CarbonCast Enclosure Systems

-

Upload

altusgroup -

Category

Documents

-

view

218 -

download

0

description

Transcript of CarbonCast Enclosure Systems

Enclosure SystemsHigh Performance Insulated Wall PanelsInsulated Architectural CladdingArchitectural Cladding

carboncast®

altusgroup®

Innovative precast wall systems that are lighter,

better insulating and more sustainable.

2 1-866-GO-ALTUS

High Performance Insulated Wall PanelPAGE 4–5

• Full composite action for load-bearing performance

• Continuous insulation to meet ASHRAErequirements.

• Aesthetic versatility

Insulated Architectural CladdingPAGE 6–7

• Continuous insulation to meet ASHRAErequirements

• Up to 40% lighter; enables reduced super-structure and foundation

• Lower carbon footprint• Aesthetic versatility

Architectural CladdingPAGE 8–9

• Up to 50% lighter; enables reduced super-structure and foundation

• Integral insulation for improved R-value• Virtually unlimited aesthetic options

CarbonCast® Enclosure Systems useadvanced technology to improve precast concrete by integrating ultra-strong, non-corrosive C-GRID® into the wall panels duringfabrication. By taking the place of steel reinforcement C-GRID provides a multitude of benefits that makes factory-made precastconcrete an even more intelligent choice forcommercial building envelopes.

Depending on design, CarbonCast panels arepriced competitively with other curtainwall systems such as brick-veneered, masonry,stud walls or concrete. And after factoring inreductions to superstructure requirementsand potential HVAC system and operatingsavings, CarbonCast enclosure systems canhelp pay for themselves immediately.

Enabling superior performance.Lightweight, non-corrosive C-GRID is the “enabling technology” that allowsCarbonCast enclosure systems to be lighter,insulating, more durable and cost competitive.C-GRID has many of the same strength-weight benefits as high-performance aerospace carbon fiber, but at a significantlylower cost. The carbon fibers used to makeC-GRID are over four times stronger in tensile

strength than steel by weight. Each carbonfiber “tow” or strand is comprised of thousandsof ultra-fine fibers that are bundled together.These tows are assembled perpendicular toeach other into a grid using a continuousrotary-forming process that chemically bindsthem with a tough, heat-cured epoxy resin.

It takes jet fighters to Mach 2. Imagine what it does for precast.The exceptional strength and durability ofcarbon fiber translate to several enhance-ments to the performance of precast concrete enclosure systems.

Lighter Weight. Because carbon fiber resistscorrosion, CarbonCast cladding with C-GRIDin the face requires less protective concrete

CarbonCast Technology: One simple change, a multitude of benefits.

CarbonCast Enclosure System Selector

Less concrete means

less weight, less

embodied energy and

a reduced carbon

footprint.

Feature High Performance Insulated Wall Panel Insulated Architectural Cladding Architectural Cladding

Length Up to 60' Up to 30' Up to 30'

Width Up to 13' Up to 14' Up to 14'

Thickness 6"–12" 6"–9" 7"–12"

Weight PSF > 65 38–65 37–501

R-Value 10–37 8–20 < 10

Continuous Insulation Yes Yes No

Fire Rating 2 hrs 2 hrs 1–2hrs2

Load-bearing Optional Optional No

Paintable Interior Face Yes Yes No

Window/Door Recess 1–2" 1–2" 1–10"

Applications

Low- and Mid-Rise n n n

High-Rise n n

Poor Soil n n

1 Weight can be reduced with lightweight backer mix. 2 Assembly rating includes interior wall system of steel studs, batt insulation, and 5/8" type X gypsum board(s). Specifications vary by precaster.

cover than conventional welded wire mesh.Less concrete means less weight, lessembodied energy and a reduced carbonfootprint. Lowering weight may also permit areduction in steel or concrete superstruc-ture, further reducing a building’s carbonfootprint. Energy costs for transportation tothe jobsite may also be lessened. Panelweight can be reduced up to 50% or moreversus conventional precast. Reducingembodied energy is an important strategy forreducing total energy in sustainable designs.

Enhanced Strength and Durability. Becauseit can be placed closer to the surface, C-GRIDoffers outstanding crack control. And its highstrength as a shear truss yields full compos-ite action in CarbonCast® High PerformanceInsulated Wall Panels and InsulatedArchitectural Cladding. Because they can bethinner than non-composite designs, load-bearing CarbonCast walls can allow you toincrease the amount of usable space insidea building without increasing its physicalfootprint.

Improved Thermal Performance. Carbon fiber epoxy grid has relatively low thermalconductivity. When used as a connectorbetween concrete wythes it eliminates hotand cold spots on interior walls, leading tomore efficient heating and cooling, lowerenergy costs, and improved occupant comfort. It permits continuous insulation (ci)to comply with ASHRAE requirements.

Aesthetic Versatility. You can enjoy the virtually limitless versatility of precast.Design projections, reveals, bullnoses andother articulations, as well as finishes rang-ing from thin brick to tile and dozens of otheroptions. CarbonCast Enclosure Systems canhelp you realize almost any design vision.

Sustainable design? Consider the benefits of CarbonCast.By using C-GRID as a reinforcing material,CarbonCast technology amplifies many of thequalities that enable precast to contribute toLEED® certification depending on the design.

Lighter Weight to Reduce Embodied Energy.CarbonCast products use less concrete thanconventional precast products. That means

we use less fuel to produce, ship and erectalong with less Portland cement and its asso-ciated greenhouse gases. You can reducesuperstructure and foundation requirements,resulting in less steel and/or concrete.

Stronger to Last Longer. C-GRID® reinforce-ment in CarbonCast products is stronger andnot susceptible to corrosion like conventionalsteel mesh reinforcement. CarbonCast products can reduce concrete cover require-ments. Meanwhile, carbon fiber grid allowsCarbonCast to maintain fire-resistive proper-ties, deliver shear support for designs withreduced concrete mass and virtually eliminatethermal bridges in insulated designs.

Better Processes for Better Products.AltusGroup® precasters have implementedsustainable manufacturing efforts such asreclaiming aggregates and slurry water andrecycling formliners and molds. And allAltusGroup® members’ plants are certifiedthrough the Precast/Prestressed ConcreteInstitute (PCI) third-party auditing programfor quality control.

3www.altusprecast.com

Clockwise:University of North Florida Student Union Jacksonville, Fla.; Precaster: Gate Precast Company (LEED Certified)Edward Jones Headquarters St. Louis, Mo.; Precaster: High Concrete Group LLCWoodmont High School Greenville County, S.C.; Precaster: Metromont CorporationThe Heldrich New Brunswick, N.J.; Precaster: High Concrete Group LLC

From ultra-modern

to historically

accurate designs,

CarbonCast meets

your objectives.

4 1-866-GO-ALTUS

Setting a new standard for sandwich wall panels.CarbonCast® High Performance InsulatedWall Panels deliver all the benefits of factoryprecasting with unprecedented thermal effi-ciency in a fully structurally composite panel.

CarbonCast High Performance Insulated Wall Panels are composed of two concretewythes separated by continuous insulation (ci),and connected by C-GRID® shear trusses. Withlow thermal conductivity, high-strength C-GRIDhelps deliver a panel with insulation values upto R-37—and above ASHRAE 90.1 (2007)requirements—depending on the thicknessand type of foam insulation.

Extensive research has unequivocally proven the outstanding load-bearing per-formance of CarbonCast High PerformanceInsulated Wall Panels. The C-GRID sheartrusses and patented pilasters render a panelwith full structural composite action, but withimproved durability. For example, an 8"CarbonCast High Performance Insulated WallPanel—4" of insulation between two 2" con-crete wythes—behaves structurally as if itwere an 8" solid panel. For primary flexuralreinforcement, prestressing strand or steelrebar is used in each wythe and in pilastersinternal to the panel.

Structurally superior. Energy efficient. Dry and mold-free.CarbonCast High Performance Insulated WallPanels are:

Energy Efficient and Lighter in Weight. Theexceptional bonding and strength of C-GRIDtrusses allow AltusGroup® precasters to useless concrete and more insulating foam toreduce energy use and lighten panels. Theydeliver superior insulation values forenhanced thermal efficiency and reducedenergy expenditures.

Superior at Load Bearing. Vertical panels are available for both load-bearing and non-structural applications and can be manufac-tured in thicknesses of 6" and up, with widthsup to 15' and heights of 50' or more. They caneliminate the need for perimeter columns andadd to usable floor space.

Dry, Mold-Free and Non-Combustible. Unlikebrick and block insulated cavity walls or brickwith steel studs, concrete does not allowwater to penetrate, eliminating the need for arain screen design. CarbonCast panels have

no voids or cavities where air or water cancombine to support mold and mildew growth.When properly designed they virtually elimi-nate the possibility for in-wall condensation.And the inherent fire resistance of concreteprovides additional peace of mind.

Ideal for Occupant Comfort. CarbonCast HighPerformance Insulated Wall Panels provide anacoustic isolating environment. Very littlesound is transmitted through the walls, whichcan provide an interior free of exterior noise.And the lack of cold spots provides a morecomfortable environment.

Pre-finished on the Inside Wall. CarbonCastHigh Performance Insulated Wall Panels canhave troweled interior wythes to eliminate thecost and time to install drywall or other surfaces.They are ready for paint or wallcovering and areultra-durable.

CarbonCast High Performance Insulated Wall Panels

COMMERCIAL AND INSTITUTIONAL USES• Office Buildings• Educational Facilities• Healthcare Facilities• Correctional Facilities• Big Box Retail• Multi-Unit Residential• Arenas, Theaters, Museums and

Convention Centers

INDUSTRIAL USES• Warehouses• Refrigerated Storage• Manufacturing Plants and

Control Room Facilities• Distribution Centers• Data Centers

Gwinnett Police HQ and 911 Call CenterGwinnett County, Ga.Precaster: Metromont Corporation

New Jersey AquariumCamden, N.J.Precaster: Oldcastle Precast Building Systems

• Full composite action for load-bearing performance• Continuous insulation to meet ASHRAE requirements • Aesthetic versatility• Fire rated

5www.altusprecast.com

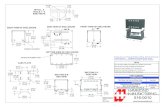

High Performance Insulated Wall Panelwith Pilaster

High Performance Insulated Wall PanelWindow/Door Head and Sill Horizontal Section

Architectural Panel

Rear Elevations

High Performance Insulated Wall PanelVertical Section at Pilaster

Steel Stud

Steel Stud

Steel Stud

Steel Stud

Steel Stud

Steel Stud

High Performance Insulated Wall PanelCorner Detail

High Performance Insulated Wall Panelwith Butt Joint

Top to Bottom: Cobb Energy Performing Arts CenterAtlanta, Ga.; Precaster: Metromont CorporationLucas Oil StadiumIndianapolis, Ind.; Precasters: High Concrete Group LLC and Gate Precast CompanyOffice DepotCharlotte, N.C.; Precaster: Metromont CorporationNordstromCincinnati, Ohio; Precaster: High Concrete Group LLC

Additional technical information is available at altusprecast.com/products

6 1-866-GO-ALTUS

Insulated Architectural Cladding Thermally Efficient Butt Corner Detail

CarbonCast Insulated Architectural Cladding

• Continuous insulation to meet ASHRAE requirements• Up to 40% lighter; enables reduced superstructure and foundation• Lowers carbon footprint• Aesthetic flexibility

Insulated Architectural Cladding Thermally Efficient Miter Corner Connection Detail

Insulated Architectural Cladding Horizontal Section

The onlythermally efficient

architectural panel on themarket, CarbonCast® Insulated

Architectural Cladding offers weightreductions of about 40% compared to solid, 6" thick precast and is engineered to deliverinsulation values of R-8 or more.

The design of this CarbonCast system is basedon the extensively tested CarbonCast HighPerformance Insulated Wall Panel. CarbonCastInsulated Architectural Cladding is intended forhorizontal and vertical placement as a non-load-bearing spandrel or column cover. The similarityin sandwich design means the CarbonCastInsulated Architectural Cladding panels areengineered to exhibit the exceptional strengthand durability benefits of their brethren.

Highly insulated for lower energy consumption. CarbonCast Insulated Architectural Claddingfeatures edge-to-edge continuous insulation(ci). The resulting thermally efficient panel pro-vides steady-state R-values of R-8 or more asadditional insulation is incorporated betweenthe panel’s inner and outer wythes. AltusGroup®

precasters can use either EPS or XPS foaminsulation depending on design requirements.All the insulation you need can be provided bythe panel. Additionally, the physical propertiesof precast concrete provide a beneficial thermal lag effect that can further reduce HVAC demands.

Lightweight and strong coexist beautifully.CarbonCast Insulated Architectural Claddingfeatures inner and outer wythes 13⁄4" thick and up (depending on reveal depth). Thewythes sandwich a layer of insulation of usually 2" or more depending on R-valuedemands. The thicker you specify the insul-ation layer, the higher the R-value can be.

C-GRID® shear trusses connect the inner andouter wythes of concrete. CarbonCast InsulatedArchitectural Cladding can also incorporate C-GRID into the exterior face should concretecover requirements—such as deep reveals—limit the use of welded wire mesh.

Reducing the amount of concrete lowers thepanel weight. Inner and outer wythes of 13⁄4"result in total concrete thickness of 31⁄2". That’s40% less concrete than a conventional 6"-thickprecast panel, which decreases embodiedenergy. The dramatic weight reduction deliverssignificant benefits.n Reduced load/superstructure: In most cases,lighter panels mean the building’s superstruc-ture and foundation can be engineered forless dead load, resulting in cost savings and alower carbon footprint.

n Lower transportation costs: Precasters canship more panels on each flatbed truck, lower-ing costly fuel consumption.

n Smaller cranes: Crane size and expense canbe reduced with lower-weight panels.

n Seismic performance: Lighter panels are generally more desirable in high-seismic areas.

Architectural finishes abound.AltusGroup® precasters are able to incorporatea variety of architectural finishes into CarbonCastInsulated Architectural Cladding to create a distinct, expressive facade that will meet awide variety of design needs. An assortment of architectural elements such as cornices,bullnoses and reveals can be cast into the con-crete carefully and cost-efficiently. Embeddedfinishes and veneers such as thin brick can alsobe used as well as simulated limestone or gran-ite instead of extracted rock to further reduceraw material extraction. In addition, CarbonCastInsulated Architectural Cladding can be speci-fied with a prefinished interior wythe. A steel-trowel treatment during manufacturing impartsa smooth, durable, surface ready for paint orwallcovering and ideal for applications like dormitories and apartments.

COMMERCIAL AND INSTITUTIONAL USES

• Mid- and high-rise office buildings

• Multi-unit residential

• Mixed use commercial/residential

• Healthcare facilities

• Education

• Hotels/Dormitories

Additional technical information is available at altusprecast.com/products

Steel Stud

Steel Stud

Steel Stud

Steel Stud

Steel Stud

Steel Stud

Insulated Architectural Cladding Thermally Efficient Butt JointSee page 5 for Window/Door Head and Sill detail.

7

CarbonCast increases R-value, reducesHVAC costs by $700k.

CarbonCast® Insulated Architectural Cladding panelson Georgia State University’s 2,000-bed student hous-ing complex in Atlanta delivered R-12 performanceand an impressive facade for the school.

The typical panels comprised four inches of expand-ed polystyrene sandwiched between two 2 1⁄2" thickconcrete wythes. C-GRID shear trusses connected theinner and outer wythes. C-GRID, unlike steel, has lowthermal conductivity, thereby preventing hot or coldspots.

Compared to comparable systems, the increasedeffective R-value could have enabled the university tospecify a less substantial heating and cooling system,saving $700,000 according to calculations. Comparedto a simulation of the original envelope design, thethermally efficient CarbonCast design saved $411,000in energy costs in the first year of operation, a 33%reduction. Additionally, the CarbonCast panels reducethe risk of mold and mildew because concreteinhibits water penetration.

CarbonCast

Insulated Architectural

Cladding Panels feature

edge-to-edge continuous

insulation (ci).

www.altusprecast.com

Georgia State UniversityUniversity CommonsAtlanta, Ga.Precaster: Metromont Corporation

Proximity HotelGreensboro, N.C.Precaster: Metromont CorporationLEED® Platinum

CarbonCast Enclosure Systems useeither EPS (expanded polystyrene) orXPS (extruded polystyrene) rigid foamboards for insulation depending onproject-specific requirements such asend-use, location, R-value and budget.Unfaced EPS foam generally costs lessper point of R-value than XPS foam. XPSfoam has a permeance rating of about1.0. Poly-faced EPS foam has a perme-ance rating of 0.5. (A permeance ratingof 1.0 or less is generally considered aneffective vapor retarder.) EPS foam isavailable in different densities thatresult in R-values from R-3.1 to R-4.9 perinch while XPS foam offers a uniform R-value of R-5. Your AltusGroup pre-caster can help you determine the idealinsulation choice for your project.

A CARBONCASTGREEN PROFILE

8 1-866-GO-ALTUS

CarbonCast Architectural Cladding

Lightweight, insulating, back-ribbed CarbonCast®

Architectural Cladding employs a steel reinforcedVierendeel-like truss frame attached to a thin,C-GRID reinforced diaphragm face. Insulatingfoam forms the ribs and displaces concrete toprovide insulation. C-GRID® carbon fiber sheartrusses mechanically link the face and trussribs to develop a rigid panel that will withstandfire, wind and rain.

CarbonCast Architectural Cladding incorporatespatented V-Ribs designed to create a thermalbreak with the face of the panel. Solid zones atthe panel’s perimeter can be covered at thefactory or in the field with rigid insulation to

create a highly insulating composite assembly.This design can increase net usable or rentablefloor area by reducing the width needed forinterior studding and other insulation. And youhave a virtually limitless selection of architec-tural precast finishes and articulations includingdeep window recesses for a distinctive facade.Additionally, CarbonCast provides the ability tofabricate thick panels with minimal additionalweight, allowing architects to impart a “massive” look without a weight penalty.

Less is more. Way more.Conventional precast panels with reveals aretypically six inches thick and weigh about 75pounds or more per square foot. Non-corrosiveC-GRID reinforcement reduces the amount ofconcrete required to fabricate a panel. Thesection properties and reduced weight ofCarbonCast wall components— which weighas little as 37 pounds per square foot—trans-late to lower transportation and erection costs.They can reduce a building’s superstructureand foundation and can shrink the structure’s carbon footprint.

Several ways to save with one decision:CarbonCast.CarbonCast Architectural Cladding can speedinstallation compared with ordinary precast.Lightweight CarbonCast panels can be erectedmore efficiently because more panels can bestaged at one time “under the hook” of thecrane, reducing delays caused by jockeyingpanels into position for picking. In addition,larger panels can speed erection by reducingthe number of picks, while lighter panels canpermit the use of smaller, less expensivecranes.

Depending on design, CarbonCast panels arepriced competitively with conventional precastor other curtainwall systems such as brick-veneered, masonry or stud walls. And after factoring in reductions to superstructurerequirements, CarbonCast ArchitecturalCladding panels can help pay for themselves—especially in mid- and high-rise buildings.

Factory insulation reduces HVAC demand. The added R-value provided by the polystyrenefoam—which can be a composite R-8 or moredepending on panel configuration—can addinsulation value leading to possible reduction inHVAC equipment.

Architectural PanelSecondary Vertical Rib

Architectural PanelPrimary Vertical Rib-A

• Up to 50% lighter; enables reduced superstructure and foundation• Integral insulation for improved R-value• Lower carbon footprint• Extensive aesthetic options

Architectural PanelButt Corner

Architectural PanelMiter Corner

COMMERCIAL AND INSTITUTIONAL USES

• Offices

• Multi-Unit and High-Rise Residential

• Healthcare

• Education

• Retail

• Cultural

• Mixed Use

Additional technical information is available at altusprecast.com/products

Lightweight CarbonCast panels delivercommand performance.The developer of the 32-story Symphony House, abreathtaking $125 million, 163-unit condominium inPhiladelphia, promises residents “a provocativedesign that takes from the grandeur and romance ofthe 1920s and gives it a 21st century transformation.”Coincidently, the same could be said about the build-ing’s exterior, the majority of which features next-generation CarbonCast Architectural Cladding thatdelivers a traditional aesthetic sensibility and aremarkable 33% weight reduction.

The weight reduction provided two benefits to theowner. First, the restrictive building site necessitateda tower crane to lift the 770 exterior panels intoplace. The CarbonCast panels, which weigh only 50lbs. per square foot, were easily accommodated bythe crane—even at the more distant corners of thebuilding.

In addition, the lower-weight panels reduced loadon the floor slab where they are mounted and on therest of the reinforced concrete structure, all the waydown to the sizing of the foundation. An innovativeslab attachment made possible by the light weight ofthe panels provided flexibility that made paneliza-tion of the structure easier by reducing the need totie back directly to columns. Further, the thinness ofthe panels and the reduction of the structure deliv-ered more interior floor space and better apartmentlayouts. And the panels were tested to withstandcategory 5 winds.

9www.altusprecast.com

Symphony HousePhiladelphia, Pa.Precaster: High Concrete Group LLC

Clockwise Millionair Airport Teterboro, N.J.; Precaster: High Concrete Group LLC55 West Orlando, Fla.; Precaster: Gate Precast CompanyEdward Jones Headquarters St. Louis, Mo.; Precaster: High Concrete Group LLC151 First Side Pittsburgh, Pa.; Precaster: High Concrete Group LLC

A CARBONCASTGREEN PROFILE

10 1-866-GO-ALTUS

Versatility as infinite as your imagination.Precast concrete gives architects and build-ing owners a virtually unlimited array ofdesign and finish options. CarbonCast®

Enclosure Systems are no exception. Theyprovide designers outstanding flexibility interms of:n Form. Articulations such as reveals, custom faces, cornices and other shapes.Deep window recesses can be included andwill likely cost less than conventional precast.

n Finish. An almost limitless variety includingcolors, applied finishes and veneers such asthin brick, tile and stone.

n Texture. Custom surface texturing can rangefrom delicate to bold, including polishing,etching and blasting, to yield the rightunique appearance.

In addition to eliminating any potential forstaining or spalling, C-GRID® reinforcement in the wall panel surface can provide superiorcrack control compared to steel mesh.Overall, CarbonCast delivers long-term peaceof mind.

Improves the job site, not to mention the restof the earth.Delivered ready to erect, precast componentsavoid the costly scheduling, quality and safetyissues associated with coordinating varioustrades, delays, scaffolding and site congestioncaused by laborers and stored materials andequipment.

For decades, architects and engineers havedepended on the strength, durability anddesign possibilities of precast concrete toachieve:n Virtually unlimited aesthetic optionsn Excellent design flexibilityn Peace of mind—quality-oriented, consistentfactory fabrication from PCI-certified plantsenables greater quality control, superiorconsistency of finish and greater strengthand impermeability

n Thermal efficiency and weather tightnesswhich can reduce HVAC system require-ments and energy consumption

n Fast-track construction—faster to erect,fewer uncontrollable delays, lower costs(Up to five times faster than field fabrication)

n Low maintenance and life cycle costs—AltusGroup® precasters will provide exten-sive design and specification assistance,connection detailing, erection planning,erection and other services to ensure a hassle-free, high-quality installation

n Outstanding durability, including fire andimpact resistance

n Improved resistance to mold compared tomost other systems

n Exceptional sound isolating properties

CarbonCast builds on the LEED® advantagesof precast.n Lighter weight to reduce embodied energyby using less cement and concrete thanconventional precast products

n Less fuel to produce, ship and erectn Reduced crane requirementsn Reduced foundation superstructure andrequirements

n Thermally efficient; reduces HVAC loads n Reduced concrete cover requirementsn Eliminates sealers and corrosion inhibitorsn Maintains fire-resistive propertiesn Shear support for designs that reduce concrete mass

n Eliminates thermal breaks in insulateddesigns

All the benefits of precast and even more sustainable.

Ready to Pass the Toughest Test: Yours.

Rigorous laboratory testing has affirmed a number of CarbonCast’s performance characteris-tics. Below is a sampling of tests that demonstrate the suitability of CarbonCast EnclosureSystems for a variety of applications. Get more information at altusprecast.com/products orcontact your AltusGroup precaster for details on tests.

C-GRID Material Propertiesn Strand Tensile Strength and Cross-Shear Strengthn Behavior Under Sustained Loads and Fatigue Behavior

C-GRID Reinforced Concrete Behaviorn Tension Tests and Pull-out Strength of Shear Gridn Effect of Temperature on C-GRID used for Shear Transfern RILEM Moisture Absorption Test for 1" Concrete Wythes

CarbonCast High Performance Insulated Wall Panel and Insulated Architectural Claddingn Axial load and flexure performance plus full-scale load testing n ASTM E119 three-hour fire test (2/4/2 panel with interior pilasters)n 50-Year wind load fatigue test

CarbonCast Architectural Claddingn Flexural Strength and Uniform Static Loadn Effects of Thermal Cyclingn Strand Bond Behavior in Panels Made with Nylon Fiber Reinforced SCC Concreten Missile Impact Testn ASTM E119 Fire Test (2 hours)** CarbonCast is safe and fire-ratable when used with gypsum board wall assemblies. Floor-to-floor fire stops

can also be cast into panels as required by fire codes.

Top to Bottom: >Academy of World Languages Cincinnati, OhioPrecaster: High Concrete Group LLCCarolina High School Greenville County, S.C. Precaster: Metromont CorporationAshley Furniture Ponchatoula, La. Precaster: Gate Precast Company Super Target Orlando, Fla.Precaster: Gate Precast Company

11www.altusprecast.com

Category Credit or Prerequisite Points Available CommentsLEED 2009

Potential LEED® Point Contributions

Sustainable Sites

SS Credit 5.1 Site Development: Protect or Restore Habitat 1 • Erection practices limit site disturbance toprescribed distances from the building

SS Credit 7.1 Heat Island Effect: Non-Roof 1 • Parking structures place 50% or more parkingunder cover

• High albedo concrete reflects energy back into the atmosphere and decreases cooling loads

Energy and Atmosphere

EA Prerequisite 2 Minimum Energy Performance — • Thermally efficient insulated sandwich wall panels help buildings comply with standards outlined in ASHRAE Standard 90.1-2007

EA Credit 1 Optimize Energy Performance 1–19 • Mass walls dampen and delay heating and cooling loads

• Thermally efficient insulated sandwich wall panels provide continuous insulation (“ci”)

• Reflective concrete efficiency is enhanced

Materials and Resources

MR Credit 2.1, 2 Construction Waste Management: 2 • Recycling crushed concrete into road bases or Divert 50% from Disposal; Divert 75% from Disposal construction fill; used to form artificial barriers

for shorelines• Erection does not contribute to construction sitewaste, since components are manufactured off site

MR Credit 4.1 Recycled Content: 10% (post-consumer + pre-consumer) 1 • Recycled concrete or slag as aggregate (post-consumer content) and supplementary cementitious materials, such as silica fume and slag cement (pre-consumer content); doubling this requirement may contribute to an Innovation and Design credit

• Steel reinforcement can be manufactured fromrecycled steel, and insulation can be made up ofpartly recycled material

MR Credit 5.1, 2 Regional Materials: 10% and 20% Extracted, 2 • Components are most often transported and Processed and Manufactured Region erected within 200 miles of the plant; use of local

cements, aggregates and other raw materialskeeps transportation distances to a minimum

Indoor Environmental Quality

EQ Credit 3.1 Construction Indoor Air Quality 1 • No on-site fabrication, reducing airborne Management Plan: During Construction particles; and concrete does not support mold

growth. Troweled interior surface can eliminatedust from drywall.

Innovation and Design Process

ID Credit 1.1 Innovation in Design 1 • An ID credit may be achieved due to exemplary performance of credit MRc4.1, 2

ID Credit 1.2 Innovation in Design 1 • Lighter weight, alternative reinforcement andmaterials reduce embodied energy and permit non-corrosive and more durable concrete

ID Credit 1.3 Innovation in Design 1 • Continuous insulation leads to excellent thermal performance, reduced HVAC demand and improved occupant comfort

ID Credit 1.4 Innovation in Design 1 • Lower weight walls reduce foundation and superstructure requirements as well as building’s overall carbon footprint

ID Credit 1.5 Innovation in Design 1 • Use of thin brick and simulated stone limits extraction of raw materials and energy needed tomanufacture and transport

ID Credit 2 LEED® Accredited Professional 1 • LEED AP: Many precasters have qualified LEEDAPs on staff to lead and support a project

PO Box 1449

Bethlehem, PA 18016-1449

866 GO-ALTUS

www.altusprecast.comaltusgroup®

Revolutionary thinking from the leading minds in precast

AltusGroup,® Inc., a company founded by some of the industry’s largest precastersand C-GRID® manufacturer Chomarat North America LLC, was incorporated tomake CarbonCast® technology—and future precast innovations—availablethroughout North America.

AltusGroup members collectively support more than 30 manufacturing and saleslocations in the United States and over 250 specification-oriented sales, marketingand engineering professionals, and generate more than $1 billion in annual revenue.With pooled research resources, knowledgeable manufacturing engineers and anational network of quality-conscious, PCI-certified plants (www.pci.org), sales support staff and university collaborators, AltusGroup can help you achieve yourdesign, construction and budget objectives.

Innovative CarbonCast products are available across the United States and inCanada, with an unparalleled network of service and support, offering: n Extensive testing and the backing of trusted industry leadersn A central source for complete technical information, including CAD details, specifications and engineering design standards

n Local sales and technical representatives to help with design and constructionchallenges

n Uniform quality standards and details consistent with the IBC and local codes.

Other high-performance CarbonCast products available from AltusGroup precastersinclude CarbonCast Double Tees for parking structures. They weigh up to 8% lessthan conventional precast double tees and eliminate the need for sealers and corro-sion inhibitors, reducing a parking garage’s carbon footprint.

For more information about AltusGroup, CarbonCast precast concrete componentsand the C-GRID technology, call 866-GO-ALTUS or visit www.altusprecast.com.

See us in Sweets in section 034500/ALT

Details and drawings may vary slightly depending on precaster and region.

All information contained herein is believed to be accurate and is subject to change without notice. No responsibility is assumed for its use by AltusGroup, or its members, and who reserve the right tomake changes without notice, to product design, product components and product manufacturingmethods. Please contact AltusGroup for more information.

C-GRID is a trademark of Chomarat North America LLC CarbonCast is a trademark of AltusGroupLEED is a registered trademark of the U.S. Green Building CouncilCarbonCast® precast products are protected under the following US patents: 6,898,908 B2; 7,100,336 B2© 2010 AltusGroup Inc.Printed in the USA

AltusGroup® Producers:Blakeslee PrestressBranford, Conn.www.blakesleeprestress.com

Central Pre-Mix Prestress Company(an Oldcastle company)Spokane, Wash.

EnCon UtahTooele, Utahwww.enconunited.com

Enterprise Precast ConcreteOmaha, Neb.www.enterpriseprecast.com

GPRM PrestressKapolei, Hawaiiwww.gracepacificcorp.com

Gage PrecastSioux Falls, S.D.www.gagebrothers.com

Gate Precast CompanyOxford, N.C.; Monroeville, Ala.; Kissimmee, Fla.; Jacksonville, Fla.; Ashland City, Tenn.; Winchester, Ky.www.gateprecast.com

Heldenfels Enterprises, Inc.San Marcos, Tex.www.heldenfels.com

High Concrete Group LLCDenver, Pa.; Springboro, Ohio; Paxton, Ill.; Buena, N.J.www.highconcrete.com

Knife River-Northwest Oregon Region, Prestress DivisionHarrisburg, Ore. www.kniferiverprestress.com

Metromont Corporation Atlanta, Ga.; Greenville, S.C.; Charlotte, N.C.; Nashville,Tenn.; Richmond, Va.; Bartow, Fla.www.metromont.com

Oldcastle Precast Building Systems Baltimore, Md.; South Bethlehem, N.Y. www.oldcastlesystems.com

Shockey Precast GroupWinchester, Va.; Fredericksburg, Va. www.shockeycompanies.com

Wells Concrete Wells, Minn.www.wellsconcrete.com

Chomarat North America LLC (C-GRID® supplier)Anderson, S.C.www.carbongrid.com

Innovation Partners:BASF Admixtures, Inc.Essroc Italcementi Group High Concrete Accessories JVIMeadow Burke ProductsOwens-Corning Sika CorporationToray Carbon Fibers America Inc.