brotanlagen matrix f20 - WP Bakery Technologies

Transcript of brotanlagen matrix f20 - WP Bakery Technologies

WP BAKERYGROUP

BREAD LINESMACHINES LINES

ALL THE ACTIVITIES OF THE WP BAKERYGROUP ARE TARGETED AT MAKING OUR CUSTOMERS SUCCESSFUL!

JÜRGEN HORSTMANN

2 _ 3

WP BAKERYGROUP

The WP BAKERYGROUP – with this portfolio of companies, we’ve comprehensively aligned ourselves with the needs of bakeries worldwide. Today we are in a position to offer total solutions – from project development to equipping complete bakeries (handcraft and industrial) and sale of used machinery.

The central element of our corporate philosophy is a networked way of thinking that stretches beyond the individual stages of production. We call it “process management”, the targeted management of the individual stages of production and the machines used within them – as fast and with as little loss of material as possible to achieve the desired result, even for small amounts – and the unlimited reproducibility of results achieved. And all this is combined with extremely high yield.

Each unit can be operated as a “stand-alone”, but can also be easily “docked on” at any time – interfaces for third-party products are sufficiently available. The complete WP line ensures reliable process management.

WP BAKERYGROUPBREAD LINES

WP BAKERYGROUP

COMMENTS ON IBA 2006

“If you’re looking for a strong partner for bakery equipment, then such a partner shouldn’t just build machines, but should also offer other fea-tures such as reliable engineering and top service. For this reason, we’ve gathered our ten companies under the specialised umbrella of the W&P brand to create the WP BAKERYGROUP – a future-orien-ted, modern machinery-engineering company. It possesses various competence centres, including those for bread, rolls and ovens, and is among the market leaders in all its segments.

Think process is at the heart of our corporate phi-losophy, and this describes the implementation of networked technology throughout all stages of production, with the goal of integrated processes. Within the implementation of consistent process-oriented thinking lie productivity reserves and op-portunities for greater quality.

WP CompetenceCenter

_ Dough/Mixing. Emil Kemper GmbH, Rietberg

_ Rolls. Emil Kemper GmbH, Rietberg

_ Bread. Werner & Pfleiderer Haton B.V., NL-Panningen

_ Ovens. Werner & Pfleiderer Lebensmitteltechnik GmbH, Dinkelsbühl

_ Instore baking. Werner & Pfleiderer Sachsen GmbH, Sohland

_ Refrigeration technology. Werner & Pfleiderer Lebensmitteltechnik Kälte GmbH, Dinkelsbühl

_ Laminate. Werner & Pfleiderer Lebensmitteltechnik GmbH, Dinkelsbühl

_ Engineering. Werner & Pfleiderer Industrielle Backtechnik GmbH, Tamm

_ Used machines. Pro-Fit-2 GmbH, Sohland

_ Bakery software. BackNet E&S GmbH, Muggensturm

Today, we are producing a new generation of machines and systems – the WP NEW GENERATION. What sets them apart:

Gentle on the dough

Best absorption rates

Best weight precision

Best product quality

Best productivity

Networked technology

Economic production of small amounts

Shortest set-up times

Highest standards for hygiene

Low energy consumption

Service, training and maintenance

Knowledge transfer

The WP BAKERYGROUP is the right partner for your future!”

Jürgen Horstmann

4 _ 5

WP BAKERYGROUP

WP BAKERYGROUPBREAD LINES

Reiner Knauf, Service Director “A comprehensive service concept, the targeting of all company activities toward the success of bakers worldwide – with this philosophy, the WP BAKERYGROUP seeks to further support its position in the industry and expand over the mid term. The cornerstones of WP services, which are directly oriented on the customer, include being available 24 hours a day, 365 days a year; the exclusive use of in-house technicians; a finely meshed ser-vice network in Germany and Europe; worldwide company representatives and service support centres; comprehensively equipped service vehicles as mobile replacement-parts warehouses; a permanent stock of about 100,000 original parts; technical support; helpline; and online remote diagnostics.”

Piet van Deur, Manager, Bakery Cooling “We present a completely new philosophy in refrigeration: the ‘aroma-refrige-rating’ principle. The NewGeneration WP-Kälteanlagen refrigeration system is designed for taste and aroma like never before – a revolution in refrigeration technology. With the AROMA+COOLER & AromaTrays from WP System Dieckmann for example: a new refrigerating concept based on suction cooling, for the in-shop-baking segment. It has an extremely positive effect on aroma, taste, crispness, shine and shelf life. And it saves in many areas. We will also show AROMAT und AROMAT+ – the aroma-maker and proving interrupter as semi- and fully-automatic machines with new dough-resting and ripening process control. And our new POWERCOOLER – a shock cooling system as a linear belt froster.”

Peter Wittmann, Managing Director “In the industrial production of sticks, we offer our customers another technological leap – with the SP-H sticks press. It’s a roller extruder for production of endless strings of dough, especially co-extruded products, and it produces Super Sticks – pressed, filled and turned. As a system provider, we deliver the complete soluti-on, from dough production to the sticks press, the lye bath, notching and cutting devices, the salt shaker and the convey-or oven, and packaging. Then there’s our new THERMADOR, the further development of the most successful tunnel oven in the world, which offers even better and faster baking with greater energy efficiency. Convection can now also be used in the burner module and therefore throughout all oven zones.”

Rainer Zeh, Managing Director “First of all we’ll be showing the current versions of the products the market is familiar with, like the MATADOR, multi-deck oven, the ROTOTHERM, convection oven, the OBER Junior loading robot, the ROTA-MAT EN dough dividing and moulding machine, the ROLLPROFI compact roll system, the MULTIROLL rolled pastry system ... One new item is our PELLADOR, a wood-burning oven concept with automated pellet heating, that was developed along with the Mitterer wood-burning oven bakery. In addition there’s our laminating system, which is equipped with a newly developed double satellite head. Highly pre-proved doughs can be processed with minimal structural influence, just as special doughs can be reduced to the desired size evenly, easily, and without losing air bubbles.”

Hans-Jürgen Kottisch, Managing Director „“Just in time for IBA, we’ve added some interesting functions to our Office Pro and Cash Pro software modules, developed especially for the bakery segment. During the further development of Office Pro, the area of “traceability of raw materials” was in the forefront, including the booking of raw materials, semi-finished and finished products, etc., to any desired number of storage sites. Cash Pro, the bakery till system, is now also available for confectioneries, cafés and restaurants, including recording of tables and seats. With Cash Pro-Orderman, recording of orders and cashier transactions is significantly improved.”

Lothar Paulick, Managing Director “Interest within the world market for good used machines is as great as ever. This is par-ticularly true for machines produced by Werner & Pfleiderer, Kemper, Haton and Winkler, which we overhaul from the ground up and deliver with long-term warranty agreements. We benefit here, of course, from direct access to the replacement parts stock within the WP BAKERYGROUP, as well as from the original design drawings for construction. We present our offerings, which are updated daily, through our Internet site at www.pro-fit-2.de. A visit to our permanent display, with more than 300 machines, can be arranged any time.

Ulrich Peitzmeier, Managing Director “This year at the IBA, we’ll first of all be presenting the now complete range of our new mixers – the mobile PRESIDENT and the POWERMIXER, which is equipped with a double-helix and guide rod. In addition, there’s the D&B Wizard, our patented doughnut and bagel module. The third highlight is the OXYLATOR, a new tool/method for oxygenating dough in the mixing area. In the area of dough dividing and moulding machines, we‘re introducing the SOFTSTAR PLUS. It’s equipped for permanent use in multiple shift operations – with gentle processing of the dough. For handcraft bakers, we’re also presenting the RULAX round- and long-moulder as a supplement to the tried and tested Consul doser.”

Henk-Jan Snellink, Managing Director „The MINICRUSTICA is our smallest and newest bread system for the entire range of classic bread varieties and shapes – with and without seeding, particularly for producing Mediterranean products such as ciabatta, baguettes, and other, very soft wheat doughs. BAGUETTA+ is a fully automatic bread system for braided breads, baguettes and brioche, which works according to the round-long principle (round-mould, prove, long-mould, pro-ve, final forming). Processing is extremely precise with regard to weight and remarkably gentle on the dough, the dough pieces are fully rested and retain their coarse texture throughout the process. Our SERVODIVIDER S 700 revolutionises dough division – the pressure necessary for precise weights is intelligently controlled throughout the dividing process.”

Comments on IBA 2006 – here and at www.wp-iba-news.com

Lothar Paulick, Managing Director “MATADOR STORE is the name of our new multi-level oven system that’s designed for more than just in-shop baking. MATADOR STORE sets itself apart with its outstanding baked results. This oven, which can be assembled according to a modular principle, is suitable not only for perfect baking in the shop, but also for producing various products in cafés, bistros, restaurants or hotels – products such as cakes, pizzas, casseroles and more, at a premium level of quality. In centralised production, it takes on the role of a finisher due to its short preheating times. We present our com-pletely revised convection in-shop oven, BRILLANT, with improved baking quality, with time and energy savings and a new cleaning programme. BAKY and STOREBEE are new highlights in the area of ‘automatic baking’ – with minimum personnel requirements, a new shopping experience, product variety and outstanding product quality.”

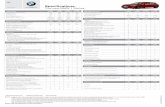

Dough dividing and moulding machines form the connection between dough preparation and proving.

Our machine program for the production of shaped dough pieces for bread production is extensive and takes

into account the different production priorities of our customers.

DOUGH DIVIDING AND MOULDING MACHINES

6 _ 7WP BAKERYGROUPBREAD LINES

Wheat dough

Mixed-wheat dough

Mixed rye dough up to 80 % rye

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

PARTA SN/SNE/SNDWater absorption from 155 to 175 %

Square breads

Long bread

Water absorption 155 – 175 %

100 – 2,400 g/piece

max. 2,400 pieces/h

Variable by means of frequency controller with digital readout

PARTA UWater absorption up to 170 %

All bread types Wheat dough

Mixed-wheat dough

Mixed rye dough

Water absorption up to 170 %

100 – 2,800 g/piece

max. 3,200 pieces/h

Frequency controller with capacity display

450 – 4,224 pieces/h

Classic bread types

Square dough pieces

Long dough pieces

Flat bread

Baguette

Rustic bread types

Rusk

Regional bread

Wheat doughs with resting times or long bowl fermentation

Mixed wheat dough

Mixed rye dough up to 80 % rye

Grain dough

Dough with additives

Baguette dough

Rusk dough

Water absorption up to 180 %

100 – 2,600 g/piece

max. 4,000 pieces/h

Variable by means of frequency controller with digital readout

1,911 – 4,368 pieces/h

B / V/ S 700Water absorption up to 175 %

All bread types Wheat dough

Mixed-wheat dough

Mixed rye dough up to 80 % rye

Pizza dough

Baguette dough

Water absorption up to 175 %

25 – 2,550 g/piece

1,000 – 9,000 pieces/h

V 500Water absorption up to 180 %

Dough divider from WP Haton

Dough divider from WP Haton

Dough divider from WP Haton

Dough divider from WP Haton

8 _ 9

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

– Wide bandwidth of dough weights

– Comprehensive processing of ingredients

– Highly precise weights

– Long lifecycle

– Robust construction

– Dough portioning hopper

– Round-moulder

– Preliminary rolling station

– Check weighter

– Very gentle to dough

– Sensitive doughs

– Highly precise weights

– Dough portioning up to 2,800 g (1-chamber design)

– Large range of dough weights

– Large dough hopper with low working height

– Recognised component principle

– Dough portioning hopper

– Round-moulder

– Preliminary rolling station

– Check weigher

– Wide range of weights

– Highly precise weights

– Extremely gentle to dough

– Simple to operate

– Simple to integrate

– Voluminator

– Touch-screen Storage for all data

– All machine settings are servo-driven

– Oil-reduced

– Dough portioning hopper

– Round-moulder

– Preliminary rolling station

– Check weigher

– Broad application area

– Modular construction

– Robust construction

– Extremely gentle to dough

– Minimal oil consumption

– Settings can be saved

– Transport belt open for visual control

– Easy to clean

– Voluminator = pressure control and pressure compensation

– Dough portioning hopper

– Round-moulder

– Preliminary rolling station

– Check weighter

DOUGH DIVIDERSBREAD LINES

V 900Water absorption up to 170 %

Toast bread

Tin loaf bread

Wheat dough

Mixed rye dough < 30 % rye

Pizza dough

Water absorption up to 170 %

150 – 1,950 g/piece

1,500 – 14,400 pieces/h

CONSUL ETWater absorption up to 180 %

All bread types Wheat dough

Mixed-wheat dough

Rye dough

Mixed rye dough

Grain dougg

Water absorption 155 – 180 %

up to 1,800 pieces/h

200 – 2,400 g/piece

Grain dough

400 – 3,600 g/piece

Round bread

Tin loaf bread

Toast bread

Baguette

Wheat dough

Mixed-wheat dough

Rye dough

Mixed rye dough

Grain dough

Round bread

Tin loaf bread

Toast bread

Baguette

Wheat dough

Rye dough

Mixed rye dough

IMPERATORWater absorption up to 175 %

Water absorption up to 175 %

200 – 2,350 g/piece

690 – 1,480 pieces/h

Water absorption up to 175 %

100 – 2,000 g/piece

max. 6,000 pieces/h

CORONAWater absorption up to 175 %

Dough divider from WP Kemper

Dough divider from WP Haton

Dough divider from WP Kemper

Dough divider from WP Kemper

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

10_ 11

– Highly precise speeds

– Recipe control

– Oil-reduced

– Easy to clean

– Dividing pistons are filled when stationary

– Cam drive

– Hydraulic control of dividing pistons

– Modern design

– Dough portioning hopper

– Round-moulder

– Preliminary rolling station

– Check weighter

– Unique weighing/dividing system with circulating ball spindle with servo drive

– Superior dough protection

– Extremely precise weights

– High process safety

– SPS control / touch-screen

– Easy to clean (No cleaning of the measuring chamber)

– WP Kemper RULAX

– Belt round moulder

– Conical round moulder

– Extremely versatile

– Gentle to dough

– Low maintenance

– Stainless steel design

– Machine is movable and guidable

– Variable hopper size

– Conical round moulder

– Belt round-moulder

– WP Kemper RULAX

– 2-way system

– Extremely versatile

– Extremely powerful

– Gentle to dough

– Low maintenance

– Stainless steel design

– Machine is movable and guidable

– Variable hopper size

– Conical round moulder

– Belt round moulder

– 2-way system

DOUGH DIVIDERBREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Round bread

Long bread

Tin loaf bread

Hearth bread

Pizza

Wheat dough

Mixed-wheat dough

Mixed rye dough

Whole-grain dough

Dough with additives

Water absorption up to 175 %

90 – 2,200 g/piece

bis 5,000 pieces/h

CCR 69 AT Water absorption up to 170 %

Toast bread

Tin loaf bread

Wheat dough Water absorption up to 170 %

350 – 1,100 g/piece

max. 10,000 pieces/h

CR 59CR 59 ATCCR 59Water absorption up to 175 %

Round bread Doughs with high rye content

Doughs with higher water absorption

SBR 2500 Water absorption up to 178 %

Water absorption 160 – 178 %

200 – 2,000 g/piece

max. 2,000 pieces/h

Conical rounder from WP Haton

High performance rounder from WP Haton

Stand rounder from WP Kemper

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Long worker from WP Kemper

PRINCESS KOMBIWater absorption up to 165 %

Toast bread

Baguette

Tin loaf bread

Wheat dough

Mixed-wheat dough

Water absorption 155 – 165 %

50 – 1,250 g/piece

max. 2,500 pieces/h

BREA

D L

INES

LO

NG

WO

RKER

BREA

D L

INES

RO

UN

DER

S

12_ 13

– Better transport

– Better proofing

– Better pore structure

– Homogeneous product

– More stability

– Moulding path up to 6 m; 236,2 "

– good processing of very soft and sticky dough

– Adjustable troughs (AT)

– Broad spectrum of weights

– Check weigher

– Intermediate proofer

– Long roller

– Moulding path up to 6 m; 236,2 "

– Consistent high quality

– Teflon-coated troughs/cones

– Stainless steel design

– Adjustable troughs

– High-performance round-moulder

– Central ventilation/oiling

– Large diameter in front of cone

– Cylindrical/conical moulding path

– Proofer

– Working belt or manual removal

– 1 vibrating flour duster

– 1 electronically controlled

– flour duster Quick-catch device

– Dough divider

– Long roller

– 2 roller pairs

– 1 adjustable roller pair

– 2 transverse moulding belts

– 1 pressure plate

ROUNDERS & LONG WORKERBREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

– Proofer

– Hand remova

Long breads

Hearth bread

Tin loaf bread

Rye dough

Mixed rye dough

Water absorption up to 180 %

320 – 2,500 g/piece

max. 2,500 pieces/h

Industrial long worker from WP Kemper

IL SPECIALWater absorption up to 180 %

Long breads up to 450 mm; 17,7 "

Wheat dough

Mixed-wheat dough

Mixed rye dough

Water absorption up to 165 %

200 – 2,000 g/piece

max. 1,500 pieces/h

Long roller from WP Haton

COMBI EWater absorption up to 165 %

COMBI UNIVERSALWater absorption up to 175 %

Round bread

Flat bread

Long bread - rolled out or lightly punched

Ciabatta

almost all other bread type

Wheat dough

Mixed-wheat dough

Mixed rye dough

Mediterranean dough

Classic dough

Water absorption up to 175 %

200 – 2,000 g/piece

bis 3,500 pieces/h

Toast bread

Tin loaf bread

Wheat dough

Mixed-wheat dough

Water absorption 155 – 165 %

100 – 2,000 g/piece

max. 4,000 pieces/h

BREA

D L

INES

LO

NG

RO

LLER

BR

EAD

LIN

ES L

ON

G W

ORK

ER

Long roller for soft doughs from WP Haton

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Long worker from WP Kemper

SELECTA KWater absorption up to 165 %

14_ 15

– Especially for rye dough

– Modular constructed

– Robust construction

– Good long roll results

– WP Kemper SBR 2500

– Hand removal

– Precise centring

– Dough pieces may be rolled out to 1 – 45 mm; 0,04 – 1,77 "

– Pressing board folds up

– Robust construction

– Long lifecycle

– Good cost-benefit ratio

– Completely made of stainless steel

– Proofer

– Working belt or manual removal

– Sensitive doughs

– Multifunctional

– extrem variabel

– Extremely variable wheat and rye roll-out part

– Bypass for cylinder mill

– Closure control

– Seeding possible

– Multiple moulding stations (pointed ends, flat, etc.)

– Proofer

– Working belt

– Manual removal

– Sheet transport belt

– Extractor

– 4 roller pairs

– 2 adjustable roller pairs

– Precise centring

– Optimal roll-out

– Reinforced cylinder mill

– Proofer

– Hand removal

– Mould transport

LONG WORKER & LONG ROLLERBREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Wheat dough

Mixed-wheat dough

BM 51Water absorption up to 165 %

Classic bread

Classic baked goods

Dough pieces up to 400 mm; 15,75 "

Water absorption up to 165 %

110 – 1,600 g/piece

max. 2,000 pieces/h

BM 54 BTWater absorption up to 165 %

Tin loaf bread

Hearth bread

Wheat dough

Mixed-wheat dough < 30% rye

Batone

Francala

Water absorption up to 165 %

200 – 1,100 g/piece

max. 3,000 pieces/h

Toast bread

Hearth bread

Wheat dough

Mixed-wheat dough < 30% rye

Water absorption up to 172 %

200 – 2,000 g/piece

max. 5,000 pieces/h

160 – 440 mm/piece; 6,3 – 17,3 "/piece

SERVOROLLER BMW 80Water absorption up to 172 %

Wheat dough

Mixed-wheat dough

Rye dough

Mixed rye dough

RULAX mit CONSUL ETWater absorption up to 170 %

Round bread

Square bread

Long bread

Water absorption 158 – 170 %

200 – 2,000 g/piece

500 – 900 pieces/h

Long roller for artisanal production from wheat and mixed wheat breads up to 70% rye from WP Haton

Rounding and long working machine from WP Kemper

Industrial long roller from WP Haton

High performance long roller for large loaves from WP Haton

BREA

D L

INES

RO

UN

D &

LO

NG

WO

RKER

BREA

D L

INES

LO

NG

RO

LLER

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

16_ 17

– Drum principle

– Optimal long-roller results

– Optimal centring of the dough

– Fine pores

– Reliable

– Punching possible

– Proofer

– Manual removal

– Highly automated

– Modular construction

– Perfect rolling-out and long-rolling

– Very fine pores in the dough pieces

– Stainless steel/aluminium design

– 4 piece

– Division of roll-out and long-rolling part

– Many moulding stations possible

– Proofer

– Panner belt

– Extractor

– Optimal adjustment to individual doughs

– Punching in by motor or according to weight

– Very gentle processing

– Robust construction

– May be recipe-controlled

– Perfect roll-out results at high speeds

– Very thin rolling out < 1,5 mm; 0,59 "

– Wide range of application (toast, rusk, hearth bread)

– Wide/long designs

– Visual control of roll-out part

– Servo drive for roller

– 4/6 piece

– Proofer

– Panner belt

– Extracto

– 1-person operation

– Processing is gentle to dough

– High process safety

– SPS control / touch-screen

– Stainless steel design

– Easy to clean

– WP Kemper CONSUL ET

– Hand removal

LONG ROLLER & ROUND AND LONG WORKER BREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Wheat dough

Mixed-wheat dough

Mixed rye dough

With ZGS bypass

With/without turning station

6/8/12 parts

BIP E/M/72Water absorption up to 165 %

Classic breads

Classic baked goods

Water absorption up to 165 %

200 – 1,600 g/piece

1,200 – 10.,000 pieces/h

AF 2002Water absorption up to 175 %

Baguettes

Brioche

Loaves placed on baking sur-face with gaps in between

Rustic breads

Baguette dough

Rustic dough

without turning station with V-belt input

Water absorption up to 175 %

150 – 1,800 g/piece

1,500 pieces/h

Proofing time

18 min. for 1,500 pieces/h

Round bread

Tin loaf bread

Toast bread

Baguette

Wheat dough

Mixed-wheat dough

max. 2,200 g/piece

max. 1,500 pieces/h

INTERMEDIATE PROOFING CABINETCapacity up tp 2,200 g/piece

Modular intermediate proving system for large loaf doughs from WP Haton

Proving chamber from WP Kemper

Modular intermediate proving system for large loaf doughs from WP Haton

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

18_ 19

– Modular system

– Perfect proofing of dough pieces

– No doubled pieces on input

– Individually removable and washable round troughs

– Many input systems < 10,000 pieces

– Many air conditioning systems available

– With or without turning of the dough pieces

– Automatic recipe control

– Modular stainless steel design

– Modular intermediate proofing system

– for large breads

– Without turning/without air conditioning

– Very soft and sticky doughs

– Dough pieces with extremely long resting periods

– Touch-screen/PCL

– Bypass possible

– For round/long dough pieces

– Round-moulder

– Long roller

– Continuous operating cycle

– Variable proofing times

– Precise centring

– Hygienic design

– Dough divider

– Long moulder

– Round moulder

PROVING SYSTEMSBREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Bread lines – here the BAGUETTA+ from WP Haton – based on a specific combination of individual machines and modules,

adjusted to the specific requirements of the actual product range. Apart from their product orientated construction they also

differ in their performance data.

BREAD-LINES

20 _ 21WP BAKERYGROUPBREAD LINES

Wheat doughs

Mixed-wheat doughs

Mixed rye doughs

– without intermediate proofing –

MINICRUSTICAWater absorption up to 180 %

Ciabatta

Flat bread

Mediterranean breads

Mediterranean baked goods

Water absorption up to 180 %

100 – 1,600 g/piece

max. 3,000 pieces/h

Wheat dough

Mixed-wheat dough

– without intermediate proofing –

CRUSTICA+Water absorption up to 180 %

Ciabatta

Baguettes

Flat bread

Mediterranean bread

Mediterranean baked goods

Classic breads

Water absorption up to 180 %

100 – 1,600 g/piece

max. 2,500 pieces/h

– with bypass –

max. 3,000 pieces/h

FERMENTAWater absorption up to 170 %

Baguettes

Baguette roll

Brioches

Pain de Campagne

Baguette dough

Wheat dough

Water absorption up to 170 %

100 – 700 g/piece

max. 1,500 pieces/h

Proofing time 17 min.

for 1,000 pieces/h

Bread line from WP Haton

Bread line from WP Haton

Bread line from WP Haton

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

22_ 23

– Soft to very soft doughs

– Without intermediate proofing

– Extremely high water absorptions

– High hourly production

– Highly precise speed

– Good cost-benefit ratio

– Automisation possible

– Flour-free

– Compact

– For round/long breads

– Broad area of application

– Soft to very soft doughs

– Without intermediate proofing

– Extremely high water absorptions

– High hourly production

– Many applications

– Many bread types/shapes

– Compact

– Precise weights

– No dough waste

– Little dusting flour

– Product with stand

– Dough dividing machine Parta SN-D 1512, 2024, V 500

– Round-moulder CR 59-AT with oiling

– Proofer AF 2002 / bypass

– Langroller Combi U

Interfaces

– Preportioning hopper

– Sediment device with V-belt

– For products that may not be turned

– Very gentle to dough

– round or long breads

– Extractor for long bread shapes on input transport Long roller

– Preliminary roll station

– Precise weights

– Long lifecycle

– Stainless steel design ZGS

– Dough dividing machine Parta SN/preliminary roller

– AF 2002 proofer

– Long roller Combi U/Combi E

Interfaces

– Preportioning hopper

– Sediment device with V-belt

– Dough dividing machine Parta SN-D 1512, 2024, V 500

– Round-moulder CR 59-AT with oiling/CCR/CR

– Long roller Combi U/Superba/Combi E

Interfaces

– Preportioning hopper

– Sediment device with V-belt

BREAD LINESBREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Wheat dough

Rye dough

Grain dough

Dough with additives

Very stiff dough

CLASSICA, CLASSICA L, CLASSICA XLWater absorption up to 165 %

Round bread

Flat bread

Tin loaf bread

Toast bread

Hearth bread

Brioch

Rusk

Baguettes

Pizza

Bio-bread

Panettoni

Water absorption up to 165 %

100 – 1,800 g/piece

Classica

max. 1,600 pieces/h

Classica L

max. 4,200 pieces/h

Classica XL

max. 10,000 pieces/h

BAGUETTA+Water absorption up to 175 %

Baguettes

Baguette rolls

Ciabatta

Rustic round breads

Rustic long bread

Wheat dough

Grain dough

Brioche

Ciabatta

Mixed dough

– Tank fermentation up to

3 hours –

Water absorption up to 175 %

100 – 700 g/piece

max. 3.000 pieces/h/string

or equivalent

of 2-3-4 cut

BAGUETTAWater absorption up to 162 %

Baguetttes

Baguette roll

Baguette dough

Wheat dough

Grain dough

Brioch

Water absorption up to 162 %

100 – 550 g/piece

max. 3,000 pieces/h/string

or

12,000 baguette rolls

Proofing time 12 min.

for 3,000 pieces/h

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

Bread line from WP Haton

Bread line from WP Haton

Bread line from WP Haton

24_ 25

– Especially effective

– with bypass

– Traditional bread types

– Tried-and-true principle

– Many applications

– Many bread types/shapes

– Precise weight

– Perfect proofing

– Finely grained consistency

– Product with stand

CLASSICA

– Dough dividing machine Parta SN-E, SN, SN-D, Parta, U, V 500

– Round moulder CR 59/CCR 59/BRW

– BIP-E or M proofer

– Long roller BM 51-A, BM 51-B, Combi E

CLASSICA L

– Parta U, V500 or B700 dough dividing machine

– Round-moulder CCR 59

– BIP-M or BIP 72 proofer

– BM 54 BT or Combi U long roller

CLASSICA XL

– Dough dividing machine B 700, V 700, S 700, V 900

– Round moulder CCR 59, CCR 69-A

– BIP 72 proofer

– Long roller BM 80 BT, BM 54 BT

Interfaces

– Preportioning hopper

– Sediment device with V-belt

– Especially for baguettes for handcrafted breads

– Very gentle to dough

– High hourly ouput

– Minimal dusting

– High weight precision

– Stainless steel design

– Centring of the dough piece in front of the long roller

– Many shaping stations

– Output after first production cycle possible

– Dough dividing machine Parta SN-D, U, V 500/V 700

– CR 59 AT round moulder

– BIP 72 proofer, without turning

– FF 700 long roller

– Combi U long roller

– BF 2003 proofer

Interfaces

– Sheet transport 180°

– Preportioning hopper

– Sediment device with V-belt

– Especially for baguettes

– Very gentle to dough

– High hourly output

– Centring of dough pieces in front of long roller

– Double track design for load reduction for dough divider and ZGS

– Stainless steel design

– Parta SN 2002 dough divider

– BF 2003 proofer

– FB 800 long roller

– Sheet transport 180°

Interfaces

– Preportioning hopper

– Sediment device with V-belt

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

BREAD LINESBREAD LINES

Round bread

Long bread, seeded

Tin loaf bread

Hearth bread

Wheat dough

Mixed rye dough

Rye dough

Water absorption up to 180%

300 – 2,400 g/piece

max. 3,000 pieces/h

max. 450 mm/piece max. 17,7 "/piece

REYNAWater absorption up to 180 %

Wheat dough

Rye dough

Mixed rye dough

ÖKOLINEWater absorption up to 170%

Wheat bread

Rye bread

Mixed rye bread

Toast bread

Baguette

Water absorption 158 – 170%

300 – 2,200 g/piece

max. 1,480 pieces/h

Square breads

Ciabatta

Baguette

All doughs

Extremely soft dough

Water absorption 135 – 180 %

35 – 150 g/piece

1 – 12 rows

max. 30.000 pieces/h

MAGIC LINEWater absorption up to 180 %

Bread line from WP Haton

Bread line from WP Kemper

MAGIC LINE Laminating line from WP Bakery Technologies

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

BREA

D L

INES

LAM

INAT

ING

LIN

EBR

EAD

LIN

ES B

READ

LIN

ES

26_ 27

– For dough with rye content

– Modular construction

– Highly robust

– Highly precise speed

– Good moulding and long-rolling result

– V 500 dough dividing machine

– B 700 dough dividing machine

– SBR 2500 belt round-moulder

– Combi E long roll machine

– Combi U long roll machine

Interfaces

– Preportioning hopper

– Sediment device with V-belt

– Bread production without flour dust

– Modular construction

– Gentle processing of dough

– Extremely soft doughs

– Long resting times for dough

– WP Kemper BOWL TIPPER

– WP Kemper RELAXER

– WP Kemper PROOFER

– WP Kemper SMALL PASTRIES LINE

– WP POWERCOOLER

– WP SPIRALFROSTER

– WP Kemper IMPERATOR II-MB

– WP Kemper cone round-moulder

– WP Kemper INTERMEDIATE PROOFER

– Transverse transport band

– Cold/warm air blower

– Individual automatic intake system

– WP Kemper SELECTA K with baguette equipment

– WP Kemper SUPERBA

BREAD LINES & LAMINATING LINEBREAD LINES

PRODUCTS DOUGHS PERFORMANCE SPECIALS INTERFACES

tam

men

.de

WP BAKERYGROUP

0906

_2.5

_010

1

VERTRIEB

Werner & Pfleiderer - Haton B.V.5980 AA Panniningen Industrieterrein 13Helden 650Niederlande Fon + 31 (0) 577 - 307 1860 Fax + 31 (0) 5 77 - 307 [email protected]

The WP BAKERYGROUP has branches in France, Italy, Belgium, Austria, Russia and the US.

In addition, representatives with service centres are located in every region of the world.

© 2006 by WP BAKERYGROUP, Stand 09/06, printed in Germany, ® = registered trademarkInformation contained herein is not legally binding. Information is subject to change, particularly as a result of technical improvements.