“Capacity Building of Officers from · “Capacity Building of Officers from Petroleum Refinery...

Transcript of “Capacity Building of Officers from · “Capacity Building of Officers from Petroleum Refinery...

“Capacity Building of Officers from Petroleum Refinery Sector on Efficient

Use of Energy” on 7th July 2017 at IOCL, Vadodara Refinery,

Presentation by

Mohit Naidu Anand Wagh

on “Best Practices and New

Technologies adopted by HPCL-MR”

07th July 2017

HP FIRST

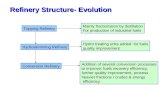

AGENDA

Refinery Configuration

Energy Performance

Energy Improvement Schemes

Best Practices in Monitoring and Reporting

REFINERY BLOCK DIAGRAM LPG

150 N G II/III

500 N G II/III

LS

HS

Stabilizer

Treating ATF

DIU/DHT HSD

SKO/MTO

Sulfur

LDO

FR CDU

VDUs

SEUs

PDA

IOH

PDU

FR E

CDU

VDU

FCC & NFCC

Spindle Oil 150 N G I

500 N G I

Bright Stock

IO-100

IO-1600

Bitumen

Gasoline

LSHS

HMU

IFO

Hexane/Sol

Prime G+

ISOM/CCR

LOUP

ENERGY PERFORMANCE

7755 7760

7497

8013

8510

7000

7400

7800

8200

8600

2012-13 2013-14 2014-15 2015-16 2016-2017

Crude Processed TMT

6.58 5.95 6.5 6.86 6.53

0.96 0.93

0.92 0.96 0.67

0

2

4

6

8

10

2012-13 2013-14 2014-15 2015-16 2016-2017

Fuel and Loss (wt%)

Fuel (wt %) Loss (wt %)

96.24

93.23 94.62

90.63

87.91

2012-13 2013-14 2014-15 2015-16 2016-2017

MBN

108.0

106.3

111.8

108.0

106.6

2012-13 2013-14 2014-15 2015-16 2016-2017

EII

Diesel Isotherming Project Implementation

Savings in Fuel, Steam and Power

20815 SRFT in 2015-2016

Reduction of gas to oil ratio in DHT from 650-750 to 540-690.

Electricity savings of 25 MWH/day

3396 SRFT/Year

ENCON MEASURES IMPLEMENTED

ENCON MEASURES IMPLEMENTED

Steam trap management

Savings in Steam generation

2282

SRFT in 2015-2016 Revamp of SEU

III furnace.

Improve in efficiency from 77% to 83.8%

710 SRFT

ENCON MEASURES IMPLEMENTED

Routing of Amine de-gassifier off gas to Prime G+ furnace

Reduction in hydrocarbon loss

72

SRFT/

month New FGRC for handling low molecular weight

Reduction in hydrocarbon loss

1094 SRFT/ month

ENCON MEASURES IMPLEMENTED

Maximization of CCR in FCCU II feed

High steam generation due to high feed CCR

2209 SRFT in 2015-2016

RENEWABLE ENERGY Renewable Energy Projects implemented

Polycarbonate sheets for harnessing day light

75 KW Solar Photovoltaic power plant in QC Lab. building.

175 KW of Renewable Energy

Consumption.

Polycarbonate sheets in QC Lab. Building for harnessing day light

PROJECTS UNDER IMPLEMENTATION

SL. No Description of Project Investment

(Rs. Cr)

EstimatedSaving

(SRFT)

1 Install Energy Efficient Lighting System 0.77 487

2 Revamp of SEU 2 furnace for improvement in efficiency

8.7 1709

3 Power Recovery Through Back Pressure Steam Turbo Generator

20.75 1026

4 Attending Air Leaks and Optimizing Air Compressor

0 1283

5 Replacement of lift steam with Refinery Gas in FCCU II

0.1 1632

PROJECTS PLANNED FOR FUTURE

SL. No Project Investment

(Rs Cr) Savings (SRFT)

1 Condensate Recovery from off site areas

1 941

2 Replacement of SBR blower in IETP with better efficiency Turbo blower

0.55 118

3 Replacement of motor with lower rating for all the FRP blade fans in CTs

0.22 1424

4 SEU 1 Furnace Revamp 8.7 1709

Title: Revamp of SEU III furnace for improvement in efficiency

Project Details:

Modification done in the Radiant section & Convection section of Extract Recovery heater and Raffinate Recovery heater using AGFIS patented Split flow technology

Implemented in April 2016

Before:

High stack flue gas temperature (350 – 460 deg C).

High tube skin temperature in extract heater.

Tube failures in convection section.

Low temperature of LPG stripping gas ex-heater convection.

REVAMP OF SEU III FURNACE

Details of modification:

Extract Recovery Heater:

Height of radiant section increased by 3 m and 8 number of turns added.

Burners inclined at an angle of 5.5 degree to prevent flame impingement.

Raffinate Recovery Heater:

Height of radiant section increased by 3 m and 12 number of turns added.

Burners inclined at an angle of 3 degree to prevent flame impingement.

New convection section:

AGFIS Split flow technology implemented (Split stream of furnace inlet of Extract recovery heater heated in convection section)

Other changes:

Two rows of new soot blowers installed in the new convection section.

Radiant and convection section metallurgy changed from SS316L to SS347.

REVAMP OF SEU III FURNACE

Benefits:

Additional flow across furnace due to reduction in coil pressure drop.

Increase in efficiency due to increase in heat recovery.

Savings : 710 SRFT/Year

Comparison of parameters before and after revamp:

REVAMP OF SEU III FURNACE

Parameters Before

Revamp

Revamp

(Design)

Post Revamp

(Actual)

Stack

temperature,

deg. C

460 220 250

Efficiency, % 74 88-90 83.8

REVAMP OF SEU III FURNACE

Split pass

Split pass

F-4202 F-4201

F-4201: Extract Recovery heater F-4202: Raffinate Recovery heater : Modifications

TIC

TIC

Coil inlet

Coil inlet

Coil outlet Coil outlet

LPG Stripping Gas

Title: Routing the rich amine flash drum gases of ARU to Prime G+ furnace.

Project Details:

The off gases for rich amine flash drum routed to Prime G+ furnace as fuel.

Implemented in August 2016

Before:

100 kg/hour rich amine flash drum gases was being routed to flare.

Details of modification:

Line laid from AU to Prime G+ furnace.

All the burners in PG+ furnace were modified.

Benefits:

Reduction in sour flare loss

Savings: 72 SRFT/month

ARU OFF GAS TO FURNACE

Title: Power recovery through Back Pressure Steam Turbine

Project Details: Installation of a Back Press Steam Turbine along with Generator.

Before:

VHP steam (40 kg/cm2,360 deg. C) is let down to HP steam (14 kg/cm2, 270 deg. C) through PRDS.

Details of modification:

Steam let down through BPST and using the enthalpy drop to generate 3.5 MW power which will be integrated with refinery electrical system.

Current PRDS will be retained for excess steam demand in refinery.

POWER RECOVERY THROUGH BPSTG

Benifits:

3.5 MW Power generation

Savings: 1096 SRFT/Year

POWER RECOVERY THROUGH BPSTG

BEST PRACTICES AT MR

• F&L estimation –Monthly

• EII estimation –Monthly

• Pressure Safety Valve Survey – Bi-monthly

• Compressed Air leak Survey – Half - yearly

• Steam trap survey - Quarterly

• FO balance – Monthly

• Furnace Stack O2 survey – Monthly one furnace

• Energy Audit of units – Monthly two units

• Loss audit – As and when required

• Online fouling monitoring

• Flare monitoring - Daily

• Furnace efficiency monitoring – Daily

• Fuel oil reconciliation – Quarterly

• Gas balance – Monthly

MONITORING & REPORTING FORMATS

Daily Fortnightly / Monthly

Quarterly Others (as & when required)

Flare report F&L Steam trap

survey Furnace O2 survey

Furnace efficiency MBN QPR Energy audit for

process units

EII

Compressed air leak survey

Loss audit

FO / Gas balance

PSV survey