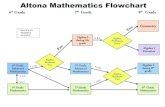

Altona Car Manufacturing Plant Closure Sale

Transcript of Altona Car Manufacturing Plant Closure Sale

Altona Car

• Aluminium Casting • Engine Lines • Weld Shop

• Unit Parts • Press Shop • Paint Shop

• Resin Shop • Assembly Shop • Miscellaneous & Cranes

FOR SALE:

OFFERS INVITED NOW

w w w.hi lcoind.com

* Production Ceases October 2017 * Removal Starts February 2018

Manufacturing Plant Closure Sale

ALUMINIUM CASTING & ENGINE LINES

MACHINERY & EQUIPMENT ERNST ROST ONNES +31 (0)20 470 0989 [email protected]

MACHINERY & EQUIPMENTSCOTT MATTHEWS +61 400 827 333 [email protected]

PROJECT MANAGER LOGAN FENEMOR +61 410 082 603 [email protected]

INSPECTION

PREVIEW BY APPOINTMENT ONLY

UNDER INSTRUCTIONS FROM REASONS FOR SALE

TOYOTA MOTOR CORPORATION AUSTRALIA LTD

CLOSURE OF TOYOTA ALTONA CAR MANUFACTURING PLANT

ENQUIRIES

ALUMINIUM CASTING HEAT TREATMENT OVEN ENGINE TEST

FURNACE HOUSE - 8T FURNACEFURNACE HOUSE - 10T HOLDINGSPRAY ROBOT

ALUMINIUM CASTING - LOW PRESSURE SYSTEM

BLOCK DEBURRING & FURNACE ALUMINIUM CASTING - T6 FURNACE SYSTEM

ALUMINIUM FOUNDRY

• AFM100 8 TONNE FURNACE (2013) Furnace Engineering, Model: B2625, Cap. 8 T, Temperature Range: 900 - 1150 degr. C, 4000mm (l) x 3000mm (w).incl.:AIK100 MOBILE FURNACE TENDING VEHICLE (2014), Hencon, 80V With: LADLES (2013, 2011), Stotek SAND SUPPLY DEVICE (2011), Meiki Ind.

• AFM009 6 TONNE FURNACE (2003), Furnace Engineering, Model: B1998-2-ZPFThern, Top Load, Cap. 6 T ,Temperature Range: 720 – 1,050 degr.C, 3000mm (l) x 2000mm (w) x 5000mm (h). With: GAS BUBBLE FILTRATION UNIT (1998), Pyrotek, Model: PAL-FIF-50, LADLE HEATER (2011), Stotek, TRANSFER LADLE (2014), Stotek, Cap.: 650kg. and SCISSOR LIFT TABLE (FURNACE CLEANING).

• AF017 10T HOLDING TILTING FURNACE (2002), Major, Model: 10T-Hold-FUR, Temperature Range: 720 - 750 degr. C., 4000mm (l) x 3000mm (w), 2 burners.With: CLEANING PLATFORM / INGOT LOADER (2010), TRANSFER LADLE (2012), Stotek.

BLOCK SPRAYING & FURNACE • AFH018 1.6T HOLDING FURNACE (ELECTRIC) (2002), Major W.O 20010800, Cap.2,500kg, Temperature Range: 730 –750 degr. C. 3000mm (l) x 1500mm (w). With: SPRAY ROBOT (2008), Yutaka Electronics EZER-1107, VACUUM SYSTEM (2011), Toyotsu Techno Corporation, CASTING UNLOADER ROBOT (2008), Yutaka Electronics, CASTING UNLOADER CONVEYOR (2011), Watanabe Machinery Co. Ltd, CYLINDER LINER FEEDER (2011), Watanabe Machinery Co. Ltd; DIE LUBE MIXING UNIT (2008), IEDA Industry Co. Ltd;

• AZE224 COOLING WATER TANK (2011), Takeda Kiko Co. Ltd, Cap. 900 Litres,

• AZE245 GAS BUBBLE FLUXING MACHINE (2013), Pyrotek

BLOCK DEBURRING, FURNACE AND ROBOT HANDLING

• CY BORE FETTLING UNIT (2011), Watanabe Machinery Co. Ltd;

• DEBURRING MACHINE (2002), Watanabe Machinery Co. Ltd; with Robot Type: UP120E, Motoman Robot;

• AFH106 HEAT TREATMENT OVEN (2011), Nitton Kohnetsu, Model: GGC-1000HT5, Type: HA, with Fanuc;

ALUMINIUM CASTING – LOW PRESSURE • ADM100-101-102 (3) DIE CASTING MACHINES (2011), Toyotsu Techno Corporation, Model: 4 column, Stainless Steel, Die Casting Station, Die Outfeed Table and Controls; Incl. AFH103,104,105: (3) HOLDING FURNACES (2008), Tounetsu (2003), Cap.300 Amp, 5000mm (l) x 2000mm (w).With: CASTING VACUUM UNITS (2012), Amano, Model: VF-2S, on stand;

• ROLLOVER JIGS (2010,2011), Toyotsu Techno Corporation;

• COOLING DEVICES (2008), Tokuden, Model: JAC60-3655;

• DIE COOLING UNIT (2008), Takedakiko Co. Ltd, Model: EZE-0220.

• ACM010 CORE MAKING MACHINE (2011), Toyo Sanki.

• ACM100 TH CORE MAKING MACHINE (2008), Sintokogio, Model: CHS74Z With:FANUC LR MATE (2001) ROBOTS (2014), Nachi Fujikoshi corp., Model: MZ07;

• ADC043 WET SCRUBBER ( 2011), Mideco, Model 1100 with Hicago 75Kw Blower;

• AFH100 T6 SOLUTION FURNACE (2014), Nihon Kohnetsu, Model: GGC-510HT6. With: T6 FANUC ROBOT, (2011) Fanuc, Model: R-2000ib.

• T6 OUTFEED FURNACE, (2011) Watanabe Machinery, Model: TMCA AR .

• T6 INFEED FURNACE (2010), Watanabe Machinery, Model: TMCA AR .

• HANDLING ROBOT (2012) Fanuc, Model: M710ic,

• FETTLING ROBOT (2012), Fanuc, Model: Alpha iS 30/4000;

ENGINE LINESCYLINDER BLOCK MACHINING • ROUGH HONING BORE MACHINE (2011), Jtekt Corp. Model 8184, 4 Axis.

• FINISHING HONING BORE MACHINE, Jtekt Corp.

• ASP185 CNC 4-AXIS HORIZONTAL CUTTING MACHINE (2004), Toyoda Machine Works, Model: TMW-555-64, Travels: X=800, Y= 550, Z=530, B= Turn Table, Spindle Speed 12.000 RpM, motor 22/18,5 KW;

• ATS124 BORE HOLE MEASURING MACHINE (2012), Jtekt Corp. Model M-8183. Marposs Measuring Data Unit, Model: EP9066N (8667 C00191), Anritsu Digital Thermometer, Model: TM-5976B, Weight 4000kg.

CLOSURE OF TOYOTA ALTONA CAR MANUFACTURING PLANT

• ATS125 BORE HOLE MEASURING MACHINE (2011), Jtetk Corp, Model: M-8186.

• AZK301 (2) HOLE DETECTION ROBOT CELLS (2011), Kito Model MCZ0-02;

• COOLANT SEPERATOR (2011), JPC Co. Ltd.

• ATS126 PRESS FIT PLUG LEAK TESTER (2011), Chita MFG Co. Ltd, Model: C-2769.

• ATS123 (2) LEAK TEST MACHINES (2011), Cosmo, Model: LU80A.

• AZK300 STAMPING ENG MODEL TYPE (2012), Shinmei Industry, Model: FF038-000000-11601

• AWB103 FINAL WASHING (2011), JPC Co. Ltd, Model: BLANK PLATE, Fanuc Handling Robot; 2x Supply Tanks, Cap. 3000 Litres with Agitator, Skimmer Waste Oil, Cap. 75 Litres .

• BLOCK DELIVERY ROBOT 6 AXIS (2009), Kawasaki, Model: 352G-A201,

• ROBOT PART HANDLING (2012), Fanuc, Model: R-30IA, Type: A05B-251U-B150.

CYLINDER HEAD MACHINING

• ASP227 HORIZONTAL MACHINING CENTRE (2011), Komatsu NTC, Model: FTL-1261CH, Type: N5H-866 X,Y,Z & A (TRUNION), travel 800/600/600, 360Deg, spindle speed (RPM): 100 to 12,000, 11/7.5Kw, ATC-24 positions,control Fanuc, model: 18i-LNB;

• ASP188 (2) 4-AXIS CYLINDER HEAD SPECIAL PURPOSE MACHINES (2007), Nippei Toyama, Model: CMC-425CH, Type N4Q-555, X,Y,Z & A (TRUNION), Travel : 500,/500/500, 360Deg. INJECTION WASHING MACHING (2011), Kito, Model: 200-A0757;

• LEAK TESTER, (2011) Kito, Model: 500-A0758;

• (2) Cell Mid Washing Machines, (2011) Kito, Model 200-A0755/A0756;

• (2) ASSEMBLY MACHINES (2011), Kyono;

• ROBOT HANDLING (2012), Fanuc, Model: R-30IA

CONROD MACHINING

• ASSEMBLING MACHINE (2011), Kyoho Model 55-2A00228;

• ABR100 BORING/GRINDING MACHINE (2011), Yasunaga, Model: M-3957, Control Fanuc Model: 18I-LNB;

• AGR100 +101 (2) GRINDING MACHINES (2011), Kyoho, Model: KVD300-CII, Control Panel: Fanuc, Model: 18I, Grinding Wheel Spindle 1500mm, max.1440m/min. Peripheral Speed, Diameter 305 mm, width 50mm, hole diam. 155mm.

• HONING MACHINE (2011), Fuji, Model: NR-32 5P5;

• ACCRETECH DIGITAL PRINTER Model: Palcom V;

• CUTTING MACHINE (2011), Nishijimax, Model: NHC-07ONC;

• TESTING MACHINE (2011), Dadei Model AFM-25 CRTA;

• WASHING MACHINES (2011), JPC Co. Ltd;

• (2) ROBOT STORAGE MACHINES (2011), Yutaka Electronics, Model: Transfer RB;

• ROBOT STORAGE MACHINE (2011), Watanabe Machinery Co.;

• (3) GANTRY LOADERS (2011), CNK Co. Ltd, Model: LN-15T1;

CRANKSHAFT MACHINING

• AMI100 CNC MILLING & DRILLING MACHINE (2011), Komatsu, Model: GPM170F2-3, X (x2), Y (x2), Z (x2), WH, X = 500, Y = 200, Z = 600, Tool Carrousel

• ASP244-251 (7) CNC 4-AXIS SPINDLE MACHINES (2012), Nachi Fujikoshi corp. Model: DH-524, Recentre DH-524, A, B, Y, Z, X = 500, Y = 200, Z = 460, Spindle Speed RPM: 3000, ATC 12.

• AGR110+106 (2) SINGLE WHEEL GRINDING MACHINES (2011), Jtekt Corp, Model: GL32M-63; X,Y,ZWC, WR.

• ALP100 PAPER LAPPING MACHINE (2011), Nachi Fujikoshi corp., Model: MF-650, Control: Fanuc, Model: 18iLNB;

MEASURING MACHINES • ATS109 BALANCING MACHINE (2011), Nagahama, 300MBRK;

• ATS110 CRANKSHAFT MEASURING TIMER GEAR

• ATS111 CRANKSHAFT MEASURING TIMER GEAR (2011), Tosei, Model: 42260.

• ATS128 BALANCING MACHINE (2011), Nagahama 400MBRK, LCD control panel

• AWB106-107 (2)WASHING MACHINE (2012), JPC Co.

• GEAR INSERTING MACHINE (2012), Hino, Model: TE-2345,

• PRESS FITTING MACHINE (2011), Shinmei Industry, Model: AAT-003

• CNC LATHE MACHINE, Mori Seiki, N2-S2500.

• WASHING MACHINE (2011), JPC Co. Ltd,

• (7) GANTRY LOADING MACHINES (2011), CNK Co., Model: LNIV-30H;

ENGINE TEST

• A.V.L DYNO-CABLE BOOM (2012), Schneider Indy, S22-2/0525;

• MOTOR EXHAUST GAS ANALYSER (Emission Gas Anal-yser), (2012) Horiba, Model: Mexa-1600D;

• AVL DYNO COMBUSTION PRESSURE METER• COOLING WATER FLOW METER AVL DYNO CONSY-SCOOL (2012) 200, TTA, 21KVA;

• AVL DYNO FUEL BALANCE METER, TTA, Model: AVL733S;

• AVL DYNO THROTTLE ACTUATOR, THA100;

• AVL DYNO COMBUSTION AIR CONDITIONER, Model: TCS1200FH;

• AVL DYNO BLOW BY METER • AVL DYNO OIL CONSUMPTION UNIT (2011). AWM, Model: 406.01, on Wheels;

• PANEL CHECKER, Toyota Technical Development Corp. Panel A111, Laptop, Asset;

• MOVEABLE OIL CONSUMPTION UNIT AVL Dyno. (2010), Model AWM, Model: 406.01;

MISCELLANEOUS

• AZY298 ENGINE STORAGE SYSTEM (2013), Control IT, Overall Dimensions: 11m x 10m With 2x Handling Robots, Nachi; Motorised Conveyor System, Vertical Storage, Un-load Station, Safety Gage, Elevated Platform .

• CNC TOOL REGRINDING MACHINE (2006 ), ANCA, Model: EGX

• SPARE ROBOT (2013), Yaskawa Motoman UP-120ED-165, Payload: 165kg, 1100kg, with Controller.

• ENGINEERING MAINTENANCE EQUIPMENT

CAMSHAFT MACHINING

• AGR113 CAM GRINDING MACHINE (2011), Jtekt, Model: GL32H-63;

• ASP254-258 (5) CNC 4-AXIS SPINDLE MACHINES (2011), Yasunaga, Model: FC4JC, X,Y,Z,A,B axis. Con-trol: Fanuc, Model: 181LNB.

• (2) CNC LATHE MACHINES (2005), Fuji, Model: GN-30, ZX, X, ZXZ, Spindle Speed RPM: 3000 RPM, 9/7.5kw (1:8), Twin Turret with 8 Tool Positions, Con-trol: Fanuc, Model: 18I LNB.

• SUPER FINISH MACHINE (LAPPING MACHINE) (2011), Chita MFG Co. Ltd,Model: C-2770.

• (3) GANTRY LOADERS (2011). CNK Co. Ltd, Mod-el: LNIV

CAM HOUSING MACHINING

• CAM HOLE DEBURRING (2011), Chita, Model: C2768;

• LEAKTESTER (2012), JPC Co. Ltd, Model: A885A-M01

• MID WASHING MACHINE (2012), Sugino, Model: SJCN02R

• FINAL WASHING MACHINE (2011), JPC Co. Ltd, Model: A875A-M01;

• CAM CAP LOOSENING NUT RUNNER (2011), Kyoho Machine Works Ltd, Model: 55-2A00230;

ENGINE ASSEMBLY

• GASKET SEALING ROBOT (2003), Aftech, Model: LR Mate 200:B, (overhauled 2012);

• GASKET ASSEMBLY ROBOT (2001), Aftech, Fanuc LR Mate 200IB

• NUT RUNNER - CONROD (2003), Giken Kogyo;

• (8) SPINDLE NUT RUNNER-CON ROD PRETIGHT-ENING (2010), Giken Kogyo, Model: NR.8X8SP;

• CAM HOUSING NUT RUNNER (2011), Giken;

• TCC NUT RUNNER (2011), Giken,;

• DAMER PULEY NUT RUNNER Atlas Copco, Tensor S9;

• HEAD COVER TIGHTENING MACHINE (2011), Giken, Model: ANZM-SH-500H;

• CRANKCASE TIGHTENING MACHINE (2011), Giken, Model: 11-M3SR-11M

• OIL PAN TIGHTNEING MACHINE (2011), Giken, Model 11-PPL-5,

• CAM CAP TIGHTENING MACHINE (2011), Giken, 2 Spindle, Model: ANZM-350

• PISTON PIN FITTING MACHINE (2011), Sanko, Model: TE-2337.

• PISTON RING ASSEMBLY MACHINE & CHECKER (2011), Sanko, Model TE-2338.

WELD SHOP17 HEMMING PRESSES, ROBOTS, WELDING, SEALING

• WBZ342 HEMMING PRESS (2014) Takatsu, Cap.150T;

• (2) HEMMING PRESSES (2011), Futaba Model, Cap.150T;

• WBZ010-013 (4) HEMMING PRESSES (2005) Marand Model, Cap. 150T;

• (8) HEMMING PRESSES (2005) Marand Model, Cap.150T;

• (6) HEMMING PRESSES (2011) Takatsu, Model JTEKT, Cap.150T;

• Robots WZZ 271-272 SEALING ROBOT CELL (2006), 2 Nachi SC50F-01 Robots;

• VZZ 269 2 MIG WELDING ROBOT CELLS (2005) Kawasaki FA20N Robots;

• WZZ298 PLASMA CUTTING ROBOT CELL (2004), Kawasaki ZX165U;

GENERAL

• FUEL TANK SPRAY LINE (2005); • Full conveyor system, NG Oven;• ENGINEERING MAINTENANCE EQUIPMENT; • MIG WELDERS, Kempi Mig 4000;• STUD WELDERS AND SPOT WELDERS;• SEALING PUMPS;

Over 300 Robots Kawasaki or Nachi* Note: Servo Arms only, no Controllers

UNIT SHOPSMALL PARTS WELDING &

E-COAT PAINTING

Contact us NOW for Inspection!

E-Coat Paint Facility

PRE-TREATMENT PLANT, 6 Stage Dip (Degreasing, Water, Conditioner, Phosphate, Water, RO);

E-COAT PLANT, 4 Stage Dip

(E-coat, First UF, Second UF, RO);

E-COAT BAKE OVEN AND COOLER (2006), HADEN DRYSYS ;SPP Oven System. Osmosis Diptank with Internal

Conveyor

COMPLETE LINE Including Twin Rail EMS Overhead Conveyor with Chain Hoist Dip operation; Boiler;

Exhaust systems; Chiller; 65000L 316s/s Tank & 30000L 304s/s Tank.

Welding WELDING – Stud Welders,

Pedestal Welders, Mig Welders.

www.hilcoind.com or www.graysonline.com

For more information, please visit us on the web at www.hilcoind.com or www.graysonline.com

TANDEM PRESS LINE (6B), (5 Presses + 7 Transfer Robots), Kobe Cap.500T/400T. Motoman Robots 2 x UP130 , 1 x UP120 , 3 x SK506, & 1 x 0UP130;

TANDEM PRESS LINE (5A) (4 Presses, 5 robots), 1000T/600T, Komatsu, Built: 1990, Motoman Robots: Model EP4000N-AT02 (2006), TANDEM PRESS LINE (4C) (4 Presses + 5 Transfer Robots) , Kobe, Cap.500T/400T. Motoman UP130 Robots

TANDEM PRESS LINE (3C) (4 Presses), Kobe, Cap.500T/400T/350T; TANDEM PRESS LINE (2C) (3 Presses + 3 Transfer Robots), Kobe, Cap. 500T; Cap. 350T ; Bliss Cap. 400T; Motoman UP130 Robot; and 2 x Motoman EPH130 Robots;

MISCELLANEOUSAPR 038 / 24145T PRESS, (2011) Seyi, Model SN1-45, Stroke: 110mm;400T PRESS, Kobe.686+687+688 RAW SHEET OIL WASHING, Taiho Seiki, Incl 2 x Motoman SR200 Robots, Stacking, Unloading & Ancillary Equipment, Robots on High Base; PACK STEEL TURN OVER DEVICE, Total Tooling; (2) ROBOTS Motoman, Model EA1400N (2016);(6) SPARE ROBOTS, Motoman, SK506; 2 x UP130; UP130; SR200 & EPH130;

PRESS SHOP

PAINT SHOPPAINT MIX SUPPLY &

ROBOTIC APPLICATION BOOTHS

PAINT MIX SUPPLY

PAINT MIX & SUPPLY STATIONS (X30), APV Including S/Steel Tanks & Pumps.

ROBOTIC APPLICATION BOOTHS (26) Spray Robots: Kawasaki KE610 (2006),

Explosion Proof;(12) Pick & Place Robots : Kawasaki KF121

(6 x 2001, 6 x 2007), Explosion Proof;(8) Underbody Sealing Robots:

( 4 x Fanuc M-16iB/10L & 4 x S-10)

MISCELLANEOUSAIR DRYERS (x7), Domnick Hunter

Pneudri DHE 110DS (2010); SPECTROMETER, Agilent Technology 200 Series AA

(2014); SPRAY BOOTH AND OVEN, Lowbake, 8 x 4.5m;ROBOT, Fanuc S-10 TANKS, Up to 12,000L, S/Steel;

MAGNETIC IRON SEPARATION SYSTEM, Gasco;WATER TREATMENT SYSTEMS;

TRADE WASTE, including Large Capacity Tanks, Pumps.

RESIN SHOPROBOTIC APPLICATION BOOTH & PAINT MIXING

ROBOTIC APPLICATION BOOTH(12) Spray Robots Kawasaki KE610H (10) x 2006; (2) x 2002;(4) Pick & Place Robots: Kawasaki KF121 (2006)

PAINT MIXING(14) PAINT MIXING & SUPPLY SYSTEMS, Haden (2005)

MISCELLANEOUSENGINEERING MAINTENACE WORKSHOP;AIR DRYER, Domnick Hunter MXS-103C-DD5;CONVEYORS

ASSEMBLY SHOP FILLING, TESTING, DELIVERY SYSTEMS,

& EMISSIONS LABORATORY

OVERHEAD CARRIERS

• OVERHEAD CAR CHASSIS SUSPENDED FRAME, Webb, Over 1000m L. Chain drive with cradles.

• OVERHEAD ‘RAM RUN’ SUSPENDED FRAME CARRIERS (DOOR AND CHASSIS), Daifuku.

• VARIOUS IN-FLOOR MOUNTED SLAT CONVEYORS.• OVERHEAD SEAT DELIVERY SUSPENDED FRAME, Conveyor Co. of Australia. Chain drive

• CAR BODY HOISTS, Daifuku.

ASSEMBLY

• VKU172 ENGINE DOCKING SYSTEM (2009), NKC Conveyors;

• VKU135-136 SPINDLE NUT RUNNERS (2006), GANG HEAD (X2), Atlas Copco, with Torque Controllers, Tyre Manipulator and Runway.

• VLT024 NUT RUNNER TEST BENCH (2008), Atlas Copco, Tensor 8-9 & 3-7.

• VKU006 WINDSCREEN URETHANE APPLICATION SYSTEM (2005), with Associated Pumps, Fanuc M16-IB Robot and Conveyors.

• VKU191 AUTO TURN OVER MACHINE (2009), Ochiai Nexus, with Torque Controller.

FILLING

• VFL001 BRAKE FLUID FILLING (2008) Amaike Sekkei;

• VFL023+024 AIR CONDITIONING FILLING (2005) IEC, Model: 134A-20/H incl. Amaike Vacuum Filter System PETROL AND DIESEL BOWSERS, FuelQuip;

• VFL009 TRANSMISSION FILLING Control IT with Associated Pumps, Controllers and Lifting Hoists;

• VFL016 RADIATOR FILLING (2006) IEC, Model RF-2 O/H (Fill Equip) WA-A/W (Mixing);

DELIVERY SYSTEMS

• VKU166 TYRE AND WHEEL RECEIVING AND DELIVERY SYSTEM (2008) Marand;

• VCV006 SEAT DELIVERY SYSTEM (2000), Webb, Including Carriers;

• BUMPER BAR DELIVERY SYSTEM (2011) Ochiai Nexus;

• VCV034 FUEL TANK DELIVERY SYSTEM

• ENGINE TRANSFER TABLE SHUFFLER

TESTING

• VKK030 +029 (2) WHEEL ALIGNERS (2003), Anzen, Model RX-Swat-1000, In Pit;

• (2) STEERING ANGLE TESTERS , In Pit;

• QCD004+005 ROLLER DRUM TESTERS (2005), Anzen, Model: SDT-1550TA2, In Pit;

• VCT010 +011 ABS BRAKE TESTERS (2003) Anzen, Model SBT-300TA;

• QCD009-006 SIDE SLIP TESTERS, In Pit;

• WATER TEST SHOWER BOOTH• TPMS DATA CHECKER

EMISSIONS LAB

• GAS ANALYSER MOTOR EXHAUST, Horiba, MEX-9200;

• GAS ANALYSER MOTOR EXHAUST GAS, Horiba, MEXA-1160TEI-L;

• ANALYSER CONSTANT VOLUME, Horiba CVS – 9100;

• X-RAY SPECTROMETER EDX-720Other various laboratory testing equipment.

AGV’S

• AGV SYSTEM (Bumper Bar) (2012), Shin-tec Hozumi, Model: Tango, 4 direction, 11 Carts;

• AGV SYSTEM (engine dress) (2009) Toyota L & F, Model: 3AB, Single direction, 28 Carts;

• AGV SYSTEM (2011),(IP) Toyota L & F, Model: 3AB, Single Direction, 12 Carts;

• AGV SYSTEM (Tyre and Wheel) (2009), Toyota L & F, 2 Direction, 5 Carts;

SITE PLANT SERVICECRANES, AIR COMPRESSORS, CHILLERS, WATER TREATMENT, EXTRACTION SYSTEMS

CRANES

• AZY200 CRANE 25T DOUBLE GIRDER (2011), Demag, Cap. 25,000kg each, 20.000 mm (Span), Twin Hoists

• AZY 147 CRANE 25T DOUBLE GIRDER (2002), Demag, Cap. 25,000kg each, 20.000 mm (Span), Twin Hoists

• AZY267 JIB CRANE 3 (2011), Melbourne Hoist & Cranes, Cap. 75kg, 4000 mm (l) x 3000mm (h), No Hoist - just Jib

• AZY268 JIB CRANE 4 (2011), Melbourne Hoist & Cranes, Model: AF10-05266, Cap. 125kg, 4000mm (l) x 3000mm (h), Gis Electric Chain Hoist, Model: GCH-250, Pendant Control

• AZY269 JIB CRANE 5 (2012) Melbourne Hoist & Cranes, Cap. 125Kg, 4000mm (l) x 4000mm (h), Anchor Chain Hoist and Pendant Control

• AZY295 JIB CRANE (2012) Redfern-Finn, Cap. 100Kg, 3000mm (l) x 4000mm (h), Gis 100kg Chain Hoist and Pendant Control

• CRANE LP DIE MAINT, 2x 3.2T Demag Hoists

• AZY241+262 3.2T TWIN HOIST UNDERSLUNG CRANE, Demag, 2 x 3.2T Hoists

• AZY261 2x CRANE 3.2T, (2011) Demag, Cap. 3,200kg, Chain Hoist

• AZY243 5T SINGLE GIRDER CRANE • AZY144+145 (2) BRIDGE CRANES, V6 ENGINE, LOADING

• ACR008 OVERHEAD CRANE, Redfurn Flynn, 2 Tonne GIS hoist, 11m Span on Runway 9m Travel

• QZY140 CRANE GANTRY 250 Kg/ 8000 X 3000 RUNWAYS, GIS Load Scale

OVERHEAD GANTRY CRANES

• Overhead Travelling Gantry Cranes 69+694+695+698+707 7 x DEMAG 35T/20T (2007&2012), 20m Span, + aux. Hoist 10T. Operate from both end. Remote and radio control. operators cabin; PRC 051 Demag 30T, 2 x 10T Hoists, 10m Span

• RLZ001 Travelling Crane GANTRY (2005), 40T/20T;

AIR COMPRESSORS• TAC 005-010 (12) CENTRIFUGAL COMPRESSORS, (X6) Centac Ingersoll Rand 750kw/430kw;

BOILERS• TB001-003 (12) AUTOMATIC PACKAGED BOILERS Maxitherm 6MW.

CHILLERS• TAC011,012,001 (12) WATER COOLED CHILLERS Trane Centravac 213kw/267kw/306kw.

WATER TREATMENT• ATA005 COOLANT RECYCLING SYSTEM, Houghton

• AHS100 WASTE WATER TREATMENT PLANTS;• ACC101+102 COOLING TOWERS Baltimore VX152153

EXTRACTION SYSTEMS• (12) TORIT DUST EXTRACTION SYSTEMS, 48/56/160 BAG, 55/75/160kw.

MISCELLANEOUS• VZT056 RETICULATED THERMAL OXIDIZER • OVER 50 SHIPPING CONTAINERS• OVER 65 RELOCATEABLE BUILDINGS, GROUP ROOMS, • ABLUTION BLOCKS OR STRUCTURES• BIKE SHEDS

w w w.hi lcoind.com

Machinery & EquipmentScott Matthews +61 400 827 333 [email protected]

Machinery & Equipment Ernst Rost Onnes +31 (0)20 470 0989 [email protected]