Bhar Oem Presentation10.5.10

-

Upload

jbaker1057 -

Category

Documents

-

view

551 -

download

0

description

Transcript of Bhar Oem Presentation10.5.10

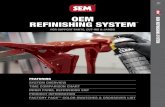

Contract Manufacturing and Injection Molding for the OEM MARKETPLACE

Bhar Incorporated History and Stats

• Established in 1976 by Norm and Urmila Bhargava • Ownership transfer in 2009 to their son Raj Bhargava.• 2010 Sales [projected] $14,000,000• Key focus and core competency is medium to large tonnage

injection molding.• In 1986 moved onto current 26 acre site.• 125,000 sq-ft of manufacturing and warehouse space• TS 16949 Certified and a registered Minority Owned

Enterprise with the Indiana Minority Supplier Development Council.

• Current 12 month rolling PPM of 4

The Team

• Richard Kelly-VP and General Manager [22 yrs]• Melissa Smith-VP Sales and Engineering[22 yrs]• Bob Clark-Production Manager [19 yrs]• Griff Neilson- Quality Manager• Jeff Baker- Mgr New Business Development• 131 production partners strong

Services and Capabilities• Injection molding from 200 ton thru 3000 ton press capacity. Plant equipped with a 20T

and 50 T crane. Robotic part picking on most presses.• Automated Material delivery system with 11 Silos and a fully integrated MRP/JRP software

system called PLEX ONLINE encompassing all areas of production including manufacturing, shipping, inventory , accounting, EDI, purchasing, quality and maintenance.

• Types of parts: Engine splash shields, HVAC baffles and shielding, radiator baffles, Belly Pans, Fan Shrouds, Air Inlet panels, Mud Guards/Fender liners, Hush Panels, Air Ducts, Glove box inner, Internal Seat back components, Steering Column Covers, Sill Plates/Cover Sills, A-B-C Pillars, end caps, vent covers, support brackets

• Materials Processed: PP filled and unfilled, LLDPE, HDPE, ABS, ABS-PC, TPO/EPO, EPDM, Nylon filled and unfilled

• Tool design and construction management.– Tools built domestically and overseas.

• Part design assistance for “mold-ability”.• Secondary assembly including hot melt glue, sonic welding, hot stake welding, assembly

of foam/fastener attachment, stapling, die cutting.• Assembly expertise.

– Manual to semi-automatic work cells.

2500 Ton Krauss Maffei

Sample Decorative Parts- Non Automotive

Bhar produces most of the molded components with the exception of the wheels (blow molded) and roll bars

Sample Interior Trim Components produced by Bhar –current and prior model

Forward Rear Cover Sill is located in the front seat next to the door. The RH FR is shown installed. Butts to the FF and glove box on the forward edge and the B Pillar /weather strip on the rearward edge.

The Forward Front Cover Sill-RH is shown in the Front Seat as installed with the Forward Rear Cover Sill-RH.

FF -RH

FR-RH

Rear Door Cover Sill-RH shown between red arrows

Steering Column Cover