Air handler

-

Upload

self-employed -

Category

Education

-

view

114 -

download

0

Transcript of Air handler

Submitted to: Presented by:Mr. Yogendra Narayana Jyoti SinghResearch Scholar ME (Regular)EE department Branch - I & CNITTTR Chandigarh Roll No:142511

Contents

• Introduction• Operation of Air Handler

• Components of Air Handler

Introduction

• An air handler is a device used to regulate and circulate air as part of a

heating, ventilating, and air-conditioning (HVAC) system.

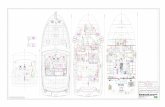

Operation of AHU

Components of Air Handler

• Blower/fan• Heating and/or cooling elements• Mixing chamber• Filters

• Dampers• Humidifier• Heat recovery device• Controls• Vibration isolators

Blower/Fan

• The blower pushes the air through the system and ducts.

• It is typically a centrifugal fan which is a fan wheel that blows the air at a

right angle to the intake direction, using centrifugal force to accelerate the

air.

• Backward curved or inclined blades have higher efficiency than forward

curved or radial blades and airfoil blades, backward curved with double

thickness, have the highest efficiency.

• The blower controls the flow rate of air by operating at a set speed or

variable speeds.

Heating/Cooling Element

• Air handlers may need to provide heating, cooling, or both to change the

supply air temperature, and humidity level depending on the location and

the application.

• Air handling units contain coils that circulate hot water or steam for

heating, and chilled water for cooling.

• Cooling coils will also employ eliminator plates to remove and drain

condensate.

• Downstream temperature sensors are typically used to monitor and control

'off coil' temperatures, in conjunction with an appropriate motorised

control valve prior to the coil.

Mixing Chamber

• The mixing chamber combines the specified proportions of outside air and

return air into the supply air.

• Mixing in outside air keeps the interior air fresh by supplying oxygen.

• In temperate climates, mixing the right amount of cooler outside air with

warmer return air can be used to approach the desired supply air

temperature.

• A mixing chamber is therefore used which has dampers controlling the

ratio between the return, outside, and exhaust air.

Filter

• Filters remove particulates including dust, pollen, and mold from the air

and are typically a fibrous material.

• It may be via simple low-MERV pleated media, HEPA, electrostatic, or a

combination of techniques. Gas-phase and ultraviolet air treatments may

be employed as well.

• Filters must be replaced regularly to prevent clogging or contamination.

Low efficiency (panel-type) Medium efficiency (bag-type)

HEPA and ULPA filters Activated carbon filter

Dampers

• A damper is a valve or set of blades that open and close to control the air

flow.

• Dampers are located in the mixing chamber to control the ratio of return

air to outside air and the amount of exhaust air.

• They also regulate the flow rate of supply air in the system.

Humidifier

• A humidifier is needed in cold climates to increase the relative humidity of

dry outside air.

• Evaporative: dry air blown over a reservoir will evaporate some of the

water.

• Vaporizer: steam or vapor from a boiler is blown directly into the air

stream.

• Spray mist: water is diffused either by a nozzle or other mechanical means

into fine droplets and carried by the air.

• Ultrasonic: A tray of fresh water in the airstream is excited by an

ultrasonic device forming a fog or water mist.

• Wetted medium: A fine fibrous medium in the airstream is kept moist with

fresh water from a header pipe with a series of small outlets. As the air

passes through the medium it entrains the water in fine droplets.

Heat Recovery device

• A heat recovery device is a heat exchanger placed between the exhaust

and supply air streams.

• It creates energy savings and increased capacity by transferring heat from

the exhaust air to the supply air before it is conditioned.

• Some common types are cross plate heat exchanger, thermal wheel, run

around coil, and heat pipe.

Controls

• Controls manage the various components of the air handler by regulating

air flow rate, temperature, humidity, and air quality.

• Controls can be manual or automatic and range in complexity.

• Simple systems may be just on/off control with or without temperature

control.

• More complex system controls may be fully automated using temperature

sensors, humidity sensors, actuators, and motors.

Vibration Isolator

• Air handler blowers, especially in large systems, create a large amount of

vibration and noise that can be transmitted through the ducts.

• Vibration isolators are flexible sections often placed on both end of the air

handler and between the fan and the rest of the AHU.

• The fan compartment can also be placed on springs to further limit

vibration.

• The vibration isolators dampen the vibration transmitted to the ducts.

THANK YOU