BR ProductReviewFL en Co 50291

-

Upload

rafael-ibelli -

Category

Documents

-

view

218 -

download

0

Transcript of BR ProductReviewFL en Co 50291

-

8/10/2019 BR ProductReviewFL en Co 50291

1/16

Product review

Primary ow elements

-

8/10/2019 BR ProductReviewFL en Co 50291

2/16

2

Part of your business

Contents

DKD/DAkkS accredited

calibration laboratories

for pressure and

temperature

Fully automatic

production of measuring

instruments

The modern high-bay

warehouse ensures

ecient logistics

Our knowledge for your success

In the course of the last six decades the name WIKA has

become a symbol for sophisticated solutions in the eld ofpressure and temperature measurement.

Our ever increasing ability is the basis for implementation of

innovative technologies in the form of reliable products and

ecient system solutions.

We owe our leading position in the world market to the con-sistent dedication towards premium quality, to which, today,

7,300 employees of the WIKA group of companies are com-

mitted. More than 500 experienced sales sta ensure thatour customers are individually and competently advised and

looked after from the outset.

Anywhere and any time.

Certied quality

The WIKA quality assurance management system has been

certied in accordance with ISO 9001 since 1994. The qual-ity and safety standards of our company meet the standardsystems of several countries.

Made by WIKA

The development and high-tech production in our owned

modern production facilities (Germany, Brazil, Canada,

China, India, Italy, Poland, South Africa Switzerland andUSA) is the best warranty for our exibility.

Whether SMD automatic insertion machines, CNC automaticmachining centres, welding robots, laser welding, sputterers,

thermotransfer printing or thin lm production - we exploit all

possibilities to achieve above-average results. And the endresult: More than 43 million quality products are deliveredyear in, year out, in more than 100 countries. Worldwide,approximately 350 million WIKA measuring instruments are

in use.

Ability to meet any challenge

WIKA product lines 3

Everything at a glance 4

Orice plates and assemblies 6

Meter runs 8

Flow nozzles 9

Venturi tubes 10

FloTec (averaging pitot tubes) 11

Restriction orices 12

The right solution 13

Technical information 14

WIKA worldwide 16

-

8/10/2019 BR ProductReviewFL en Co 50291

3/16

3

WIKA product lines

WIKA product linesThe WIKA programme covers the following product lines for various elds of application.

Electronic pressure measurement

WIKA oers a complete range of electronic pressure meas-uring instruments: pressure sensors, pressure switches,

pressure transmitters and process transmitters for the

measurement of gauge, absolute and dierential pressure.Our pressure measuring instruments are available in the

measuring ranges 0 ... 0.6 mbar to 0 ... 15,000 bar. Theseinstruments come supplied with standardised current or volt-

age output signals (also intrinsically safe per ATEX or with

ameproof enclosure), interfaces and protocols for variouseld buses. Whether ceramic thick lm, metal thin lm or

piezo-resistive, WIKA is the leading manufacturer worldwidethat develops and produces the full range of todays leading

sensor technologies.

Mechatronic pressure measurement

As a result of the almost unlimited options for dierentcombinations of mechanical and electrical connections, an

extraordinary range of instrument variants is possible. Various

digital and analogue output signals are also available for

these measuring instruments.

For our measuring instruments we use latest sensors, tested

in automotive applications millions of times over. They workwithout any kind of mechanical contact, consequently they

are wear-resistant, and there's absolutely no retroaction to

the mechanics.

Mechanical pressure measurement

Indicating instruments for gauge, absolute and dierentialpressure with Bourdon tube, diaphragm or capsule pressure

element have been tested millions of times over. These

instruments cover scale ranges from 0 0.5 mbar to

0 7,000 bar and accuracies of up to 0.1 %.

Diaphragm seals

WIKA diaphragm seals, tted with pressure gauges, pres-sure transducers, pressure transmitters etc., are recognised

and valued internationally for the most dicult of measuringtasks. The measuring instruments can therefore be used at

extreme temperatures (- 90 ... +400 C), and with aggressive,corrosive, heterogeneous, abrasive, highly viscous or toxic

media. The optimal diaphragm seal designs, materials and

lling media are available for each application.

For all product lines product reviews are available.

Electrical temperature measurement

Our range of products includes thermocouples, resistance

thermometers (also with on-site display), temperatureswitches as well as analogue and digital temperature trans-

mitters for all industrial applications, covering measuring

ranges from -200 ... +1,600 C.

Mechatronic temperature measurement

As a result of the integration of switch contacts and output

signals into our mechanical temperature measuring instru-

ments, we can oer a wide variety of combined instruments.With switch contacts the pointer position triggers a change-

over. Electrical output signals are realised via an additional,

independent sensor circuit (resistance thermometer or

thermocouple).

Mechanical temperature measurement

The mechanical temperature measuring instruments work on

the bimetal, expansion or gas actuation principle and cover

scale ranges from -200 ... +700 C. All thermometers aresuited for operation in a thermowell as required.

Level measurement

WIKA has a comprehensive range of level measuring

instruments available for temperatures up to 450 C, specicgravity from 400 kg/m and pressure ranges up to 420 bar.This includes standard instruments and customised products.

Primary ow measurement

Orice plates, meter runs, ow nozzles, Venturi tubes and

pitot tubes are part of our portfolio of primary ow elements

and restriction orices. The wide range of our products is able

to cover the majority of industrial applications. Customised

solutions can be developed to meet your special needs.

Calibration technology

WIKA oers a broad product spectrum of calibrationinstruments for the physical measured values of pressure

and temperature, and for electrical measured values. A

multitude of specic patents ensure unmatched performancecharacteristics with many of our calibration instruments.

The range of services comprises the calibration of pressure

and temperature measuring instruments in our accredited

DKD/DAkkS calibration laboratories and a mobile service tocalibrate your instruments on site.

-

8/10/2019 BR ProductReviewFL en Co 50291

4/16

4

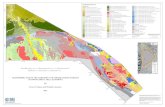

Primary ow elements

The most common way to measure ow is dierential-pressure ow measurement. This measuring principlehas proven itself over many years and is applicable for all

common types of media.

Our portfolio of primary ow elements includes orice plates(page 6), orice assemblies (page 7), ow meters (page 8),ow nozzles (page 9), Venturi tubes (page 10) and averagingpitot tubes (page 11).

Pressure drop

Restriction orices

When the process requires a pressure drop, a restriction

orice can be installed in the line. The design must take intoconsideration the ow conditions, and the dierential pres-sure required to avoid issues (cavitation, choking and noise).

Single- or multi-step restriction orice solutions (page 12)are selected dependig on the dierential pressure and uid,single- bore or multi-bore options must be selected to ensure

an acceptable noise level.

Your needs ... our solutions

When using a dierential pressure ow meter a permanentpressure drop is always generated. The graph shows a

comparison between the dierent types of dierential-

pressure ow measurement instruments. Pressure loss isshown as a percentage of the measured dierential pressure.

90

80

70

60

50

40

30

20

10

0

Example:

Orice plateDierential pressure at full scale 1,000 mbar

= d/D = 0.65% of unrecovered pressure loss = 58 %Unrecovered pressure loss = 580 mbar

Unrecoveredpressureloss-%o

fmeasureddierentialpressure

= beta ratio = d / D0,4 0,45 0,5 0,55 0,6 0,65 0,7 0,75

The graph can assist in the selection of the best instrument for your application.

Orice plate

Flow nozzle

Venturi 15 outlet

Venturi 7 outlet

-

8/10/2019 BR ProductReviewFL en Co 50291

5/16

5

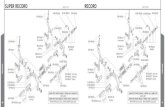

Everything at a glance

Fluid characteristics

Not all instruments can be used in all applications. The type of uid (gas, liquid or steam) and its conditions must be taken intoaccount when selecting the right instrument for your uid condition.

The following selection chart will assist in choosing the right instrument:

Reynolds number

Orice plate and related assemblies(Orifice flange / Meter run / Annular chambers)

Flownozzle

Venturitube

Pitottube

Square edge Quadrant Conical

entrance

Eccentric Segmental

GasClean

++ + + ++ ++ ++Dirty ++ ++ + +

Liquids

Clean ++ ++ ++ + + ++ ++ ++

Viscous ++ ++ + + +

Dirty + + + ++ ++ + +

Corrosive + + + + + + + +

Steam + + + + + ++ +

Page 6 ... 8 9 10 11

Dimensions ReynoldsnumberN ND

Orifice plate

and related

assemblies

Orifice flange

Meter run

Annular chambers

Integral < 1.5" < 40 > 100

Square edge > 1.5" > 40 > 2,000

Quadrant > 1.5" > 40 > 200

Conical entrance > 1.5" > 40 > 200

Eccentric > 4" > 100 > 10,000

Segmental > 4" > 100 > 1,000

Flow nozzle > 2" > 50 > 75,000

Venturi tube > 2" > 50 > 12,500

Pitot tube > 4 > 100 no limits

It is dicult to evaluate the many variables aecting thevelocity prole for all ow meters and for all pipelineconditions. To combine uid properties (density andviscosity), ow rate and geometrical aspects the Reynoldsnumber is used.

Not suitable++Preferred +Suitable

The table shows you the smallest possible Reynolds

number that can be used with each instrument.

-

8/10/2019 BR ProductReviewFL en Co 50291

6/16

6

Orice plates represent the most common primary elementsin the world due to their proven technology and ease of

installation and maintenance.

Main characteristics

Maximum operating temperature up to 800 C Maximum working pressure up to 400 bar Suitable for liquid, gas and steam ow measurement Accuracy 0.5 % of actual ow rate or higher Repeatability of measurement 0.1 %

Orice plates and assemblies

FLC-OP

Orice plate

Standards: ISO 5167-2 ASME MFC3M

Pipe size:

2" 50 mm

: 0.2 ... 0.75

Accuracy: 0.5 % of full scale flow rate or higher

Data sheet: FL 10.01

detail

detail

detail

detail

Designs

Square edge orice plates (standard version)This design is intended for general applications in clean

uids and gases.

Quarter circle and conical entranceorice plates

The best choice for measurement of liquids with low

Reynolds number.

Segmental orice plates

For measurements with two-phase uids, dirty uids anduids with particles.

Eccentric orice platesThe application areas are similar to the segmental version.

However, an eccentric orice plate is the better solution for

smaller pipe diameters.

-

8/10/2019 BR ProductReviewFL en Co 50291

7/16

7

Orice plates and assemblies

FLC-FL

Orice anges

Standards: ISO 5167-2

Pipe size: 2"

50 mm: 0.2 ... 0.75

Accuracy: 0.5 % of full scale flow rate or higher

Data sheet: FL 10.01

FLC-AC

Annular chambers

Standards: ISO 5167-2

Pipe size: 2"

50 mm: 0.2 ... 0.75

Accuracy: 0.5 % of full scale flow rate or higher

Data sheet: FL 10.01

Orice anges are intended for use instead of standard pipeanges when an orice plate or ow nozzle must be installed.Pairs of pressure tappings are machined into the oriceange, making separate orice carriers or tappings in thepipe wall unnecessary.

Main characteristics

Wide range of materials available

The number and type of pressure tapping ("ange"or "corner" type) can be manufactured to customerrequirements

Special assemblies can be designed on request

Annular chambers are designed to be mounted between

standard pipe anges. Versions are available to suit allcommon ange standards, including DIN and ANSI B16.5.

Main characteristics

Standard material of construction is 316/316L stainless

steel, but a wide range of alternative materials is available

Gaskets are included in the scope of delivery (as standard,

1.5 mm thick spiral-wound gasket 316/graphite ller, unless

requested otherwise)

-

8/10/2019 BR ProductReviewFL en Co 50291

8/16

8

Meter runs

Meter runs

FLC-MR

Meter run

Standards: ISO 5167-2

Pipe size: ... 1 in

12 ... 40 mm: 0.2 ... 0.75

Accuracy: 1 % of full scale flow rate

Data sheet: FL10.02

To ensure high accuracy in the ow measurement of liquids,gases and steam the primary ow element is supplied asan assembly incorporating the upstream and downstream

pipe sections required by ISO5167-1:2003. This assembly isknown as a "meter run".

Main characteristics

Nominal width > " Pressure rating 300 ... 2,500

Wide range of materials available

A calibration of the instrument can be performed if higheraccuracy is required.

An integral orice plate is normally selected when the pipesize is " or smaller and the uid is clean. An extremelycompact installation can be ensured as the pressure

transmitter can be mounted directly onto the meter run.

Without a calibration, an accuracy of 1 % can be expected.

-

8/10/2019 BR ProductReviewFL en Co 50291

9/16

9

Flow nozzles

Flow nozzles

A ow nozzle consists of a convergent section with, arounded prole and a cylindrical throat. This design isgenerally selected for steam ow at high velocity.

To reduce pressure loss an axisymmetric solution, called

a Venturi nozzle, can be oered. It combines the standardfeatures of a ow nozzle with a divergent section.

Main characteristics

Liquid, gas and steam ow measurement Ideal solution for steam measurement

Designed in accordance with the following standards:ISO 5167-3, ISA 1932 and ASME MFC-3M Special solutions to cover specic requirements possible

FLC-FN-FLN

Flow nozzle for ange assembly

Pipe size: 2 in 50 mm

: 0.3 ... 0.8Accuracy: 1 % of full scale flow rate or higher

Data sheet: FL 10.03

FLC-FN-PIP

Flow nozzle for in-pipe installation

Pipe size: 2 in 50 mm

: 0.2 ... 0.8Accuracy: 1 % of full scale flow rate or higher

Data sheet: FL10.03

FLC-VN

Venturi nozzle

Pipe size: 2 in 50 mm

: 0.2 ... 0.8Accuracy: 1 % of full scale flow rate or higher

Data sheet: FL 10.03

Flow nozzle for in-pipe installation

Venturi nozzle

-

8/10/2019 BR ProductReviewFL en Co 50291

10/16

10

Venturi tubes

A Venturi tube is a reliable and easily-managed and main-

tained instrument that can measure a wide range of clean

liquids and gases.

The main advantage of a Venturi tube over other dierentialpressure ow measurement instruments is the higherpressure recovery and the lower upstream and downstream

straight pipe length requirements.

Main characteristics

In accordance with ISO 5167-4 & ASME MFC-3M

standards Fabricated from plate or machined from bar/forgings Flanged or weld-in construction

Wide range of materials available

Pipe sizes from 50 ... 1,200 mm Wide variety of pressure tappings available

Calibration service available on request

FLC-VT-BAR

Venturi tube, bar body

Pipe size: 2 ... 32 in

50 ... 800 mm

: 0.3 ... 0.75Accuracy: 0.5 %of full scale flow rate or higher

Data sheet: FL 10.04

FLC-VT-WS

Venturi tube, welded sheet

Pipe size: 14 in 350 mm

: 0.4 ... 0.7Accuracy: 1.5 %of full scale flow rate

Data sheet: FL 10.04

Venturi tubes

Venturi tube, bar body

-

8/10/2019 BR ProductReviewFL en Co 50291

11/16

11

FloTec (averaging pitot tubes)

FloTec (averaging pitot tubes)

Flotec (a multi-port, averaging pitot ow meter) measuresthe dierence between the static pressure and the dynamicpressure of the media in the pipe. The volumetric ow iscalculated from that dierence using Bernoullis principleand taking into account the pipe inside diameter. Using

four dynamic ports this instrument is able to evaluate a

better velocity prole inside the pipe. This ensures a higheraccuracy in the ow measurement.

Main characteristics

Low installation costs

Long-term accuracy Minimal unrecovered pressure loss

Fixed and removable versions available

FLC-APT-E

FloTec, removable

Pipe size: 3 in 75 mm

: n.a.Accuracy: 2 % of full scale flow rate or higher

Data sheet: FL 10.05

FLC-APT-F

FloTec, xed

Pipe size: 3 in 75 mm

: n.a.Accuracy: 2 % of full scale flow rate or higher

Data sheet: FL 10.05

Vortex generation

Vortex shedding frequency

Depending on the internal diameter, the uid characteristicsand the Reynolds number, a vortex will be generated aroundthe pitot tube. A support mounted on the opposite side of the

pipe can be supplied should the natural frequency of the pitot

coincide with the vortex shedding frequency. The necessity

test is performed during the design phase.

-

8/10/2019 BR ProductReviewFL en Co 50291

12/16

12

FLC-RO-ST

Single-step restriction orice

Data sheet: FL 20.01

FLC-RO-MS

Multi-step restriction orice

Data sheet: FL 20.01

Multi-step restriction orice

When a reduction of pressure or a limitation of the ow rateis required a restriction orice must be inserted into thepipeline. Our technical department will produce the correct

design for the restriction orice, depending on customerrequirements and ow conditions.

If high dierential pressures, a change in phase or sonicissues can occur, a more-complex design will be required.

The solution in these cases is to decrease the dierentialpressure in several steps, avoiding all the issues created

by these factors. This solution is called multi-step restriction

orice.

Main characteristics

Multi-step restriction orices to reduce the pressure bymore than 50 % of the inlet value

Multi-bore option to reduce the noise level

Restriction orices

Restriction orices

-

8/10/2019 BR ProductReviewFL en Co 50291

13/16

13

The right solution

Not all customer needs can be fullled with standardproducts. Some challenges require an individual approach:As a result of our long experience we are able to cover

special requirements such as o-shore and petrochemicalinstallations, high-pressure line and meter tubes for

measurement in gas turbine power plants.

For all of these special applications and many more, we are

able to deliver the optimal solution. Talk to us.

Special applications

The accuracy of the measuring solution is often an important

issue for many customers.

Sometimes the end-user needs best-in-class measurementlevels, in terms of accuracy, precision and repeatability of the

measurement.

CalibrationWe can support you in this challenge through the entire

design and manufacturing process - suggesting the

best solution for your project, ensuring the highest class

manufacturing quality and providing the relevant calibration

certicates in accordance with ASME PTC6, ISPESL andIBR standards.

-

8/10/2019 BR ProductReviewFL en Co 50291

14/16

14

All our primary ow elements are designed in accordancewith the principles and requirements of international

standards:

ISO 5167/ISO TR 15377 ASME MFC ASME PTC6 BS 1042 DIN 19206 UNI 10023

Standards

Stainless steels are the standard materials used in industrialprocess technology. The most commonly used material

worldwide is 316L. For high-pressure measurement,high-strength stainless steel is used, while for pressure

measurements at elevated temperatures, temperature-

resistant stainless steel is needed.

For chemical processes involving highly-aggressive media an

extensive range of chemically-resistant materials is available.

In these cases, all wetted parts are manufactured from theappropriate special material. Our primary ow elements aremanufactured from 316L stainless steel as a standard.

International standards are our standard. We are able to

deliver products in accordance with ASTM or ASME inline with your requirements. In addition we are able to oermaterials to EN ISO 15156-3/NACE MR 0175 and NACE MR0103 for the petrochemical industry.

All pressure-bearing materials used can be supplied with a

3.1 traceability certicate.

Materials Carbon steel (ASTM A105/LF2) Stainless steel (316/316L, 304/304L) Duplex/Superduplex Hastelloy B3

Hastelloy C22

Hastelloy C276 (ASTM B426 UNS N10276) Incoloy alloy 825 Inconel alloy 718 Monel alloy 400 (ASTM B564 UNS N0440)

Pressure equipment conformity

If required the technical documentation may be supplied

with pressure equipment certicates. The European PressureEquipment Directive 97/23/EC, must be applied to mostmechanical and electrical pressure measuring instruments,

throughout the European Union. For ABSA certication oninstruments, Canadian design and construction requirements

must be followed.

-

8/10/2019 BR ProductReviewFL en Co 50291

15/16

15

Non-destructive testing/evaluation

Non-destructive testing (NDT) and non-destructive

evaluation (NDE). A number of dierent tests can be carriedout by WIKA to determine deciencies or defects in or on thesurface of materials depending on your requirements.

Liquid penetrant inspection (LPI) is used to locate surface

defects on relatively smooth and non-porous materials. This

test method is normally used for welded parts to guaran-

tee a good quality of the weld surface. Typical weld defects

that can be discovered are cracks, porosities, overlaps and

laminations.

Magnetic particle inspection (MPI) is a non-destructive

test method for the detection of surface and sub-surface

discontinuities in ferrous materials. The test method involves

the application of an external magnetic eld to the materialor applying an electric current through the material, which in

turn produces a magnetic ux in the material. Simultaneously,visible ferrous particles are sprinkled or sprayed on the

test surface. The presence of a surface or near-surface

discontinuity in the material causes distortion in the magnetic

ux which in turn causes leakage of the magnetic eld atthe discontinuity. The magnetic particles are attracted by

the surface eld in the area of the discontinuity and adhereto the edges of the discontinuity, indicating the shape of thediscontinuity.

X-ray testing (RT)is used extensively on the weld seams

of pipes, ttings, etc.. The method is based on the dieringabsorption of penetrating radiation and thus it detects dier-ences in density due to material composition, thickenings

and aws. Defects are found internally and may typically bepresent in raw materials, castings, and forgings, as well as in

welded and soldered joints. X-ray tests are normally used for

components that must full critical requirements. Irregularitiesor aws that can be detected include: surface and internalcracks, voids, laminations, thickenings, lack of fusion, lack

of penetration, excessive penetration, porosity, inclusions,

misassembly and misalignments.

Hydrostatic pressuretests are used to (statically) testassemblies, piping systems and Venturi tubes under their

working pressure. The hydrostatic pressure and strength test

is conducted with water at ambient temperatures.

Ultrasonic testing is used as an independent test or in

conjunction with X-ray testing. It is a method in which high

frequency sound waves are introduced into a material. Any

surface or subsurface discontinuities or aws that are presentinterrupt the sound waves and reect a proportion of them.The magnitude of the reected waves depends on the size

of the discontinuity or aw. The defects that can be detectedare similar to those that can be found through X-ray testing.

Ultrasonic testing often replaces X-ray methods when there

is diculty in positioning the X-ray lm or where the requireddistance from the radiation source cannot be maintained,

which may lead to safety risks.

Positive material identication (PMI):A common method

is spectroscopy with X-ray uorescence analysis (RFA).With this method the analysing instrument has a low-level

radioactive source. The basic principal is based upon the fact

that each material has a dierent electron energy level and

the instrument determines the required energy to removean electron and thus, for example, to cause an ionisation.

The analyser can only identify a limited number of metallic

elements. This testing of material composition is fast, easy

and eective when determining the accuracy of materialcerticates, of identifying material that has lost its marking, orwhen a large quantity of material must be checked.

Technical information

-

8/10/2019 BR ProductReviewFL en Co 50291

16/16

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Strae 3063911 KlingenbergGermanyTel. +49 9372 132-0Fax +49 9372 132-406E-Mail [email protected]

Europe

AustriaWIKA MessgertevertriebUrsula Wiegand GmbH & Co. KG1230 ViennaTel. (+43) 1 86916-31Fax: (+43) 1 86916-34

E-mail: [email protected]

BelarusWIKA BelarusUl. Zaharova 50BOce 3H220088 MinskTel. (+375) 17-294 57 11Fax: (+375) 17-294 57 11E-mail: [email protected]

BeneluxWIKA Benelux6101 WX EchtTel. (+31) 475 535-500Fax: (+31) 475 535-446E-mail: [email protected]

BulgariaWIKA Bulgaria EOOD

Bul. Al. Stamboliiski 2051309 SoaTel. (+359) 2 82138-10Fax: (+359) 2 82138-13E-mail: [email protected]

CroatiaWIKA Croatia d.o.o.Hrastovicka 1910250 Zagreb-LuckoTel. (+385) 1 6531034Fax: (+385) 1 6531357E-mail: [email protected]

FinlandWIKA Finland Oy00210 HelsinkiTel. (+358) 9-682 49 20Fax: (+358) 9-682 49 270E-mail: [email protected].

FranceWIKA Instruments s.a.r.l.95610 Eragny-sur-OiseTel. (+33) 1 343084-84Fax: (+33) 1 343084-94E-mail: [email protected]

GermanyWIKA Alexander WiegandSE & Co. KG63911 KlingenbergTel. (+49) 9372 132-0Fax: (+49) 9372 132-406E-mail: [email protected]

ItalyWIKA Italia Srl & C. Sas20020 Arese (Milano)Tel. (+39) 02 9386-11Fax: (+39) 02 9386-174E-mail: [email protected]

www.wika.it

PolandWIKA Polska spka z ograniczonodpowiedzialnoci sp. k.ul. Legska 29/3587-800 WloclawekTel. (+48) 542 3011-00Fax: (+48) 542 3011-01E-mail: [email protected]

RomaniaWIKA Instruments Romania S.R.L.Bucuresti, Sector 5Calea Rahovei Nr. 266-268Corp 61, Etaj 1Tel. (+40) 21 4048327

Fax: (+40) 21 4563137E-mail: [email protected]

RussiaZAO WIKA MERA127015 MoscowTel. (+7) 495-648 01 80Fax: (+7) 495-648 01 81E-mail: [email protected]

SerbiaWIKA Merna Tehnika d.o.o.Sime Solaje 1511060 BelgradeTel. (+381) 11 2763722Fax: (+381) 11 753674E-mail: [email protected]

SpainInstrumentos WIKA, S.A.

C/Josep Carner, 11-1708205 Sabadell (Barcelona)Tel. (+34) 933 938630Fax: (+34) 933 938666E-mail: [email protected]

SwitzerlandMANOMETER AG6285 HitzkirchTel. (+41) 41 91972-72Fax: (+41) 41 91972-73E-mail: [email protected]

TurkeyWIKA Instruments IstanbulBasinc ve Sicaklik lcme CihazlariIth. Ihr. ve Tic. Ltd. Sti.Bayraktar Bulvari No. 1734775 erifali-Yukar Dudullu - IstanbulTel. (+90) 216 41590-66Fax: (+90) 216 41590-97E-mail: [email protected]

UkraineTOV WIKA PryladM. Raskovoy Str. 11, APO 20002660 KyivTel. (+38) 044 496-8380Fax: (+38) 044 496-8380E-mail: [email protected]

United KingdomWIKA Instruments LtdMerstham, Redhill RH13LGTel. (+44) 1737 644-008Fax: (+44) 1737 644-403E-mail: [email protected]

North America

CanadaWIKA Instruments Ltd.Head OceEdmonton, Alberta, T6N 1C8Tel. (+1) 780 46370-35Fax: (+1) 780 46200-17

E-mail: [email protected]

MexicoInstrumentos WIKA Mexico

S.A. de C.V.06600 Mexico D.F.Tel. (+52) 55 50205300Fax: (+52) 55 50205300E-mail: [email protected]

USAWIKA Instrument, LPLawrenceville, GA 30043Tel. (+1) 770 5138200Fax: (+1) 770 3385118E-mail: [email protected]

WIKA Process Solutions, LP.950 Hall CourtDeer Park, TX 77536

Tel. (+1) 713-475 0022Fax: (+1) 713-475 0011E-mail: [email protected]

Mensor Corporation201 Barnes DriveSan Marcos, TX 78666Tel. (+1) 512 3964200-15Fax: (+1) 512 3961820E-mail: [email protected]

South America

ArgentinaWIKA Argentina S.A.Buenos AiresTel. (+54) 11 47301800Fax: (+54) 11 47610050E-mail: [email protected]

BrazilWIKA do Brasil Ind. e Com. Ltda.CEP 18560-000 Iper - SPTel. (+55) 15 34599700Fax: (+55) 15 32661650E-mail: [email protected]

ChileWIKA Chile S.p.A.Coronel Pereira 72Ocina 101Las CondesSantiago de ChileTel. (+56) 2 23651719E-mail: [email protected]

ColombiaInstrumentos WIKA Colombia S.A.S.Dorado Plaza,Avenida Calle 26 No. 85D 55Local 126 y 126 A

Bogot ColombiaTel. (+57) 1 744 3455E-mail: [email protected]

Asia

AzerbaijanWIKA Azerbaijan LLCCaspian Business Center9th oor 40 J.Jabbarli str.AZ1065 BakTel. (+994) 12 497 04-61

Fax: (+994) 12 497 04-62

ChinaWIKA International Trading (Shanghai)Co., Ltd.A2615, NO.100, Zunyi RoadChangning DistrictShanghai 200051Tel. (+86) 21 538525-72Fax: (+86) 21 538525-75E-mail: [email protected]. wika.com.cn

WIKA Instrumentation (Suzhou)Co., Ltd.81, Ta Yuan Road,SND, Suzhou 215011Tel. (+86) 512 68788000Fax: (+86) 512 68780300E-mail: [email protected]. wika.com.cn

India

WIKA Instruments India Pvt. Ltd.Village Kesnand, WagholiPune - 412 207Tel. (+91) 20 66293-200Fax: (+91) 20 66293-325E-mail: [email protected]

JapanWIKA Japan K. K.Tokyo 105-0023Tel. (+81) 3 543966-73Fax: (+81) 3 543966-74E-mail: [email protected]

KazakhstanTOO WIKA Kazakhstan050050 AlmatyTel. (+7) 727 2330848Fax: (+7) 727 2789905E-mail: [email protected]

KoreaWIKA Korea Ltd.#569-21 Gasan-dongSeoul 153-771 KoreaTel. (+82) 2 869 05 05Fax: (+82) 2 869 05 25E-mail: [email protected]

MalaysiaWIKA Instrumentation (M) Sdn. Bhd.47100 Puchong, SelangorTel. (+60) 3 80 63 10 80Fax: (+60) 3 80 63 10 70E-mail: [email protected]

PhilippinesWIKA Instruments Philippines, Inc.Unit 102 Skyway Twin Towers351 Capt. Henry Javier St.Bgy. Oranbo, Pasig City 1600Tel. (+63) 2 234-1270

Fax: (+63) 2 695-9043E-mail: [email protected]

SingaporeWIKA Instrumentation Pte. Ltd.569625 SingaporeTel. (+65) 68 44 55 06Fax: (+65) 68 44 55 07E-mail: [email protected]

TaiwanWIKA Instrumentation Taiwan Ltd.Pinjen, TaoyuanTel. (+886) 3 420 6052Fax: (+886) 3 490 0080E-mail: [email protected]

ThailandWIKA Instrumentation Corporation

(Thailand) Co., Ltd.850/7 Ladkrabang Road, LadkrabangBangkok 10520Tel. (+66) 2 326 6876-80

Fax: (+66) 2 326 6874E-mail: [email protected]

Africa / Middle East

EgyptWIKA Near East Ltd.Villa No. 6, Mohamed FahmyElmohdar St. - of Eltayaran St.1st District - Nasr City - CairoTel. (+20) 2 240 13130Fax: (+20) 2 240 13113E-mail: [email protected]

NamibiaWIKA Instruments Namibia (Pty) Ltd.P.O. Box 31263PioniersparkWindhoekTel. (+26) 4 6123 8811Fax: (+26) 4 6123 3403

E-mail: [email protected]

South AfricaWIKA Instruments (Pty.) Ltd.Gardenview,Johannesburg 2047Tel. (+27) 11 62100-00Fax: (+27) 11 62100-59E-mail: [email protected]

United Arab EmiratesWIKA Middle East FZEJebel Ali, DubaiTel. (+971) 4 8839-090Fax: (+971) 4 8839-198E-mail: [email protected]

Australia

AustraliaWIKA Australia Pty. Ltd.Rydalmere, NSW 2116Tel. (+61) 2 88455222Fax: (+61) 2 96844767E-mail: [email protected]

New ZealandWIKA Instruments LimitedUnit 7 / 49 Sainsbury RoadSt Lukes - Auckland 1025Tel. (+64) 9 8479020Fax: (+64) 9 8465964E-mail: [email protected]

WIKA worldwide