Butt Joint Assembly Method - Fletcher Terry

Transcript of Butt Joint Assembly Method - Fletcher Terry

Interior & Exterior TrimUp to 1" x 6"

Max DistanceBetween V-Nails

(Stroke)5 3/4"

Pre-set V-NailPosition Stops

Multiple

V-Nail Sizes3, 5, 7,10,12,15mm

(SW-HW-HDF)

V-Nail Channel Capacity

220 V-Nails

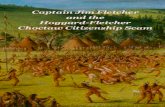

U-500 Frame Joining Capabilities

AMP BusinessPartner

(Formerly Model VN4 Memory Program) Butt Joint Material Fencing

for V-Nail Fastener Joining

Butt Joint Assembly Method – Replaces Common Method of Stapling

Butt JointAssembly shown on a U-500 Machine

Simms Machinery and AMP have developed a market exclusive Butt Joint Assembly Method for joining together both interior and exterior trim sizes up to 1" x 6". This new joining process consist of AMP’s U-500 Backnailer Joining Machine equipped with a 90 degree Material Fencing System.

The material fencing consist a of Moveable Fencing Arm, a Fixed Rear Fence with Magnetic Inserts, three (3) different sized Spacer Blocks for Off-Set Joining, and pre-set production stops for setting the left and right side joining positions for Hoop Assembly. A Double Hydraulic Clamping System is used for securing the trim moulding in place during the joining process.

The Butt Joint Assembly System can be purchased separately with new machines or can be field installed on existing customer units. The joining method can also be used with AMP’s U-600 if a Multi-Channel Backnailer is needed.

Spacer Blocks for Off-Set Joining

Simms Machinery represents and offers AMP’s U-Series Backnailer Machines for providing door casing joining solutions. Simms Machinery sells

and services complete machine packages including delivery, installation, operation set-up, tool kit and on-site machine operator training. Supported

by AMP’s Technical and Manufacturing teams, Simms Machinery offers unmatched millwork joining experience.

www.simmsmachinery.comwww.fletcher-terry.com

Business Partners in Frame Joining Technology

AMP | P: 847.821.2170 | [email protected] | www.fletcher-terry.com

Simms Machinery, Inc | P: 717.246.6333 | F: 717.246.6555 | [email protected] | www.simmsmachinery.com

STEP #1Setting Joining Line

STEP #2Setting Left and Right Production Stops

STEP #3Double Hydraulic Clamp used for Trim Material Clamping during V-Nail Insertion Step

Butt Joint Assembly Method - Process Steps and Operation:

Finished Off-Set Joint

Setting the Joining LineTo set the joining line, the operator positions the trim directly in the center of V-Nail Head, then slides the moveable arm into position. After setting the joining line and securing the sliding carriage in place, a pre-set production stop is then tighten for production repeatability. This step is repeated for

both the left and right position for completing Hoop Assembly.

Part No InformationPart # 04-100 – Butt Joint Assembly Kit

Off-set joints are possible using a range of various sized spacer blocks included in the equipment purchase package, 1", 1/2" and 1/4" sizes are included.