BASICS OF I.C. ENGINE

description

Transcript of BASICS OF I.C. ENGINE

-

APPLIED

THERMAL

ENGINEERING

Prof. K. K.SHARMA

Prof. K. K. Sharma

-

Internal combustion

engine

Prof. K. K. Sharma

-

CLASSIFICATION OF I.C.

ENGINE

a) According to number of stroke

1. Two stroke engine

2. Four stroke engine

b) According to cycle of combustion

1. Otto cycle engine

2. Diesel cycle engine

3. Dual cycle engine Prof. K. K. Sharma

-

c) According to fuel used

1. Petrol engine

2. Gas engine

3. Diesel engine

d) According to method of ignition

1. S.I. engine

2. C.I. engine

CLASSIFICATION OF I.C.

ENGINE

Prof. K. K. Sharma

-

e) According cooling system

1. Air cooled engine

2.Water cooled engine

Classification of I.C. engine

Prof. K. K. Sharma

-

f) According to speed of engine

1. Low speed engine

2. Medium speed engine

3. High speed engine

Classification of i.C. Engine

Prof. K. K. Sharma

-

g) According to arrangement of cylinder

Classification of I.C. engine

1. Horizontal engine 2. Vertical engine

3. V-type engine 4. Radial engine

Prof. K. K. Sharma

-

h) According to number of cylinder

1. Single cylinder engine

Classification of I.C. engine

2. Multicylinder engine Prof. K. K. Sharma

-

I) According to their use

1. Stationary engine

2. Marine engine

3. Automobile engine

4. Aero engine

Classification of I.C. engine

Prof. K. K. Sharma

-

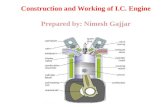

CONSTRUCTION OF I.C.

ENGINE

A. Parts common to both Petrol and Diesel engine:

1.Cylinder, 2.Cylinder head,

3. Piston, 4.Piston rings,

5.Gudgeon pin, 6.Connecting rod,

7.Crankshaft, 8.Crank,

9.Engine bearing, 10.Crank case.

11.Flywheel, 12.Governor,

13. Valves and valve operating mechanism. Prof. K. K. Sharma

-

B. Parts for Petrol engines only:

1. Spark plug,

2. Carburetor,

C. Parts for Diesel engine only :

1. Fuel pump,

2. Injector.

Prof. K. K. Sharma

-

Cylinder

Piston

PARTS OF

I.C.

ENGINE

Prof. K. K. Sharma

-

It is heart of the engine, in which the piston

reciprocates (moves to and fro) in order to develop

power. It is made of C.I.

Cylinder

It is reciprocating member of an I.C. engine.

Main function is to transmit the force exerted by the

burning of charge to the connecting rod. The piston

are generally made of aluminum alloys which are light

in weight.

Piston

Prof. K. K. Sharma

-

PARTS OF I.C. ENGINE

Piston

Piston

Ring

Prof. K. K. Sharma

-

Piston Ring

Generally, there are two sets of rings mounted for

the piston.

The function of the upper rings is to provide air tight

seal to prevent leakage of the burnt gases into the

lower portion.

Similarly, the function of the lower rings is to

provide effective seal to prevent leakage of the oil

into the engine cylinder

Prof. K. K. Sharma

-

Cylinder Head Fuel

Injector

Cylinder

Head

Prof. K. K. Sharma

-

It is fitted on one end of the cylinder, while

other end is open to crank case.

The cylinder head contains inlet and exit

valves for admitting fresh charge and

exhausting the burnt gases

Cylinder Head

Prof. K. K. Sharma

-

Connecting Rod

Connecting

Rod

Gudgeon

Pin

Crank-

Shaft Prof. K. K. Sharma

-

Connecting Rod

It is a link between the

piston and crankshaft.

whose main function is

to transmit force from

the piston to the

crankshaft.

Moreover, it converts

reciprocating motion of

the piston into circular

motion of the crankshaft. Prof. K. K. Sharma

-

Gudgeon Pin

Gudgeon Pin

Gudgeon pin is used to connect piston and connecting rod Prof. K. K. Sharma

-

Crank & Crank Shaft

Crank-Shaft Prof. K. K. Sharma

-

Crank shaft

It is considered as the backbone of an I.C.

engine.

The power developed by the engine is

transmitted outside by this shaft.

Prof. K. K. Sharma

-

Valves Inlet valve

Exhaust valve

Prof. K. K. Sharma

-

Spring

Inlet

Passage Exhaust

Passage

Inlet Cam

& Valve Exhaust Cam

& Valve

Valves Inlet valve

Exhaust valve

Prof. K. K. Sharma

-

Two types of valves are used in I.C engine :-

1) Inlet valve :- This

valve is used to admit

charge into cylinders.

2) Outlet valve :- This

valve is used to remove

exhaust gases from the

cylinder.

Valves

Prof. K. K. Sharma

-

Flywheel

Crank-

Shaft Prof. K. K. Sharma

-

It is a big wheel, mounted on the crankshaft.

It is done by storing excess energy during

power stroke, which is returned during other

stroke.

Flywheel

Prof. K. K. Sharma

-

PARTS FOR PETROL ENGINES ONLY

Carburetor

Prof. K. K. Sharma

-

Carburetor

Main function of carburetor is to supply limited quantity of fuel to engine

Prof. K. K. Sharma

-

Spark plug

PARTS FOR PETROL ENGINES ONLY

Prof. K. K. Sharma

-

It is provided on

petrol engine.

Main function is

ignite air fuel

mixture by

producing spark at

the end of

compression stroke

Spark plug

Prof. K. K. Sharma

-

Fuel Injector

PARTS FOR DIESEL ENGINES ONLY

Nozzle tip with

several small

holes for fuel

spray Prof. K. K. Sharma

-

Fuel Injector

It is provided on Diesel

Engine.

Its function is to inject

diesel at the end of

compression stroke at

very high pressure

Prof. K. K. Sharma

-

Fuel Pump

It is used in diesel engine

It forces the fuel at high pressure

through fuel injector in to the

cylinder at the end of compression

stroke.

PARTS FOR DIESEL ENGINES ONLY

Prof. K. K. Sharma

-

I . C. engine terminology

Prof. K. K. Sharma

-

1.Bore

The inside diameter of the

cylinder is called

bore.

Prof. K. K. Sharma

-

2. Top dead centre (TDC)

The top most

position of piston

towards the cylinder

head is called top

dead centre.

Prof. K. K. Sharma

-

3. Bottom dead centre (BDC)

The Lowest position

of piston towards the

crank case is called

bottom dead centre.

Prof. K. K. Sharma

-

4. Stroke

The maximum distance travel by

the piston during

its motion from

TDC to BDC is

called stroke.

Prof. K. K. Sharma

-

5. Clearance Volume

The volume

contained in the

cylinder above the

top of the piston,

when the piston is at

top dead centre, is

called the clearance

volume.

Prof. K. K. Sharma

-

Four Stroke petrol Engine

(S.I. Engine)

The four strokes of a internal combustion engine are:

Intake

Compression

Power

Exhaust

Each stroke = 180 of crankshaft revolution.

Each cycle requires two

revolutions of the crankshaft (720

rotation), and one revolution of the camshaft to complete (360

rotation). Prof. K. K. Sharma

-

Intake Stroke

First Stroke The piston moves down the

cylinder from TDC (Top Dead

Center) to BDC (Bottom Dead

Center). This movement of piston causes

low air pressure in the cylinder

(vacuum)

Mixture of Air and Fuel in the

ratio of 14.7 : 1 (air : fuel) is drawn

into the cylinder.

Intake valve stays open and the

Exhaust valve stays closed during

this stroke. Prof. K. K. Sharma

-

Compression stroke

Second stroke

The piston moves from BDC to TDC

Intake and exhaust valves stay closed

Air and fuel mixture is compressed

8:1 to 12:1

The pressure in the cylinder is raised

Prof. K. K. Sharma

-

Power stroke

Third stroke

Both the valves stay closed

in this stroke.

The expanding gases from

the combustion in the cylinder

(with no escape) push the piston

down.

The piston travels from TDC

to BDC.

At the end of compression

stroke the sparkplug fires, igniting

the air/fuel mixture.

Prof. K. K. Sharma

-

Exhaust stroke

Fourth and last stroke

The momentum created

by the Counter-weights on

the crank shaft, move the

piston from BDC to TDC.

The exhaust valve

opens and the burned gases

escape into the exhaust

system.

Intake valve remains closed. Prof. K. K. Sharma

-

Four strokes

All four strokes :-

1.Suction

2.Compression

3.Power

4.Exhaust

Prof. K. K. Sharma

-

No sparkplug on Diesel

engine.

Has a higher compression

ratio(14:1 to 25:1)

Better fuel mileage.

Four Stroke Diesel Engine

(C.I. Engine)

The only difference

between diesel engine and a

four-stroke gasoline engine

is:

Prof. K. K. Sharma

-

Diesel Engine

Intake Stroke:

Piston moves from

TDC to BDC creating

vacuum in the cylinder

Intake valve opens

allowing only air to enter

the cylinder and exhaust

valve remains closed

Prof. K. K. Sharma

-

Diesel Engine

Compression Stroke

Both valves stay closed

Piston moves from

BDC to TDC , compressing

air to 22:1

Compressing the air

to this extent increases the

temperature inside the

cylinder to above 1000

degree F. Prof. K. K. Sharma

-

Diesel Engine

Power Stroke Both valves stay closed

When the piston is at the

end of compression stroke(TDC)

the injector sprays a mist of

diesel fuel into the cylinder.

When hot air mixes with

diesel fuel an explosion takes

place in the cylinder.

Expanding gases push the

piston from TDC to BDC

Prof. K. K. Sharma

-

Diesel Engine

Exhaust Stroke

Piston moves from

BDC to TDC

Exhaust valve

opens and the exhaust

gases escape

Intake valve remains

closed

Prof. K. K. Sharma

-

Stroke 1 (intake) only air enters

cylinder.

Diesel Engine Operation

Stroke 2 (compression) air is compressed to high extent, raising its temperature.

Stroke 3 (power) diesel is injected, high air temperature ignites diesel.

Stroke 4 (exhaust) burnt gases are expelled from the engine.

Prof. K. K. Sharma

-

Diesel Engine

Four Strokes of Diesel Engine

Prof. K. K. Sharma

-

Sr.

no.

PETROL ENGINE

(S.I. ENGINE)

DIESEL ENGINE

(C.I. ENGINE)

01 Based on Otto cycle Based on diesel cycle

02 Petrol used as fuel. Diesel used as fuel .

03 For ignition Spark plug

is required.

Spark plug is not

required.

04 In these engine, air fuel mixture is sucked

during suction stroke.

In these engine, only

air is sucked during

suction stroke.

Prof. K. K. Sharma

-

Sr.

no.

PETROL ENGINE

(S.I. ENGINE)

DIESEL ENGINE

(C.I. ENGINE)

05 Compression ratio is low (about 6 to 12)

Compression ratio is high

(about 14 to 22)

06 Light in weight. Heavier in weight.

07 Due to light in weight threes engines can rotate at high

speed.

Due to heavy in weight

threes engines can not

rotate at high speed

08 The operation of these engine is silent

The operation of these

engine is noisy.

09 Initial cost is low. Initial cost is high.

10 These engines are used in light duty vehicle like

motor cycle, scooters,

cars etc.

These engines are used

heavy duty vehicle like

buses, trucks etc. Prof. K. K. Sharma

-

SR.

NO. TWO STROKE

ENGINE

FOUR STROKE

ENGINE

01 The cycle is completed in two stroke of piston or

one revolution of crank

shaft.

The cycle is completed in

four stroke of piston or

two revolution of crank

shaft.

02 One power stroke is obtained in each

revolution of crank shaft.

One power stroke is

obtained in every two

revolution of crank shaft

03 2- stroke engine have port mechanism.

4- stroke engine have valve

mechanism.

04 The piston head has crown shape.

The piston head is flat.

Prof. K. K. Sharma

-

SR.

NO.

TWO STROKE

ENGINE

FOUR STROKE

ENGINE

05 Engine is lighter. Engine is heavier.

06 Construction is

simple.

Construction is

complicated.

07 Initial cost is less. Initial cost is high.

08 Efficiency is low Efficiency is high.

Prof. K. K. Sharma

-

AIR STANDARD CYCLE

The operating cycle of an internal

combustion engine can be broken down into

a sequence of separate processes: intake,

compression & combustion, expansion, and

exhaust.

Why it is necessary to break the operating

cycle of I.C. Engine?

During every engine cycle, the medium

changes sometimes it is a mixture of fuel

and air or products of combustion, the

specific heats and other properties of the

medium change with temperature and

composition. Prof. K. K. Sharma

-

AIR STANDARD CYCLE

In an air standard

cycles, a certain mass of

air operates in a

complete thermodynamic

cycle, where heat is

added or rejected with

external heat reservoirs

and all the process in the

cycle is reversible.

Prof. K. K. Sharma

-

ASSUMPTION IN AIR STANDARD CYCLE

1. The working fluid is air, which continuously

circulates in a closed loop and always behaves as

an ideal gas.

2. All the processes that make up the cycle are

internally reversible.

3. The combustion process is replaced by a heat-

addition process from an external source.

4. The exhaust process is replaced by a heat-rejection

process that restores the working fluid to its initial

state.

Prof. K. K. Sharma

-

DEMERITS OF AIR STANDARD

CYCLE

The basic problem in the air-cycle analysis

is that it is based on highly simplified

approximations.

This is why the results obtained from such

analysis are much greater than the actual

performance.

Prof. K. K. Sharma

-

RESAONS FOR DEMERITS OF

AIR STANDARD CYCLE

This is mainly due to the following reasons:

1. Non-instantaneous burning of the fuel.

2. Non-instantaneous operation of the valves.

3. Over simplifications in using the values of

the properties of the working fluids.

4. Incomplete combustion of the fuel.

5. Assuming constant specific heat of the

working fluid.

6. Assuming the working fluid to be only air. Prof. K. K. Sharma

-

FUEL AIR CYCLE

The theoretical cycle based on the

actual properties of the cylinder

contents is called the fuel air cycle.

Prof. K. K. Sharma

-

No chemical changes in either fuel or air prior

to combustion.

No Heat exchange between the gases and

cylinder walls.

The process is frictionless and adiabatic.

Charge is in chemical equilibrium after

combustion.

Combustion process is instantaneous.

Fuel is completely vaporized and perfectly

mixed with the air (for SI only).

FUEL AIR CYCLE ASSUMPTIONS

Prof. K. K. Sharma

-

The Fuel-Air cycle takes into account the following:

1. The actual composition of the cylinder gases

(air + fuel + water vapor + residual gases).

2. The variation of the specific heat of these

gases with temperature.

3. The incomplete mixing (in-homogeneous) of

fuel and air at higher temperatures (@ above

1600oK).

4. The variations in the number of molecules

present in the cylinder as the temperature and

pressure change.

FUEL AIR CYCLE

Prof. K. K. Sharma

-

1- The actual composition of the cylinder

contents.

2- The variation in the specific heat of the

gases in the cylinder.

3- The dissociation effect.

4- The variation in the number of moles

present in the cylinder as the pressure

and temperature change.

PARAMETERS FOR ANALYSIS OF

FUEL AIR CYCLE

Prof. K. K. Sharma

-

The air fuel Ratio changes during the

engine operation.

This Change affects the composition of

gases before and after combustion.

Particularly the % of CO2, CO & Water

Vapor

1- Composition of the cylinder contents.(Gases)

Prof. K. K. Sharma

-

Specific heat increases with the increase

in temperature except for monatomic

gases.(inert gases)

Therefore the value of also changes

with temperature

Its Value decreases with increase in

temperature.

2- Variation in the Specific Heat

Prof. K. K. Sharma

-

Dissociation is defined as the disintegration

of combustion products (burnt gases) at high

temperatures.

This can be considered as reverse process

to combustion.

During combustion heat is released but in

dissociation heat is absorbed.

The dissociation mainly is of CO2 into CO and O2 : 2CO + O2 + Heat 2CO2

There is also a very little dissociation of H2O :

2H2 + O2 + Heat 2H2O

3- Dissociation Effect.

Prof. K. K. Sharma

-

3- Dissociation Effect. The effect of dissociation

on combustion temp. is

as shown in figure

The dotted line represents

the maximum combustion

temperature attained

with no dissociation, and

the full line is with

dissociation.

Dissociation reduces the

maximum temperature by

about 300oC. Prof. K. K. Sharma

-

Effect of operating variable on Cycle

1) Compression

Ratio:-

The Fuel air cycle

efficiency increases

with compression ratio

in the same manner as

air standard efficiency.

As there is more

scope for expansion of

work. Prof. K. K. Sharma

-

Effect of operating variable on Cycle 1) Fuel air Ratio:-

a) Effect on Thermal Efficiency

Prof. K. K. Sharma

-

Effect of operating variable on Cycle 1) Fuel air Ratio:-

b) Effect on Maximum Power Output

Prof. K. K. Sharma

![(K 10619) krishna murari yadav [i.c. engine]](https://static.fdocuments.in/doc/165x107/58a408b41a28ab7d758b4bdf/k-10619-krishna-murari-yadav-ic-engine.jpg)