AUTOSAR in Agricultural (& Construction) Machinery

Transcript of AUTOSAR in Agricultural (& Construction) Machinery

| AUTOSAR at John Deere | 27 Nov 20141

27 Nov 2014/Stuttgart

AUTOSAR in Agricultural (& Construction) Machinery

| AUTOSAR at John Deere | 27 Nov 20142

A Proud Past

John DeereFounder and President 1837 to 1886

1804 Born in Vermont

1821 Became blacksmith apprentice

1837 Built his first plow

1848 Moved business to Moline

1858 Handed leadership of company to his son, Charles

| AUTOSAR at John Deere | 27 Nov 20143

Today’s tractors are highly automated and integrated with farm management via electronics

| AUTOSAR at John Deere | 27 Nov 20144

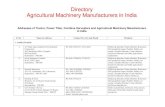

John Deere Manufacturing Locations

2013 Net Sales and Revenues: $37.8 Billion

Agriculture & Turf 73.4%

Construction & Forestry 18.5%

Financial Services 6.9%

Other 1.2%

| AUTOSAR at John Deere | 27 Nov 20145

John Deere

| AUTOSAR at John Deere | 27 Nov 20146

Where are electronics used?

| AUTOSAR at John Deere | 27 Nov 20147

How are electronics used?

Precision control

machine coordination

Task planning

Prescription farming

Automation

| AUTOSAR at John Deere | 27 Nov 20148

Work site coordination

| AUTOSAR at John Deere | 27 Nov 20149

Modern Tractor Electronic Architecture

Cab Controls Right Console

RoofControls

Ride control

Primary Display

Hydraulic Controls

RearControls

Func-AFunc-BFunc-C

Pump

| AUTOSAR at John Deere | 27 Nov 201410

Why AUTOSAR? Business–Leverage larger supply base–Speed of development

Quality–Widely used software, improved architecture–Easier to meet Functional Safety standards (ISO 25119 and

ISO 13849)

Complexity management–Machine variants, feature proliferation–Integration of worksite solutions–Mixed systems - ISOBUS

| AUTOSAR at John Deere | 27 Nov 201411

John Deere Electronics

Proprietary, structured but optimized

clusters, displays, and armrests

high end graphical displays

Traveling electronics – virtual terminal, GPS, rate controllers

16-bit common hardware

3rd party electronics integration for radio, ATC, …

Standard, strict architecture

AUTOSAR

file-based OS

AUTOSAR compliant when it adds business value

32-bit common hardware

same

Current Future

| AUTOSAR at John Deere | 27 Nov 201412

AUTOSAR is part of larger vision

System level design and architecture

Model based design Simulation & Test in virtual

environment PV&V throughout

| AUTOSAR at John Deere | 27 Nov 201413

John Deere AUTOSAR adoption approach

Phase out JD/OS and FOCUS. Move all new development to AUTOSAR

Compatibility class 3 32-bit micro common hardware Common BSW and tool set across all product

divisions Leverage suppliers for BSW, CDDs JD develops all applications (features) Drive a top-down design methodology compatible

with model based development and AUTOSAR

| AUTOSAR at John Deere | 27 Nov 201414

AUTOSAR Architecture & Workflow

(Software Systems Engineer)

Integrate and Build Software

(Software Development

Teams)

Implement and Test Software

(Software Development Teams)

Implement and Test BSW

(AUTOSAR Infrastructure Team)

| AUTOSAR at John Deere | 27 Nov 201415

Organization and Governance

Business Steering Team

Technical Steering Team

OS Support

Development Teams

AUTOSARInfrastructureSupport Org

AUTOSAR COP

| AUTOSAR at John Deere | 27 Nov 201416

AUTOSAR adoption challenges

Different Tier 1 relationships

License models Legacy subsystems,

mixed systems Business case on a per

product level ISOBUS compatibility

| AUTOSAR at John Deere | 27 Nov 201417

Common needs with passenger cars

Functional safety – autonomous driving

Security (hackers)

V2V /V2X – M2M / worksite

High speed networks

| AUTOSAR at John Deere | 27 Nov 201418

Common needs with passenger cars

Functional safety – autonomous driving

Security (hackers)

V2V /V2X – M2M / worksite

High speed networks

| AUTOSAR at John Deere | 27 Nov 201419

Differences from passenger cars

Open communication protocols – SAE J1939 & ISO 11783 (ISOBUS)

Need for common diagnostic protocols for mixed systems

–ISOBUS and Agricultural Electronics Foundation

Automotive is selling “creature comforts” and safety features

Ag and Construction are selling productivity and economy features

| AUTOSAR at John Deere | 27 Nov 201420

Conclusions

AUTOSAR is an enabler in agricultural electronics for methodology changes systems engineering managing costs of infrastructure

Adoption strategy must be “tuned” to the business cannot wait for complete cost justification. fully commit to AUTOSAR discover opportunities and optimize them

Adopt standard solutions to common problems. Extend the cooperation within agricultural equipment companies.

| AUTOSAR at John Deere | 27 Nov 201421