Ammonia Synthesis at Reduced Pressure via Reactive …ring/Design II/Articles...Ammonia Synthesis at...

Transcript of Ammonia Synthesis at Reduced Pressure via Reactive …ring/Design II/Articles...Ammonia Synthesis at...

Ammonia Synthesis at Reduced Pressure via Reactive SeparationMahdi Malmali,† Yongming Wei,‡ Alon McCormick,† and Edward L. Cussler*,†

†Department of Chemical Engineering and Materials Science, University of Minnesota, 421 Washington Ave. SE #151, Minneapolis,Minnesota 55455, United States‡State Key Laboratory of Chemical Engineering, Membrane Science and Engineering R&D Lab, Chemical Engineering ResearchCenter, East China University of Science and Technology, 130 Meilong Rd., Shanghai 200237, China

ABSTRACT: Ammonia is normally made at high temperature and pressureusing a promoted iron catalyst. High temperatures are needed to get fastkinetics; the high pressure is used to ensure high conversion. Alternatively,ammonia can be made at high temperature but lower pressure if the productammonia is rapidly separated. Here, we have systematically studied the effect oftemperature and pressure on the rates of reaction. We then have qualitativelyinvestigated the absorptive separation of ammonia using calcium chloride in areaction−separation process. Rapid separation reduces the constraint ofreversible reaction and enables us to obtain appropriate reaction rates atrelatively lower pressure. The effect of different operating conditionsreactiontemperature, pressure, absorption temperature, and gas transportonproduction rates is carefully measured, and this elucidates the potential andthe limits of this type of low-pressure ammonia synthesis.

■ INTRODUCTION

Those in the global chemical enterprise now agree that thefuture of the chemical industry is dependent on becoming moresustainable.1 Such a goal includes developing energy sourcesthat are not based on nonrenewable fossil fuels, and that do notrelease large quantities of carbon dioxide. This goal impliesimproving the efficiency of energy collected from the sun andthe wind. Solar energy is continuing to get less expensive, but isstill more expensive than fossil fuels. Wind energy is moreimmediately attractive and is being rapidly developed in areas ofhigh population density, especially in northern Europe.2

However, both wind and solar energy are periodic and,hence, may not be available at times of highest demand. No onewants light only in the middle of a sunny day; similarly, no onewants power only when the wind is blowing. Moreover, windand solar productions are distributed geographically, withpractical limitations in supplying the electrical grid in remotelocations. Thus, both of these resources must be coupled tomethods of energy storage, especially as liquid fuels. Methanoland ammonia are two such fuels. Methanol is attractive becauseit meshes well with the existing infrastructure for distributingfuel. Ammonia is interesting because it can be made fromtotally renewable resources: nitrogen produced from pressureswing adsorption of air, hydrogen produced from electrolysis ofwater, and electricity obtained from stranded solar arrays orwind turbines. A major advantage of ammonia over methanol asa fuel is that ammonia does not require a carbon source for thesynthesis.We are especially attracted by ammonia because much of the

potential wind power is far from areas of high population. As aresult, wind is sometimes called “stranded energy”.3 At thesame time, much of the stranded wind energy is where

ammonia-based fertilizer is needed. Thus, by working onammonia, we are investigating a possible chemical synthesisvaluable both as a carbon-neutral liquid fuel4,5 and as afertilizer.6

We have begun to investigate making ammonia from windusing a small ammonia plant operating at the West CentralResearch and Outreach Center (WCROC) in Morris, MN.6

This plant lets us explore what parts of a conventional processwork well, and what parts are potential problems. The plantuses a reactor, a condenser, and a compressor, all of which arescaled down parallel to a conventional large-scale plant. Thereaction rates observed in the plant are consistent with parallellaboratory experiments with the same catalyst, and with valuesfrom the literature.7−10 Analysis of this process gives threecharacteristic times: one for the reaction, one for thecondensation, and one for the pump recycling unreactedgases. As the process is currently operated, the reaction time islargest, so that the small process is currently controlled by thechemical kinetics. However, the analysis also shows howprocess changes could increase productivity until one of theother characteristic times became largest, and hence the limit ofproduction. Thus, this plant supplies a test for process changesthat may make sense for a small-scale plant, even when they areknown to have limited effectiveness in a large fossil-fuel-basedsynthesis.In this paper, we explore the potential of process changes to

reduce the pressure needed for production. In seeking these

Received: May 16, 2016Revised: July 24, 2016Accepted: July 25, 2016Published: July 25, 2016

Article

pubs.acs.org/IECR

© 2016 American Chemical Society 8922 DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

Dow

nloa

ded

via

UN

IV O

F U

TA

H o

n Fe

brua

ry 2

4, 2

020

at 1

7:13

:25

(UT

C).

See

http

s://p

ubs.

acs.

org/

shar

ingg

uide

lines

for

opt

ions

on

how

to le

gitim

atel

y sh

are

publ

ishe

d ar

ticle

s.

process changes, we have decided not to focus on the reactionchemistry, feeling that this has been so carefully studied overthe last century that the chances of big improvements at anyscale are small.11−14 Instead, we are investigating three otheraspects of this process. First, we are investigating synthesis atlower pressure, because such pressure could reduce processcomplexity and make a small-scale process less expensive andless hazardous. Second, we are investigating ammonia-selectiveabsorbents to reduce the need for recycle. Third, we arebeginning to explore processes that avoid recycle altogether.In this paper, we limit the discussion just to the first aspect:

studies of lower pressure synthesis. After a summary of theprocess itself, we report measurements of chemical kinetics toshow that at low pressures and a range of temperatures, we getthe same results as others working under these conditions. Wethen report the measurements of ammonia production in areaction-separation process. Calcium chloride absorbents areemployed, where absorption occurs not just on the surface ofthe solid, but also by diffusion into the solid. Absorption anddesorption15 of ammonia on chlorides of alkaline-earth metalshave been studied in numerous applications, such as chemicalheat pumps,16 ammonia storage,4,17,18 indirect hydrogenstorage,19,20 and enhanced ammonia synthesis.21 We use themeasured combination of reaction and absorption to estimatethe feasibility of ammonia synthesis at lower pressures.Overall Production Rate. Here, we employ a model that

we developed in our earlier work6 for the reaction−separationprocess with recycle, which guides the analysis of ourexperiments. This theory helps us to understand the complexbehavior of the reaction−separation process, and we feel thatthis theoryspecifically, the time constants of the reaction,separation, and transportmakes it easier to compare thefindings of our reaction−separation process. In the following,we give more details about the model that eases thecomprehension of the theory and the model. More details onthis model can be found elsewhere.6

In this simplified model, we assume that the process is insteady state, and that the reactor and absorber are each well-mixed. (The steady-state assumption is accurate only at thebeginning of our experimental test.) The well-mixedassumption implies that the average nitrogen concentration inthe reactor is equal to the nitrogen concentration at the exit.22

While this is untrue if most of the nitrogen entering the reactorreacts in a single pass, it is much closer to being almost truewhen only a small fraction of the nitrogen reacts per pass,which will be the case here. However, this will not interferewith our findings, as will be discussed later. The model predictsthe rate of ammonia production (a) to be defined as

=* −

+ + − *ax x

k V k PSx

m

A A0

1 1 1

R R ab t

A

(1)

where xA* and xA0 are the mole fractions of ammonia at reaction

equilibrium and in the absorber, respectively; kR and kab are thelinearized chemical reaction rate constant and the absorptionmass-transfer coefficient, respectively; Pt is the operatingpressure; S is the surface area of the absorber; and m is thetotal molar flow rate. In this result, the term (1/kRVR) is theresistance to ammonia production due to the chemical reaction.Similarly, (1/kabPtS) and (1 − xA*)/m are the resistances of theabsorber and of the recycle loop, respectively.In this model, the absorber’s performance is assumed to

behave as a first-order rate process. In reality, before the

breakthrough of the absorber’s packed bed, we have a perfectseparation of ammonia from the gas mixture. Hence, beforebreakthrough, the absorption resistance is effectively zero.However, after breakthrough, the production rate can becomedominated by the increasing absorption resistance.The presence of three resistances in series is observed in

many rate processes, where the amount produced is propor-tional to the overall driving force divided by the totalresistance.23 The total resistance is the sum of the resistancesof reaction, absorption, and recycle. Phrased in other terms, thetotal resistance is a harmonic average of the speeds of thesethree steps, so that the slowest speed has the biggest effect onthe rate of ammonia production. If the reactor is operating at atemperature that is too low, the reactor resistance will bedominating: if the absorber is undersized, the absorptionresistance can be largest, and if the recycle rate is too low totake full advantage of the other unit operations, the recycleresistance will be most important. We will use this model laterin this paper to discuss the experiments and, hence, to explorehow the reaction−separation process can be made moreproductive.

Linearized Chemical Reaction Rate Constant. Beforewe make this analysis, we want to review how the linearizedreaction rate constant can be estimated from earlier studies.The reaction rate is most often correlated using the Temkin−Pyzhev8,9,24 equation:

= −⎛⎝⎜⎜

⎞⎠⎟⎟

⎛⎝⎜⎜

⎞⎠⎟⎟r k

P P

Pk

PP1

N H1.5

A2

A

H1.5

2 2

2 (2)

where k1 and k2 are forward and reverse reaction rate constants,respectively; and PN2

, PH2, and PA are the partial pressures of

nitrogen, hydrogen, and ammonia, respectively. This equationis rewritten by defining the following variable:

=* −

*XP P

PA A

N2 (3)

Linearization using the Taylor series for small values of Xsimplifies this expression:

=* *

* +** − *

+*

*

** − − *

= ′ − *

⎛

⎝⎜⎜

⎞

⎠⎟⎟⎡⎣⎢⎢

⎤⎦⎥⎥

⎛

⎝⎜⎜

⎞

⎠⎟⎟⎡⎣⎢⎢

⎤⎦⎥⎥

r kP P

P

P

PX X

kP

P

P

PX X

k X X

94

( )

14

( )

( )

1N H

1.5

A

N

A

2A

H1.5

N

A

R

2 2 2

2

2

(4)

where kR′ has the dimension of moles of ammonia per catalystvolume per time. The kR′ parameter is related to kR because

=* −

* = * −− *

⎡⎣⎢

⎤⎦⎥X

P PP

xx

x4

(1 )A A

NA

A

A2

2 (5)

Hence, when the conversion is close to zero, which is the casein our analysis, then

′ ≈k k4R R (6)

where kR′ is the corrected linearized reaction rate constant afterthe change of variables. Equation 4 shows that the linearized

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8923

reaction rate constants kR′ and kR obtained here are functions ofconcentration. When xA approaches xA*, kR′ decreases to zero;however, when xA approaches zero, kR′ increases to itsmaximum value, representing only the forward reaction rate.

■ EXPERIMENTAL SECTION

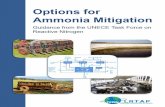

Materials. Anhydrous CaCl2 in granular form (>7 mm)with 93% purity (CAS No. 10043-52-4, Lot No. SLBL2770 V)was purchased from Sigma−Aldrich (St. Louis, MO). Thereactant gases N2 and H2 with ultrahigh purity were purchasedfrom Matheson (New Brighton, MN). We employed aprereduced nonstoichiometric ferrous oxide catalyst (wustite)with promoters (AmoMax-10 RS, Clariant, Charlotte, NC).The catalyst is provided in the form of irregularly shapegranules, with a nominal size range of 1.5−3 mm, and isstabilized with an oxygen-rich protective layer.Apparatus. The experimental apparatus, a schematic

diagram of which is shown in Figure 1, was built usingSwagelok (Chaska, MN) 316 stainless steel tubing and fittingsof 6 mm inner diameter. The reactor was 0.15 m long. Catalystparticles were ground from their produced size until smaller(<1 mm) before loading the reactor. The absorber was a 0.3-m-long stainless steel tube, with an inner diameter of 0.022 m,bundled with heating tape. The absorber and heating tapebundle were insulated with silica woven insulation (AVSIndustries, New Castle, DE). A variable piston pump (ModelPW2070N, PumpWorks, Inc., Minneapolis, MN) circulated thegas mixture between the reactor and the absorber.A ceramic heater (Model CRFC-36/115-A, Omega,

Stamford, CT), equipped with a multiramp proportional−integral−differential (PID) controller (Omega, ModelCN96211TR) controlled the temperature of the reactor. Theinlet and outlet gas temperatures and the temperature on theouter surface of the reactor were measured using Type Kthermocouples connected to a signal conditioner (Omega,Model DRG-SC-TC). The system pressure was recorded usinga pressure transducer (Model 50426877, WIKA, Lawrenceville,GA) with a 0−10 V dc output. The experiments were carriedout in a recirculation batch mode. All instruments and

controllers were connected to a National Instrument Labviewcard (Austin, TX), with the data being recorded every second.Labview controlled the mass flow controllers (ModelSLA5850S, Brooks Instruments, Hatfield, PA) installed in theapparatus inlet, which injected known volumetric flows ofreactant gases. The inlet and outlet of the system wereequipped with needle valves.

Procedure. Three grams of catalyst, loaded in the reactor atroom temperature, was reduced by pumping hydrogen gasthrough the catalyst bed while slowly increasing the reactortemperature. Hydrogen gas was pumped through the catalystbed at the flow rate of 0.5 standard liters per minute (SLPM).The hydrogen reacted with the coating layer, forming watervapor. A multiramp temperature profile heated the catalyst veryslowly to ensure that the water vapor concentration during theactivation is <1000 ppm. The temperature ramp required ∼27h for the temperature to increase from room temperature to723 K. After the reactor reached 723 K, hydrogen flowcontinued through the reactor for at least 24 h. After this initialreduction, the apparatus was always kept under nitrogen.We performed two sets of experiments. During the first set,

which we refer to as “reaction experiments”, we were onlyinterested in the kinetics of ammonia synthesis, so the absorberwas bypassed and the gas mixture circulated only through thereactor. We investigated the effect of operating pressure on thereaction rate constants. In the second set of experiments, whichwe refer to as “reaction−separation experiments”, the gasmixture was circulated between the reactor and absorber usingthe pump. This set of experiments was similar to theconventional Haber−Bosch process, except that we replacedthe condenser with an absorber. In both sets of experiments, weutilized the pressure reading data log to calculate the ammoniareaction rates and conversion.The reaction experiments utilized a three-way valve to direct

the circulation loop toward the bypass line, without theabsorber. The catalyst remained unchanged throughout theexperiments. The hydrogen and nitrogen were fed to thereactor with the ratio of 3:1. We stopped the flow and closedthe inlet valve once the system reached to the desired pressure.

Figure 1. Schematic diagram of the apparatus. The gas mixture is recirculated between the reactor and absorber using a piston pump.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8924

After pump started to recirculate the gas mixture with the flowrate of 0.7 mL/s, we began to record pressure data. Theseconditions are summarized in Table 1.

Unless otherwise mentioned, the reaction−separation experi-ments were at 700 K. The three-way ball valve included theabsorber in the recirculation loop. The absorber was initiallyfilled with ∼70 g of fresh anhydrous CaCl2 and was always keptat temperatures greater than 460 K. The absorber was purgedwith dry nitrogen for 24 h at 673 K before starting the first test.The absorber and catalyst were unchanged throughout theexperiments. An initial pressure of 55 bar was used, and theapparatus was fed with hydrogen and nitrogen gas mixture withthe ratio of 3:1. The pump rates of 0.7 mL/s recirculated thegas mixture for 3 h. After each test, the absorber wasregenerated by heating to 600 K, decreasing the systempressure to 2−3 bar, and pumping nitrogen through theabsorber at 0.1 SLPM for 20 h. Details of these experiments aregiven in Table 1.

■ RESULTSReaction Experiments without Absorption. To under-

stand the reaction kinetics with our catalyst, we carried outseveral experiments to investigate the effect of operatingtemperature and pressure. For example, Figure 2a reports thepressure versus time for the catalytic reaction of ammoniainitially at 74 bar and reaction temperatures of 660 and 740 K.The slopes of the pressure profiles represent the apparent rates

of ammonia reaction at each operating temperature. The rate ofreaction at 740 K is much faster than the rate at 660 K, and weshall determine if these rates are consistent with the literature.25

The reaction rate is initially fast, but quickly slows at longertimes, because the reverse reaction rate accelerates as the partialpressure of ammonia increases.The half-lives of reaction, as an alternative representation of

the reaction rates, are shown as an Arrhenius plot versustemperature in Figure 2b. To determine the half-life from thepressure−time profiles, the equilibrium conversion and finalpressure at each specific temperature were calculated, followingthe analysis of Gillespie et al.25 The time at which the half-lifeoperating pressure occurred then was extracted. The half-livesrange from 0.15 h to 12 h. This variation in the half-life ofreaction is evident in the pressure profiles as well. For instance,in the test at 740 K, the pressure reaches equilibrium after∼2000 s, while the pressure at 660 K continues to decreaseuntil 5000 s. This affirms the common conclusion for thissystem, that higher temperature is advantageous for reactionrate, while lower temperature favors the thermodynamicequilibrium.The operating pressure also affects the reaction kinetics, but

to a lesser degree than the temperature does. The data in Figure3, for a variety of temperatures and pressures, illustrate this.

This figure reports the reverse reaction rate constant in theform of an Arrhenius plot. We chose reverse reaction rateconstants rather than our more directly measured forward rateconstants, because most previous literature8,26 on catalyticreaction of ammonia is rather focused on disassociation ofammonia, so more data are available on reverse rate constants.The reverse reaction rate constant is simply proportional to theforward reaction rate constant

=Kkkp

2 1

2 (7)

and has the following stoichiometry:

+ ⇔12

N32

H NH2 2 3 (8)

where Kp is the equilibrium reaction constant calculated fromGillespie et al.,25 which includes fugacities that can alter theequilibrium reaction constant by a few percent.The reverse reaction rate constants in Figure 3 exponentially

increase with temperature, but change less with pressure.

Table 1. Conditions for Reaction and Reaction−SeparationExperiments

Experimental Conditions

reaction reaction−separation

reaction temperature (K) 620−740 700absorption temperature (K) 460initial pressure (bar) 74 55H:N ratio 3:1 3:1pump flow rate (mL/s) 0.7 0.7reaction/reaction-absorption time (h) 3 3desorption temperature (K) 600purge flow (SLPM N2) 100desorption time (h) ∼20

Figure 2. Effect of reaction temperature on (a) kinetics of reaction and(b) half life of reaction. Higher temperature increases the rates ofreaction; however, at higher temperature, the mole fraction ofammonia at equilibrium decreases.

Figure 3. Arrhenius plot of reverse rate of reaction versus 10 000/T.Results indicate a strong dependency of the reverse rate constant ontemperature, but a smaller variation with pressure.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8925

Specifically, the rate constant increases by a factor of 10 000when the operating temperature is increased from 600 K to 730K; however, the rate constant at 650 K varies by only a factor of2 when the operation pressure is increased from 20 bar to 69bar. At 740 K, there is an order-of-magnitude difference in thereaction rate constants at 20 and 69 bar, which is certainlysignificant but less than the variation with temperature. Loweroperating pressures give larger reaction rate constants whilehigher operating pressures give lower ones. The tests at 20 and28 bar show less variation, probably because the times to reachthe operating pressures are smaller and more reproducible.Nevertheless, the experimental errors for reaction engineeringin this range are typical (cf. Figure 4).

These reaction rate measurements are compared with thosereported in the literature27,28 in Figure 4. This shows anArrhenius plot of the Temkin reverse reaction rate constant k2,both as reported in the literature and as found from this study.Our work displays a systematic negative deviation, most likelydue to experimental error associated with the time to start ourexperiment. Again, these data and those of others all show thatthe reaction rate constants vary much less with pressure thanwith temperature.Reaction−Separation Experiments. Effect of Absorbent

History. Earlier work says that the absorption−desorption ofammonia on CaCl2 absorbent can generate a nanoporousstructure with a Brunauer−Emmett−Teller (BET) surface areathat is up to 10 times larger than was there originally.20,29

Hence, the absorption rates into the CaCl2 structure canchange. Thus, we repeated the reaction−absorption and thendesorption cycles until we obtained reproducible results. Thedata are illustrated in Figure 5a for selected cycles. The totalpressure, our measure of reaction−separation, is linear withtime during the first cycle. The pressure changes increasenotably in subsequent cycles, consistent with a structuralchange in the CaCl2. The initial production rates (slopes) arerelatively fast, and the rates then go through a transition region;finally, they slow to a rate very similar to that of the first cyclefor all cycles. The initial rates get faster after desorption of eachcycle, and take longer to slow down. If we plot the reciprocal ofthe apparent ammonia capacity after 10 000 s versus thereciprocal of the cycle number, we get a straight line, as shownin Figure 5b. The time period of 10 000 s chosen here isarbitrary, but it illustrates some of the implications of Figure 5a.The intercept in Figure 5b corresponds to the inverse capacityfor an infinite number of cycles (that is, for the maximumchange in the solid geometry). In practice, we always usedsamples subjected to seven or more cycles, which are thuswithin ∼10% of the maximum absorption that is obtainable atthe operating temperature.

Effect of Reaction Temperature. To determine whether thechemical reaction is the rate-limiting step, we carried out testswith reaction temperatures of 680, 700, 720, and 740 K, whilekeeping all other conditions unchanged. The pressure−timegraphs for these tests are shown in Figure 6. The results show

Figure 4. Comparison of the reverse reaction rate constants withliterature. Reverse reaction rate constants are independent of operatingpressure.

Figure 5. Effect of absorption history of the CaCl2 on the production rate of reaction/absorption: (a) the production rate increases until the seventhcycle, and (b) the accessible volume of the CaCl2 increases gradually.

Figure 6. Effect of reaction temperature on the production rates pfreaction/absorption. The small effect on the overall kinetics of thereaction temperature shows that reaction kinetics is not the rate-limiting step of the combined reaction−absorption.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8926

that the initial overall rate is almost the same, independent ofthe temperature. Later, the rates at higher catalyst temperaturesare systematically slower. This implies that the overall kineticsare not controlled by catalytic reaction. It is also likely that, withsmall reactor residence time and effective absorber operation,the reverse reaction for ammonia synthesis is not significantbecause the ammonia mole fraction is kept low.Effect of Initial Pressure. The initial rate of reaction is

proportional to the system operating pressure, as shown inFigure 7. The operating pressure has two synergistic effects on

rates of the reaction−separation experiments. First, the catalyticreaction rate is higher at higher operating pressure. Second, thelarger ammonia concentration in the gas stream leaving thereactor increases the driving force for the absorption ofammonia into CaCl2 crystals. At longer times, the behavior ismore complex, for example, when the conversion curves forinitial pressures of 55 and 69 bar cross. These complexitiesprobably come from factors like the onset of reverse reactionrate, increased mass-transfer resistance, and changes inabsorbent structure. This more-complex behavior is beyondour current objective. Instead, we will focus on maintaining thehigh initial rate seen here with appropriate choice of absorbentand recycle operation.Effect of Absorber Temperature. The effect of absorber

temperature on the rate of ammonia production, displayed in

Figure 8a, may indicate that two competing mechanisms arecontrolling the absorption of ammonia. First, the diffusioncoefficients in the solid CaCl2 increase with temperature.Second, the capacity of the absorbent decreases with temper-ature: for instance, the equilibrium absorption capacity of theCaCl2 at 325 and 470 K at an ammonia partial pressure of 1 baris 4 and 1.5 mol of ammonia per mole of CaCl2, respectively.

20

As Figure 8a shows, there is no significant effect of temperatureon absorption: the rate is greatest at 460 K, smaller at 510 K,and somewhat larger at 600 K. The apparent production rateper capacity versus the absorber temperature shown in Figure8b is approximately constant, implying that diffusion andabsorption capacity counterbalance. Earlier experiments on theabsorption of ammonia without reaction in magnesium chloridealso show only a weak absorption dependence on temper-ature.30

Effect of Recycle Flow Rate. A key route to reducing thetotal resistance to ammonia synthesis is to increase the fluidvelocity in the system, as shown in Figure 9. While the flow ofgas has an insignificant effect on the forward or reversechemical rate constants, it may affect both the absorptionresistance and the recirculation resistance. At the beginning ofthe test, the packed-bed absorber works as a perfect separator.Thus, the absorption time constant is equal to zero until thebreakthrough point. We can then infer that the film mass-transfer resistance around the particle is not important. Weexpect that the resistance to absorption will gain moreimportance once the breakthrough occurs. As a result, wesuspect that the resistance of the recycle flow, which isrepresented by the term (1 − xA*/m) in eq 1, influences theoverall rate significantly. This is true: faster pumping acceleratesthe process, as Figures 9a and 9b show. Even increasing theflow rates by a factor of 12 does not yet suggest an asymptote inFigure 9b.If we could maintain almost-complete removal of the

ammonia in the absorber, increasing the recycle flow decreasesthe single-pass conversion of ammonia. In other words, fasterrecycle flow accelerates forward reaction and decelerates reversereaction, because of the lower ammonia concentration in thereactor. However, the fast recirculation rates required maycompromise the reactor and absorber temperatures. In ourcase, increasing the pump flow rates to more than 3 mL/minreduced the reactor temperature because of the heat loss to the

Figure 7. Higher initial operating pressure enhances the productionrates of absorption and apparent capacity of the absorbent.

Figure 8. Absorption temperature effect on production rates: (a) pressure versus time graphs at different absorption temperatures and (b) apparentrates versus absorption temperatures. Higher absorption temperature increases the production rate constant but decreases the driving force. Theapparent rates and capacities shown are calculated for the initial 1000 and 10 000 s, respectively. (In panel (b), r′ [mmol NH3/s] represents theproduction rate, and C is the apparent absorbent capacity [mmol NH3/mmol CaCl2].)

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8927

gas flowing out of the reactor, so none of those data are shownhere. This must be a concern in future process design.Figure 10 shows the production rates at different time

intervals for different pumping rates. Results suggest that during

the initial 1000 s, the transport resistance in eq 1, representedas (1 − xA*/m), is much larger than the reaction resistance in eq1, which is defined as [1/(kRVR)]. Because the regeneratedpacked bed absorber is removing the ammonia completely, theabsorption resistance is zero; therefore, the recycle flow iscontrolling the reaction−separation process, which leads to thelinear increase in the production rate. At times between 1000and 4000 s, the absorber’s packed bed breakthrough starts toappear, so the absorber is no longer capable of completeremoval of the ammonia from the gas stream. By contrast, atlonger times in the range of 4000−5000 s, we observe smallerproduction rates at higher recycle flows; this lower productionrate is attributed to the appearance of the breakthrough pointand (partial) exhaustion of the bed. Note that at higher recycleflow, we had larger production rates, which led to faster loadingof the absorbents. This is consistent with our earlierobservation of the slower slopes at ∼5000 s.

■ DISCUSSIONThe results shown above confirm the viability of the reaction−absorption process for the enhanced production of ammonia atsignificantly lower operating pressures. For example, in one setof measurements, we obtained more than 80% conversion with

relatively fast ammonia synthesis rates (unchanged for up to5000 s). This suggests that high production rates at pressures aslow as 25 bar are viable when ammonia is removed from thesystem efficiently. The absorption separates the synthesizedammonia from the reaction environment and reduces thereverse reaction.However, while we have developed a reaction−separation

process with enhanced rates and conversion, we do notunderstand the detailed performance of each unit operation.We have investigated the impact of different operatingconditions. For instance, we find that the reaction temperaturehas a minor effect on the process, while increased recyclepumping shows significantly increased production. In thefollowing paragraphs, we discuss this performance in moredetail.To do so, we employ the model summarized in the theory

above to understand the rate constants for each unit at differentoperating conditions. The complete reaction conditions andcalculated times for each unit are summarized in Table 2. Thefirst column in this table identifies the experimental category.Columns 2−5 identify the reaction conditions, including theoperating pressure, reaction temperature, absorption temper-ature, and pumping flow rate. Columns 6 and 7 give themeasured time constants for the reaction and the recycleobtained from eq 1, respectively. When the absorber isremoving all ammonia from the gas flow before thebreakthrough of the bed, the absorption time constant iszero. The values of these three rate constants merit carefulconsideration, because they are the key by which the processcan be improved. The longest time constant corresponds toslowest step in the reaction−separation and, hence, controls theoverall rate of the process under the conditions studied.Table 2 shows that the recycle flow is the rate-controlling

step before breakthrough of the packed bed absorber. The timeconstant for the recycle is 100 times larger than the reactiontime constant. Thus, our reactive separation process can beimproved significantly by faster recycle flows. However, this isnot a trivial change, because controlling the operatingparameters of the reaction−separation systems becomesdifficult.These results still guide speculation about the design of a

small, efficient process which includes the synthesis andsimultaneous removal of the ammonia at reduced pressure. Inthe widely verified rate equations, there are three factors thatdirectly affect the reaction rate: the temperature, which affectsall the reaction rate constants; the partial pressures of reactants,

Figure 9. (a) Effect of pumping flow rates on production rates, and (b) initial rates of absorption in different pumping flow rates. Results indicatethat film resistance surrounding the particle is not important. The production rates shown are calculated from the initial 1000 s.

Figure 10. Effect of recycle flow rate on the production rate indifferent time intervals of the test. Absorber column breakthroughleads to the formation of the asymptote at different flow rates; largerrecycle flow results in faster absorber breakthrough.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8928

which influence the forward reaction rate; and the partialpressure of the ammonia, which influences the reverse rates. Ifwe can remove ammonia from the reaction chamber efficiently,then the disassociation of ammonia through the reversereaction no longer proceeds rapidly. Thus, we can obtainrespectable rates of reaction at reduced pressure if we keep theconcentration of ammonia low with an efficient separation.We now compare the performance of a conventional reaction

with a reaction−separation process. One attractive design forthe reaction−separation would be mixed catalyst and absorberin the same bed. However, the catalyst can be poisoned bywater and other impurities on the absorbent. Another attractivedesign would be a conventional reactor divided into shortsegments with absorption beds between them. Our resultsshow that faster pumping increase production, but higherrecycle flows may be difficult in practical applications. Still, thenew process has promise.To explore this promise, we compare the reactor used by

Nielsen et al. with that proposed here using the specifics shownschematically in Figure 11.27 From Neilsen’s extensiveexperiments, we choose the one summarized in Table 3,which is capable of producing 1.8 moles of ammonia per hour.In our simplified reaction−separation process, we can set themole fraction of ammonia at the outlet of each catalytic sectionto <1% and then determine the required initial operatingpressure, which satisfies the production rate of 1.8 moles of

ammonia per hour. We assume that the absorber works perfectand the gas stream leaving the absorption sections has noammonia.To illustrate this, we use the rate equation proposed by

Nielsen et al.27 (eq 9) for the synthesis of ammonia. We choosethis form of rate equation because the reaction rate does notdiverge to infinity when the ammonia partial pressure is zero(although we acknowledge that the authors tested this rate onlydown to PA = 0.2 bar):

=−

+α

ω

⎜ ⎟

⎜ ⎟

⎛⎝

⎞⎠

⎡⎣⎢

⎛⎝

⎞⎠⎤⎦⎥

rk P K

K1

PP

PP

20

N a2

3

2

2

A2

H23

A

H2 (9)

Table 2. Examples of Process Conditions and Time Constantsa

pressure (bar) reaction temperature (K) absorption temperature (K) pumping flow rate (L/h) 1/(kRVR) (× 10−3 h/mol) 1/m (h/mol)

Absorption History Test55 700 460 2.5 5.8 0.18

Reaction Temperature Test55 680 460 2.5 16 0.1855 700 460 2.5 5.8 0.1855 720 460 2.5 2.2 0.1855 740 460 2.5 1.1 0.18

Pressure Test55 700 460 2.5 5.8 0.1869 700 460 2.5 5.8 0.1483 700 460 2.5 5.8 0.12

Absorption Temperature Test55 700 460 2.5 5.8 0.1855 700 510 2.5 5.8 0.1855 700 600 2.5 5.8 0.18

Pumping Flow Rate Test55 700 460 1 5.8 0.4655 700 460 2.5 5.8 0.1855 700 460 10 5.8 0.04

aThe largest time constant, for the absorption, is the step which most affects the overall rate.

Figure 11. Schematic diagram of a conventional reactor (top) and a reaction−separation reactor with absorption (bottom). In the reaction−separation design, green, blue, red arrows shown represents the bed in process, transition, and regeneration, respectively.

Table 3. Experimental Conditions of the Nielsen Experiment

parameter value

P 304 barT 765 KVcat 2.5 cm3

Lcat 130 mmspace velocity 94200 1/houtlet % NH3 19.7

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8929

where Pi is the partial pressure of component i; Ka and K3 areequilibrium and reaction rate constants; and α and ω are theparameters of ammonia reaction rate. In our case, we used α =0.64 and ω = 1.564. Other constants of this equation, inaccordance with these parameters, can be found elsewhere.27 Asthe equation shows, the concentration of ammonia productdoes have a significant influence on the rate of ammoniaproduction.Our data show that such a process is capable of producing

1.8 mol of ammonia per hour at 25 bar, i.e., at pressures ∼12times lower than the pressure used in the Nielsen experiment.Figure 12 shows the rate of ammonia production and molefraction of ammonia along the length of the reactor for twoexample designs.As shown, the rate of ammonia production in conventional

reactor rapidly decreases at the entrance of the reactor. By thetime the mole fraction of ammonia reaches 5%, the rate ofreaction decreased significantly. Alternatively, if we alternatecatalytic and absorption sections, the reaction rate in oursimplified reaction−separation process is high while operatingat 25 bar. In principle, we can make ammonia rapidly and atlower pressure. We look forward to exploring the practicalutility of the science that we have now demonstrated.The proof-of-the-concept for the viability of enhanced

ammonia synthesis at reduced pressure via reaction−separationprocess is displayed in Figure 13. The dimensionless pressure(P/P0) versus normalized time (t,̅ which is defined as time

divided by the total initial charge in the system) is shown. Theblack data points (square markers) represent data from thereaction test at 723 K and an initial operating pressure of 55bar; red data points (circle markers) represent data from theresult for the reaction test at 723 K and an initial operatingpressure of 55 bar; blue data points (rectangular markers)represent data from the result for the reaction−separation test,where the reaction occurs at 723 K, absorption occurs at 460 K,and the initial operating pressure is 55 bar, and the pump wasalso set to a value of 0.7 mL/s. The data points are averaged foreach 50 s. The slopes of these curves represent the apparentrates of ammonia synthesis.When the absorber is introduced to the batch−recycle−loop

system, the rate of production remains comparable to the initialrate seen in the absence of the absorber. The absorber ismanaging to keep the product concentration above the catalystlow, so the rate is comparable to just the forward rate. Doingso, it permits us to attain rates comparable to just the forwardrate. Figure 13 clearly indicates that, after a short period, thereaction−separation test system is showing faster apparentrates, compared to the reaction test system. While during theinitial stage (t ̅ = 100 s/mol), the reaction test shows the fastestrate at 90 bar, the reaction test at 55 bar displays a slower rate,similar to that observed in the reaction−separation test.However, the apparent rates change significantly after a while(t ̅> 100 s/mol). Comparison of reaction test at initial pressuresof 90 and 55 bar with the reaction−separation test at an initialpressure of 55 bar shows that the rates of the reaction testsdecrease very quickly while the apparent rate of the reaction−separation test remains unchanged. For instance, at t ̅ = 2500 s/mol, the apparent rate of the reaction−separation test is fourtimes larger than the apparent rate of the reaction test, althoughthe operating pressure is almost half. At t ̅ > 5000 s/mol, thereaction tests approach equilibrium while the apparent rate ofthe reaction−separation test is still unchanged at pressures aslow as 25 bar. While the concept of enhanced ammoniasynthesis using metal chlorides has been demonstrated in ourearlier work,25 here, we show the viability of ammonia synthesisat much reduced pressure with comparable rates.

■ CONCLUSIONS

In this study, we have reported the application of a reactive−absorption process for enhanced production of ammonia atreduced operating pressure. Absorption on calcium chlorideprovides an efficient separation for the removal of ammonia,

Figure 12. Comparison of rate of ammonia synthesis and ammonia mole fraction along the length of the reactor. We need ∼17 catalytic sections,followed by absorption, to maintain the concentration of ammonia at <1% in this design.

Figure 13. Comparison of reaction and reaction−separation tests atdifferent operating pressures. Greater apparent reaction rate isobserved via the reaction−separation test at lower operating pressures.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8930

even at temperatures close to the reaction temperature. Bothour analysis and model predictions indicate that both reactionand separation rates are fast and recycle flow is the rate-limitingstep in our proposed process.

■ AUTHOR INFORMATION

Corresponding Author*Tel.: 612-625-1596. Fax: 612-626-7246. E-mail: [email protected].

NotesThe authors declare no competing financial interest.

■ ACKNOWLEDGMENTS

This work was primarily supported by the MinnesotaEnvironment and Natural Resources Trust Fund as recom-mended by the Legislative-Citizen Commission on MinnesotaResources (LCCMR), and by the MNDrive, an initiative of theUniversity of Minnesota. Joshua Prince is also acknowledgedfor assisting with the rate constant calculations.

■ NOMENCLATURE

a = rate of ammonia production (mol/h)C = apparent absorbent capacity (mmol NH3/mmol CaCl2)k = absorption initial ratek1 = forward rate of reaction constantk2 = reverse rate of reaction constantkab = absorption mass-transfer coefficient (mol/m2 Pa h)kR = linearized catalytic reaction rate constant (mol/L h)Ka = equilibrium constant in Nielsen rate expressionKp = reaction equilibrium constantK3 = reaction rate constantm = number of moles of gas mixture per hour in the recycleflow (mol/h)Pi = partial pressure of component iS = total surface area of the absorberr = rate of reactionr′ = apparent production rate (mmol NH3/s)VR = volume of catalyst (m3)xA* = ammonia mole fraction at equilibriumxi = mole fraction of component i in the recycle streamxA0 = mole fraction of ammonia in the absorber

Subscriptsi = component iA = ammoniaH = hydrogenN = nitrogenα, ω = parameters of the ammonia reaction rate

■ REFERENCES(1) Russo, M. V. The Emergence of Sustainable Industries: Buildingon Natural Capital. Strateg. Manag. J. 2003, 24, 317.(2) Henderson, A. R.; Morgan, C.; Smith, B.; Sørensen, H. C.;Barthelmie, R. J.; Boesmans, B. Offshore Wind Energy in EuropeAReview of the State-of-the-Art. Wind Energy 2003, 6, 35.(3) Piwko, R.; Osborn, D.; Gramlich, R.; Jordan, G.; Hawkins, D.;Porter, K. Wind Energy Delivery Issues [Transmission Planning andCompetitive Electricity Market Operation. IEEE Power Energy Mag.2005, 3, 47.(4) Klerke, A.; Christensen, C. H.; Nørskov, J. K.; Vegge, T.Ammonia for Hydrogen Storage: Challenges and Opportunities. J.Mater. Chem. 2008, 18, 2304.

(5) Wojcik, A.; Middleton, H.; Damopoulos, I.; Van Herle, J.Ammonia as a Fuel in Solid Oxide Fuel Cells. J. Power Sources 2003,118, 342.(6) Reese, M.; Marquart, C.; Malmali, M.; Wagner, K.; Buchanan, E.;McCormick, A.; Cussler, E. L. Performance of a Small-Scale HaberProcess. Ind. Eng. Chem. Res. 2016, 55, 3742.(7) Dyson, D. C.; Simon, J. M. Kinetic Expression with DiffusionCorrection for Ammonia Synthesis on Industrial Catalyst. Ind. Eng.Chem. Fundam. 1968, 7, 605.(8) Temkin, M.; Pyzhev, V. Kinetics of Ammonia Synthesis onPromoted Catalysts. Acta Physiochim. USSR 1940, 12, 327.(9) Annable, D. Application of the Temkin Kinetic Equation toAmmonia Synthesis in Large-Scale Reactors. Chem. Eng. Sci. 1952, 1,145.(10) Horiuti, J.; Takezawa, N. The Mechanism of CatalyzedSynthesis of Ammonia in the Presence of Doubly Promoted IronCatalyst. J. Res. Inst. Catal., Hokkaido Univ. 1960, 170−187.(11) Stoltze, P. Surface Science as the Basis for the Understanding ofthe Catalytic Synthesis of Ammonia. Phys. Scr. 1987, 36, 824.(12) Ertl, G. Primary Steps in Catalytic Synthesis of Ammonia. J. Vac.Sci. Technol., A 1983, 1, 1247.(13) Ertl, G. Surface Science and CatalysisStudies on theMechanism of Ammonia Synthesis: The P. H. Emmett AwardAddress. Catal. Rev.: Sci. Eng. 1980, 21, 201.(14) Catalytic Ammonia Synthesis: Fundamentals and Practice;Springer Science & Business Media: New York, 2013.(15) Jones, M. O.; Royse, D. M.; Edwards, P. P.; David, W. I. F. TheStructure and Desorption Properties of the Ammines of the Group IIHalides. Chem. Phys. 2013, 427, 38.(16) Lebrun, M.; Spinner, B. Models of Heat and Mass Transfers inSolidgas Reactors Used as Chemical Heat Pumps. Chem. Eng. Sci.1990, 45, 1743.(17) Sharonov, V. E.; Aristov, Y. I. Ammonia Adsorption by MgCl2,CaCl2 and BaCl2 Confined to Porous Alumina: The Fixed BedAdsorber. React. Kinet. Catal. Lett. 2005, 85, 183.(18) Liu, C. Y.; Aika, K. Ammonia Absorption into Alkaline EarthMetal Halide Mixtures as an Ammonia Storage Material. Ind. Eng.Chem. Res. 2004, 43, 7484.(19) van Hassel, B. A.; Karra, J. R.; Santana, J.; Saita, S.; Murray, A.;Goberman, D.; Chahine, R.; Cossement, D. Ammonia SorbentDevelopment for On-Board H2 Purification. Sep. Purif. Technol.2015, 142, 215.(20) Sørensen, R. Z.; Hummelshøj, J. S.; Klerke, A.; Reves, J. B.;Vegge, T.; Nørskov, J. K.; Christensen, C. H. Indirect, ReversibleHigh-Density Hydrogen Storage in Compact Metal Ammine Salts. J.Am. Chem. Soc. 2008, 130, 8660.(21) Himstedt, H. H.; Huberty, M. S.; McCormick, A. V.; Schmidt, L.D.; Cussler, E. L. Ammonia Synthesis Enhanced by MagnesiumChloride Absorption. AIChE J. 2015, 61, 1364.(22) Kumar, A.; Daoutidis, P. Nonlinear Dynamics and Control ofProcess Systems with Recycle. J. Process Control 2002, 12, 475.(23) Baldea, M.; Daoutidis, P. Dynamics and Nonlinear Control ofIntegrated Process Systems; Cambridge University Press: Cambridge,U.K., 2012.(24) Guacci, U.; Traina, F.; Ferraris, G. B.; Barisone, R. On theApplication of the Temkin Equation in the Evaluation of Catalysts forthe Ammonia Synthesis. Ind. Eng. Chem. Process Des. Dev. 1977, 16,166.(25) Gillespie, L. J.; Beattie, J. A. The Thermodynamic Treatment ofChemical Equilibria in Systems Composed of Real Gases. I. AnApproximate Equation for the Mass Action Function Applied to theExisting Data on the Haber Equilibrium. Phys. Rev. 1930, 36, 743.(26) Emmett, P. H.; Kummer, J. T. Kinetics of Ammonia Synthesis.Ind. Eng. Chem. 1943, 35, 677.(27) Nielsen, A.; Kjaer, J.; Bennie, H. Rate Equation and Mechanismof Ammonia Synthesis at Industrial Conditions. J. Catal. 1964, 3, 68.(28) Larson, A. T.; Tour, R. S. Contributions to the Study ofAmmonia CatalystsIV. Chem. Metall. Eng. 1922, 26 (14), 647.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8931

(29) Hummelshøj, J. S.; Sørensen, R. Z.; Kustova, M. Y.;Johannessen, T.; Nørskov, J. K.; Christensen, C. H. Generation ofNanopores during Desorption of NH3 from Mg(NH3)6Cl2. J. Am.Chem. Soc. 2006, 128, 16.(30) Huberty, M. S.; Wagner, A. L.; McCormick, A.; Cussler, E.Ammonia Absorption at Haber Process Conditions. AIChE J. 2012,58, 3526.

Industrial & Engineering Chemistry Research Article

DOI: 10.1021/acs.iecr.6b01880Ind. Eng. Chem. Res. 2016, 55, 8922−8932

8932