Alternative Chemical Used for Dirt Determination in ... NMK IRRDB China 2010... · Alternative...

Transcript of Alternative Chemical Used for Dirt Determination in ... NMK IRRDB China 2010... · Alternative...

Alternative Chemical Used for Dirt

Determination in Standard Malaysian

Rubber (SMR) Testing

M.K Noraziah, J.Sa’ari, K.Ruth, Faridah H.A.H & A. R. Ruhida

INTRODUCTION

DIRT ANALYSIS

• the foreign matter in raw natural rubber which fails to pass a sieve of 44 µm (325 mesh size) side-square aperture

• have adverse effects on certain vulcanizate properties such as fatigue and tensile strength, thus lowering the dynamical property of the rubber

INTRODUCTION

• solvent addition gives partial dissolution and swelling of the gel ~ caused by the cross linked gel fraction in rubber solution

• for a good dissolution rubber peptizer is added

• this will causes polymer scission and the ultimate destruction of the weak network

• the rate of dissolution is accelerated at higher temperature

Ref: Lau, C.M. & Ong, C.O., Basic Factors Affecting SMR Tech Prop, Training Manual on NR Processing, 1979

INTRODUCTION

• Current test method is using turpentine as a dissolution solvent

• Very hazardous in case of ingestion

• May cause damage to the following organs:

Central nervous system (CNS)

Upper respiratory tract

Gastrointestinal tract

Urinary system

Kidneys

Lungs

Skin, eyes, ears, nose/sinuses

OBJECTIVES

1. To identify alternative dissolution solvent for dirt determination in SMR testing.

2. To replace turpentine with less hazardous and friendlier solvent.

MATERIALS & METHODS

Materials

• SMR 10

• SMR 20

• SMR L

• SMR CV60

• SMR GP

Solvents

• Mineral Turpentine (Control)

• Kerosene

• Dimethylformamide

• Toluene

• White Spirit

TEST METHOD

Sampling Procedure

• SMR Bulletin No. 7 Part B.1

Sample Homogenization

• SMR Bulletin No. 7 Part B.2

• SMR Bulletin No. 7 Part B.3

Dirt Testing

• SMR Bulletin No. 7 Part B.4

SAMPLE HOMOGENIZATION

• Samples passed through 2-roll mill

• Size: 150 x 300 mm (6 times)

• Friction Ratio: 1:1.4

• Roller Gap: 1.65 0.16 mm

• Temperature: Room temp.

SAMPLE PREPARATION

1. Cutting of sample strips

2. Samples prior to dissolution

3. Dissolution process

RESULT EXPRESSION

Dirt Content (%) =B – A

X 100C

where

A is the mass of initial sieve, g

B is the mass of sieve with dirt, g

C is the mass of test piece, g

QUALITY CONTROL PROCEDURE

1. Checking the boiling temperature of the solvent by using Differential Scanning Calorimetre (DSC)

2. Positive identification of solvent used by using Fourier Transform Infrared Spectroscopy (FTIR)

PRELIMINARY FINDINGS

SolventBoiling Point(oC)

DirtContent

(%)Observation Remarks

Mineral Turpentine(Control)

160 0.092 Normal USD1.17/L

Toluene 111 0.095

Longer time needed to

achieve proper dissolution

USD71.71/L

Dimethylformamide 153 NASlight swollen of test piece

USD128.43/L

Kerosene 168 0.087 Normal USD1.48/L

White Spirit 187 0.073 Normal USD19.02/L

Note: NA = not available

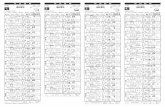

MEAN VALUES

GradeMean (%)

Kerosene Turpentine

SMR L 0.004 0.004

SMR GP 0.051 0.048

SMR CV 0.013 0.013

SMR 10 0.034 0.034

SMR 20 0.028 0.029

F-test: There is no significant difference between the precision of dirt content

results for both solvents.

COEFFICIENT OF VARIATION (%)

GradeCoefficient of Variation (%)

Kerosene Turpentine

SMR L 2.63 15.91

SMR GP 4.01 0.46

SMR CV 5.34 18.6

SMR 10 1.96 2.05

SMR 20 8.19 5.12

REPEATABILITY AND REPRODUCIBILITY

GradeRepeatability (Sr) Reproducibility (SR)

Kerosene Turpentine Kerosene Turpentine

SMR L 0.0016 0.0023 0.0016 0.0021

SMR GP 0.0027 0.0027 0.0027 0.0035

SMR CV 0.0051 0.0066 0.0052 0.0076

SMR 10 0.0043 0.0051 0.0042 0.0047

SMR 20 0.0035 0.0044 0.0040 0.0043

MEASUREMENT OF UNCERTAINTY (MU)

Grade Kerosene Turpentine

SMR L 0.01 0.01

SMR GP 0.03 0.04

SMR CV 0.02 0.02

SMR 10 0.02 0.03

SMR 20 0.02 0.02

ADVANTAGES

Kerosene Turpentine

Hazards

IdentificationLess hazardous Very hazardous

Flash points 38 C 35 C

Vapor pressure

(@20 C)0.1 kPa 76.9 kPa

HMIS regulations

– Fire hazard2 3

QUALITY CONTROL PROCEDURE(DSC)

Method: kerosene

150.0-280.0°C 10.00°C/minIntegral

-10.79e+03 mJ

normalized-708.31 Jg^-1

Onset166.95 °C

Peak

185.26 °C

Endset195.23 °C

Heating Rate10.00 °Cmin^-1

turpentene, 27.12.2007 12:27:12

turpentene, 15.2300 mg

mW

-120

-100

-80

-60

-40

-20

0

min

°C

150

160

170

180

190

200

210

220

230

240

250

260

270

0

1

2

3

4

5

6

7

8

9

10

11

12

^exo

turpentene

27.12.2007 13:33:06

SW 8.10e

RT AS

Lab: MET T LER

Method: kerosene

150.0-280.0°C 10.00°C/min

Integral -4346.58 mJ

normalized -316.81 Jg^-1

Onset 184.92 °C

Peak 200.46 °C

Endset 232.10 °C

Heating Rate 10.00 °Cmin^-1

kerosene, 27.12.2007 11:56:14

kerosene, 13.7200 mg

mW

-35

-30

-25

-20

-15

-10

-5

0

min

°C150 160 170 180 190 200 210 220 230 240 250 260 270

0 1 2 3 4 5 6 7 8 9 10 11 12

^exo kerosene 27.12.2007 13:34:16

SW 8.10eRT ASLab: MET T LER

Kerosene (Tb = 197.5 oC)

QUALITY CONTROL PROCEDURE(FTIR)

FTIR SPECTRUM Wed Dec 26 16:34:08 2007Collection time: Wed Dec 26 11:35:31 2007

6

98

8

06

10

38

16

08

28

46

29

26

29

58

30

16

RR/0712/0472 Noraziah Kassim KEROSENE pyr

RR/0712/0473 Noraziah Kassim TURPENTINE pyr

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

Ab

so

rba

nc

e

1000 1500 2000 2500 3000 3500

Wavenumbers (cm-1)

Kerosene

Turpentine

CONCLUSION

• There is no significant difference between the meanvalues recorded for the dirt content using bothsolvents.

• Values of coefficient of variation for kerosene wereobserved to be in the range of 2% – 8%. Whilst theMU, Sr and SR generated were in the acceptableranged.

• Thus, it is recommended for kerosene to be used asan alternative dissolution media for dirt contentdetermination in SMR testing.

ACKNOWLEDGEMENT

Thank You to;

1. Director General of MRB for her permission topresent this paper

2. Directorate members of MRB

3. Head of Materials Characterization Unit (MCU)

4. Colleagues of MCU

5. Staff of SMR Control Lab,MCU