observe the correct assembly andfitting instructions in the routerinstruction manual for fitting the collet,nut and cutter.

11.Tool and tool bodies shall be clampedin such a way that they will notbecome loose during operation. Careshall be taken when mounting cuttingtools to ensure that the clamping is bythe shank of the cutting tool and thatthe cutting edges are not in contactwith each other or with the clampingelements.

12. It is advisable to periodically checkthe collet and collet nut. A damaged,worn or distorted collet and nut cancause vibration and shank damage.Do not over-tighten the collet nut

13.Do not take deep cuts in one pass;take several shallow or light passes toreduce the side load applied to thecutter and router. Too deep a cut inone pass can stall the router.

15. In case of excessive vibrations whilstusing the router stop immediately andhave the eccentricity of the router,router cutter and clamping systemchecked by competent personnel

15.All fastening screws and nuts shouldbe tightened using the appropriatespanner or key and to the torquevalue provided by the manufacturer.

16. Extension of the spanner ortightening using hammer blows shallnot be permitted.

17.Clamping screws shall be tightenedaccording to instructions provided bythe manufacture. Where instructionsare not provided, clamping screwsshall be tightened in sequence fromthe centre outwards.

Using Routers In A Fixed Position

1. Attention should be made to theHSE’s Safe Use of Vertical SpindleMoulding Machines Information SheetNo.18 and any revisions.

2. After work, release the router plungeto protect the cutter.

3. Always use a push-stick or push-blockwhen making any cut less than300mm in length or when feeding thelast 300mm of the cut.

4. The opening around the cutter shouldbe reduced to a minimum usingsuitably sized insert rings in the tableand closing the back fence cheeks orfitting a false fence on the back fence.

5. Whenever possible use a workholding device or jig to secure

component being machined. Ensureany attachment is securely fitted to theworkbench, with table surface atapproximately hip height.

6. Use a No-Volt Release Switch. Ensureit is fixed securely, easily accessibleand used correctly.

7. In router table (inverted) mode, standto the front right of the table. Thecutter will rotate anti-clockwise whenviewed from top so the feed directionis from the right (against the rotation ofthe cutter). In overhead mode, standto the front left of the machine tableand the feed direction is from the left.

8. Do not reach underneath table or putyour hands or fingers at any time inthe cutting path while tool is connectedto a power supply.

9. Never thickness timber between theback of the cutter and the backfence.

Useful Advice When Routing1. Judge your feed rate by the sound of

the motor. Feed the router at aconstant feed rate. Too slow a feedrate will result in burning.

2. Trial cuts should be made on wastematerial before starting any project.

3. When using some attachments e.g. arouter table or dovetail jig, a fineheight adjuster is recommended.

4. When using a template guide bush,ensure there is sufficient clearancebetween cutter tip and inside edge ofbush and that it cannot come intocontact with collet and nut. Ensurecutter and guide bush are concentric.

Router Cutter Repair/Maintenance1. Repair of tools is only allowed in

accordance with the manufacturersinstructions.

3. The design of composite (tipped) toolsshall not be changed in process ofrepair. Composite tools shall berepaired by a competent person i.e. aperson of training and experience, whohas knowledge of the designrequirements and understands thelevels of safety to be achieved.

4. Repair shall therefore include, e.g. theuse of spare parts which are inaccordance with the specification ofthe original parts provided by themanufacturer.

5. Tolerances which ensure correctclamping shall be maintained.

6. Care shall be taken that regrinding ofthe cutting edge will not causeweakening of the body and theconnection of the cutting edge to thebody.

Version 7.1 06/2006

MANU-CDJ v4.0 20/7/10 10:33 Page 3

CDJ300

-4-

ITEMS ENCLOSED

x1

x2

x4

x4

x4

x2

x2

x2

x2 nylon

x4

x4

x1

x1

x1

x2

x4

x2

x4

x4 silver

x1 2.5mm

x2

x1

x1

x4

For CDJ600 only

x2

x2

plusx2

x2

x2

x2 M6

x1

x1

x1

x1

ITEMS REQUIRED� Router with suitable collet size fitted.

� False base board.

� 2 x clamps.

� No. 2 Pozi Screwdriver.

� Hand tools.

MANU-CDJ v4.0 20/7/10 10:33 Page 4

CDJ300 & CDJ600

-5-

3

15

14

13

12

8

2

9

10

11

7

6

15

4

12

34

5

18

17

16

9

Jig body

Front clamp bar

Top clamp bar

Edge guide

Clamp bar knob

Template comb

Template comb

bracket

Comb adjustment

lock knob

Comb adjustment

lock

Bench rubber feet

Bench fixing hole

Guide bush

15.8mmØ

Guide bush fixing

screw

Dovetail cutter 104°

x 12.7mmØ

Edge guide andscrew storagelocation

For CDJ600Sliding edge stop

Sliding edge stop

locking knob

Sliding edge stop

scale

10

9

8

7

6

5

4

3

2

1

17

18

16

15

14

13

12

11

DESCRIPTION OF PARTS

MANU-CDJ v4.0 20/7/10 10:33 Page 5

ASSEMBLY CDJ300

4.0mm

nylon

2.5mm

U1F1

2.5mm

CDJ300

-6-

Fit edge guides in positionF1 & U1 (see opposite)

The templates are

supplied with a

protective oil coating

which should be

removed before use.

MANU-CDJ v4.0 20/7/10 10:33 Page 6

CDJ300

-7--7-

9.5mm

F1 F2

U1 U2U2 U1

F2 F1

Top view ofjig

Front viewof jig

CDJ300 Template

Edge Guide Holes

The edge guides are usedto position the workpiecewithin the jig. There arefour holes in each jig.The CDJ300 has fixededge guides, thereforethese will dictate whethera whole or part pin will becut on the workpiece. Thisis called the offset.User made spacers couldbe used to pack out fromboth edge guides to equalthe joint and givesymmetrical joint.

The distance between U1and U2 is 9.5mm. This isfor rebated drawer fronts.

MANU-CDJ v4.0 20/7/10 10:33 Page 7

CDJ600

-8-

12

34

5

U1

F1

12

34

5

4.0mm

nylon

54

32

10

ASSEMBLY CDJ600

12

34

5

54

32

1

6

2.5mm

2.5mm

2.5mm

x4

Fit edge guides in positionF1 & U1 (see opposite)

The templates are

supplied with a

protective oil coating

which should be

removed before use.

MANU-CDJ v4.0 20/7/10 10:33 Page 8

CDJ600

-9-

U2 U11 2 3 4 5

9.5mm

F2 F1

F1 F2

U1 U2

CDJ600 Sliding

Edge Guide Stops

Adjustment

The CDJ600 has slidingstops. This enables theworkpiece to be centred,giving a symmetricaldovetail joint.The sliding stop has ascale to allow a moreprecise offset to becalculated to ensuresymmetrical joints.

Loosen knob. Movesliding stop awayfrom centre of jig

Loosely fit workpieceunder top clamp.

Fit comb assemblyand tighten knobs

Move workpiece sothat edge lines upwith edge of sighthole on template - forlapped, dowel andthrough dovetailsonly. For othertemplates seeappropriate section.

Lock top clamp barknobs. Slide slidingstop towards edge ofworkpiece and lock inposition with knob.

Repeat for other side.

CDJ600 Middle

Clamp Bar Knobs

Middle clamp bar knobsare provided when usingworkpiece less than305mm. This ensuresworkpiece is heldsecurely.

When using workpieceover 305mm wide themiddle knobs must beremoved.

Top view ofjig

Side viewof jig

1

2

3

4

5

6

Workpiece

MANU-CDJ v4.0 20/7/10 10:33 Page 9

CDJ300 & CDJ600

-10-

Mounting to

Workboard

Fix the jig body to aworkboard with the screwssupplied.

Aligning

Workpieces

Ensure top of frontworkpiece is flush withback workpiece using asquare.

Clamping Bars

and Knobs

Do not overtightenclamping knobs. Theclamping bar must betightened parallel to the jig.If working to one side of jigit is advisable to releasethe opposite side clampingknob first.

Requires:

No.2 Pozi®

Screwdriver

(not supplied)

No.2

x4

CDJ300 & CDJ600

All drawings show

left hand edge

guides being used.

The same

procedure is

carried out for

right hand edge

guides.

Please note that

dimensions are

approximate.

All cutter depths

are as a guide

only.

MANU-CDJ v4.0 20/7/10 10:33 Page 10

CDJ300 & CDJ600

-11--11-

170mmØ

60mmØ

50mmØ

Template Comb

Fitting and

Adjustment

To adjust depth oftemplate comb andtherefore pin socket,loosen adjustmentstop using a hex key.

Turn adjustment stoptowards jig body fordeeper sockets.

To set up the positionfor the template comb,a setting line is drawnon a workpiece. Thisis used to line up theback of the templatecomb.

One revolution equals1mm movement.

Once set lockadjustment stop withhex key.

Ensure template combis always parallel toworkpiece.

A packing piece the samethickness as the timberbeing clamped in the topclamp should be used tosupport the template comb.

Guide Bushes

The bushes supplied withthe jig and accessories area standard Trend pattern.They will fit most Trend,Elu and DeWalt routersdirectly.

For other makes andmodel of router a sub-basemay be required to allowthe guide bush to be fitted.The Ref. UNIBASE hasbeen designed for use witha variety of routers; it alsoensures concentricitybetween cutter and guidebush ensuring accuracy.

For Trend T3/T4 it isrecommended that theRef. UNIBASE is used toprovide greater accuracyand support to the routerbase.It also ensures that theguide bush spigot willproject sufficiently fromthe router base,alternatively a longerspigot guide bush issupplied for certaintemplate accessories.

Settingline

1

2

3

4

5

6

50mmø

60mmø

170mmø

MANU-CDJ v4.0 20/7/10 10:33 Page 11

CDJ300 & CDJ600

-12--12-

Setting up the

Router

Isolate router frompower supply.

Fit relevant guidebush to router. Referto table in eachappropriate section.

Fit fine height adjuster(if available) to router.(Not required fordowel jointing.)

Plunge the router sothat the collet nearlytouches guide bush tominimise protection ofthe cutter.

Fit router cutter intorouter.

Set cutter height.Refer to table inrelevant sections.

1

2

3

4

5

6

MANU-CDJ v4.0 20/7/10 10:33 Page 12

CDJ300 & CDJ600

-13-

Making a Router

Stand Block

As the cutter should not beretracted into the routerwhen dovetailing, a usefulaid is a Router StandBlock.This is simply a piece ofscrap timber with a holelarge enough to take theprotruding guide bush andcutter. This will allow therouter to stand up safelybetween operations.

MANU-CDJ v4.0 20/7/10 10:33 Page 13

CDJ300 & CDJ600

-14--14-

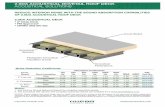

9.5mm (3/8”)

12.7mm (1/2”)

6.3mm (1/4”)

max.20mm

12.7mm (1/2”)

6.9mm

21.5mm

min.12mm

max.25mm

min.8mm

max.12mm

min.8mm

max.20mm

25.4mm

11.3mm

STANDARD

1/2” (12.7mm) Lapped Dovetail

OPTIONAL ACCESSORIES

CDJ300/01

CDJ600/01

1/4” (6.35mm) Lapped Dovetail

CDJ300/02

CDJ600/02

1/2” (12.7mm) Box Joint

TEMPLATE SPECIFICATION

MANU-CDJ v4.0 20/7/10 10:33 Page 14

CDJ300 & CDJ600

-15--15-

10mmØ x 10mm

Silver

10mmØ x 10mm

Silver

15.8mmØ x 6mm*

12.7mm

12.7mm

104°

6mm

6.9mm98°

C041A

C154

Cutters RequiredCDJ300 CDJ600

7.8mmØ x 4mm

12.55mm

25mm

C021A

* This bush should also be used with the T3/T4 (and similar routers) and accessories: 1/2” comb, 32mm dowel and 1/2” through templates.

15.8mmØ x 6mm

Green

28.7mmØ x 4mm

Green

20.1mmØ x 10.5mm

Green

10mmØ x 10mm

Silver(from CDJ600 x2)

19.7mmØ x 6mm

Red

17.3mmØ x 31mm

Red

11.3mmØ x 8.5mm

Red

11mmØ x 33mm

Red

x1 x2 x2

x1x2 x2

x1 x2 x2

x2 x2

x2

15.8mmØ x 4mm

MANU-CDJ v4.0 20/7/10 10:33 Page 15

CDJ300 & CDJ600

-16-

20mm

8mm

16mm

min.8mm

max.15mm

min.17mm

max.25mm

min.8mm

max.17mm

max.25mm

CDJ300/03

CDJ600/03

8mm Box Joint

CDJ600/04*32mm Dowel

CDJ300/05

CDJ600/05

1/2” (12.7mm)Through Dovetail

CDJ600/06

3/4” (19.1mm)Through Dovetail

15mm

32mm

12.7mm (1/2”)

20mm

19.1mm (3/4”)

Heavy Duty

Routers Only.

OPTIONAL ACCESSORIES CONTINUED

*While stocks last

MANU-CDJ v4.0 20/7/10 10:33 Page 16

16.4mmØ x 6mm

Violet

CDJ300 & CDJ600

-17-

8mm

25mm

C012A

8mm

25mm

C012A C178

D

C

D C Ref.

3mm 14mm C180

5mm 35mm C174

6mm 35mm C175

8mm 35mm C176

10mm 35mm C177

12.7mm (1/2”)

20mm

12.7mm (1/2”)

25mm

C021 C179

19mm

25mm

98°

97°

Cutters Required

11.1mmØ x 4mm

15.8mmØ x 4mm

22mmØ x 4mm

15.8mmØ x 4mm

x.m

x.m

11.1mmØ x 5.5mm

* For use with the T3/T4 (and similar routers)

* For use with the T3/T4 (and similar routers)

14mmØ x 6mm

Blue

21mmØ x 25mm

Blue

CDJ300 CDJ600

11.1mmØ x 5.5mm*

11.1mmØ x 4mm

15.8mmØ x 4mm

11.5mmØ x 6mm

Grey

13mmØ x6mm

Grey

21.9mmØ x 5.5mm

Brown

10mmØ x 10mm

Silver(fromCDJ600 x2)

12.4mmØ x 10.5mm

Grey

10mmØ x 10mm

Silver (from CDJ600 x2)

10mmØ x 10mm

Silver(from CDJ600 x2)

x1

x1

x1

x1

x1

x1

x1

x1

x2

x2

10mmØ x 26mm

Blue

x2

x2

x2

*

MANU-CDJ v4.0 20/7/10 10:33 Page 17

CDJ300 & CDJ600

-18--18-

A4A3

A1

A2

B4

B3

B1 B2

A4 A3

A1 A2

B4 B3

B1 B2

TIMBER

PREPARATION

It is important to plan yourwork before starting tosave set-up time andavoid costly mistakes.Both sides of the jig canbe used to make joints. Itis advisable however toclamp the workpiece toone side of the jig. Thisensures it is clampedsecurely.

Lapped Dovetails

When lapped dovetailinglabel the pieces as front,back, and sides. Markfaces as inside and out.

Label the dovetail piecesas shown, A parts will beclamped under frontclamp bar, B pieces undertop clamping bar. Evennumbers against left-handedge guide odd numbersunder right hand edgeguides.

Face sides must betowards jig body.

For drawers the front isthicker than the sides.

Before jointing the actualworkpiece make trial cutsin pieces of waste timber,the same thickness as theworkpieces in order totest depth of pin sockets.

Ensure all pieces are cutto size and checked forsquareness.

1/2” (12.7mm) Lapped Dovetail Template(21.5 mm pitch with 3mm offset line)

No. of whole tails1 2 3 4 5 6 7 8 9...

21.5 43 64.5 86 107.5 129 150.5 172 193.5Optimum width of timber in mm

ie Pitch x No. of tails = Width (when 3mm offset line used).

1/4” (6.35mm) Lapped Dovetail Template(11.3 mm pitch with 2mm offset line)

No. of whole tails1 2 3 4 5 6 7 8 9

11.3 22.6 33.9 45.2 56.5 67.8 79.1 90.4 101.7Optimum width of timber in mm

ie Pitch x No. of tails = Width (when 2mm offset line used).

MANU-CDJ v4.0 20/7/10 10:33 Page 18

CDJ300 & CDJ600

-19-

B4

B3

B1

B2

A4

A3

A1 A2

A4

A3

B1 B4

A1

A2

B2 B3

Cut all four pieces for thebox to the exactdimensions of the finalunit.

Make sure ends areperfectly square and exactwidths.

The workpieces areclamped together for thecut. Ensure the workpieceface sides are towards thefront of the jig.

Before joining the actualworkpiece make a trial cutin waste scrap timber.

Box Joint Waste

Piece

For box joints, the wastepiece must be 5mmthicker than the workpiece. It should be longenough to be heldsecurely by the clampbars. The width should be atleast 5mm wider than workpiece. The waste piecereduces likelihood ofbreakout.

8mm Comb Template(16mm pitch with symmetrical sockets)

No. of sockets1 2 3 4 5 6 7 8 9...24 40 56 72 8 104 120 136 152

Optimum width of timber in mmie Pitch x No. of sockets + 8mm = Width

1/2” (12.7mm) Comb Template(25.4mm pitch with Symmetrical Sockets)

No. of Sockets1 2 3 4 5 6 7 8 9...

38.1 63.5 88.9 114.3 139.7 165.1 190.5 215.9 241.3Optimum width of timber in mm

ie (Pitch x No. of Sockets) + 12.7mm = Width.

x + 5mm

xWaste piece

The waste piece for

box joints must be

5mm thicker than the

workpiece to prevent

the cutter touching

the jig body.

Workpiece

Box Joint

(Optional Accessory)

MANU-CDJ v4.0 20/7/10 10:33 Page 19

CDJ300 & CDJ600

-20-

B4

B3

B1

B2

A4

A3

A1 A2

A4 A3

A1 A2

B3

B2

B4

B1

1/2” (12.7mm) Through Dovetail Template(25.4mm pitch with 15.8mm offset line)

No. of whole tails1 2 3 4 5 6 7 8 9...

31.6 57 82.4 107.8 133.2 158.6 184 209.4 234.8Optimum width of timber in mm

ie Pitch x No. of Tails = Width (when 15.8mm offset line used)

3/4” (19mm) Through Dovetail Template(38mm pitch with 25.3mm offset line used)

No. of whole tails1 2 3 4 5 6 7...

50.6 88.6 124.6 164.6 202.6 240.6 278.6Optimum width of timber in mm

ie (Pitch x No. of Tails) = Width (when 25.3mm offset line used

Through Dovetails

(Accessory)

When through dovetailinglabel the pieces as front,back, and sides. Mark facesas inside and out.

Label the dovetail pieces asshown. A parts will beclamped under front clampbar and routed first withdovetail cutter. B pieces areclamped under front bar androuted with a straight cutter.

When routing pins - outsidefaces (face side) must beaway from jig body (B1,B2,B3, B4).

When routing tails - outsidefaces (face side) must betowards the jig body (A1, A2,A3, A4).

Before joining the actualworkpiece make a trial cut inwaste scrap timber.

Ensure all pieces are cut tosize and checked forsquareness.

Through Dovetail

Waste Piece

For comb and throughdovetail joints, the wastepiece of workpiece must be5mm thicker than the workpiece. It should be longenough to be held securelyby the clamp bars. The width should be at least5mm wider than work piece.The waste piece reduceslikelihood of breakout.

x + 5mm

x

Workpiece

Waste piece

The waste piece for

through dovetail

joints must be 5mm

thicker than the

workpiece to prevent

the cutter touching

the jig body.

MANU-CDJ v4.0 20/7/10 10:33 Page 20

CDJ300 & CDJ600

-21-

OPERATION

Routing the

Workpiece

For Lapped Dovetail

Joints

Make one very light cut fromright to left, cutting only thefront edge. This will preventbreakout.

Carefully rout from left to rightfollowing the guide bush ineach of the template combslots (see illustrations onright).

For Box Joints

Carefully rout from left to rightfollowing the guide bush inthe each of the slots. Ensurethe guide bush is kept againstthe left hand side of thetemplate comb fingers on allcuts.

Cut full depth in one passwhere possible. If timber ishard, achieve depth in anumber of passes.

For Dowel Joints

For dowel hole in face ofworkpiece, the depth of cutwill be half thickness ofworkpiece.

For dowel hole in end ofworkpiece, depth will need toallow for remainder of dowellength.

For Through

Dovetails

Carefully rout from left to rightfollowing the guide bush inthe each of the template slots.

Cut full depth when using thedovetail cutter. If timber ishard take fine cuts.

Preventing Tear Out

This occurs when cuttingacross the grain and can beovercome by scribing theends of the timber with amarking knife or gauge at theheight of the cutter.

Setting the Depth

of Cut in the Future

To ease setting up of thecutter height in the future,rout another joint and keepthis piece to set the cutterdepth in future.

Do not lift the router

from the template

with the guide bush

engaged in the slots

as damage to the

template will occur.

MANU-CDJ v4.0 20/7/10 10:33 Page 21

CDJ300 & CDJ600

-22-

Both parts of joint arerouted at same time.

(Drawing shown CDJ300only.)

Set Up

Fit edge guides into holes according totable.

Draw a 15mm settingtemplate line onto theworkpiece.

Place one piece of workpiece into front clamp and push tight against edge guide.

Tighten clamp bar knobs to hold workpiece.

Place other piece ofworkpiece under topclamp and buttagainst workpiecealready fitted andagainst edge guide.

Tighten top clampknobs.

6

5

4

3

2

1

Size Colour Hole Dia. Dia. Setting Line Depth

CDJ300/CDJ600 10Øx10 Silver U1 15.8 12.7 15 171/2” Standard 10Øx10 Silver F1

15mm

Dimensionsshown in mm.

STANDARD 1/2" (12.7MM)

LAPPED DOVETAILS

MANU-CDJ v4.0 20/7/10 10:33 Page 22

CDJ300 & CDJ600

-23-

15mm

13

12

11

10

9

8

7

Ensure that the cutter

does not foul the

comb brackets before

and after cutting the

joints.

Ensure top of frontworkpiece is flushwith the backworkpiece using asquare.

Fit brackets totemplate comb withcountersunk holesuppermost and withslots to front.

Fit template combassembly onto jig.

Adjust comb positionto line up back oftemplate slots to the15mm line.

Fit guide bush torouter according totable.

Fit dovetail cutter intorouter according totable.

Adjust the height ofthe cutter accordingto table.

MANU-CDJ v4.0 20/7/10 10:33 Page 23

CDJ300 & CDJ600

-24-

Routing the Joint

(Tail and Pin

Socket)

Place the router ontothe template combensuring the cutterdoes not touch theworkpiece

Switch on.

Make one very lightcut from right to left,cutting only the frontedge.

Carefully rout from leftto right following theguide bush in theeach of the slots.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove templatecomb assembly.

Remove workpiecefrom jig.

Test fit joint.22

21

20

19

18

17

16

15

14

Joint too loose = increase depthadjustment of cutter.

Joint too tight = decrease depthadjustment of cutter.

Dovetail joint too shallow = move template combtowards the jig body.

Dovetail joint too deep = move template combaway from the jig body.

MANU-CDJ v4.0 20/7/10 10:33 Page 24

CDJ300 & CDJ600

-25-

Each part of joint is routedseparately. (Drawings showCDJ300 only.)

Set Up

Fit edge guides intoholes according to table.

Fit brackets to templatecomb with countersunkholes uppermost andwith slots to front.

For Drawer Front

Rout a 9.5mm wide by11.1mm deep rebateonto the edges of theworkpiece.

Draw a setting templateline 15mm back from the9.5mm rebate shoulder.

Place a packing piece of9.5mm thick timber intofront clamp and pushtight against edge guide.

Tighten front clamp barknobs to hold workpiece.

Place drawer front undertop clamp and buttagainst packing piecealready fitted, and edgeguides.

Tighten top clamp knobs.

Remove packing piecefrom front clamp.

Fit template combassembly onto jig.

Adjust comb position toline up back of templateslots to the 15mm line.

Fit guide bush to router,according to table.

Fit dovetail cutter intorouter according to table.

Adjust the height of thecutter according to table.14

13

12

11

10

9

8

7

6

5

4

3

2

1

9.5mm

11.1mm(7/16")

9.5mm(3/8")

INSIDE

Size Colour Hole Dia. Dia. Setting Line Depth

CDJ300/CDJ600 10Øx10 Silver U2 15.8 12.7 15 171/2” Rebated 10Øx10 Silver F1

Dimensionsshown in mm.

1/2" (12.7MM) REBATED LAPPED

DOVETAIL USING STANDARD TEMPLATE

MANU-CDJ v4.0 20/7/10 10:33 Page 25

-26-

CDJ300 & CDJ600

Routing Pin Socket

in the Drawer Front

Place router ontotemplate comb.

Switch on.

Carefully rout from leftto right following theguide bush in the eachof the slots.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove templatecomb assembly.

Remove workpiecefrom jig.

For Drawer Sides

Place drawer sideworkpiece into frontclamp and push tightagainst edge guide.

Tighten front clamp barknobs to holdworkpiece.

Place packing pieceunder top clamp andbutt against workpiecealready fitted. Packingpiece must be 5mmthicker than theworkpiece.

Ensure top of frontworkpiece is flush withback workpiece usinga square.

Tighten top clampknobs.

Fit template combassembly onto jig.

Routing Tails on

27

26

25

24

23

22

21

20

19

18

17

16

15

Drawer Sides

Place router ontotemplate comb.

Switch on.

Make one very light cutfrom the right to the left,cutting only the frontedge.

Carefully rout from left toright following the guidebush in the each of theslots.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove template combassembly.

Remove workpiece fromjig.

Test fit joint.

29

36

35

34

33

32

31

30

28

Joint too loose = increase depthadjustment of cutter.

Joint too tight = decrease depthadjustment of cutter.

Dovetail joint too shallow = move template combtowards the jig body.

Dovetail joint too deep = move template combaway from the jig body.

MANU-CDJ v4.0 20/7/10 10:33 Page 26

-27-

CDJ300 & CDJ600

7.5mm

7.5mm

Both parts of joint are routedat same time. (Drawingsshow CDJ300 only.)

Set Up

Fit edge guides intoholes according to table.

Draw a 7.5mm settingtemplate line onto thepiece of workpiece.

Place one piece ofworkpiece into frontclamp and push tightagainst front edge guide.

Tighten clamp bar knobsto hold workpiece.

Place other piece ofworkpiece under topclamp and butt againstworkpiece already fitted.

Tighten top clamp knobs.

Ensure top of frontworkpiece is flush withback workpiece using asquare.

Fit brackets to templatecomb with countersunkholes uppermost andwith slots to front.

Fit template combassembly onto jig.

Adjust comb position toline up back of templateslots to the 7.5mm line.

Fit guide bush to routeraccording to table.

Fit dovetail cutter intorouter according to table.

* From CDJ600 jig.

12

11

10

9

7

8

6

5

4

3

2

1

Size Colour Hole Dia. Dia. Setting line DepthCDJ300/01 15.8Øx6 Green U1 7.8 6.0 7.5 111/4” Lapped 28.7Øx4 Green F2

CDJ600/01 20.1Øx10.5 Green U1 7.8 6.0 7.5 111/4” Lapped 10Øx10* Green F1

Dimensionsshown in mm.

OPTIONAL ACCESSORIES

1/4" (6.35MM) LAPPED

DOVETAIL TEMPLATE

MANU-CDJ v4.0 20/7/10 10:33 Page 27

-28-

CDJ300 & CDJ600

Adjust the height ofthe cutter accordingto table.

Routing the Joint

(Tail and Pin

Socket)

Place router ontotemplate comb.

Switch on.

Make one very lightcut from right to left,cutting only the frontedge.

Carefully rout fromleft to right followingthe guide bush in theeach of the slots.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove templatecomb assembly.

Remove workpiecefrom jig.

Test fit joint.

15

22

21

20

19

18

17

16

14

13

MANU-CDJ v4.0 20/7/10 10:33 Page 28

-29-

CDJ300 & CDJ600

Joint too loose = increase depthadjustment of cutter.

Joint too tight = decrease depthadjustment of cutter.

Dovetail joint too shallow = move template combtowards the jig body.

Dovetail joint too deep = move template combaway from the jig body.

Fit edge guide into holeaccording to table.

For drawer front rout a9.5mm wide by 6.35mmdeep rebate.

Draw a setting templateline 7.5mm back from9.5mm rebate shoulder.

Routing Tails on

Drawer Sides

Place router ontotemplate comb.

Switch on

Carefully rout from leftto right following theguide bush in the eachof the slots.

Switch off router andremove from jig.

Examine each of theslots to ensure all thematerial has beencleanly routed.

Remove template combassembly

Remove timber from jig.

Test fit joint.

* From CDJ600 jig.

11

10

9

8

7

6

5

4

3

2

1

Size Colour Hole Dia. Dia. Setting line DepthCDJ300/01 15.8Øx6 Green U1 7.8 6.0 7.5 111/4” Rebated 28.7Øx4 Green U2

CDJ600/01 20.1Øx9.5 Green U1 7.8 6.0 7.5 111/4” Rebated 10Øx10* Green U2

Dimensionsshown in mm.

For Drawer Fronts

See points toon pages 25 to 26.

For Drawer Sides

See points to on page 26.

For Routing Tails on

Drawer Sides

See points to on page 25 to 26.

3628

2722

214

1/4” (6.35MM) REBATED LAPPED

DOVETAIL TEMPLATE

MANU-CDJ v4.0 20/7/10 10:33 Page 29

-30-

CDJ300 & CDJ600

Both parts of joint arerouted at same time.(Drawings show CDJ300only.)

Set Up

Fit edge guides intoholes, according totable.

Place one piece ofworkpiece into frontclamp and push tightagainst edge guide,place second pieceof workpiece in frontof first piece andpush tight againstedge guide

Tighten front clampbar knobs to holdworkpiece

Place waste piece ofworkpiece under topclamp and buttagainst workpiecealready fitted. Wastepiece must be 5mmthicker thanworkpiece.

Tighten top clampknobs

Ensure top of bothfront workpieces areflush with packingpiece using asquare.

Fit brackets totemplate comb withcountersunk holesuppermost and withslots to front

Turn adjustmentstops until they aretight against thebody.

Fit template combassembly onto jig.

Fit guide bush torouter according totable.

11

10

9

8

7

6

5

2

4

3

1

F2

F1

Non-symmetricalEven number of

pins/sockets

ForCDJ300/03

Comb Size Colour Hole Dia. Dia.

CDJ300/02 1/2” 19.7Øx6 Red F1 15.8 12.5517.3Øx31 Red F2

CDJ600/02 1/2” 11.3Øx8.5 Red F1 15.8 12.5510Øx33 Red F2

CDJ300/03 8 14Øx6 Blue F1 11.1 8.021Øx25 Blue F2

CDJ600/03 8 10/26Ø Blue F2 11.1 8.0

Dimensionsshown in mm

Fit straight cutter intorouter according totable.

Adjust the height ofthe cutter to suitworkpiece thickness,this can be achievedby drawing thethickness of the pinboard onto the tailboard and vice versa.

12

BOX COMB TEMPLATE

Waste piece must be

5mm thicker than

workpiece.

MANU-CDJ v4.0 20/7/10 10:33 Page 30

-31-

CDJ300 & CDJ600

Routing the Box

Joint

Place router ontotemplate comb.

Switch on.

Carefully rout from leftto right following theguide bush in each ofthe slots. Keep theguide bush against theleft hand side of thecomb finger, on all cuts.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove template combassembly.

Remove workpiece fromjig.

Test fit joint.

For CDJ600

As above but to set up slidingedge guide as follows:-

Fit same edge guides.

Draw a centre line onworkpiece and draw a1.6mm offset line to leftand right of centre line.

Place one piece ofworkpiece into frontclamp.

Fit template comb to jig.

For left hand side of jigalign right hand 1.6mmline to left hand side of atemplate comb fingerand vice versa for otherend of jig.

Tighten front clampknobs.

Slide edge guideagainst edge of timber.

Tighten edge guidelocking knob.

5

8

7

6

4

3

2

1

20

19

18

17

16

15

14

13

1.6mmoffset

Box comb joint too shallow = increase depthadjustment ofcutter

Box comb joint too deep = decrease depthadjustment ofcutter

1.6mmoffset line

LH

1.6mmoffset line

RH

MANU-CDJ v4.0 20/7/10 10:33 Page 31

-32-

CDJ300 & CDJ600

CL

Each part of joint is routedseparately. (Drawings showCDJ300 only.)

Set Up

Fit edge guides intoholes according totable.

Draw centre line onend of workpiece.

Place marked upworkpiece into frontclamp and push tightagainst front edgeguide.

Repeat operation forright hand side.

Tighten clamp barknobs to holdworkpiece.

Place other piece ofworkpiece under topclamp and butt againstworkpiece alreadyfitted.

Tighten top clampknobs.

Ensure top of frontworkpiece is flush withback workpiece usinga square.

Fit screws intobrackets fromunderside and tightenwith hex key.

Fit brackets totemplate comb with32mm centre dowelholes towards front.Use inner slots forCDJ300/04 and outerslots for CDJ600/04.Fit washer and knobsto secure. Leaveknobs loose.

* From CDJ600 jig.

10

9

8

7

6

5

4

3

2

1 Comb Size Colour Hole Dia. Dia.

CDJ300/04 32mm 11.5Øx6 Grey U1 15.8 3-1013Øx6 Grey F2

CDJ600/04 32mm 10Øx10* Silver U1 15.8 3-1012.4Øx10.5 Grey F2

Dimensionsshown in mm.

DOWEL JOINT TEMPLATE

MANU-CDJ v4.0 20/7/10 10:33 Page 32

-33-

CDJ300 & CDJ600

Fit two screws intofence bar and then fitassembly to two innerslots on templateusing two washersand knobs. Leaveknobs loose.

Turn adjustment stopsuntil they are tightagainst jig body.

Fit template combassembly onto jig.Tighten combadjustment knobs.

Adjust comb positionso that sight marks ondowel holes line upwith centre line onworkpiece. Tightenthe four bracketknobs.

To create symmetrical

dowel joints, it may be

necessary to move

timber away from the

edge guides. A packing

piece must be used.

14

13

12

11

CL

For CDJ600

For CDJ300

MANU-CDJ v4.0 20/7/10 10:33 Page 33

-34-

CDJ300 & CDJ600

Adjust position of fencebar so that it touchesthe edge of theworkpiece in the frontclamp. Tighten fencebar knobs.

Fit guide bush torouter.

Fit suitable diameterrouter dowel drill intorouter.

Set the plunge depthon the router.

Routing the Dowel

Joint on End of

Workpiece

Place router ontotemplate comb.

Switch on.

Plunge down untildepth stop limitsplunge.

Repeat for number ofdowel holes.

Switch off router andremove from jig.

Examine each of theholes to ensure all theworkpiece has beencleanly bored.

Remove frontworkpiece from jig.

Routing the Dowel

Joint on Face of

Workpiece

Loosen top clamp andmove workpiecetowards fence bar.

Tighten top clamp.

Place router ontotemplate comb.

Switch on.29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

Dowel joint too shallow = increase plunge

depth of cutter.

Dowel joint too deep = decrease plunge

depth of cutter.

Plunge down untildepth stop limitsplunge.

Repeat for number ofdowel holes.

Switch off router andremove from jig.

Examine each of theholes to ensure all theworkpiece has beencleanly bored.

Test fit joint.34

33

32

31

30

MANU-CDJ v4.0 20/7/10 10:33 Page 34

-35-

CDJ300 & CDJ600

=

Set up for Dowel

Template when off

Jig

Remove all thebrackets.

Leave fence barknobs loose.

Mark up workpiecewith position of dowelholes from edge.Ensure holes areparallel to edge.

Place template ontoworkpiece and aligncentre of dowel holesonto marked positionon workpiece. Clamp template withclamps.

Adjust fence bar toedge of workpieceand tighten knobs.

Loosen clamps andreposition template tocorrect position fordrilling.

Routing of Dowel

Holes off Jig

Place router ontotemplate comb.

Switch on.

Plunge down untildepth stop limitsplunge.

Repeat for number ofdowel holes.

Switch off router andremove from jig.

Examine each of theholes to ensure allthe workpiece hasbeen cleanly bored.

If a longer series of

12

11

10

9

8

7

6

5

4

3

2

1

dowel holes arerequired (longer thantemplate), placesuitable size dowel pininto last hole andmove whole templatelong, ensuing templateis located over dowelpin.

Test fit holes to suitfixing.

13

14

MANU-CDJ v4.0 20/7/10 10:33 Page 35

-36-

CDJ300 & CDJ600

Each part of joint is routedseparately. Offset is 15.8mmto centre of tail. (Drawingsshow CDJ300 only.)

Set Up

Fit edge guide intoholes according totable.

Place one piece ofworkpiece into frontclamp bar and pushtight against edgeguide.

Tighten front clamp barknobs to holdworkpiece.

Place a waste pieceunder top clamp barand butt againstworkpiece alreadyfitted. Waste piecemust be 5mm thickerthan workpiece.

With a square ensuretop of front piece ofworkpiece is flush withback piece ofworkpiece.

Tighten top clamp barknobs.

Fit brackets to templatecomb with tapered slottowards front.

Fit template combassembly.

Adjust stop to line upsight mark on templateto back of workpiece.

Lock stop using hexkey.

Repeat for other side.Ensure template isparallel to workpiece.

Loosen screws holdingtemplate comb tobrackets, and removecomb. Leave bracketsattached to jig.

12

11

10

9

8

7

6

5

4

3

2

1 Comb Dia. Dia. Colour Hole Dia. Dia. Dia. Dia.

CDJ300/05 1/2” 21.9Øx5.6 Brown F2 15.8 12.7 11.1 8

CDJ600/05 1/2” 10Øx10* Silver F2 15.8 12.7 11.1 8

CDJ600/06 3/4” 10Øx10* Silver F2 22 19 15.8 12.7

Flip over

Flip over template combwith parallel slottowards front.Refit template comb tobrackets and tightenscrews.

* From CDJ600 jig

14

13

Dimensionsshown in mm.

Waste piece

must be 5mm

thicker than

workpiece.

THROUGH DOVETAIL TEMPLATE

MANU-CDJ v4.0 20/7/10 10:33 Page 36

-37-

CDJ300 & CDJ600

Routing the Tails

Fit guide bush torouter according tothe table.

Fit dovetail cutter torouter according tothe table.

Adjust the height ofthe cutter to equalworkpiece thickness.This can be achievedby drawing thethickness of the pinboard onto the tailboard and vice versa.

Place router ontotemplate comb.

Switch on.

Carefully rout from leftto right following theguide bush in each ofthe slots. Take gentleback and forth cuts torout out the pocket forthe tail.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove templatecomb assembly

Remove workpiecefrom jig.

24

23

22

21

20

19

18

17

16

15

MANU-CDJ v4.0 20/7/10 10:33 Page 37

-38-

CDJ300 & CDJ600

Routing the Pins

Loosen screws holdingtemplate comb tobrackets, and removecomb. Leave bracketsattached to jig.

Flip over templatecomb 180° withtapered slot towardsfront.

Refit template comb tobrackets and tightenscrews.

Fit guide bush torouter according totable.

Fit straight cutter intorouter according totable.

Adjust the height ofthe cutter to equalworkpiece thickness.

Place router ontotemplate comb.

Switch on.

Carefully rout from leftto right following theguide bush in each ofthe slots. Take lightcuts to rout out thepocket for the tail.

Switch off router andremove from jig.

Examine each of theslots to ensure all theworkpiece has beencleanly routed.

Remove templatecomb assembly.

Remove workpiecefrom jig.

Test fit joint.38

37

36

35

34

33

32

31

30

29

28

27

26

25

Joint too loose = move template for pin awayfrom jig body.

Joint too tight = move template for pins towardsjig body.

MANU-CDJ v4.0 20/7/10 10:33 Page 38

-39-

CDJ300 & CDJ600

MAINTENANCE

This jig has been designed to operate over a longperiod of time with a minimum of maintenance.Continual satisfactory operation depends uponproper tool care and regular cleaning.

Cleaning� Regularly clean the jig and remove resin

build-up on all threads.

Lubrication� Your jig requires no additional lubrication.

Storage� Store accessory in a cupboard.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing aswaste.Packaging should be sorted for environmental-friendlyrecycling. The product and its accessories at the end of their lifeshould be sorted for environmental friendly recycling.

GUARANTEE

The jig carries a manufacturers guarantee inaccordance with the conditions on the enclosedguarantee card.

MANU-CDJ v4.0 20/7/10 10:33 Page 39

-40-

CDJ300 & CDJ600

CDJ300 & CDJ600 - SPARE PARTS LIST v4.0 01/2010

No. Qty. Desc. Ref.1 1 Jig Body CDJ300 WP-CDJ300/01

1 Jig Body CDJ600 WP-CDJ600/012 2 Clamping Bar with Grip CDJ300 WP-CDJ300/02

2 Clamping Bar with Grip CDJ600 WP-CDJ600/023 4 Spring WP-CDJ/034 4 Washer 8.5mm x 16.5mm x 1.5mm WP-CDJ/045 4 Clamp Knob Male M8 x 80mm CDJ300 WP-CDJ/05

2 Clamp Knob Male M8 x 80mm CDJ600 WP-CDJ/056 4 Edge Guide 10mmx10mm Dia CDJ300 Silver WP-CDJ300/06

4 Edge Guide 10mmx10mm Dia CDJ600 Silver WP-CDJ600/067 4 Machine Screw Csk M4 x 16mm Skt WP-SCW/848 1 Template Comb 1/2 Lapped CDJ300 WP-CDJ300/08

1 Template Comb 1/2 Lapped CDJ600 WP-CDJ600/089 2 Template Comb Bracket WP-CDJ300/0910 4 Machine Screw Csk M4 x 6mm Skt WP-SCW/7711 1 Trend CDJ300 Label WP-CDJ300/11

1 Trend CDJ600 Label WP-CDJ600/1112 2 Machine Screw Csk M6 x 40mm Skt WP-SCW/8113 2 Knob Female M6 WP-CDJ/1314 2 Washer 6.5mm x 24.5mm x 1.5mm <2004 WP-WASH/12

2 Washer 8.5mm x 23.5mm x 2mm <2004 WP-WASH/172 Nylon spacer for M6 >2004 WP-CDJ300/14

15 2 Comb Adjustment Stop M6 CDJ300 <2004 WP-CDJ300/152 Comb Adjustment Stop M8 CDJ600 <2004 WP-CDJ600/152 Comb Adjustment Stop M6 >2004 WP-NUT/15

16 4 Set Screw M5 x 5mm WP-CDJ/1617 4 Rubber Foot WP-CDJ/1718 1 Hex Key 2.5mm A/F WP-AP/2519 1 Hex Key 4mm A/F WP-AP/0420 1 Guide Bush 15.8mm x 6mm GB15821 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0922 4 Self Tapping Screw Csk No.8 x 25mm Pozi WP-SCW/10023 1 Dovetail Cutter 12.7mm Dia x 104 Deg C041A24 1 Manual MANU/CDJ

FOR CDJ600

46 2 Knob Female M6 CDJ600 WP-CDJ/4667 1 Sliding Stop Bar Left CDJ600 WP-CDJ600/67

FOR CDJ600 <04/2010

9 2 Template Comb Bracket CDJ600 <04/2010 WP-CDJ/600/0912 2 Machine Screw Csk M8 x 50mm CDJ600 <04/2010 WP-SCW/8213 2 Knob Female M8 CDJ600 <2010 WP-CDJ/600/1314 2 Nylon Spacer for M6 CDJ600 >2000 <04/2010 WP-CDJ/600/1415 2 Comb Adjustment Stop M8 CDJ600 <04/2010 WP-NUT/0919 1 Hex Key 5mm A/F CDJ600 <04/2010 WP-AP/03

MANU-CDJ v4.0 20/7/10 10:33 Page 40

-41-

CDJ300 & CDJ600

CDJ300 & CDJ600 - SPARE PARTS LIST v4.0 01/2010

No. Qty. Desc. Ref.68 1 Sliding Stop Bar Right CDJ600 WP-CDJ600/6869 1 Label Scale Pack (Left & Right) CDJ600 WP-CDJ600/6970 2 Sliding Stop U Bracket CDJ600 WP-CDJ600/7071 2 Sliding Stop Spacer CDJ600 WP-CDJ600/71

CDJ300 & CDJ600 - SPARE PARTS LIST v3.0 12/2003

72 2 Sliding Stop Clamp Spacer (Hole) CDJ600 WP-CDJ600/7273 2 Sliding Stop Clamp Spacer (Tapped) CDJ600 WP-CDJ600/7374 4 Machine Screw Csk M4 x 12 Skt CDJ600 WP-SCW/7875 4 Machine Screw Csk M4 x 25mm Skt CDJ600 WP-SCW/7976 8 Shim 6mm x 10mm x 0.2mm CDJ600 WP-CDJ600/7677 2 Set Screw Hex M6 x 35mm CDJ600 WP-CDJ600/77

1/4" LAPPED CDJ300/01 & CDJ600/01

7 4 Machine Screw Csk M4 x 6mm Slot WP-SCW/849 2 Template Comb Bracket CDJ300 WP-CDJ300/09

2 Template Comb Bracket CDJ600 WP-CDJ600/0910 4 Machine Screw Csk M4 x 6mm Skt WP-SCW/7719 1 Hex Key 2.5mm A/F WP-AP/2521 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0925 1 Template Comb 1/4 Lapped CDJ300 WP-CDJ300/25

1 Template Comb 1/4 Lapped CDJ600 WP-CDJ600/2526 2 Edge Guide 15.8mm Dia x 6mm CDJ300 Green WP-CDJ300/26

2 Edge Guide 20.1mm Dia x 10.5mm CDJ600 Green WP-CDJ600/2627 2 Edge Guide 28.7mm Dia x 4mm CDJ300 Green WP-CDJ300/27

0 Edge Guide 10mm Dia x 10mm CDJ600 Silver WP-CDJ600/0628 1 Guide Bush 7.8mm x 4mm GB7829 1 Dovetail Cutter 6.0mm Dia x 98 Deg C154

1/2" BOX CDJ300/02 & CDJ600/02

7 4 Machine Screw Csk M4 x 16mm Slot WP-SCW/849 2 Template Comb Bracket CDJ300 WP-CDJ300/09

2 Template Comb Bracket CDJ600 WP-CDJ600/0910 4 Machine Screw Csk M4 x 6mm Skt WP-SCW/7719 1 Hex Key 2.5mm A/F WP-AP/2521 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0930 1 Template Comb 1/2 Box CDJ300 WP-CDJ300/30

1 Template Comb 1/2 Box CDJ600 WP-CDJ600/3031 2 Edge Guide 19.7mm Dia x 6mm CDJ300 Red WP-CDJ300/31

2 Edge Guide 11.3mm Dia x 8.5mm CDJ600 Red WP-CDJ600/3132 2 Edge Guide 17.3mm Dia x 31mm CDJ300 Red WP-CDJ300/32

2 Edge Guide 10mm x 33mm Dia CDJ600 Red WP-CDJ600/3233 2 Machine Screw Csk M4 x 40mm Skt WP-SCW/80

MANU-CDJ v4.0 20/7/10 10:33 Page 41

-42-

CDJ300 & CDJ600

CDJ300 & CDJ600 - SPARE PARTS LIST v4.0 01/2010

No. Qty. Desc. Ref.34 1 Guide Bush 15.8mm x 4mm <2010 GB158/A

1 Guide Bush 15.8mm x 4mm >2010 GB158/B35 1 Straight Cutter 12.55mm Dia x 25mm Cut C021A

8MM BOX CDJ300/03 & CDJ600/03

7 4 Machine Screw Csk M4 x 16mm Slot WP-SCW/849 2 Template Comb Bracket CDJ300 WP-CDJ300/09

1 Template Comb Bracket CDJ600 WP-CDJ600/0910 4 Machine Screw Csk M4 x 6mm Skt WP-SCW/7719 1 Hex Key 2.5mm A/F WP-AP/2521 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0933 2 Machine Screw Csk M4 x 40mm Skt WP-SCW/8036 1 Template Comb 8mm Box CDJ300 WP-CDJ300/36

1 Template Comb 8mm Box CDJ600 WP-CDJ600/3637 2 Edge Guide 14mm Dia x 6mm CDJ300 Blue WP-CDJ300/37

2 Edge Guide Stepped 10/26mm Dia CDJ600 Blue WP-CDJ600/3737A 2 Edge Guide 21mm Dia x 25mm CDJ300 Blue WP-CDJ300/37A38 1 Straight Cutter 8mm Dia x 25mm Cut C012A59 1 Guide Bush 11.1mm x 3mm <2010 GB111/B

1 Guide Bush 11.1mm x 4mm >2010 GB111/C59A 1 Guide Bush 11.1mm x 5.5mm T3 GB111/B

32MM DOWEL CDJ300/04 & CDJ600/04

9 2 Template Comb Bracket CDJ300 WP-CDJ300/092 Template Comb Bracket CDJ600 WP-CDJ600/09

21 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0934 1 Guide Bush 15.8mm x 3mm <2010 GB158/A

1 Guide Bush 15.8mm x 4mm >2010 GB158/B39 1 Template Dowel 32mm CDJ300 WP-CDJ300/39

1 Template Dowel 32mm CDJ600 WP-CDJ600/3940 1 Fence Bar Dowel Template CDJ300 WP-CDJ300/4041 2 Edge Guide 11.5mm Dia x 6mm CDJ300 Grey WP-CDJ300/41

0 Edge Guide 10mm Dia x 10mm CDJ600 Silver WP-CDJ600/0642 2 Edge Guide 13mm Dia x 6mm CDJ300 Grey WP-CDJ300/42

2 Edge Guide 12.4mm Dia x 10.5mm CDJ600 Grey WP-CDJ600/4243 4 Machine Screw Cap M4 x 20mm Skt WP-SCW/7844 4 Knob Female M4 WP-CDJ/4445 4 Washer 4.3mm x 9mm x 0.8mm WP-WASH/04 46 2 Knob Female M6 WP-CDJ/4647 2 Machine Screw Cap M6 x 25mm Skt WP-SCW/7948 2 Washer 6.4mm x 12mm x 1.5mm WP-WASH/1249 1 Dowel Pin Hole Stop 3mm Dia Pin WP-CDJ/4950 1 Dowel Pin Hole Stop 5mm Dia Pin WP-CDJ/5051 1 Dowel Pin Hole Stop 6mm Dia Pin WP-CDJ/5152 1 Dowel Pin Hole Stop 8mm Dia Pin WP-CDJ/5253 1 Dowel Pin Hole Stop 10mm Dia Pin WP-CDJ/5354 1 Hex Key 3mm A/F WP-AP/03

MANU-CDJ v4.0 20/7/10 10:33 Page 42

-43-

CDJ300 & CDJ600

CDJ300 & CDJ600 - SPARE PARTS LIST v4.0 01/2010

No. Qty. Desc. Ref.55 1 Hex Key 5mm A/F WP-AP/0556 1 Router Dowel Drill 3mm Dia x 14mm Cut C180

1 Router Dowel Drill 5mm Dia x 35mm Cut C1741 Router Dowel Drill 6mm Dia x 35mm Cut C1751 Router Dowel Drill 8mm Dia x 35mm Cut C1761 Router Dowel Drill 10mm Dia x 35mm Cut C177

1/2" THROUGH CDJ300/05 & CDJ600/05

7 4 Machine Screw Csk M4 x 16mm Slot (CDJ300) WP-SCW/849 2 Template Comb Bracket CDJ300 WP-CDJ300/09

2 Template Comb Bracket CDJ600 WP-CDJ600/0910 4 Machine Screw Csk M4 x 6mm Socket WP-SCW/7719 1 Hex Key 2.5mm A/F WP-AP/2521 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0934 1 Guide Bush 15.8mm x 3mm GB158/A57 1 Template Comb 1/2 Through CDJ300 WP-CDJ300/57

1 Template Comb 1/2 Through CDJ600 WP-CDJ600/5758 2 Edge Guide 21.9mm Dia x 5.6mm CDJ300 Brown WP-CDJ300/58

0 Edge Guide 10mm Dia x 10mm CDJ600 Silver WP-CDJ600/0659 1 Guide Bush 11.1mm x 3mm <2010 GB111/B

1 Guide Bush 11.1mm x 4mm >2010 GB111/C59A 1 Guide Bush 11.1mm x 5.6mm T3 GB111/B60 1 Straight Cutter 8mm Dia x 25mm C012A61 1 Dovetail Cutter 12.7mm Dia x 98 Deg C178

3/4" THROUGH CDJ300/06 & CDJ600/06

7 4 Machine Screw Csk M4 x 16mm Skt (CDJ300) WP-SCW/849 2 Template Comb Bracket CDJ300 WP-CDJ300/09

2 Template Comb Bracket CDJ600 WP-CDJ600/0910 4 Machine Screw Csk M4 x 6mm Socket WP-SCW/7719 1 Hex Key 2.5mm A/F WP-AP/2521 2 Machine Screw Csk M5 x 8mm Slot WP-SCW/0934 1 Guide Bush 15.8mm x 3mm <2010 GB158/A

1 Guide Bush 15.8mm x 4mm >2010 GB158/B62 1 Template Comb 3/4 Through CDJ300 WP-CDJ300/62

1 Template Comb 3/4 Through CDJ600 WP-CDJ600/6263 2 Edge Guide 16.4mm Dia x 6mm CDJ300 Violet WP-CDJ300/63

0 Edge Guide 10mm Dia x 10mm CDJ600 Silver WP-CDJ600/0664 1 Guide Bush 22mm x 4mm GB22/A65 1 Straight Cutter 12.7mm Dia x 25mm C02166 1 Dovetail Cutter 19mm Dia x 97 Deg C179

MANU-CDJ v4.0 20/7/10 10:33 Page 43

-44-

CDJ300 & CDJ600

CDJ600

5

4

3

8

10

9

1

23

2

11

2

7

6

18

19

17

12

15

1314

22

21

2077

2470

46

15

12A

72

73

75

67

68

69

7176

74

5

10

23

45

43

21

0

CDJ300

16

15

< 2004

12

131412A

CDJ300 & CDJ600 -

SPARE PARTS DIAGRAM

V4.0 01/2010

MANU-CDJ v4.0 20/7/10 10:33 Page 44

-45-

CDJ300 & CDJ600

CDJ300 & CDJ600 -

SPARE PARTS DIAGRAM

V4.0 01/2010

9

29

28

10

21

27

19

267

25

7

7

34

21

31

32

19

35

10

9

30

59

37A

10

9

21

37

19

38

36

59A

33

33

CDJ300/01

CDJ600/01

CDJ300/02

CDJ600/02

CDJ300/03

CDJ600/03

MANU-CDJ v4.0 20/7/10 10:33 Page 45

-46-

CDJ300 & CDJ600

CDJ300 & CDJ600 -

SPARE PARTS DIAGRAMV4.0 01/2010

34

4241

21

44

9

55

54

47

39

4648

45

40

43

56

49 50 51 52 53

59

59A

21

60

10

34

5819

9

61

57

7

64

21

34

63

62

19

10

659

66

7

CDJ300/04

CDJ600/04

CDJ600/05

CDJ300/06

CDJ600/06

CDJ300/05

MANU-CDJ v4.0 20/7/10 10:33 Page 46

-47-

CDJ300 & CDJ600

TROUBLE SHOOTING

� Tear out - this occurs whencutting across the grain andcan be overcome by scribingthe ends of the timber with amarking knife or gauge at theheight of the cutter.

� Lapped Dovetail joint too

loose - increase depthadjustment of cutter.

� Lapped Dovetail joint too

tight - decrease depthadjustment of cutter.

� Lapped Dovetail joint too

shallow - move templatecomb towards the jig body byadjusting the lock stop.

� Lapped Dovetail joint too

deep - move template combaway from the jig body byadjusting the lock stop.

� Box comb joint too

shallow - increase depthadjustment of cutter.

� Box comb joint too deep -decrease depth adjustment ofcutter.

� Through dovetail joint too

loose - move template for pinaway from jig body.

� Through dovetail joint too

tight - move template for pintowards jig body.

MANU-CDJ v4.0 20/7/10 10:33 Page 47

-48-

CDJ300 & CDJ600

NOTES

MANU-CDJ v4.0 20/7/10 10:33 Page 48

MA

NU

/CD

J v4

.0

© Copyright Trend 2010. No part of this publication may be reproduced, stored or transmitted in any form without prior permission.Our policy of continuous improvement means that specifications may change without notice. Trend Machinery and Cutting Tools

cannot be held liable for any material rendered unusable or any form of consequential loss. E&OE

RECYCLABLE

Trend Machinery & Cutting Tools Ltd.Odhams Trading Estate St Albans RoadWatford WD24 7TR EnglandTel: 0044(0)1923 [email protected]

MANU-CDJ v4.0 20/7/10 10:33 Page 49