05 Encyclopedia Engines - NICO Club - Nissan Forums | Infiniti Forums

Building Enhanced Experience for Wire-line Segment …...2 TCS Confidential Lean Six Sigma Culture...

Transcript of Building Enhanced Experience for Wire-line Segment …...2 TCS Confidential Lean Six Sigma Culture...

1

1 •Copyright © 2013 Tata Consultancy Services Limited

1

Building Enhanced Experience for Wire-line Segment (NPS)

Project Leader : Srividhya B

Sponsors : Joy Mohanty/ Client GM

Champion : Manick/Client Business Manager

Process Owners : Allwin/Hashim

MBB : Dhananjay Hegde

Lead BB : Prasannarani S

BB : Ram Gopalan

Project Team : Vasanth, Santhosh, Abinathan, Habeeb

Sector – Telecom

Project Methodology – DMAIC

TCS Confidential

TCS CBO BPS: A Bird’s Eye View

TCS Confidential

$2.7B 330+ $2.2 B

Revenues for FY18

80,000+

Employees

134

Nationalities Organization

Certified at Level 5 - ISO 30105

Business Value Delivered (FY17-

FY18) Transactions

4.5B+ 1st

Banking Capital

Markets Insurance Mortgage

Drug Safety

Life Sciences

R&D Retail Telecom

Supply Chain

Procurement

Finance & Accounting

Digital Marketing Operations

Analytics BPO

Services

Order-to-Cash

Analytics & Insights

Wealth & Asset

Management

Technology in BPS

Telecom Operations

-as-a-Service

F&A-as-a-Service

Insurance-as-a-

Service

> LEADER

Gartner

IDC

Everest Group

Nelson Hall

HfS

Life & Pensions

Retail Banking

Mortgage-as-a-

service

Capital Markets-

as-a-service

Industry Analyst Recognitions Across Domains:

TCS Confidential 2

2

TCS Confidential

Lean Six Sigma Culture in TCS

25+ National/ International awards won at External forums in the last 4 years

$ 86.29 Mn savings & 2.85Bn BVA delivered in 2017-18 through

Improvement Initiatives

50.32% savings delivered

in 2017-2018 through Customer facing projects positively impacting the Business metrics

49.68% savings delivered in 2017-2018 through TCS specific projects - Seat Utilization, Gross margin, Productivity etc

2318 CI projects

closed in 2017-2018 225 Lean

58 Six Sigma

374 SPS

1661 Idea max/ Kaizen

projects

63 Events Six Sigma,

Lean/Herculean

SPS

Data Science Session

conducted across various locations in 2017-2018

2038 associates participated in CI events in 2017-2018

99 Lean 1876 GB 63 BB

4120 associates certified

in different process improvement methodologies in 2017-2018

Savings Projects Events Trained

Robust deployment of Process Improvement / Lean Six Sigma Culture focused on

Competency Development and Business Benefits 3

TCS Confidential

Enablers for Lean Six Sigma Culture

Emphasis on training the workforce for data-based problem analysis

10 MBBs

66+ BBs

4000+ GBs

18000+ Lean/ SPS Improved Business Results with Better Project

Governance through Robust Workflow

Internally developed Body of Knowledge specific to BPS Industry – SPS, Lean, Six Sigma

Green Belt, Six Sigma Black Belt

End to End workflow tool for Project Management

Best Practices Sharing Mechanism for sharing the learnings from PI Projects

Enablers for Lean Six Sigma Culture

TCS Confidential

4

3

TCS Confidential

Our client a leading Australian Telecommunications Service provider with 40% Market share……

TCS –Client Partnership

Partnering with TCS

since 2011

4500+ associates

Managing all the Telecom offering

Honored Account of the year in Disha award-

2015-2016

Best Adoption of Digital lever

Honored best productivity Account in CBS symphony 2018

• Founded in 1975, they are the largest Telecom and Information Services provider in Australia

• Builds and operates telecommunications networks and markets voice, mobile, internet access, pay television and other entertainment products and services.

• 5.8 BN profit with the total revenue

of 27.1 BN in 2016. Number of Employees 36K+,

Digital Tech

17.4 MN Mobile services

3.5 MN Broadband

Services Presence 20+ countries

6.7 MN 4G consumers

24 MN Customers

About Our Client

More than 70+ Years in Telecom

Licensed Operator in china

India’s First Mobile Call

…is a proud partner with 6 years of engagement employing 4500+ TCS people

130+ GB Certified Associates 207 Improvement Initiatives –FY18

5

6 •Copyright © 2013 Tata Consultancy Services Limited

6

Project Background and Purpose

Section 1

4

7 TCS Confidential

1.0.1 Organization approach to project planning

How the projects are selected with in the organization

Organization Approach

Our Success Story

Organization Approach of Planning for Selection project from Pre Planning( Voice & Source of Opportunity) and execution (Outcome) standardized across organization

The Planning is extended to a multi year process delivering the financial benefits YOY

8 TCS Confidential

Thought Leadership Framework

1.0.2 Project Identification Process (General)

How the projects are selected with in the organization

5

9 TCS Confidential

BVA

Gri

d a

nd

Leve

rs

Our Approach and Outcome

1 2

Thought Leadership Outcome

Menu Card –Thought Provocation

BVA Grid : Process VS Business Metric

Identify and list down, Prioritize and engage Projects

Project Prioritization Matrix Using Menu card

Benchmark

Robos with Cognitive ability

Business Metric Beyond SOW

Agile and Machine Learning

• Governance :Systematically track and ensure sustained focus and

rigor on projects till value realization / Closure

• Project closures in Impact (PI System)

Objective –

• Understand client's business environment, their business

• objectives/Business Metrics (Financial / Operational)

• Identify, List down, Prioritize and engage Projects

Client Business Objectives

TCS Offering Capability Improvement Projects

Industry Analysis

• 32 Opportunities identified as part transformation Roadmap for

FY’18-19

• All projects aligned to Internal or Customer key goals & priorities

• Financial Benefits projected : BVA $50MN & FORE & $3.32MN

• Monthly Governance and reporting will be executed for successful

completion

How the Projects was Identified

1.0.2 Project Identification Process (General)

Prioritization with Defined Criteria

Alignment to Change in Business 4.0 Strategy

10 TCS Confidential

1.0.3, 1.0.4 Project Selection and Prioritization Process

How the Project Prioritized and Selected with in Organization

Voice of Business

NPS as key metric as to

improve customer

experience, simplify the

existing structure and

increase revenue %

Voice of Customer Voice of Stakeholder

Client TCS Leadership Project Team

To enhance client experience

and add value to business, the

focus will be on improving NPS

score

TCS being the leading

partner and had end to end

visibility on the processes was

required to transform the

existing process and improve

the NPS scores to help Client

increase the revenue

6

TCS Confidential 11

What Specific goals and/or measures was the team trying to achieve with the project

Business Growth Customer Advocacy Profitability

Cost to Serve reduction

Time to Market

Net promoter score in Negative

Target

Keep the Brand Promise

First Time Right

Reduction of Customer Churn

Cost Reduction

Better Replication opportunities

%Advocates - % Detractors Any score between 0-6 (Detractor) is considered a Defect

Operational Definition of Metric :

Benefits

Baseline Performance -43.7 Detractor - 62%

NPS Improvement greater > 40% Detractor less than 50%

Goal : To improve NPS (Net Promoter Score) by 40% from -43.7 to -26

1.0.5. Project Goals and Benefits

Revenue Market Share

Aligned to the Business

and Client outcome of Customer

satisfaction &customer experience

TCS Confidential 12

1.0.6. Success Measures/Criteria Identified

time

Order Build Fallout/Remediation/Push the order Back

Installation Activation Delay

or Issue

WIP Days Profitability

Lead time to activate %Order rework & Fallouts

Accuracy Lead Tiime

Secondary Metric Secondary Metric

Approach for Identifying Additional Benefit:

Metrics Benefit Category

Lead Time Reduction in time to connect the customer will add early revenue to Client

Additional Success

Accuracy Reduction in rework & Fallout orders will reduce operational cost

Additional Success

Cost to Serve Focus on Enhance service might have a impact of increase in cost to serve

Counter Metric

7

13 •Copyright © 2013 Tata Consultancy Services Limited

13

Project Framework

Section 2

TCS Confidential 14

.

About our Client and Project Business Case Problem Statement

.

2.0.1 Concise Project Statement

2.0.2 Type of Project

2.0 Project Framework

Our client is an leading Australian telecommunications provider, provides voice, mobile, internet access and pay television products and services to customers across Australia

TCS Back of House team handles the order fulfilment process for the various telecommunication products sold

NPS is the measure of willingness of customers to recommend a services to others. NPS is key strategic metric to improve customer experience & increase revenue. The Team currently handles a volume of 3 Lac spread across 4 products. The net promoter score is negative across all operators & it is a important metric for improvement across the industry. Our client with highest market share was looking to scale up on this metric first. TCS being the leading partner and had end 2 end visibility on the processes was required to transform the existing process and improve the NPS scores to help our client and increase the revenue .

NPS score is trending at -43.7 for the period Apr- June ‘17.Lower the NPS has impact on increase in churn, drop in revenue and market share. The Industry standards quote that one detractor is equal to a potential churn of 2 customer and 1 advocate is equal 2 new customer. This is an opportunity for TCS to further enhance it’s partnership with Client by adding value and create benchmark improvement in satisfaction score across other operators

Kaizen Copper- Wirelines Product All Types of order PSTN Foxtel

Fiber Product Mobility and Broadband Technological Changes in design

process from client

2.0.3 Scope Statement

Inscope Out Of Scope

Bundles Big pond

SPS

Direct Improvement

Simple Analysis- 7 QC Tools

Lean

DMAIC

Waste Elimination

Variation/Chronic Issue

8

TCS Confidential 15

• Requires investment in training hours • Additional FTE effort required to manage

change • Separate teams for specialized tasks • Feasibility analysis and Development of

any automations for improvement • Approval for UAT deployment • Rewarding initiative • Timeline Of Implementation of Solutions

2.0.4 Assumptions/ Expectation Phase July'17 July'17 Aug'17 Sep'17 June'18

Define

Measure

Analyze

Improve

Control

2.0.5 Project Schedule /High Level Plan

• Hiring of Lead for managing the Automation development • Operating Budget will be discussed during the course of the project • TCS Gems points for the R&R

2.0.6 Budget( Financial or Resource)

2.0.7 Risk Management

2.0. Project Framework

• Structured Project management Risk Framework deployed to proactively identify risk

• will be reviewed by on a monthly basis and go for approval on a quarterly basis. Custodian Process Owner/Black Belt

Assumptions/ Expectation learning from Completed Projects

Fiber roll out Consumer segment Net promoter score improvement from -8 to +10.5

Wireless Net promoter score improvement for copper customers from 6 to 12

16 •Copyright © 2013 Tata Consultancy Services Limited

16

Project Stakeholders and the Project Team

Section 3

9

TCS Confidential 17

3.0.1 How were the Stakeholders Group Identified

Quality lead Team Leads DDL CL Client GM Process Specialist

BB,MBB & Lead BB

Automation lead Process Onshore

SME

• IT Team (Third Party)

Low Interest

High Interest

Low

Infl

uen

ce

Hig

h In

flu

ence

3.0 1 Project Stakeholders and the Project Team

TCS Confidential 18

3.02 Project Champion and Team Selection

Project Steering Committee

General Manager (Client)

Domain Delivery Lead ( TCS)

BRM (TCS)

Customer Leaders (TCS)

Project Management Group

Master Black Belt

Black Belt

Process Tower Leaders

• Ensure the team is trained on project

management and methodologies

• Observe team performance & take

timely corrective actions

• Review projects with stakeholders

• Approval committee

• Enablement

Project Team

Project Lead (TCS)

Project Lead (Client)

SME (Client)

Green Belts (TCS)

Process Experts(TCS)

• Execute the project as expected

• Identifying key drivers and

designing feasible solutions

• Making control plan

• Getting the project reviewed by

• stakeholders in a timely manner

Process Owners

Process Managers(TCS)

Process Manager (Client)

IT Manager (Third Party)

• Ensure project goal is

achieved

• Review the progress of

project internally

Sta

keh

old

ers

Project Champion

3.0.2 Project Champion and Project Team Selection

The roles & expectation were

clearly documented during the

selection

KPI Aligns to drive business

Improvement and success

10

TCS Confidential 19

What knowledge or skill sets were determined to be necessary for successful completion of the project?

“I-Evolve” is the defined organization practice standard to enable all the skill set requirement

I-EVOLVE

3.03 Team Selection

20 TCS Confidential

Before the project started, what specific training was done?

Before the project started, what was done to prepare the team to work together as a team?

3.0.4 Team Selection & Preparation

Launch

Quick Wins Identification (7 types of Wastes) Impact: Low Workshop : 01 Hr. on floor activity .Target Audience- All process associates (100% associates covered) Understanding Root Causes (5 Why & Fish Bone techniques) Impact: Low Training Duration: 04 Hr. training on Causal Analysis Target Audience- Project Stakeholders

Team Building Activities

Problem Solving (7QC Tools) Impact: Low Refresher Session: 1 Day Training 1 Day Workshop on Quality Tools Target Audience- All Project execution Stakeholders Waste Elimination@ process levels (VSM) Impact: High Training Duration: 1 Days Training & 1 Days Workshop on Lean Six Sigma Target Audience- Team leader and above

Specific Skillset

Solving problems in a complex process Impact: High Training Duration:- 1.5 Days, Black Belt CORE Committee members on the critical tools

AGILE & Behavioral

skills Training Duration: 3 Hours

Target Audience- All

Stage 1

Stage 2

Stage 3

1

2

3

4

5

Total 4 days of team preparation Journey enabled for the successful execution of the project as per the organization defined standards

6

11

21 TCS Confidential

3.05 Team Routines

What roles and expectations were determined ahead of the project?

Name Define Measure Analyze Improve Control

Project Sponsor A, I I I I A

Project Champion

A, I A, I A, I A, I A, I

Process Owners I, R A,I, R A,I, R A,I, R A,I, R

Project Leader M M M M M

Project Members

R R R R R

* When Populating the Stakeholder, consider the ARMI:

• A = Approver of team decisions

• R = Resource to the team, one whose expertise, skills, are needed

• M = Member of team

• I = Interested Party who will need to be kept informed on direction

and findings

Stakeholder Role & Expectations

Project

Steering

Committee

1)Set objective & purpose 2)Ensure availability of adequate resources 3)Monitor progress 4)Resolves escalated matter/bottleneck 5)Organize team

Project Leader

1)Chair team meeting and maintain focus on the goal 2)Ensure progress towards the goal 3)Act as a communication hub and as a liaison with management 4)Ensure execution of action items assigned for individual team

members

Execution

Group

1)Complete all action items assigned on time 2)Participate in team meetings 3)Communicates ideas and expertise

Process

Owners

1)Support team members with resources and information 2)Participate in project review 3)Share required information with team

Project

Management

Group

1)Ensure project is moving in the right direction 2)Ensure right set of tools & techniques are used 3)Facilitate in removing bottlenecks

22 TCS Confidential

22

3.0.5 Team Routines

How communication, were established?

Go

ve

rna

nc

e

Pla

n

Re

po

rtin

g P

lan

Recurring meeting invites to be accepted

Be on time for meetings

Provide advance notice of being absent for a meeting

Action points should be closed before the next scheduled meeting

Agenda of the meeting to be shared 2 days before the meeting date

Review Agenda Attendees Frequency Host

Project Meetings Ensure that the team is working towards objective/ goal

Project Team Weekly Project Lead

Project Working Sessions

Live working sessions to complete project related documents and files

Project Team Weekly Twice

Black Belt

Project Review Meeting Moving in right direction Timely issue resolution

Process Owners

Monthly Project Leader

Tollgate Review To get formal go ahead on completion of every tollgate

Project Champion

As per Milestone

Master Black Belt

Req

uir

emen

t

Report Frequency Custodian Recipients

NPS Report Daily MIS All Stakeholders

Status Report Weekly Project Team All Stakeholders

12

23 •Copyright © 2013 Tata Consultancy Services Limited

23

Project Overview

Section 4

24 - Summary of Organization standard and repeatable approach to executing DMAIC project

4.0.1 Project Approach

Project Methodology and Standard Organization approach

13

25

Quick Glance on Tools used & Output

Define

Measure

Analyze

Improve

Control

Tools Phases

VOC to CTQ Project Charter –Storyboard SIPOC & Stakeholder Analysis

VSM MSA CA-DPMO Brainstorming, Fishbone Analysis, Affinity Diagram

Validated Causes .Hypothesis test -Tool Chi-square, Regression and Pareto Analysis

Prioritize Using Gantt Chart Control Impact Grid Improvement validation using 2Proportion FMEA

Control Plan Control Chart Replication

Output

Project Charter –Sponsor Approval Obtained Baseline Performance, Scope, Goal – Baseline -43.7 Process Map, SIPOC & Stakeholder - Core Team formed Benefits from Project - $28MN BVA

Value Analysis & Quick Wins- 7 Quick Wins MSA –Gage Accepted Cause Effect Diagram -65 Cause Identified Affinity- Categorize and grouping X’s

Statistical approach for validating the facts Validated 14x, 11 Significant

65 Improvements are identified based analysis and 40 of them implemented

NPS Improved from -43.7 to -18.66 Reduction in detractors by 14.5% from 63.7%(Jun’17)

to 49% (Jun’18)

Control Impact Grid- Prioritize solutions for deployment Performance Sustenance validated BVA Savings of $41 MN

4.0.2 Tools Used Throughout Project

15+ Tools were Used throughput the Project

26

What tools were used

Define Phase Measure

1 2

4.0.3 Tools Output at Different Stages of Project aligned to the organization approach

SIPOC was charted & team charter enabled us in ensuring support

and partnership from all the stakeholder

NVA’s and Manual activities Identified thru VSM Capability Analysis

Process was deep through Process Map

Cause Identified Using Fishbone Affinity Diagram -Causes to X’s

14

27

4.0.3 Tools Output at Different Stages of Project

Analyze

3

Improve

4

Control

5

Hypothesis Testing Solution/Improvement Development Plan Control Chart

Control Plan Made

What tools were used

28

4.0.4 How Team was Prepared to use the Tools

Web based training –

• Mandatory completion of online LSSGB self learning module

Class room training

o 3 Day training program for new candidates

o Objective evaluation at the end of the training session

Online Assessment

• After the training mandatory completion of online assessment

LSSGB Training Tools How Prepared Who were trained Who Trained?

Six Sigma Quality Tools

Green Belt Session /LSS Capsules

Project Management Team

LSSGB COE & Black Belt

Automation Themes

Agile Online Course

Project Management Team

Self Serve

Telecom Skills Online and Class room Training

Project Management Team

Telecom COE

Monthly Governance & Toll Gate Review

Preparing Team using Methods

15

29

4.0.5 Dealing with Project Risk

Risks Risk Effect Risk

probability

Risk Mitigation

Method

Risk

Encountered

Status

Close Out

Environmental

Changes High Low

Ensure the capacity is planned

to handle season impacts Y

Cross Skilled Team on 2 Products

from Other location based on

Utilization study for closure of order

on the customer committed date

without impact in Service

Technical problem High Low

To list all possible technical

problem may arise and make

prevention plan for the same

Y

Unplanned Outages leading to

sudden fallouts addressed through

Keep me informed process to ensure

low impact of detractors

Human/Organization

al resistance Low Low

To organize weekly meetings

with the employees to discuss

about the problems

N

Inadequate Planning High Low Work on Revisiting the entire

project plan N

Snap shot of the encountered risk and closeout action

Project Risk Monitoring and Mitigation

30

4.0.6 Encountering and Handling Resistance – to be updated with live examples

What Type of Resistance How Identified Stakeholder Resolution

Caller FTEs were not ready to be cross trained

Revised utilization / Effort required report

• Process Tower Lead • Discussed with Tower leads behind the

necessity for cross Skill

Client SPOCs pushing ideas without sufficient data for validation

During Weekly connect

• Project Steering Committee

• Rules were set in discussion with Project Steering Committee about the necessity of performing validation before the final solutions were identified

IT team was not agreeing for a milestone SLA to capture their TAT performance

Dependency Report • Project Champion • Process Tower Lead

• Upskilled TCS on specific IT skillset to avoid handoff from TCS to IT

• Priority matrix defined for all critical queues and defined priority SLA

Inter departments in onshore were not providing real time support

Pended Orders Report • Process Manager (Client) • Process Tower Lead

• Mailbox created for instant escalation • Automated IVR deployed to seek

approval for all credit override orders

Resistance was identified and/or addressed in this phase of the Project

16

31

4.0.7 Stakeholder Involvement in the Project

Stakeholders Involvement Communication

Project Steering Committee

Attending weekly reviews Approved man-hour required Resolution on Escalation Toll gate signoff

Weekly review- 37 Reviews Monthly review-9 Reviews

Toll gate review – 7 Reviews Spark Best practice Sharing-1 Review

Project Execution Group

Attend Brainstorming session Data collection Statistical Analysis Sharing progress update Escalate & engage team towards project objective

Project Management Group

Ensuring timeliness Providing necessary knowledge & expertise to execution group Validating hypothesis with data Helped in escalating items Review projects with stakeholders

Process Owners Provided process perspective during the data collection & analysis Training & meeting participation

Head of Center of Excellence Knowledge sharing from other domains

32 •Copyright © 2013 Tata Consultancy Services Limited

32

Project Walkthrough

Section 5

17

TCS Confidential 33

5.0.1 Data Driven Project Flow

EXPECTED Benefits

BUSINESS CASE

PROBLEM STATEMENT

GOAL STATEMENT

PROJECT SCOPE INCLUDES

NPS score is trending at -43.7 for the period Apr- June ‘17.Lower the NPS has impact on increase in churn, drop in revenue and market share. The Industry standards quote that one detractor is equal to a potential churn of 2 customer and 1 advocate is equal 2 new customer. This is an opportunity for TCS to further enhance it’s partnership with Client by adding value and create benchmark improvement in satisfaction score across other operators

Reduction in Turn Around Time, CSS,Complaints Per customer, Improved customer satisfaction and increased customer confidence in our network

Copper- Wirelines Product All Types of order PSTN, Foxtel, Bundles, Big pond

To improve NPS by 40% from -43.7 to -26 by 30th June 2018

PROJECT MILESTONES

PROJECT SCOPE EXCLUDES

Project Leader Srividhya B

Team Members Vasanth, Santhosh

Project Champion Joy Mohanty

Process Owner Hashim/Allwin

Project Mentor Prasannarani/Ram

Project Sponsor Rhonda Rumler/Madhu C

Fiber Product, Mobility and Broadband Technological Changes in design process from client

CRITICAL ITY OF THE PROCESS

High

IMPACT ON

Internal ,Client and End Customer

Our client is an leading Australian telecommunications provider, provides voice, mobile, internet access and pay television products and services to customers across Australia. TCS Back of House team handles the order fulfilment process for the various telecommunication products sold. NPS is the measure of willingness of customers to recommend a services to others. NPS is key strategic metric to improve customer experience & increase revenue. The Team currently handles a volume of 3 Lac spread across 4 products. The net promoter score is negative across all operators & it is a important metric for improvement across the industry. Our client with highest market share was looking to scale up on this metric first. TCS being the leading partner and had end 2 end visibility on the processes was required to transform the existing process and improve the NPS scores to help our client and increase the revenue .

Phase July'17 July'17 Aug'17 Sep'17 June'18

Define

Measure

Analyze

Improve

Control

Project Charter

D M A I C

TCS Confidential 34

Metrics & Operation Definition

Name of the metric (with unit of measure): Net Promoter Score (NPS) Operational Definition: Net Promoter Score is an index ranging from 0 to 10 that measures the willingness of customers to recommend a company’s products or services to others. It is used to gauge the customer’s overall satisfaction with a company’s product or service and the customer’s loyalty to the brand. Advocates is a customer who recommends the service to his friends, relatives .Detractor is a customer who spreads negative word about the product/company. Passive is in different about product/company.

Formula: %Advocates - % Detractors Any score between 0-6 (Detractor) is considered a Defect Period of Data: Apr ‘17 to June’17 Current Performance: -43.17 (Apr’17-June’17 NPS score) Target: -26

Measure Data type What How Frequency Source Period Size

NPS (Net Promoter Score)

Discrete NPS

report

Report via NPS

reporting tool

Weekly Reporting

Tool June’17

151 data

points

-46.00

-44.00

-42.00

-40.00

-38.00

Apr'17 May'17 Jun'17

NP

S

Apr'17 May'17 Jun'17

NPS -44.46 -41.26 -45.38

NPS Trend –Apr’17 to June ‘17

5.0.1 Data Driven Project Flow

What Data was generated to select the project

D M A I C

18

35 TCS Confidential

35

35

Name ARMI Strongly Opposed

Opposed Neutral Supportive Strongly

Supportive

Client General Manager A, I X

Madhusudhan Calastry A, I X

Joy Mohanty A, I X

Manickavachakam R X

Client –Business Manager R X

Vasanth M X

Santhosh M X

TCS SME Team M X

Supplier Input

Process Output Customer

End Customer

Sales Channel

Order Build Team

Client Internal Teams

Web forms

Siebel Orders

Inbound Calls

Logistics

(Systems/Applications)

Outbound Call

SMS/Email/Letter

Service Activation

SIK Kit delivery

NPS Feedback

(Interaction and Episode)

End Customer

Client Internal Teams

Activation team

End Customer

Order Build

Fallout Remediation

Field Appointment

Modem Installation

Service Activation

* When Populating the Stakeholder, consider the ARMI:

• A= Approver of team decisions

• R= Resource or subject matter expert (ad hoc)

• M= Member of team

• I= Interested Party who will need to be kept informed

SIPOC was charted & team charter enabled us in ensuring support and partnership from all the stakeholder

5.0.1 Data Driven Project Flow

SIPOC and Stakeholder Analysis

D M A I C

TCS Confidential 36

Process was deep dive through Process Map. Detailed Process Map has been drafted

5.0.1 Data Driven Project Flow

Process Mapping

D M A I C

19

TCS Confidential 37

7Quick Win solutions identified and implemented before moving into full fledged problem solving

Tech Visit

Address issue

Customer Reachability

Activity Quick win opportunity Area Quick win solutions Lean Tools

Applied

A technician visits to the customer premise and install the

services

Tech visiting the customer only to activate the PSTN service, Internet activation happens post the PSTN connection which delays the service activation by 4 business days.

One Step appointment proposed to Client which activates the PSTN & internet at the same time. This saves the time & truck roll cost and quicker service to the customer.

Waiting

Activity Quick win opportunity Quick win solutions Type

Order failing to EP due to Address issue

Address issues are occurring due to mismatch between Australian Council and Client database. This causes delay in service activation and unnecessary rework

Root cause identified and fixed the bug in the system which help orders not failing in EP because of this error message

Defect

Activity Quick win opportunity Quick win solutions Type

Contacting customer to acquire missing/incorrect information

The reachability of the customer is very low as the customer not available which resulted in delay in processing the request/ withdrawn the request

Proposed solution Client to amend a preferred contact time in all the web forms, so that call will be made during that time.

Standardize

5.0.1 Data Driven Project Flow

Quick Win

TCS Confidential 38

Web form

Knowledge Management

Reporting

Activity Quick win opportunity Area Quick win solutions Type

Service request to be reviewed for processing the order built

Orders were getting delayed due manual validation and processing. Multiple navigation between applications

In-house Macro tool developed to fetch the details and enable us in a single view. This helped us in avoiding transport, Defect and waiting waste

TIMWOOD -LEAN

Activity Quick win opportunity Quick win solutions Type

Parked /Clarification orders Consultant reach out to onshore stakeholders for different scenarios / process confirmation .waiting for resolution to proceed further

Dedicated experts deployed across all LOB with systematized approach of tracking aged orders. Repository created and OLAs defined

Intellectual

Activity Quick win opportunity Quick win solutions Type

Preparing Reports to identify Duplicate/Closed records

Associates are preparing the reports manually. Huge time consuming activity which will eliminate rework effort.

In-house Expert developed VB Scripts which help us to eliminate the manual efforts and generate automatic reports

Jidoka

Number Designation

Activity Quick win opportunity Quick win solutions Type

Designation Number is mandate to process the number redirection

request

Associates manually referring the contact details in the application . Time consuming activity

Proposed Idea to Client to enhance the current operation model. Developed interface which dials automatically to

the customer

Standardize)

5.0.1 Data Driven Project Flow Quick Win

7Quick Win solutions identified and implemented before moving into full fledged problem solving

D M A I C

20

TCS Confidential 39

Process Sigma Calculator - Discrete Data

Total Number of orders Survey N 2366

Total Number of Detractors D 1508

Number of Defect Opportunities per Unit O 1

Defects per million opportunities dpmo 637362.6

Defects as percentage 63.74%

Process Sigma Level Sigma 1.15

Interpretation: • The process is at 1.15 Sigma level

5.0.1 Data Driven Project Flow

Capability Analysis

D M A I C

TCS Confidential 40

Data Collection Plan

Metrics

Net Promoter Score Improvement

Definition

NPS is a difference between % detractors from % Advocates. Any score between 0-6 (Detractor) is considered a Defect

How Measured

NPS = % Advocates - % Detractors

NPS Improvement

Project Y

Measure What Data Type Frequency Source Period Responsible

Y1

SM

SM

CM

NPS

Lead Time

Accuracy

Cost to Serve

Discrete

Continuous

Discrete

Attribute

Monthly

Monthly

Monthly

Monthly

Apr’17 –Jun’17

Apr’17 –Jun’17

Apr’17 –Jun’17

Apr’17 –Jun’17

Vasanth

Allwin

Rajesh

Vijay

Function Client O2A

FTE Size 650+

BAU Period Since August 2011

Opn. Window

Multiple Shift

Service Offering

Service Fulfilment

Products Internet, Voice

Billing Type Transaction Based Pricing

Process Information

5.0.1 Data Driven Project Flow

Data Collection Plan for Y

D M A I C

21

TCS Confidential 41

Less NPS Score

Materials People

Methods / Procedures Methods / Procedures

Reward/Offers not updated as process

Potential Causes (Xs)

Not cross trained

Call back not done as promised

POD not submitted

Customer not in attendance/Rescheduled

Provisioning Escalations (PET delay)

Modem not received

PODS Delay

Third Part Order

Non availability of automated system

Frequent discounts/promotion campaign

Webform not used by sales team

SIK offered by Sales to customers with out proper expectation setting

High Repeated Fallout Ports\Wire not available

Incorrect address\Product by FOH

No proper work allocation

Multiple tech visit but issue is not fixed

Delay or unavailability of appointment

incorrect/Invalid service activated by FOH

No Escalation matrix

Wrong commitment given to customer

High Shrinkage & Attrition

Customers very particular about appointments

Price comparison with Other service provider

Siebel Latency

Planned/unplanned outages

Intermittent connectivity issue

VDI Latency

System Issues leading to fallouts

Effect (Y)

ITAM dependency-No Lead time

System

Communication skill issue

Poor service in T-store

Service activation process not communicated

SME’S & Agent not aligned

Order not tracked properly

Delay in picking request

Technician work is incomplete

Stock unavailable

…and 65 probable causes was identified with fish bone

People

- 41 -

Frequent Bundle Change

Less Technicians

High Dependency on Multiple Products

Site not ready

Tenurity

Disconnect between various Tools/Applications

Multiple sources of information

Lack of floor support

Long Hold/Delay

misinterpretation / Process gap

Incomplete Cutover as work not completed

Lack of adherence to WI

Not following user procedure

Call Handling issues

Delay due lag btw sale and Order creation

TCD Compliance

Training Gaps

Process Knowledge Gap

Incomplete/Incorrect Action

Unhappy with Installation

Customer Request Untouched

High Touch Points

Held Orders

5.0.1 Data Driven Project Flow

Brainstorming

Unreachable Customer No network coverage

NPS score differ between states

D M A I C

TCS Confidential 42

5.0.1 Data Driven Project Flow

Probable X’s

Cause-Effect Matrix

Lead time

Accuracy Cycle Time <<- Output Indicators

10 9 3 << - Importance (1-

10 scale)

- Input/Process Indicators - - Correlation of Input to

Output - Total Rank

High Repeated Fallout 9 9 9 198 1

High EP Lead Time 9 9 9 198 1

High Customer Disatisfication due to Retail

and contact Center 9 9 9 198 1

Incomplete/Incorrect Action 9 9 9 198 1

Incorrect address\Product by FOH 9 9 9 198 1

Webform not used by sales team 9 9 9 198 1

incorrect/Invalid service activated by FOH 9 9 9 198 1

FOH user error 9 9 9 198 1

Technician work is incomplete 9 9 3 180 2

Call back not done as promised 9 9 3 180 2

Wrong commitment given to customer 9 9 3 180 2

Unhappy with Installation 9 9 3 180 2

Multiple tech visit but issue is not fixed 9 6 1 147 3

Siebel Latency leading to fallouts 9 3 9 144 4

System Issues leading to fallouts 9 3 9 144 4

Unwarranted Volume due to planned/unplanned outages 9 3 9 144 4

ITAM dependency-No Lead time 9 3 9 144 4

High TAT for Provisioning Escalations 9 3 9 144 4

High Dependency on Multiple Products 9 3 9 144 4

High Touch Point 9 3 9 144 4

orders Held in various stages 9 3 9 144 4

Long Hold/Delay 3 9 9 138 5

Tenurity 3 9 6 129 6

High TAT for PODS 9 3 3 126 7

POD not submitted 9 3 3 126 7

Delay or unavailability of appointment 9 1 9 126 7

Customer Request Untouched 9 3 3 126 7

NPS score differ between states 9 3 3 126 7

Expectation not Set during Sales 3 9 3 120 8

Incomplete Cutover as work not completed 9 3 1 120 8

Call Handling issues 3 9 3 120 8

Communication skill issue 3 9 3 120 8

SIK offered by Sales to customers with out proper expectation

setting 6 6 1 117 9

Poor service in T-store 3 9 1 114 10

Delay due to Unavailable of Escalation matrix 9 1 3 108 11

Cause-Effect Matrix

Lead time

Accuracy

Cycle Time

<<- Output Indicators

10 9 3 << - Importance

(1-10 scale)

- Input/Process Indicators - - Correlation of Input to

Output - Total Rank

Stock unavailable 9 1 3 108 11

Customers very particular about appointments 9 1 1 102 12

Customer not in attendance/Rescheduled 9 1 1 102 12

Process Knowledge Gap 3 6 1 87 13

Not following user procedure 3 6 1 87 13

Lack of adherence to WI 3 6 1 87 13

Unreachable Customer 6 1 3 78 14

BQ Performers 1 6 3 73 15

SME’S & Agent not aligned 1 6 3 73 15

Modem not received 6 1 1 72 16

TCD Compliance 6 1 1 72 16

Order not tracked properly 6 1 1 72 16

Delay in picking request 6 1 1 72 16

Not cross trained 6 1 1 72 16

VDI Latency 6 1 1 72 16

No proper work allocation 6 1 1 72 16

No network coverage 6 1 1 72 16

Ports\Wire not available 6 1 1 72 16

Less Technicians 6 1 1 72 16

Training Gaps 1 6 1 67 17

High Shrinkage & Attrition 3 3 3 66 18

misinterpretation / Process gap 3 3 3 66 18

Non availability of automated system 3 1 6 57 19

Lack of floor support 1 3 3 46 20

Frequent discounts/promotion campaign 3 1 1 42 21

Frequent Bundle Change 3 1 1 42 21

Third Party Order 3 1 1 42 21

Disconnect between various Tools/Applications 3 1 1 42 21

Intermittent connectivity issue 3 1 1 42 21

Site not ready 3 1 1 42 21

Price comparison with Other service provider 3 1 1 42 21

Reward/Offers not provided to customer 1 1 1 22 22

D M A I C

22

TCS Confidential 43

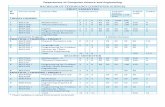

X's Shortlisted Causes Corresponding X Data Type

1 High TAT for PODS

Lead Time PODS Continuos POD not submitted

2

High EP Lead Time

Count of Fallout orders Discrete

Delay due to Unavailable of Escalation matrix

ITAM dependency-No Lead time Siebel Latency leading to fallouts System Issues leading to fallouts

Unwarranted Volume due to planned/unplanned outages

High Repeated Fallout Incomplete/Incorrect Action

3

Poor service in T-store

Count of FOH errors Discrete

Communication skill issue Expectation not Set during Sales Incorrect address\Product by FOH Web form not used by sales team

incorrect/Invalid service activated by FOH

Wrong commitment given to customer

FOH user error

4

Customers very particular about appointments

Count of Held orders Discrete Delay or unavailability of appointment

Technician work is incomplete High Held orders

5

Multiple tech visit but issue is not fixed

Count of Installation orders Discrete SIK offered by Sales to customers with out proper expectation setting

Incomplete Cutover as work not completed

Unhappy with Installation

6 High Dependency on Multiple Products Product wise Activation Survey Discrete

7 Segment Segment wise Activation Survey Discrete

8

Customer not in attendance/Rescheduled

Lead Time Customer Contact

Discrete

Call back not done as promised Discrete Long Hold/Delay Discrete Call Handling issues Discrete

9 High Touch Point Count of Touchpoints Discrete 10 Tenurity Tenurity wise NPS Survey Discrete 11 High Customer Disatisification due to Retail and contact center Channel wise Activation Survey Discrete 12 High TAT for Provisioning Escalation Lead Time PET Continuous 13 NPS score less in TAS State wise Activation Survey Discrete

13 Countable Unique X’s has been identified for data collection and validation

X’s

5.0.1 Data Driven Project Flow

Affinity Diagram –Causes to X’s

D M A I C

TCS Confidential 44

X Corresponding X Data Type Frequency Source Period Responsible

X1 Lead Time PODS Continuous Monthly WFM Dashboard/NPS Report

3 Months Santhosh

X2 Count of Fallout orders Discrete Monthly Fallout Report 3 Months Vasanth

X3 Count of FOH errors

Discrete Monthly NPS Report 3 Months Vasanth

X4 Count of Held orders Discrete Monthly NPS Report 3 Months Vasanth

X5 Count of Installation orders Discrete Monthly NPS Report 3 Months Vasanth

X6 Product wise Activation Survey Discrete Monthly NPS Report 3 Months Vasanth

X7 Segment wise Activation Survey Discrete Monthly NPS Report 3 Months Vasanth

X8 Lead Time Customer Contact Continuous Monthly WFM Dashboard/NPS Report 3 Months Vasanth

X9 Tenurity wise NPS survey

Discrete Monthly

Master Database

3 Months Santhosh

X10 Count of Touchpoints Discrete Monthly

NPS Report

3 Months Vasanth

X11 Channel wise Activation Survey Discrete Monthly NPS Report 3 Months Santhosh

X12 Lead Time PET

Continuous Monthly WFM Dashboard/NPS Report

3 Months Santhosh

X13 State wise Activation Survey

Discrete Monthly WFM Dashboard/NPS Report

3 Months Santhosh

5.0.1 Data Driven Project Flow

Data Collection Plan for X’s

D M A I C

23

45

X1 – Lead Time PODS VS NPS Rating

Hypothesis

Objective of the test is to validate the relationship between Lead time PODS VS NPS rating Ho : PODS Lead time do not affect NPS rating Ha : PODS Lead time do affect NPS rating Tool : Regression

Test Output

Interpretation

As the P-Value is less than the<0.05, it has been considered that there is a significant relationship between Lead time PODS VS NPS Rating

High Lead time affect NPS rating

5.0.1 Data Driven Project Flow D M A I C

46

X3 – Count of Fallout orders VS NPS

Hypothesis

Objective of the test is to validate the relationship between Fallout order and NPS Ho : Fallout orders do not affect NPS Score Ha : Fallout orders affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the <0.05, it has been considered that there is a significant relationship between between the Fallout orders and NPS

Fallout order is affecting the NPS score

5.0.1 Data Driven Project Flow

Sno Healthy

1 Non Fallout

2 Fallout

D M A I C

24

47

X4 – Count of FOH Errors VS NPS

Hypothesis

Objective of the test is to validate the identified X’s are the major contributors for completion Tool : Pareto Chart

Test Output

Interpretation

Pareto has been done and validated that the identified

X’s are the major contributors for Low NPS score.

Hence decided to put control to reduce the number of

detractors for the above contribution

Error 18 16 15 22184 99 72 56 25 22 18 18

Percent 3.2 2.8 2.7 3.932.6 17.5 12.7 9.9 4.4 3.9 3.2 3.2

C um % 90.6 93.5 96.1 100.032.6 50.1 62.8 72.7 77.2 81.1 84.2 87.4

FO H

Other

R ude beh

av ior

Cust

omer S

erv ice

-Com

muni

catio

n sk

i ll is

sue

Tech

nicia

n w

ork is in

com

plete

Long

hold

tim

e

inco

rrect/Inv

alid ser

v ice

activ

ated

by F

OH

Call

back

not

done

as pr

omiss

ed

Poor se

rvice in

T-sto

re

Com

mun

icatio

n sk

il l is

sue

Wro

ng com

mitm

ent

Expec

tatio

n no

t Set

durin

g Sales

FOH u

ser erro

r

600

500

400

300

200

100

0

100

80

60

40

20

0

Erro

r

Pe

rce

nt

Pareto Chart of FOH

5.0.1 Data Driven Project Flow D M A I C

48

X6 – Installation Type VS NPS

Hypothesis

Objective of the test is to validate the relationship between Installation Type VS NPS Ho : Installation do not affect NPS Score Ha : Installation do affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the alpha value, it has been considered that there is a significant relationship between between the installation Type and NPS

The Chi-square value indicates that the products which does required the installation has low NPS score.

5.0.1 Data Driven Project Flow D M A I C

25

49

X5 – Count of Held Orders VS NPS Score

Hypothesis

Objective of the test is to validate the relationship between Held Order and NPS Ho : Held order do not affect NPS Score Ha : Held Order affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the <0.05 it has been considered that there is a significant

relationship between between the Held orders and NPS

Chi-Square Test: Advocates, Detractor

Expected counts are printed below observed counts

Chi-Square contributions are printed below expected

counts

Advocates Detractor Total

Held 10 71 81

17.09 63.91

2.939 0.786

Non Held 17 30 47

9.91 37.09

5.065 1.354

Total 27 101 128

Chi-Sq = 10.143, DF = 1, P-Value = 0.001

5.0.1 Data Driven Project Flow D M A I C

50

X7 – Product VS NPS

Hypothesis

Objective of the test is to validate the relationship between Product and NPS Ho : Product do not affect NPS Score Ha : Product do affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the >0.05, it has been considered that there is no significant relationship between Products and NPS

p >0.05, hence Ho is accepted. Product do not effect Episode NPS

5.0.1 Data Driven Project Flow

Sno Product

1 Big pond

2 Bundle

3 Foxtel

4 PSTN

D M A I C

26

51

X8 – Segment VS NPS

Hypothesis

Objective of the test is to validate the relationship between Segment order VS NPS Ho : Segment category do not affect NPS Score Ha : Segment Category affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the <0.05, it has been considered that there is a significant relationship between the segment and NPS

The Chi-square value at the segment level indicates that the Family & Fun(4) and Friend ,fun & Fashion (7) Safe and respected (9), segment contributes to detractor high compared to other segments

5.0.1 Data Driven Project Flow D M A I C

52

X10 – Tenurity of agent VS NPS Score

Hypothesis

Objective of the test is to validate the relationship between Tenurity of agent and NPS Ho : Tenurity do not affect NPS Score Ha : Tenurity affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the >0.05, it has been considered that there is no significant relationship between NPS and Tenurity

5.0.1 Data Driven Project Flow

Sno Tenurity

1 <1 Year

2 2-3 Year

3 >3 Years

D M A I C

27

53

X11 – Touch Point VS NPS

Hypothesis

Objective of the test is to validate the relationship between touch point and NPS Ho : Touch Point do not affect NPS Score Ha : Touch Point affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the <0.05, it has been considered that there is a significant relationship between between the touch Point and NPS

It’s been observed that the orders which have more than 2 touch points shows dip in NPS scores on all months

Touch point is influencing towards NPS

5.0.1 Data Driven Project Flow D M A I C

54

X12 – Channel Type VS NPS

Hypothesis

Objective of the test is to validate the relationship between Channel Type order VS NPS Ho : Channel Type do not affect NPS Score Ha : Channel do affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the <0.05, it has been considered that there is a significant relationship between the channel Type and NPS

The Chi-square value indicates that Contact Center channel contributes to detractor high compared to other channels

5.0.1 Data Driven Project Flow D M A I C

28

55

X2 – Lead Time Customer Contact VS NPS Rating

Hypothesis

Objective of the test is to validate the relationship between Fallout Lead time VS NPS Ho : EP Lead time do not affect NPS Score Ha : EP Lead time do affect NPS score Tool : Regression

Test Output

Interpretation

As the P-Value is less than the<0.05, it has been considered that there is a significant relationship between Lead time EP VS NPS Rating

High EP Lead time affect NPS score

5.0.1 Data Driven Project Flow D M A I C

56

X14 – State VS NPS

Hypothesis

Objective of the test is to validate the relationship between State wise and NPS Ho : State wise do not affect NPS Score Ha : State wise do affect NPS score Tool : Chi square

Test Output

Interpretation

As the P-Value is less than the >0.05, it has been considered that there is no significant relationship between between the State wise and NPS

Failed to reject Null hypothesis.

5.0.1 Data Driven Project Flow

Sno Customer State

1 NSW

2 VIC

3 QLD

4 WA

5 SA

6 ACT

7 TAS

D M A I C

29

57

S. No Validated X’s X Data Type Y Data Type Test Used Accepted

X1 Lead Time PODS Continuous Continuous Regression Significance

X2 Count of Fallout orders Discrete Discrete Chi Square Significance

X3 Count of FOH errors

Discrete Discrete Pareto Significance

X4 Count of Held orders Discrete Discrete Chi Square Significance

X5 Count of Installation orders Discrete Discrete Chi Square Significance

X6

Product wise Activation Survey

Discrete Discrete Chi Square Non Significant

X7

Segment wise Activation Survey Discrete

Discrete Chi Square Significance

X8 Lead Time Customer Contact

Discrete Discrete Chi Square Significance

X9 Tenurity wise NPS survey

Discrete Discrete Chi Square Non Significant

X10 Count of Touchpoints Discrete Discrete Chi Square Significance

X11

Channel wise Activation Survey

Discrete Discrete Chi Square Significance

X12 Lead Time PET

Continuous Continuous Regression Significance

X13 State NPS Survey

Continuous Continuous Chi Square Non Significance

5.0.1 Data Driven Project Flow

Summary- Statistical Test Plan and Results

D M A I C

5.0.1 Data Driven Flow

- 58 -

Validated X’s Root Cause List of Solutions Responsible

Lead Time PODS

1)20% of Order form had incorrect POD of Document Submitted or critical document not submitted for service activation due to non availability of mistake proof frond end systems 2)The attempt to reach the customer to collect the document is significantly high as 7 to 10 days impacting the overall lead time 3)Document submitted but misalignment between system for processing

1. Two Way SMS : Two Way SMS to implemented for to improve customer reachability, reduce calling dependency.

2. Overall Equipment Effectiveness (OEE) :Trigger about right document submission for the FOH while orders submission.

3. Process Reengineering : New mail box has to be developed for handling the POD validation for not reachable scenario

4. IT Intervention :All orders should flow to PODS submission queue without any interruptions

Srividhya/Allwin

Team

Fallout orders

1) No Specific prioritization for fall out order leading to delay of service activation

2) IT issue Orders Piled up during weekend and no defined escalation matrix

3) Fallout due to multiple product configuration due to undefined business rule in the legacy system

4) Mobile Add new order should not contains initials , spaces in Siebel since MICA will not accept the same leading to fallouts

5) Customer requested VAS is incompatible for the products already active for the customer

6) Order failed as the address in customer portal/ billing account address provided in Siebel is not mapped with E-East

7) Foxtel move orders landed in VIVA successfully, but failed in Siebel . Orders getting failed as B2B handler unable to handle the orders on time/sending response back to Siebel

8) Customer migrated to Mx9 platform in network however Siebel is still active with MX8 platform asset

5.Dedicated Team :Ring fence to be created in EP to prioritize Activation & Move request to fast track action turn around time 6. Heijunka (Scheduling): IT weekend support required to handle and mitigate the system fallout orders 7.One Stop Solution (MUDA) : Analyzed all the products and business matrix developed to provide all service at one instance 8. Poke Yoke. Automatic Tool to be developed to overcome the system challenges in order to avoid the human errors 9. System Enhancement ( First Time Right) Business rules developed to indicate the right component with the user friendly approach on selecting the Product 13. Make the Complex Simple : Address database to be reinforced with Siebel and the Australian Govt. Database 14. Continuous Flow: Refine the existing system to have the seamless flow to avoid the order fallout in B2B system 15. Continuous Flow: Refine the existing system to have the seamless flow to avoid the order fallout in 15. Standardize: Siebel to be aligned with the network model for all customer Mailboxes

Srividhya/Abi

D M A I C

30

- 59 -

Validated X’s Root Cause List of Solutions Responsible

Count of Fallout orders

Error occurs due to Data alignment between Siebel, USM and Network.

Order getting failed due to Planned / Unplanned System outages. This is due to system maintainenace

17. PDCA: Analyze the list of misaligned service data and establish protocol to verify the alignment in the service inventory 18. Proactive Engagement :System should pro-actively get inputs from the requestor and provision the requests once the system running up - Simultaneous customer should be informed about the delay. OM should be holding the order until IT system up and Running

Srividhya/Abi

Segment wise Activation Survey

Offers not applied as promised Incorrect information received which lead to high TAT No Prioritization done on the segment request

19. IT team need to verify the offers applied for all the product release

20. Dedicated Team to create for emergency and High value customer

Srividhya/Abi

Count of FOH errors

Work Instruction not effectively maintained

Not procuring the right information during sales/order submission.

Communication/skill issue

Wrong commitment provided to the customer

21. Collaborative Session: Joint session between FOH/TCS to exchange effective Knowledge Session on the detractor feedback and user errors and 22.Work Instruction : Standardized Work – Documented procedures for

Inbound/Store /Back office on the alignment of work 23. Feedback Management Tool: Feedback provided to the users on the

committed error, discovering the true underlying problem. Strengthening the weakest area .

Srividhya/Jucel

Count of Held orders

No Prioritization on the orders held up in the “ Held order management Queue “

Non Availability of Technicians Port Unavailability Less Infrastructure Customer been not informed about the delay

24. Priority Support : Team choose the Held orders for managing the New provision order to enhance the customer advocacy 25. Dedicated Slots for Fallout :Reserved slot for fall out queues to meet the

original date 26. Elevate Network Footprint : Feasibility to be explored to fix splitter in

precedence to port pillar to augment port availability. 27.Case Managers : Deployed Case Manager to be deployed for effectively managing the held request without any delay. Ride on

Srividhya/Rhond

a

5.0.1 Data Driven Flow D M A I C

- 60 -

Validated X’s Root Cause List of Solutions Responsible

Lead Time Customer Contact

Missed to call the customers on all available contact and less reachability

No prioritization on calling attempt based on order type

SMS not sent for all unsuccessful attempts(KMI not done)

Multiple hands off on internal contacts to remediate the order

28. Jidoka (Autonomation ) :Automated Caller out to be connected for all the outbound calls which will increase customer reachability Increase the number of attempts in automated system from 2 to 3 for better reachability. 29.Priority : Customer Preferred contact time slot to be made available in Siebel to increase customer reachability % 30. Automated SMS Report to be sent for every unsuccessful attempt 31. Cross Skill BOH to contact Internal team areas which will avoid volume for

customer contact

Client/Srivid

hya

Count of Touchpoints

Customers requests untouched in SOTB due to user negligence

Incorrectly moved and actioned the request Lack of Cross Training and multiple process

dependency

33. Live Dashboard : Reports to be developed to check the touch status of each action with the order journey details 34. Process Standardization: Matrix to be developed to meet all the critical requirements of transferring the orders to the right department on the first instance 35. Cross Skill to be done in the back of house team to contact internal teams for order remediation and handle the orders end to end by the consultant

Srividhya/Le

ads/Client

Channel wise Activation Survey

WI not aligned between Retail and GCC 36. Work Instruction to be reviewed between GCC and Retail Live and Workshop to be

arranged between GCC , Retail team and Back of House

Srividhya/Cli

ent

Lead Time PET

Orders stuck in provisioning system due to system challenges

Systems not enhanced High TAT on IT resolution Multiple teams involved in resolving issues

37.Fast tracking: Provisioning escalation turn around time from IT will influence 11.8% of detractors from Push to cancel/Push to complete dependencies. 38Governance : Fortnightly call to be organized to discuss the dependency and way forward action for early closure

Habeeb

Installation orders

Tech work Incomplete Customer not been informed on the appointment No proper information on the KIT

39. Service Verification Call : Once technician work get completed , verification call to be initiated to confirm the service assurance 40 Automated KMI to be sent to customer if there is any appointment or commitment done in the customer request with the Prevalidation requirement 41. Self Installation user guide to be simplified for ease of connection

Srividhya

5.0.1 Data Driven Flow D M A I C

31

61

Easy Difficult Lo

w

Hig

h

1 3 5 4 9

11

10

13 12 16

18 21 27 28 32

4 23 8

Imp

act

to N

PS

Ease of Implementation

2

14 17

22

6

33 38 37 31 34

15 24 20 7 19

26 30 25 29

20 4

35 36 40 39

5.0.1 Data Driven Flow

What tools were used to identify the final solution

41

62

EP Fallout Improvement Validation

5.0.2 Solution Validation

Customer Contact -Improvement Validation

PODS Improvement Validation

We had significant improvement ….

32

63

Validated Root Cause PODS Fallout Orders

Segment FOH

Errors Held

Orders Customer Contact

Touch Points

Channel PET Installation

Orders Training Cost $0.04 $0.01 $0.000 $0.03 - - $0.02 $0.01 $0.01

Automation Cost - $0.01 - $0.001 0.000 - - $0.00 Man hours Spent $0.01 $0.07 $0.000 0.012 0.005 $0.014 0.01 $0.02 $0.01 $0.01

Total Cost $0.31 FTE Cost Save(Proj) $0.96 Customer Business

Value add save(Proj) $31.48

Total Benefit Annualized $32.44

Total Net Benefit $32.13

5.0.2 Solution Justification

Cost Benefit Analysis

TCS Confidential

64

64

IMPACT CLOSURE

HUMAN CLOUD ANALYTICS

• Employee Social Network Analysis • Sentiment Analysis

• Employee Collaboration Index

Pre Project Post Project

NPS -43.7 -18.66

-43.7

-18.66

-100

-80

-60

-40

-20

0

20

NP

S

NPS Pre VS Post

5.0.4 Results

Primary Metric Secondary Metric

0

1

2

3

4

5

6

Pre Project Post Project

Lead Time 5.29 4.28

Lead

Tim

e-I

n D

ays

Lead Time -Pre VS Project

96.50%

97.00%

97.50%

98.00%

98.50%

99.00%

Before After

Lead Time 97.50% 98.79%

Acc

ura

cy-D

efec

tive

Accuracy-Pre VS Project

Secondary Metric

$0.00

$1.00

$2.00

$3.00

$4.00

$5.00

$6.00

Pre Project Post Project

Cost to Serve $5.79 $3.31

Un

it R

ate-

Per

Ord

er-A

UD

Cost to Serve -Pre VS Project

Counter Metric

33

TCS Confidential 65

Process Sigma Calculator - Discrete Data

Total Number of orders Survey N 1324

Total Number of Detractors D 652

Number of Defect Opportunities per Unit O 1

Defects per million opportunities dpmo 492447.1

Defects as percentage 49.24%

Process Sigma Level Sigma 1.52

Interpretation

Sigma Score for NPS has been improved from 1.15 to 1.52

Improvement

Test and CI for Two Proportions

Claim: There is significant difference in NPS before and after improvement (HA)

Sample X N Sample p Detract-Pre 1508 2366 0.637363 Detract-Post 652 1324 0.492447 Difference = p (1) - p (2) Estimate for difference: 0.144916 95% CI for difference: (0.111742, 0.178089) Test for difference = 0 (vs not = 0): Z = 8.56 P-Value = 0.000

Fisher’s exact test: P-Value = 0.000

5.0.4 Results

Validation of Y – Improvement, Stability & Capability

66 - 66 -

NPS Wireline -Saving Calculations

Business Value Benefit Pre Project Post Project Potential Detractor % 62% 49% Volume 346163 Potential Business Value delivery threat per customer 64 ARPU

Potential Projected Loss Monthly $ 13,661,167.02 Volume x Detractor% Before

Potential Loss actually Monthly $ 10,823,340.06 Volume x Detractor% After

Monthly Business value Add -AUD $ 2,837,826.97

Annual Business Value Delivered in AUD $ 34,053,923.59

AUD to INR Conversion – ₹ 52.5100

Annual Business Value Delivered in INR ₹ 1,788,171,527.72

Annual Business Value Delivered in USD $ 41,701,761.37

Annualised Savings IN mn $ 41.70

Improvement Project Financial Benefit Calculation Sheet

PI Project Title: Building Enhanced Experience for Wire-line Segment (NPS)

PI Project Lead (GB/ BB/ LEAN/ SPS/ Other): Srividhya

Project Mentor: Prasannarani

Project Champion: Manick

Project Sponsor: Joy Mohanty

Project Start Month (MM/DD/YYYY): 1-Jul-17

Project End Month (MM/DD/YYYY): 30-Jun-18

Project Type: Customer Facing

Benefits from Project

5.0.4 Results

Total Business Value Add

Saving of $41.7 MN. Endorsed from client end

34

TCS Confidential 67

Interpretation

NPS Score has improved from -43.7 to 18.66

5.0.5 Maintaining the Gains

What were the results

68

5.0.5 Maintaining the Gains

Interpretation: 26 point improvement in NPS (-43.7 to -18.51) with reduction in variation of the scores

Interpretation:15% reduction in detractor improved from (62% to 55%) .

151413121110987654321

0.70

0.65

0.60

0.55

0.50

0.45

Sample

Pro

po

rtio

n

_P=0.5311

UCL=0.6022

LCL=0.4600

Pre Implementation Post

Tests performed with unequal sample sizes

P Chart of NPS Detractor by Stagewise

June

-18

May

-18

Apr

il-18

Mar

ch-1

8

Febr

uary

-18

Janu

ary -

18

Dec

embe

r-17

Nov

embe

r-17

Octob

er-1

7

Septem

ber-17

Aug

ust-17

July-1

7

June

-17

-10

-20

-30

-40

-50

Month

In

div

idu

al

Va

lue

_X=-23.29

UC L=-12.62

LC L=-33.95

Pre Implementation Post

June

-18

May

-18

Apr

il-18

Mar

ch-1

8

Febr

uary

-18

Janu

ary -

18

Dec

embe

r-17

Nov

embe

r-17

Octob

er-1

7

Septem

ber-17

Aug

ust -17

July-1

7

June

-17

15

10

5

0

Month

Mo

vin

g R

an

ge

__MR=4.01

UC L=13.10

LC L=0

Pre Implementation Post

I-MR Chart of Netpromoter by Stages

35

69

Control Plan

Process Step

What's

Measurement Method Control Method Frequency Responsibility Controlled?

EP Remediation EP Fallout Reports Responsibility assigned to Team Leads Daily Team Leads

PODS –Two Way SMS Lead time Siebel Report Quality check –Random

Audit Daily Quality Team

ITAM Escalation NPS affected by Aged ITAM’s Report SPOC assigned Daily SME SPOC

Customer Contact Customer Reachability Two Hours Report SPOC assigned Hourly Team Leads

Cycle time AHT WFM Report

Responsibility assigned to Team Leads

Weekly WFM

Own CODE Orders landing to CO tool without any miss

NPSO Report SOM SME’s Monthly TL

5.0.5 Maintaining the Gains

Control Plan

70

CAR-Best Practice Sharing

Newsletter : Standard Communication

Process Improvement Portal : Formal Communication

5.0.6 Project Communication

How did the team communicate the results to the various stakeholder groups?

36

71 TCS Confidential

71

Standard Communication Across multiple Stakeholders

5.0.6 Project Communication

72 TCS Confidential

72

5.0.6 Project Communication

Communicate the results to the various stakeholder

groups

Client

Client Endorsement

Acknowledgement

How did the team communicate the results and get acknowledgment?

37

TCS Confidential

- 73 -

Client General Manager– “Congratulations on this great achievement, it is a fabulous success story,

This is a true reflection of a great partnership and collaboration across the teams to help drive these fantastic results. My sincere appreciation and thanks to the entire teams”.

TCS Customer Leader– “Well done in enabling this improvement through the year and for the successful closure of this project. Pls pass my compliments to your teams

Delivery Excellence Head – “Excellent! Congratulations Team !

Business Team Manager– Great work and collaboration on this initiative across the teams.

5.0.6 Project Communication

Testimonials

74 TCS Confidential

Thank You!