b12750-54

-

Upload

mihaela-let -

Category

Documents

-

view

214 -

download

0

Transcript of b12750-54

-

8/11/2019 b12750-54

1/4

328

Concrete Repair, Rehabilitation and Retrotting III Alexander et al. (eds) 2012 Taylor & Francis Group, London, ISBN 978-0-415-89952-9

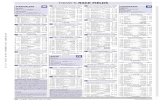

Modeling of moisture distribution in concrete in 3D

J. Skramlik, M. Novotny & K. SuhajdaBrno University of Technology, Czech Republic

ABSTRACT: Into porous material of concrete structures can penetrate moisture in liquid or gaseousform. Humidity affects the physical properties of building material. To express the negative effects ofmoisture on building materials or building structures more accurately, it is needed to use the most accu-rate method of detecting moisture diffusion. Capillary conductivity is influenced in dependence not onlyat external fluids and change of heat, but also by the processes inside the porous structure. These influ-ences should be explored in text of European standard EN ISO 15026 is informative link that presentsthe description of the distribution of moisture in porous material based on measurements using NMR

(Nuclear Magnetic Resonance), which is essentially a curve of wetting of material in time intervals. Theaim of this paper is to present information about detection of distribution of moisture in concrete bymeans of EMWR (electromagnetic microwave radiation) and to record moisture curve in 3D for calcula-tion of capillary conductivity coefficient and his dependence on moisture by weight.

Model presents a complex of physical phenom-ena and the process which is affected by externalinfluences. Each stage has lower levels, which arecarried out separately as individual process.

qd = density of diffuse flow of controlled bytemperature; qd=density of diffuse flow of con-

trolled by moisture; qu=density of liquid flow dueto capillary of water; q=is the heat flow density;u=moisture; t=middle temperature.

Enthalpyis the heat due to heat sources such assunlight. Latent heatis released in the conversionof water-drying, evaporation and condensation.

1 INTRODUCTION

Excessive moisture in building materials affects thephysical characteristics of building structures andcauses its degradation. To evaluate the negativeeffects of humidity on the material it is necessary

to determine moisture characteristics. Buildingconstruction which is made of concrete should bedesigned with respect to a number of factors thatsomehow impede its function. Such factors includewater vaporas a liquid moisture phase.

Diffusion of water vapor is sufficiently exploredbut for the transport of moisture in porous struc-ture there however is necessary to know informa-tion about the condensation of water vapor. Ifwater in porous material condensed, liquid mois-ture emerges in part of construction. This phenom-enon is called capillary conductivity of moisture.

2 THE MOISTURE IN POROUS MEDIUM

2.1 Moisture and capillary medium

Water gets in porous material from the environ-ment and the equilibrium between the materialmoisture and the ambient air moisture is reachedunder steady temperature and moisture conditions.If the partial pressure of water vapor in a buildingmaterial is lower than that in the ambient air, thenthe material absorbs water vapor from the air.

Figure 1 shows model of impact of externalinfluences on the porous material. By influence ofcondensation and by change of temperature gradi-ent is accelerated the diffusion of moisture.

,dq

,dqVapor ,d

q

,dq

Equilibrium

uq , Water uq ,

Latent heat

q Enthalpy q

Source of heat

Source of moisture

u

u

Convection

inwardsAccumulation

Convection

outside

2

1

3

1

2

3

Figure 1. Model of external influences on porous mate-rials [1] 1diffusion, 2liquid water, 3heat.

-

8/11/2019 b12750-54

2/4

329

In an area where the porous material is in con-tact with the water surface is cause of moisturetransport for example capillary pressure. For themoisture behavior of porous building materials isstill lacking a clear description.

2.2 Moisture distribution in capillary medium

Due to the heterogeneity of porous structure whichdetermines the movement of individual phases ofthe moisture, cannot be accurately analyticallydescribed diffusion of moisture(Fig. 2).

Porous materials consist of cavities in variousforms.

2.3 The moisture diffusion inside materials

Sorption and desorption isotherm expresses

the value of the absorption and release of mois-ture from the air when air reaches equilibriummoisture.

Progressive increase in material moisture from60% relative humidity is attributed to capillarycondensation (Fig. 3). Therefore the capillariesare filled up to 90% relative humidity with waterand at the same time there appears condensation(Kiel. K).

Fig. 4present increase of condensation on thewalls of porous medium.

2.4 Moisture accumulation in a construction

Many technical studies show that the moisturemonitoring is prevailingly based on experiments.

Previous calculating methods e.g. by Glaser (tothe condensation occurs between the points A andB as seen on the graph (Figure 5),which becamethe basis for the standard calculations in manyEuropean countries in the 1960s are not alwayssufficient with respect to the demands for the civil

structures.In reality dampness does not remain in delimited

zone. Condensation extends in porous material inall directions and is affected by moisture gradient.

Moisture spreads in porous texture - for exam-ple within the range of A1B1to A3B3(Figure 6).

This fact subsequently effects the physical char-acteristics of concrete and also changes heat con-ductivity .

2.5 The moisture transport coefficient

In case of high water content the liquid transporthas a particular influence on moisture transportbehavior of porous materials.

Figure 2. Capillary profile a) water b) vapor c) adhesivewater.

Figure3 . Dependence of dampness on diffusion coef-ficient [2].

Figure 4. Multilayer of condensation on the walls of

capillaries.

Figure 5. Determination of the condensation zonein a construction by means of a numerical calculation(Glaser) [4].

Figure 6. Distribution of condensate out of condensa-tion zone.

Downloadedby[RMITUn

iversity]at13:0916April201

4

http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-004.jpg&w=104&h=86http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-003.jpg&w=137&h=107http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-001.jpg&w=81&h=74http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-000.jpg&w=127&h=97 -

8/11/2019 b12750-54

3/4

330

The material property to describe this process isthe liquid conductivity. The determination of thevapor coefficient according to European standard15026 is described in EN ISO 12572:

Kp

Dw p

Dsuc

su

su)puc

)w

)w

w

(1)

where Kis liquid conductivity [s.m-1], Dw is diffu-sion of moisture as transfer coefficient [m2.s-1],psucis suction [Pa], wis moisture by weight [kg.m-3].

Capillary pressure is primarily if its minimumvalue is (Kiessl):

rk= = .

cos cos

(2)

pk=capillary pressure;=r1=curvature; =mois-

ture; =surface tension of water; r =pore radius;t =temperature (constant).

. .cos

(3)

= r 1

(4)

The smaller the pore radius = the greater thecapillary pressure, which causes the suction ofwater from the large pores.

Informative mention in conclusion of this Euro-

pean Standard presents the moisture distributionsas the wetting curves in length of sample in timeand calculates K is based on the difference of par-tial pressures. This standard recommends using todetermine the nuclear resonance.

Characteristic parameter for describe the mois-ture in the porous material is the wetting curve(Figure 7) the distribution of moisture in timeclassic set by the gravimetric method for calculat-ing coefficient of capillary conductivity.

2.6 Capillary conductivity coefficient

The basic theoretical concept for the description ofmoisture transport in porous material in this caseis based on a combination of continuity equationwith Lykovs equation, which expresses capillary

conductivity and moisture gradient.From distribution of moisture in a given timeinterval (t is constant and x is a function of onevariable) can be expressed the capillary conductiv-ity coefficient (Kutilek):

uu

(5)

where t= time interval [s], = substitution of thedistance [-], = new variable [-], =Boltzmanntransformation [m.s-1/2], x=length of a sample [m],

u1=maximal value of moisture [-], u2=moisture byrelative humidity [-].

3 DETECTION OF MOISTUREDISTRIBUTION BY HELP OF EMWRADIATION

To detect moisture transport in concrete there wasused apparatus developed at the Brno Universityof Technology (Figure 8).

3.1 The procedure to obtain of curves

At the Fig. 9 is a graph of functional depend-ency changes of the intensity of electromagneticmicrowave radiation on the amount of moisture inconcrete.

a. Dependence between EMW radiation and con-tent of moisture in material from regression for-mula, (Fig. 3, 4and 9),

um=1,342033167.107 z3+0,0001936510773

z20,1038753765 z+20,78641097

b. Dependence between change of EMWR andmoisture into distance from source of dampness,

c. Moisture distribution (Fig. 11):

um,t =f(zt(x)) (6)

um = specific moisture, z = EMWR intensitywhich come through Specimen, x=position dataof moisture, t=time interval of measurement.

3.2 Grafical presentation of measured valuesin 3D

At theFig. 10is the results of continuous measure-ments on one sample of material from where it ispossible use sectional view at any time interval tocalculate the coefficient of capillary conductivity

Figure 7. Moisture profiles u(x) at the time intervals tx-moisturizing of the measured sample showing the initialand boundary conditions for the determination of thecapillary conductivity coefficient [1].

Downloadedby[RMITUn

iversity]at13:0916April201

4

http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-005.jpg&w=187&h=100 -

8/11/2019 b12750-54

4/4

331

3.3 Wetting curves

At the Fig. 11is a graphical representation of thechanges in moisture by weight obtained by transferof electromagnetic microwave radiation intensityon the content of moisture (see Fig. 7)in time of ashift of waveguide within the length of sample.

The values determined by help experimentallyassembled apparatus allows calculating the coef-ficient of capillary conductivity. In addition, thereare several other ways we can to use these data, forexample to express the capillary conductivity coef-ficient depending on the moisture by weight (see

Capt. 2.6).

4 CONCLUSIONS

By measurements on the experimental appara-tus were attained of curves, comparable with themethod presented in the Standard ISO 12572 andit is not differences in the method by using of par-tial pressures. It has been shown that microwaveradiation is sufficient for the detection of moisture.Measurement results can be applied to calculatethe coefficient of capillary conductivity. Comparedwith the gravimetric method are curves for calcu-lation of capillary conductivity coefficient usingMattan method more accurate as well as for anintegral method, which requires more curves on the

same material. By using of mathematical method ispossible to continue processing the results of meas-urement for expressing of capillary conductivitycoefficient depending on the moisture by weightfor expression the thermal insulation properties ofmaterials depending on the moisture.

In addition for monitoring of moisture inporous material adequate and also sufficient forthis purpose instead NMR is EMWR.

ACKNOWLEDGEMENT

This article was supported by GACR P104/10/P388Experimental analysis of the effect of microwaveradiation for destruction of biological agents andby GACR P104/10/1390 The analysis of influ-ence of MW drying while application of chemical

grouting into moist brickwork.

REFERENCES

1. Kiessl, K. Kapillarer und dampffrmigerFeuchtetransport in Bauteilen. Essen 1983.

2. European Standard EN ISO 15026 Assessment ofmoisture transfer by numerical simulation, 2007.

3. Gertis, K. & Kiessl, K. Feuchte Transport in Baustof-fen, 1980.

4. Kutilek, M. Dampness porous material, CZ, PragueSNTL, 1992.

5. Krischer, K. Die Wisenschaftliche Grundlagen derTrocknugstechnik, Springer Verlag 1978.

6. Skramlik, J. & Novotn, M. Moisture transfer inbuilding material, PROHITECH 09, Italy, Taylor andFrancis Group, UK, ISBN 978-0-415-55803-7, 2009.

R2= 0,98

0

2

4

6

8

10

12

14

16

18

20

0

change of intensity of EMWR [mV]

mosisturebyweight[%

]

500400300200100

Figure 9. Functional dependence of microwave radia-tion on humidity by weight.

Figure 10. Three-dimensional distributions of moisturein the reference sample material.

Figure 11. The moisture distribution in non-stationarystate of wetting of sample.

Figure 8. Apparatus for monitoring the moisture trans-port in 3D view.

Downloadedby[RMITUn

iversity]at13:0916April201

4

http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-008.jpg&w=130&h=126http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-007.jpg&w=149&h=72http://www.crcnetbase.com/action/showImage?doi=10.1201/b12750-54&iName=master.img-006.jpg&w=149&h=86