Anderson Greenwood Pilot Operated Pressure Relief...

-

Upload

hoangkhanh -

Category

Documents

-

view

266 -

download

4

Transcript of Anderson Greenwood Pilot Operated Pressure Relief...

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

www.tycoflowcontrol.com/valvesCopyright © 2011 Tyco Flow Control. ANGMC-0276-US-1111

General applicationFood and beverage processing, dry bulkconveying, paper mills, slurry handling etc. Inthe highly specialized field of pressure reliefdevices, no manufacturer can match thediversified products and experience ofAnderson Greenwood. With more designsthan any other worldwide manufacturer,Anderson Greenwood’s product technologysolves applications from the most severeproblem to very basic service conditions.

Specifications• Durable but replaceable Teflon® or PEEK

seat in main valve, located on the piston totake the wear. A totally captive seat designeliminates seat extrusion at elevatedtemperatures.

• Teflon®/PEEK seals throughout main valveand pilot for optimum chemical resistance,such as needed for various chemicals inboiler feedwater.

• Single point set pressure adjustment.

• Field replaceable main valve nozzle.

• Non-flowing, all plastic seat/seals, pilot.

• Lifting Lever and Pilot Supply Filter arestandard accessories.

Technical dataSizes: 1" x 2" to 8" x 10"

Orifices: 0.307 to 38.96 in2[1.981 to 251.3 cm2]

Inlet Ratings: ANSI Class 150 to 2500

Max Temperature: 515°F [268°C]

Set Pressures: 15 to 6170 psig [1.03 to 454.4 barg]

Code: ASME I

Features and Benefits• Reduced product loss and pollution:

Soft seats for premium tightness before and after relief cycles.

• All plastic soft goods: There are noelastomer seats or seals providing forchemical compatibility with corrosioninhibitors which may be found in feedwater service.

• Increased system output: Because of totalvalve tightness to at least 96 percent of setpressure, the system can be operated closerto set pressure without valve leakage. Theresult is greater system productioncapability.

• Reduced maintenance costs: Resilientseats greatly extend service life. Costly andtime consuming metal seat lapping isunnecessary.

• Balanced design: Proper valve operationand lift are unaffected by back pressure.Costly and fragile metal bellows are notrequired. The Series 5100 pilot is exhaustedto the outlet of the main valve with no effecton its set pressure.

• ASME Section I Stamp: Certified National Board capacities for steam andwater per Code Case 2446 assures the userof independent third party flow rateverification.

• Reduced noise:Modulating actionminimizes flow and resultant noise duringnormal system upset reducing noiseabatement costs.

• Non-flowing pilot:Minimizes entrance of dirt and debris in the pilot. Due to lowvelocities within the pilot and supply tubing,most particles will drop out upstream of thepilot inlet screen.

• Ease of Adjustment: Single adjustment for set pressure allows for accurate anddependable testing.

• Rugged pilot mounting: Rigid, low profilebracket mounting protects against vibrationand careless handling.

Series 5100 Modulating Pilot Operated Pressure Relief Valve

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 2

Specifications

Piston Seal

Seat

Sense Pickup

Dome

Pilot

Anderson Greenwood has developed therevolutionary Series 5100 specifically toserve Economizer applications requiringpressure relief under the stringentrequirements of ASME Section I and CodeCase 2446. This unique and challengingapplication requires premium performanceon a valve that must have ASME Section Icertified capacities for both steam andwater.

A modulating pilot operated pressure relief valve would be the ideal solution tothis difficult application. Since the ASMESection I valve on an Economizerhistorically was certified only on steam, the valve would chatter when exposed toeither water or flashing water service whichis the typical real world scenario. CodeCase 2446 was developed and approved tocorrect this situation. Instead of openingquickly (as occurs with a spring-loadedvalve or a snap-acting pilot operated valve),a modulating pilot operated valve wouldonly open proportional to the specificoverpressure need, thereby eliminatingvalve chatter.

Anderson Greenwood Series 5100 was the first and is the ONLY non-flowing,modulating pilot operated pressure reliefvalve that is certified under ASME Section I.The Series 5100 is a unique soft seatedpressure relief valve that requires noelastomer seats or seals. All plastic softgoods trim materials provide an economicalway to handle high temperatures andaggressive lading fluids. This designprovides an alternative to the traditionalmetal seated direct acting pressure reliefvalves used in these installations.

The result is a modulating, soft-seated, pilot operated valve offering premiumtightness with the ability to handle relievingtemperatures to 515°F [268°C] and a setpressure range of 15 to 6250 psig [1.03 to430.9 barg].

The Series 5100 pilot is the latesttechnology from Anderson Greenwood. It is the first all plastic soft seat and sealedvalve that operates as a non-flowingmodulating pilot. There are no pilotcomponent changes required to handle

service conditions changing to and fromsteam and water.

The soft seat in the Series 5100 main valveis more resistant to particulate damagethan a metal seat, has a longer service life,and can be quickly replaced while the valvebody remains installed in the line.

Its unique design enables the main valve tobe tight at pressures up to set point. Afterrelieving and reseating, it stays bubble-tight, cycle after cycle.

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 3

Sizing

Effective API Orifice Area, in2 [cm2]Valve Size Type 5146 Type 51661in [mm]

1 x 2 [25 x 50] 0.307 (“F”) [1.981]2 –

11/2 x 2 [40 x 50] – 1.320 [8.516]3

11/2 x 3 [40 x 80] 0.785 (“H”) [5.065]2 –

2 x 3 [50 x 80] 1.287 (“J”) [8.303]2 2.554 [16.47]3

3 x 4 [80 x 100] 2.853 (“L”) [18.41]2 5.938 [38.31]3

4 x 6 [100 x 150] – 9.489 [61.21]4

6 x 8 [150 x 200] – 20.57 [137.7]5

8 x 10 [200 x 250] – 38.96 [251.3]5

Dow

n Force on Main Valve Piston

Set

Pressure

0 0

Pressure

Main Valve Piston Lift

Set

Closing

100% Lift

Opening

Operation

95% Set PressureMinimum

In normal operation, the system pressureacts on the area contained by the mainvalve seat at the bottom of the free-floating differential area piston and onthe top of the piston. Since the top of thepiston is larger than the bottom (seatarea), there is a large downward net forceholding the piston closed. Under staticconditions, the seating force increases asthe system pressure increases andapproaches set point.

Just prior to set pressure the pilot opensand partially depressurizes the dome.This reduces the force on the top of the

piston. The set pressure is the pointwhere the upward force on the mainvalve seat area can overcome thereduced downwardloading. This causesthe piston to lift, resulting in modulatedflow through the main valve. As the mainvalve is relieving the flow through thepilot stops.

When the relief demand has beensatisfied, the pilot closes, full systempressure is diverted to the dome, and thepiston moves downward, closing themain valve.

A patented, pressure responsive piston drag system in the larger Series 5100valves eliminates resonant chatter andthe severe valve and/or piping damage itcan cause. The wedge ring creates apressure-actuated sliding friction forcebetween the piston and liner, preventingresonant chatter.

Notes:1. There are no recognized API “full-bore”orifice areas. These effective areas arespecific to Anderson Greenwood.

2. Set pressure range 15 - 6250 psi

3. Set pressure range 15 - 3750 psi

4. Set pressure range 15 - 2250 psi

5. Set pressure range 15 - 1500 psi

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 4

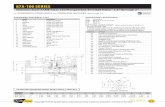

Standard main valve – materials of construction

14

1

13

18

10

3

2

5

4

6

12 8

7

15

9

417

11

20

2116

/S1515°F [268°C]

Item Description Maximum Relieving Temperature

1 Body SA216-WCB/WCC CS

2 Piston A564-630 (17-4 PH), A479-316 or A351-CF8M SS3 Liner A479-316 or A351-CF8M SS

4 Nozzle A479-316 or A351-CF8M SS5 Seat Teflon® or PEEK

6 Seat Retainer A479-316 SS7 Seat Retainer Bolt 316 SS

8 Cap SA479-316 SS9 Dipper Tube 17-4 PH SS

10 Piston Seal Teflon®/Elgiloy11 Nozzle Seal Flurosint

12 Liner Seal Teflon®

13 Retaining Ring SST 302

14 Cap Bolt A449/A325 CS15 Lock Washer SST 18-8

16 Dome Spring 316 SS17 Nozzle Retainer A747-CB7CU-1 SS or 17-4 PH SS

18 Wedge Ring TFE 35% Carbon20 Siphon Tube Assembly 316 SS

21 Bushing Seal Teflon®

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 5

Pilot materials of construction

17

40

3

2

13

18

16

4

39

36

8

5

12

37

15

39

14

10

9

26

25

30

27

28

24

21

41

42

1

11

38

20

45

44

22

45

43

23

19

35

31, 32

29

39

7

6

33

34

Item Description Material

1 Body 316 SS

2 Piston Connector 316 SS3 Inlet Seat 316 SS

4 Exhaust Seat Retainer 316 SS5 Exhaust Seat Stem 316 SS

6 Exhaust Nozzle 316 SS7 Exhaust Washer 316 SS

8 Stop Washer 316 SS9 Outer Spool Spring Inconel® X750

10 Inner Spool Spring Inconel® X75011 Piston Plate 316 SS

12 Piston 316 SS13 Bushing 316 SS

14 Inlet Nozzle 316 SS15 Dome Spool 316 SS

16 Dome Seal Backup Ring PEEK17 Piston Seal Teflon®/Elgiloy

18 Dome Seal Teflon®/Elgiloy19 Spring Bonnet 316 SS

20 Bonnet Ring 316 SS21 Bonnet Ring Screw 18-8 SS

22 Spring 316 SS23 Washer Spring (upper) 316 SS or 17-7 SS

24 Washer Spring (lower) 316 SS

Item Description Material

25 Pressure Set Screw 17-4 SS

26 Adjusting Screw Locknut 316 SS27 Lifting Rod 17-4 SS

28 Spindle Bushing 316 SS29 Cap SA351-CF8M SS

30 Lever SA351-CF8M SS31 Lever Pin 316 SS

32 Cotter Pin 18-8 SS33 Spindle Nut 316 SS

34 Cotter Pin 18-8 SS35 Cap Screw 18-8 SS

36 Stem Seal Teflon®/Elgiloy37 Exhaust Seat Teflon®/15% Graphite

38 Piston Plate Screw 17-4 SS39 Spool/Body Seal Teflon® TFE

40 Body/Piston Plate Seal Teflon® TFE41 Roll Pin 420 SS

42 Pipe Plug 316 SS43 Pilot Nameplate 304 SS

44 Nameplate – Patents 304 SS45 Drive Pin SS

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 6

Steam capacity (lbs/hr)/water capacity (GPM) at 3% overpressure

5146 5146 5166 5146 5166 5146 5166Valve Set Steam Water Steam Water Steam Water Steam Water Steam Water Steam Water Steam WaterPressure 1 x 2 1 x 2 1.5x3 1.5x3 1.5x2 1.5x2 2x3 2x3 2x3 2x3 3x4 3x4 3x4 3x4(psig) F F H H FB FB J J FB FB L L FB FB15 1306 109 2074 166 2139 178 4013 322 4744 394 9332 74820 1512 124 2401 189 2477 202 4645 366 5492 449 10804 85130 1924 149 3055 228 3152 244 5911 441 6988 541 13748 102640 2335 171 3709 261 3827 280 7177 505 8485 620 16692 117650 2747 190 4363 291 4502 311 8443 562 9981 690 19636 130860 3159 207 5017 317 5177 340 9709 614 11478 753 22580 142870 3575 224 5678 342 5858 366 10987 662 12989 812 25553 154080 3999 239 6351 366 6553 392 12291 708 14530 868 28585 164790 4424 254 7025 388 7248 415 13595 751 16072 921 31618 1746100 4848 267 7699 409 7944 438 14898 792 17613 971 34650 1841120 5696 293 9046 448 9334 480 17506 867 20696 1064 40714 2017140 6545 316 10394 484 10724 518 20113 937 23778 1149 46779 2178160 7393 338 11741 517 12115 554 22721 1001 26861 1228 52843 2329180 8242 359 13089 549 13505 587 25329 1062 29944 1303 58908 2470200 9090 378 14436 578 14895 619 27936 1119 33026 1373 64972 2604220 9939 396 15784 607 16285 649 30544 1174 36109 1440 71036 2731240 10787 414 17131 634 17676 678 33151 1226 39192 1504 77101 2852260 11636 431 18478 660 19066 706 35759 1276 42274 1566 83165 2968270 12060 439 19152 672 19761 720 37062 1301 43816 1595 86197 3025280 12484 447 19826 684 20456 733 38366 1325 45357 1625 89230 3081300 13333 463 21173 708 21847 758 40974 1371 48439 1682 95294 3189320 14181 478 22521 732 23237 783 43581 1416 51522 1737 101359 3293340 15030 493 23868 754 24627 807 46189 1460 54605 1790 107423 3395360 15878 507 25216 776 26018 831 48796 1502 57687 1842 113487 3493380 16727 521 26563 797 27408 854 51404 1543 60770 1893 119552 3589400 17575 534 27911 818 28798 876 54011 1583 63853 1942 125616 3682420 18424 548 29258 838 30189 897 56619 1622 66935 1990 131681 3773440 19272 561 30606 858 31579 919 59227 1660 70018 2037 137745 3862460 20121 573 31953 877 32969 939 61834 1698 73101 2082 143810 3948480 20969 585 33300 896 34359 959 64442 1734 76183 2127 149874 4033500 21818 598 34648 915 35750 979 67049 1770 79266 2171 155939 4117600 26060 655 41385 1002 42701 1073 80087 1939 94679 2378 186261 4509700 30303 707 48122 1082 49653 1159 93125 2094 110092 2569 216583 4871800 34545 756 54860 1157 56604 1239 106162 2239 125506 2746 246905 5207900 38788 802 61597 1227 63556 1314 119200 2375 140919 2913 277227 55231000 43030 845 68334 1294 70507 1385 132238 2503 156332 3070 307550 58221100 47273 886 75071 1357 77459 1452 145275 2625 171745 3220 337872 61061200 51515 926 81809 1417 84410 1517 158313 2742 187159 3363 368194 63771300 55758 964 88546 1475 91362 1579 171351 2854 202572 3501 398516 66381400 60000 1000 95283 1530 98313 1638 184388 2962 217985 3633 428838 68881500 64243 1035 102021 1584 105265 1696 197426 3066 233398 3760 459161 71301600 68805 1069 109267 1636 112741 1752 211448 3166 249975 3884 491772 73641700 73521 1102 116754 1687 120467 1805 225938 3264 267106 4003 525473 75901800 78324 1134 124383 1735 128339 1858 240701 3358 284558 4119 559806 78111900 83227 1165 132169 1783 136372 1909 255767 3450 302370 4232 594847 80252000 88240 1195 140130 1829 144587 1958 271174 3540 320584 4342 630679 82332100 93379 1225 148290 1874 153006 2007 286965 3627 339252 4449 667404 84362200 98658 1253 156674 1919 161657 2054 303190 3713 358433 4554 705139 86352250 101357 1268 160960 1940 166079 2077 311483 3755 368237 4605 724427 87322300 104098 1282 165314 1962 170571 2100 319908 3796 378198 4656 744022 88292400 109723 1309 174245 2004 179786 2145 337192 3878 398631 4756 784219 90192500 115558 1336 183513 2045 189349 2189 355126 3958 419833 4855 825929 92052600 121640 1363 193170 2086 199313 2233 373815 4036 441927 4951 869394 93872700 128008 1389 203283 2125 209748 2275 393385 4113 465063 5045 914910 95662800 134714 1414 213933 2164 220737 2317 413995 4189 489427 5138 962842 97412900 141823 1439 225222 2203 232385 2358 435841 4263 515254 5228 1013650 99143100 157597 1488 250272 2277 258231 2438 484316 4407 572562 5406 1126391 102503200 166506 1512 264419 2314 272828 2477 511694 4478 604928 5492 1190064 10414

For capacities above 3200 psig set pressure - contact your local sales representative.

511591752913107412351398156417301896222725592891322335553886421845504716488252135545587762096541687272047536786881998531101901184913508151671682618485201432180223461251202690428748306263254334504365133855739632407044290445185475635005352676554556162365107

424858677481879399104114124132140148155162168172175181187193198204209214219224229234256276296313330347362377391405418431443455467479490496501512522533543553563582591

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 7

Valve 5166 5166 5166Set Steam Water Steam Water Steam Water

Pressure 4x6 4x6 6x8 6x8 8x10 8x10(psig) FB FB FB FB FB FB

15 14911 1195 32333 2591 61234 490720 17263 1359 37433 2948 70892 558330 21967 1640 47633 3555 90209 673340 26670 1878 57833 4073 109525 771450 31374 2090 68033 4532 128842 858360 36078 2282 78233 4949 148158 937270 40829 2461 88534 5337 167668 1010680 45674 2631 99040 5705 187564 1080490 50519 2791 109546 6051 207460 11460100 55363 2941 120052 6378 227356 12080120 65053 3222 141063 6987 267149 13232140 74743 3480 162075 7547 306941 14293160 84433 3721 183087 8068 346733 15280180 94123 3946 204098 8558 386525 16206200 103812 4160 225110 9020 426317 17083220 113502 4363 246122 9461 466110 17917240 123192 4557 267133 9881 505902 18714260 132882 4743 288145 10285 545694 19478270 137727 4833 298651 10481 565590 19849280 142571 4922 309156 10673 585486 20213300 152261 5095 330168 11048 625279 20922320 161951 5262 351180 11410 665071 21609340 171641 5424 372191 11761 704863 22274360 181330 5581 393203 12102 744655 22919380 191020 5734 414215 12434 784447 23547400 200710 5883 435226 12757 824240 24159420 210400 6028 456238 13072 864032 24756440 220090 6170 477249 13379 903824 25338460 229779 6309 498261 13680 943616 25908480 239469 6444 519273 13974 983408 26465500 249159 6577 540284 14263 1023201 27011600 297608 7205 645342 15624 1222162 29589700 346057 7782 750401 16876 1421123 31960800 394506 8320 855459 18041 1620084 34166900 442954 8824 960517 19135 1819045 362391000 491403 9302 1065575 20170 2018006 381991100 539852 9756 1170633 21155 2216967 400631200 588301 10190 1275691 22095 2415928 418451300 636750 10606 1380749 22998 2614889 435531400 685199 11006 1485807 23866 2813850 451981500 733648 11392 1590866 24703 3012811 467841600 785755 11766 – – – –1700 839601 12128 – – – –1800 894460 12480 – – – –1900 950447 12822 – – – –2000 1007701 13155 – – – –2100 1066380 13480 – – – –2200 1126672 13797 – – – –

2250 1157491 13953 – – – –

Steam capacity (lbs/hr)/water capacity (GPM) at 3% overpressure

Anderson Greenwood Pilot Operated Pressure Relief ValvesSeries 5100

ANGMC-0276-US-1111 page 8

Model numbering

51 4 6 10 J 23 /S1

Pilot series

51 – Series 5100

Main valve lift

4 – Full Lift, API Orifice6 – Full Lift, Full Bore Orifice

Main valve piston type

6 – Teflon® Soft Seat/Seals

Inlet flange rating, ANSI

05 – 150#10 – 300#12 – 600#14 – 900#16 – 1500#18 – 2500#

Orifice designation

Letter – API Equivalent— – Full Bore (Largest practical orifice area for a given valve inlet size)

Inlet x Outlet, inches

Main valve materials

/S – SS Body and Trim/S1 – CS Body, SS Trim/SPL – Special