Br Mining

-

Upload

steven-tremol -

Category

Documents

-

view

31 -

download

1

Transcript of Br Mining

Pumps for the Mining and

Mineral Processing Industries

First rubber-lined pumps (Circa 1921)

Hard metal slurry pump (Circa 1959)

Pumping Engine (Circa 1889)

Performance Provenfor Over 150 Years...

ITT Industries. Everything you need - and more!A-C PUMP • GOULDS PUMPS

Where it counts - on the job.At ITT Industries we know the vital role that mining and mineralprocessing plays in the world economy. That’s because we’vebeen a part of the success and aleading partner in solving the problems of these industries forwell over 100 years. We have been there with you all the waydesigning and manufacturingslurry and process pumps. Our long proud history in the mining and minerals processingindustries includes companies thatare part of ITT Industries such as:

•Allis-Chalmers — Established in1861, A-C Pump has been aleader in the mining industry with many “firsts” including thedevelopment of the RL rubberlined pump in 1921 and the development of the expeller fordynamic sealing.

•Goulds Pumps — Established in1848, Goulds over the years hasgrown into one of the world’spremier pump companies and aleading supplier of water, process,and slurry pumps to the miningand mineral processing industry.

•Goyne Pumps — Established in1881, Goyne became one of theleading suppliers of slurry andmine dewatering pumps for thecoal industry.

Today, ITT Industries produces thewidest range of pumps for the mining and mineral processingindustry of any pump manufacturerin the world; elastomer-lined andhard-metal slurry pumps, verticalturbine pumps, ANSI and end suc-tion process pumps, submersibleand cantilever pumps, water supplyand wastewater treatment pumps,magnetic drive pumps, API andboiler feed pumps, and UL/FMapproved fire pumps.If you’re looking for a dependablepartner in the ongoing challenge to keep the mining and mineralprocessing industry profitableunder ever-increasing competitiveand changing conditions, take alook at the following products.They cover the extensive range ofpumps that ITT Industries offers foryour industry.Simply stated, ITT Industries designsand builds the highest qualitypumps and provides the most complete service and value in theindustry today, and is committed to meeting your every pumpingrequirement.

2

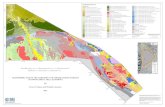

Mining & Mineral ProcessingPump Selection Chartg plays in the world

Goulds makes the widest range of pumps in the industry – pumps to handle virtually any service. This selection chart is designed to help you find and specify the best pump for your service.

Ideally Suited for Service Indicated. Visit www.gouldspumps.com for additional information.

3

Nature of Pumpage

Pump Category Goulds Model Pump Type Corrosive High Temp. SolidsAbove 250°F (120°C) Abrasive Non-Abrasive Fibrous/Stringy Large Solids

Control Solutions PumpSmart® ALLPRO Services ALL ALL Repair and Service of all Rotating Equipment Types and Manufacture

3196 ANSI Chemical ProcessLF 3196 Low Flow ANSI ProcessHT3196 ANSI High Temperature ProcessCV3196 Non-Clog Process3796 ANSI Self Priming Process3996 ANSI In-Line Process

ANSI 3296EZMAG ANSI Metallic Sealless ProcessProcess 3298 ANSI Tefzel Lined Sealess

SP3298 ANSI Tefzel Lined Sealless Self PrimingV3298 ANSI Vetical In-Line Tefzel Lined Sealless3299 ANSI PFA Teflon Lined Sealless3198 ANSI PFA Teflon Lined ProcessNM3196 ANSI FRP ProcessIC ISO Chemical Process

ISO ICB Close Coupled ISO ProcessProcess ICP ISO High Temperature ISO Process

ICM ISO Metallic SeallessICMP ISO Metallic High Temperature Sealless

Large 3175 Large Process

Process 3180 / 3185 Large Process 3181 / 3186 High Temperature Large Process3700 / 3710 API-610 Process

API 3910 API-610 In-Line ProcessProcess 3620 High Temperature Double Suction

3640 High Temperature Two-Stage3400 Series Single Stage Double Suction3316 Two-Stage

Double Suction 3355 Multi-Stageand 3310H High Pressure Multi-Stage

Multi Stage 3935 Diffuser Type Multi-Stage3335 Diffuser Type Multi-Stage3600 Heavy Duty High Pressure Multi-StageAF Axial FlowHS Recessed Impeller Solids HandingJC Abrasive Slurry

Abrasive Slurry CW Back Pull-Out Heavy Duty Slurryand CWX Back Pull-Out Heavy Duty Slurry

Solids Handling RX Side Suction Heavy Duty Slurry5500 Severe Duty Abrasive SlurrySRL Rubber-Lined Abrasive Slurry3171 Vertical Sump and processCV3171 Non-Clog Vertical Sump and ProcessNM3171 FRP Vertical Sump and ProcessTrash Hog® Solids Handling Self Priming

Sump VHS Recessed Impeller Vertical CantileverVJC Abrasive Slurry Vertical Cantilever5150 Heavy Duty Slurry Vertical CantileverHSU Recessed Impeller Solids Handling Sub.HSUL Recessed Impeller Non-Clog SubmersibleJCU Abrasive Slurry SubmersibleVIT Vertical Turbine

Vertical Turbine VIC Vertical Can Type TurbineVIS Vertical Submersible TurbineNSW Non-Clog Solids Handling

Waste handling NSX Non-Clog Shearpeller, Solids HandlingNon-Clog NSY Non-Clog Mixed Flow

NSS, WSY Large Capacity Non-Clog*TEFZEL and TEFLON are registered trademarks for fluorpolymer resins.Films and fibers made by DuPont.

9

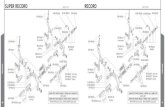

1SRL

2

4

6

3

Heavy Duty Elastomer-Lined Slurry Pumps

1

2

3

4

5

6

7

8

9

706050

40

30

20

10

80 100

150

200

300

400

500

600

800

1000

1500

2000

3000

4000

5000

6000

7000

8000

1000

0

1500

0

2000

0

3000

070

8090

100

150

200

2x2x

10 S

RL

3x3x

10 S

RL-

C

3x3x

10 S

RL

5x4x

14 S

RL-

C5x

5x14

SR

L

6x6x

15 S

RL

8x6x

18 S

RL-

C

10x8

x21

SR

L-C

12x1

0x25

SR

L-C

14x1

2x29

SR

L-C

20x1

8x40

SR

L-C

16x1

4x34

SR

L-C

CAPACITY (USGPM)

56

10

15

20

2530

40

50

60

4

3

2000100050040030020010050

CAPACITY (M3/HR)25 3000 4000 6000

HEAD (METERS)

HEAD(FEET)

8

5 7

SRL-C

Five discharge positions are available tosuit most piping arrangements.Wide range of natural and synthetic elastomers are available. Ceramic composite wear plates available forextreme service conditions.Metal impellers available in HC600 hardened chrome iron and alloys. UniqueSHEARPELLER™ impeller available for frothslurries.Pressure molded bolt-in liners are bondedto skeleton for easy field replacement.Larger sizes utilize unique hybrid designwhich resists collapse and aids in handling.Packed box provided with full and weepflush arrangement for seal water supply.316SS split gland is standard. Detachablestuffing box available in wide range ofmaterials to suit most applications andaccommodate most mechanical seals.

800BHN hard-coated shaft sleeve are standard for maximum life. Special alloysavailable.Rigid, short shaft with labyrinth greasepacked seals offer maximum bearing protection, minimum shaft deflection, reliability, ease of maintenance and long life.Axially adjustable bearing cartridge to maintain proper impeller-suction wear-plate clearance for maximum efficiency.High pressure casings available for seriesoperation.

Sizes: 2” to 20” (50mm-500mm)Flows to: 20,000 GPM (4542 m3/hr)Heads to: 164 feet (50m)Solids to: 1⁄4” (6.4mm)Temperatures to: 250°F (121°C)

The SRL/SRL-C pump is typically applied on slurriesthat contain solids that areround in shape and up to 1/4”(6.4mm) in diameter.A wide variety of elastomersare available for handling slurries containing chemicalsor hydrocarbons.Special synthetic elastomersmake the SRL/SRL-C suitablefor handling slurries contain-ing chemicals or hydrocarbonswhere natural rubber may notbe suitable.

4

Shearpeller

Severe Duty Elastomer-Lined Slurry Pumps

5

20000

30000

1500

0

1000

0

8000

6000

4000

3000

2000

1500

1000

200

150

100

70

50

30

20

10

5

10

20

30

40

50

60

200015001000750500250 400

CAPACITY (M3/HR)300 3000 4000 7000

HEAD (METERS) HEAD

(FEET)

CAPACITY (USGPM)

6x6x

21 S

RL-

XT

8x8x

25 S

RL-

XT

10x1

0x28

SR

L-X

T

14x1

2x36

SR

L-X

T

SRL-XTSizes: 6” to 14” (150mm -350mm)Flows to: 10,000 GPM (2,271 m3/hr)Heads to: 140 feet (42m)Solids to: 1⁄2”+ (12.7mm)Temperatures to: 212°F (100°C)

Extra-thick liner—up tothree times conventionalthickness for very severeand abrasive applications.The SRL-XT pump has beenspecifically designed to handleextra-coarse slurries. The extrathick rubber linings coupledwith the large diameter, lowrotational speed impellersmakes this the ideal pump forSAG and ball mill discharge,primary cyclone feed andother extremely abrasive applications.The SRL-XT has proven to have superior wear life compared to hard metalpumps and conventional rubber lined pumps. Thereplaceable rubber liners areless expensive and last longer than hard metal, thusmill operating cost are dramatically reduced with the SRL-XT.

Ceramic composite Wearplate

2

4

3

8

7

1

65

1

2

3

4

6

7

85

Axially adjustable bearing cartridge tomaintain proper clearance for maximumefficiency and wear life. Oil Lubricated asstandard. Heavy duty shaft and bearingswith labyrinth grease packed seals providesminimum shaft deflection, and assures maximum bearing life and power end reliability.Five discharge positions available to suitmost piping arrangements.Tongue and groove fit between casinghalves assures positive locking of liner intocasing.

Extra thick rubber linings for handlingcoarser materials and extended wear life.Elastomers are molded to skeletons forrigidity and accurate fit.Bolted in liners provide quick, easy fieldreplacement with minimum downtime.Suction wearplate removal is fast and easy– no need to split the casing. Ceramiccomposite wear plates are available forextended life in severe conditions.800BHN hard-coated shaft sleeve are standard for maximum life. Special alloysavailable.

Severe Duty Hard Metal Slurry Pumps

CAPACITY–GALLONS PER MINUTE

TO

TA

L H

EA

D–

FE

ET

TO

TA

L H

EA

D–M

ET

ER

S

10000500020001000500 70040030020050 100 20000

12500

400

300

200

60

80

100

40

20

10

5

10

15

20

30

40

5060

80

100

120

15015 20 30 50 75 100 150 200 300 400 600 8001000 1500 2000 3000 4000

CAPACITY–m /h3

3x4-17

4x6-294x6-29 HP

3x4-12

3x4-12S

2x3-12S1.5x2-12S

4x6-214x6-21 HP

4x6-12S

6x6-22

8x10-21

8x10-29

12x14-38

12x14-29

10x12-346x8-266x8-26 HP

3x4-183x4-18 HP

4x6-15

6x6-186x8-19

10x12-25

5500Sizes: 1.5” to 12” (38mm to 300mm)Capacities to: 17,000 GPM (3861 m3/hr)Heads to: 400 feet (122m)Pressures to: 500 PSIG (3448 kPa)Solids to: 5 inches (127mm)Temperatures to: 250°F (121°C)

The Goulds Model 5500 is built tohandle the toughest abrasive slurryservices. It is designed to providemany years of service under theseverest of operating conditions.

The 5500 is the first choice for tough abrasive slurry applications.• Primary metals—ball mill

discharge, SAG mill discharge,tailings, cyclone feed.

• Coal preparation—heavy media,hydrocyclone, cyclone feed,thickener underflow.

• Non-metallic mining-clay slurries,phosphate slurries, soda ash,potash.

• Sand and gravel—sand andaggregate slurries, tailings.

• General—foundry sand, plantwaste, mill scale, sand slurries,lime slurries, ash slurries.

• Alumina—Ball Mill Discharge,Injection, Seed Pumps, BauxiteBlow-Off, Hydrate, Underflow,Red Mud.

6

3

4

7

1 25

6

1

2

3

4

5

6

7

Knock-off deflector protects bearings and facilitates threaded impeller removal.Means less maintenance time, lower maintenance costs.External impeller adjustment facilitatesmaintenance of original hydraulic performance. Up to 8 inches of axialadjustment extends useful life parts and allows easy access to impeller formaintenance.Free standing pump eliminates bedplateand the need for special foundation, providing safe installation at greatlyreduced costs.

Dead set heavy duty bearings. No shims,adjusting rings or springs. 50,000 hr B10life. Oil lubrication standard.Extra heavy duty shaft—long bearing span and large diameters reduce shaftdeflection, extend bearing and packing life. Ideally suited for mounting largemotors overhead.Large diameter impeller provides higherheads at lower operating speeds. Extra thick wall sections in high wear areasfor maximum life.

HS7 SizesCapacities to: 7,000 GPM (1,590 m3/h)Heads to: 140 feet (43m)Temperatures to: 200°F (93°C)Pressures to: 100 PSIG (690 kPa)Solids to: 10 inches (254mm)Materials: Cast Iron, HC600,316SS, CD4MCu, and other Alloys

Hydro-SolidsFeatures fully recessed non-clog impeller. Ideal forhandling sludges and slurriescontaining large solids,entrained air, fibrous material,corrosives and abrasives.

JC 15 SizesCapacities to: 7,000 GPM (1,600 m3/h)Heads to: 240 feet (73m)Temperatures to: 250°F (120°C)Pressures to: 150 PSIG (1,034 kPa)Solids to: 2.25 inches (57mm)Materials: Cast Iron, HC600,316SS, CD4MCu, and other Alloys

Abrasive SlurryIdeal for abrasive and/or corrosive slurry services.Designed for ease of maintenance and long hours of operation. It is perfect forhandling sludge, clay slurries,lime mud and services whereprocess pumps are not up tothe task. The JC is available in a wide variety of configurationsand materials.

7

Abrasives / Solids Handling Pumps

CW/CWX11 SizesCapacities to: 13,000 GPM(2,950 m3/h)Heads to: 300 feet (90m)Temperatures to: 250°F (120°C)Solids to: 5 inches (127mm)Materials: HC600 Only

Heavy Duty SlurryThe CW is designed to efficientlypump liquids with abrasive solidsin suspension. With it’s back pull-out design and wear parts madeof HC600 hardened chrome iron,the CW/CWX provides ease ofmaintenance along with superiorwear life and performance in alltypes of slurry applications. TheCWX with ShearpellerTM has air,froth and solids handling capabil-ities superior to conventionaldesigns.

RX8 SizesCapacities to: 3,7000 GPM (840 m3/h)Heads to: 325 feet (100m)Temperatures to: 250°F (120°C)Pressures to: 200 PSIG (1,380 kPa)Solids to: 2.875 inches (73mm)Materials: HC600

Severe Duty Side Suction SlurrySpecifically designed for economi-cal handling of abrasive slurries athigh heads and low speeds. TheRX’s unique side suction designprovides very low stuffing boxpressure for minimal flush waterand pressure along with easyaccess to wear components with-out disturbing piping. Thesepumps have gained unparalleledacceptance in mineral processingbecause of their reliability andease of maintenance.

Double Suction Pumps

7

3400 SeriesSizes to: 78” (1980mm)Flows to: 225,000 GPM (51,098 m3/hr)Heads to: 850 feet (244m)Temperatures to: 350°F (117°C)

Because of their low thrustloads, ease of piping, smallfootprint, and reliability horizontally split case pumpshave always been used in services such as cooling water,quench water, spray waterand cold well. Now howeverwith more mineral recoverybeing accomplished by chemical methods thesepumps are being applied inservices such as pregnantleach solution, rich electrolyte,lean electrolyte, and raffinate. ITT’s ability to furnish an industrial grade split caseproduct out of various metallurgies makes us ideal for these services.

4

9

3

26

11

8

57

10

1

1

2

3

4

5

6

7

8

9

10

11

Renewable case wearing rings permit easymaintenance of proper running clearances.Double lock in lower half casing to preventrotation. Hooked (shrouded) configurationto guide flow into impeller eye anddecrease recirculation reduces NPSHrequired and improves efficiency.Heavy casing walls are designed to with-stand pressure extremes. Rugged designresists external forces and vibrations. Bothsuction and discharge connections in lowerhalf casing. Removal of upper half casingpermits inspection, maintenance andremoval of the complete rotating elementwithout disturbing piping or driver.Renewable impeller wearing rings allow forproper maintenance of running clearances.Locked into impeller with stainless steel set screws.Positive liquid sealing—Buna-O rings in controlled compression protect shaft andthreaded areas from pumpage or confinedcorrosive attack.Standard labyrinth protection on all models optimizes the bearing environmentfor extended pump life.

Large inlet areas assure smooth flow toimpeller inlets for efficient, quiet operation.Stuffing box bushing protects casing fromwear. Easily replaceable. Secured withdouble lock in lower half casing.Double suction impeller minimizes axialthrust. Highly efficient for smooth vibration free operation. Staggered vaneswith center shroud available on some sizes. Dual volute design has cutwaters 180°apart to provide opposing radial forces,reducing radial loads on bearings and minimizing shaft deflection. Permitssmooth, trouble-free operation over a wide range of flow rates.Heavy duty shaft is designed to reducedeflection. Renewable shaft sleeves protect shaft from pumpage. Threadedsections removed from stress areas.High thrust capability...spherical roller bearings or double row ball thrust bearings handle unexpected thrusts.Secured with locknut and washer. Ring oil lubrication standard.

8

IC 34 Sizes - Capacities to: 1,980GPM (450 m3/h)Heads to: 482 feet (150m)Temperatures from: -40°F to 350°F (-40°C to 177°C)Pressures to: 235 PSIG (16 bar)Materials: Ductile Iron, 316SS,Duplex Stainless, Alloy 20, Hastelloy C and Titanium

ISO ProcessThis series is designed in accordance with ISO 5199 andISO 2858, making it ideal forworldwide mineral processingapplications. IC pumps are fittedwith a patented “Cyclone SealChamber“ design proven to provide the optimum sealingenvironment for extendedmechanical seal life.

319629 Sizes - Capacities to: 6,000GPM (1,364 m3/h)Heads to: 730 feet (222m)Temperatures to: 500°F (260°C)Pressures to: 375 PSIG (2586 kPa)Materials: Ductile Iron, 316SS,CD4MCu, Alloy 20, Monel, Nickel,Hastelloy B and C, Titanium

ANSI ProcessThe original ANSI pump that hasbecome the industry standard. Available with wide range ofANSI PLUSTM features for handlingdifficult applications. X-Seriespower ends provide standard features for improved bearingand mechanical seal life.

329815 SizesCapacities to: 320 GPM (270 m3/h)Heads to: 460 feet (129m)Temperatures to: 250°F (121°C)Pressures to: 225 PSIG (1551 kPa)Lining Material: Tefzel® (ETFE)

Magnetic Drive ANSI LinedDesigned to handle moderate tosevere corrosives with or withoutsolids. Sealless design provideseffective alternative to pumpswith mechanical seal problems.Thick TEFZEL® linings for extended pump life.

9

Process Pumps

AF Sizes from 6” - 66”600 - 1400mm SizesCapacities to: 200,000 GPM(45,000 m3/h)Heads from: 2ft- 30ft (0.5m - 9m)Temperature to: 600°F (315°C)Solids to: 9” (225m)Available in virtually ALL Materials

Axial FlowGoulds line of axial flow pumps isunmatched in the industry for lowhead/high capacity pumpingrequirements...especially whencorrosive or abrasive solutions orslurries are involved. Extendedservice life, mechanical reliability,custom designs and a wide rangeof materials allow the Model AF topump practically any liquid.

3180 / 318533 SizesCapacities to: 26,000 GPM (6,000 m3/h)Heads to: 410 feet (125m)Temperatures to: 446°F (230°C)Pressures to: 232 PSIG (1,600 kPa)Materials: All Iron / 316SS Trim,316SS, 317SS, CD4MCu

Large ProcessIdeal for Liquor, and process applications in mineral processing.The 3180/3185 was designed formaximum efficiency, excellenthydraulic coverage, extreme easeof maintenance, and mechanicalreliability for the toughest processservices. Available with open orenclosed impellers.

10

Vertical Turbine PumpsVIT

Capacities to: 70,000 GPM (15,900 m3/hr)Heads to: 3,500 feet (1067m)Pressures to: 2,500 PSI (175 kg/cm2)Solids to: 2” (50m)Temperatures to: -40°F (-40°C) to +450°F (232°C)Pump length to: 1,500 feet (457m)

The Vertical Industrial Turbine(VIT) offers a wide range ofcapabilities with flexibility ofdesign features. The fabricat-ed discharge head, flanged column and multistage bowlassembly allow this customdesigned product to be engi-neered to meet rigid customerrequirements. Availability ofhigh alloy materials through-out and the ability to isolate bearings from harsh pumpedliquids make the VIT ideallysuited to the mining industry.Services•Barren solution pumps•Pregnant solution pumps•Dewatering pumps•Production well pumps•Wastewater pumps•Make up water pumps•Booster pumps

1

2

3

4

5

6

8

7

10

9

Vertical solid shaft motors with integralthrust bearings provide high reliability withminimal vibration for superior seal life.Discharge head design offers flexibility tomount any vertical driver.

Flanged adjustable couplings allow foraccurate impeller adjustment. Optionalspacer is available when mechanical sealsare required.

Large access openings offer ease of maintenance for seals and couplings.

Flexibility of sealing methods. Packing ormechanical seals are offered to match service requirements. External flush orinternal recirculation extend seal life.

Fabricated discharge heads allow flexibilityto meet existing field piping.

Close clearance registered fits are used onall components to maintain concentricalignment throughout the pump.

Intermediate bearings are spaced to avoidshaft critical speeds. Optional bearing surfaces are offered to match service environment.

Open or enclosed lineshaft designs areavailable to maximize bearing life.

Impeller options include semi-open orenclosed design, taperlock or keyed attachment and various wear ring options.

Multistage bowl assembly allows alterationfor future pumping conditions. Wholestages can be added in the field, orimpellers can be added to empty bowls.

Flows to: 7,500 GPM(1,700 m3/h)Heads to: 260 feet (79m)Temperatures to: 200°F (93°C)Solids to: 10 inchesMaterials: Cast Iron, HC600,316SS, and other Alloys

Sump / Abrasives / Solids Handling Pumps

Flows to: 13,000 GPM (295 m3/h)Heads to: 230 feet (126m)Temperatures to: 450°F (232°C)Lengths to: 20 feet (6M)Materials: Cast Iron, CD4MCu, and other Alloys

11

CV3171 Vertical SumpThe CV3171 is a recessed impeller, circular volute type sump pump.Ideal for large solids and shearsensitive fluids. It will pass anysolid that will pass through thedischarge pipe. Its circular voluteminimizes radial loads making this the ideal pump for low flowapplications.

Capacities to: 6,000 GPM (1,363 m3/h)Heads to: 140 feet (43m)Temperatures to: 225°F (107°C)Pressures to: 85 PSIG (586 kPa)Suction Lifts to: 25 feet (7.6m)Spherical solids to: 3 inches(76mm)Materials: Cast Iron, StainlessSteel, CD4MCu, HC600 Fitted

Trash Hog® Solids Handling Self-PrimingGoulds Trash Hog is designed forsuperior solids handling capabilities,optimum pump performance, andextreme ease of maintenance.Available in a wide variety of materials including HC600 ChromeIron, the Trash Hog is ideal for a wide range of services such as minedewatering and wash down sumps.No matter what the service, there’sno other pump that compares tothe Trash Hog.

JCU / HSU / HSUL Submersible PumpsDesigned specifically to handlelarge solids and abrasive servicesfound in the mining and mineralprocessing industry. Goulds’ submersible pumps provide superior wear life, performance,reliability and interchangeability for a wide range of services. FromShaft bottoms, and wash downsumps, to mill scales and coal pilerunoff, Goulds has the submersibleto handle the service.

Capacities to: 4,000 GPM(910 m3/h)Heads to: 240 feet (73m)Temperatures to: 194°F (90°C)Solids to: 6 inches (150mm)Materials: Cast Iron, HC600,316SS, CD4MCu

VHS / VJC / 5150 Vertical CantileverAvailable in 3 models, Goulds’cantilevers are ideal for a rangeof tough services. With their seal-less design and no submerged bearings, they provide long, trouble free operation in services such as mine slurry, fly ash, clay, coal, mill scale and wash down sumps.

Product Repair (all types and brands of rotating equipment)• Service Center Repair• Field Service• Parts SupplyReliability Improvement• Inventory Management• Replacement / Exchange• Turnkey Repair / Installation• TrainingOptimization of Assets• Predictive Analysis / Condition

Monitoring • Root Cause Failure Analysis• Pump & System Assessments• Upgrades - Mechanical & Hydraulic• Maintenance Management /

Contract Maintenance

• Technical Expertise• Fast Turnaround• Factory Trained Service Personnel• Emergency Service - 24 hours/day, 7 days/week• Quality• ISO and Safety Certified

PRO Service Centers: Worldwide...Wherever You Need Us.

Form BRMINING 6/06© copyright 2006 Goulds Pumps, Incorporated,

A subsidiary of ITT Industries, Inc.

Visit our website at www.gouldspumps.com

PUMPSMART®

CONTROL SOLUTIONSSimplicityDedicated pump control and protection logic in an easy to use package

Reliability & SafetyLonger Pump and Seal life means reduced maintenance and down time

ControlImproved pumping accuracy and repeatability means better process control

Operating CostVariable speed cuts energy cost up to 70%; Reduced maintenance & downtime cuts cost

FlexibilityControl any centrifugal pump up to 700 HP

PRO ServicesTM...Extending Equipment Life