AgOps Vol1 2017 - Grownetics · Hydroponics was born from a desire to grow plants where soil was...

Transcript of AgOps Vol1 2017 - Grownetics · Hydroponics was born from a desire to grow plants where soil was...

Vol. 1

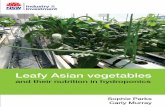

Efficient Cultivation Technology for a Changing World

Vol. 1Trends & Methods inEfficient Indoor Cannabis Cultivation

Vol.12017

AgOps

ops.ag

Cannabis Controlled Environment Ag

Cannabis cultivation facilities are the most advanced in the world. Consistently growing the highest quality crop requires tight environmental controls, optimal efficiency, rigorous quality audits, and maximum square foot utilization. Managing all this can be a challenge unless all components are carefully designed to work together flawlessly. Grownetics leads the industry in efficient cultivation systems and has dropped operating costs over 60%. See our testimonials and University of Colorado affiliated study at grownetics.co

Grow Ops Delivered

Flora Crop Monitoring & AlertsLive Crop Monitoring, Mapped Interface, Custom Alerts

Optima Batch Analytics & ReportingBatch Analytics, Custom Reports, Breeding Tools

Atmos Crop Directed Automation Strain Specific Environment & Automation Recipes

Crop Monitoring & AlertsObservation

Grow Automation & ControlsCultivation

Batch Planning, Analysis& Reporting

Batch Mgmt

CropCircle Enterprise Cultivation SuiteFull CEA Facility Optimization, Process Automation, Task Mgmt, Real Time Cross SiteMonitoring & Analytics.

One platform, all sub-systems, real time monitoring, batch analytics, and crop driven automation

Grownetics makes tools for modern cultivation facilities.

2

(CCEA)

grownetics.co | [email protected]

. . . . . . . . . . . . . . . . . 13 . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . .12

Contents:

0.1 - What is CCEA? 0.1 - Contents

1.0 - Intro to CCEA Goals 1.1 - Grow in Soil or Hydroponics 1.2 - Example Floorplan: CCEA Warehouse 1.3 - Example Floorplan: CCEA Greenhouse

2.0 - Cultivation Systems 2.1 - Flora™ - Sensing & Crop Monitoring 2.2 - Atmos™ - Automation & Controls 2.3 - Optima™ - Batch Management & Analytics 3.0 - CCEA Grow Ops 3.1 - CropCircle™ - Multi-Site ECS 3.2 - Grownetics Efficiency Study 4.0 - Trends & New Technologies 4.1 - Efficiency Spotlight DSS Lighting 4.2 - Featured Service & Hardware Partners 4.3 - Notes

. . . . . . . . . . . . . 4

. . . . . . . . 8

. . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . 6. . . . . . . . 7

. . . . . . . . . . . . . .10 . . .11

. . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . .16 . . . . . . . . . . . . . . . . . .18

. . . . . . . . . . . . . . . . . 14

. . . . .15

. . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

grownetics.co | [email protected]

grownetics.co | [email protected]

What it really takes to be successful.

CCEA Facility Design Goals

Efficiency Research& Breeding

Quality & Consistency

The better your CEA facility prep work, the better your outcomes will be. The rapidly dropping wholesale price as well as the serious challenges that come with cultivation and compliance at scale need to be considered. In every industry there are standards that must be met. This is especially true when your product is a living, breathing plant. One that has been cultivated in a multitude of environments from the high mountain deserts of the Himalayas, to the tropical islands of Southeast Asia. Will your GrowOps be dynamic enough to produce consistent quality no-matter the genetic variety being grown? Will you be efficient enough in time and energy to run research and

breeding programs of your own?

There are many options when it comes to cultivation methods and systems, the key is tuning your facility and operations towards your specific goals.

4

grownetics.co | [email protected]

Grow in Soil or Hydroponics?Soil has been fundamental for the evolution of the cannabis plant for its entire existence. Soil gives the plant a sturdy foundation on which it can create a strong root base, which is the first step towards healthy plants. Different fungi and mychroriza work to break down all of the usable nutrient elements in a particular soil. Depending on where in the world the plant is located, that soil will be different as well. But plants, like humans, require a steady diet of balanced micro and macro-nutrients to stay healthy and produce the most flower possible. Today, soils range from very basic and inert with almost no nutrient value, to “Super Soils” that provide all of the nutrition a plant will need for at least the first few weeks.

Hydroponics was born from a desire to grow plants where soil was either not available or not convenient. From NASA to classrooms to 30,000sqft hydroponic farms, it has become a highly efficient and productive way to grow plants. In commercial production facilities, ‘Flood & Drain’ and drip systems are most common and easy to setup. In a flood and drain setup the plants sit in a rockwool cube (which is basically limestone spun like cotton candy). It is in an inert and pH stable media that allows the roots to overtake it and create a strong base without the use of soil. This tray is flooded by a reservoir once or twice a day, depending on the size of the plants and desired growth speed. Another style used commonly employs drip stakes or a drip device and piping from the reservoir, usually in an adjacent room

with the dosing machines for nutrients. This system will run anywhere from 1 minute to an hour depending on the size and desired growth schedule of the plant. Most of this water is drained to waste and the reservoir refilled and remixed when empty. Deep water culture systems use a linked together system of large 15 or 30gal buckets. A chiller is commonly used to maintain a water temperature of 68-70 deg F. The plants in this

system will be very, very large as well making DWC an efficient system, especially since the water is recycled and not drained to waste.

The most common approach is a hybrid one, leveraging hydroponic and soil techniques for a high-output, resilient cultivation. Combining porous soils with a coco coir base allows a living soil to buffer the roots with excellent drainage for regular feeding cycles.

The Black Hole dripper (pictured above) has large drip holes so less clogging will happen, especially with thicker nutrients.

5

grownetics.co | [email protected]

Example Floorplan: CCEA Warehouse

40,000sqft CCEA Warehouse

6

Res SensorArray

3D Crop SensorArray Control Servers

Network Hub

Lighting & Automation Control Panel

Grownetics Hardware Key:

Site Appliance Key:

Fan or Air VentingEquipment

LightFan Coil UnitHot & Cold Air Dehumidifier

40,000sqft Warehouse Cultivation

The following floorplans are designed to give a high level overview of the types of cultivation systems you may consider employing. We use a 40,000sqft urban cultivation warehouse and 50,000 sqft greenhouse as our guides to see two common approaches to CCEA cultivation at scale. These are not complete

plans but are enough to give a clear picture of cultivation sub-systems.

grownetics.co | [email protected]

Example Floorplan: CCEA Greenhouse

42' -

0"

251'

- 6"

42' -

0"

42' -

0"

42' -

0"

42' -

0"

42' -

0"

216' - 0"

42' -

0"

168' - 0"

25' - 0" 15' - 0" 30' - 0" 14' - 10" 17' - 10" 61' - 0"

19' -

9"

19' -

9"

DR DR DR

DR

SECURITY

NVR SAFE

WALK-IN RINSE TROUGH

STORAGENOOK

103

113

112

BREAK ROOM109

CAST IN PLACECONCRETE

VAULT110

RESTROOM107

CHANGING AREA/ SHOWER

108RESTROOM

105

LOCKER AREA106

ENTRY /SECURITY POINT

104

CORRIDOR19

JANITOR'SCLOSET

111

OFFICE102

LOADING AREA /PREPARATION

101

SECURITY17

LOCKABLE SECURITYCLOSET

THREE WIRELESSPANIC DEVICES

Clone & Propagation

Dry & Cure

Processing

Flower 1

Flower 2

Flower 3

Flower 4

Veg 1

7

Res SensorArray

3D Crop SensorArray Control Servers

Network Hub

Lighting & Automation Control Panel

Grownetics Hardware Key:

Site Appliance Key:

Fan or Air VentingEquipment

LightStandaloneHeating Unit

50,000sqft Greenhouse Cultivation

grownetics.co | [email protected]

Cultivation Systems

+ Tight Environmental Controls+ Security+ Insulation+ Location and Logistics

+ High in Efficiency+ Mass Production Oriented+ Expandable+ Affordable

Warehouse or Greenhouse

+ Root Buffer+ Beneficial Bacteria+ Lower Startup Cost+ Tried & True+ Better Flavor

+ Tighter Feeding Controls+ Highly Automated+ No Soil Pests+ Recirculating Setup Possible+ Faster Growth

Soil or Hydroponics

+ Organic+ Beneficial Bacteria+ Tried & True+ Better Flavor

+ Consistent Feed Recipes+ Proven Results+ Clean Accurate Feeding+ Many Options

Custom Blend/Nute Teas or Multi-Part Nute Systems

+ High Efficiency+ Heating/Cooling/Dehum in One+ Tight Zone Climate Control

+ Cost Effective+ Scalable & Modular+ Widely Available &Serviceable+ All-in-one Systems Available

Water-Based Chillers or Split Systems

+ High Efficiency+ High Output+ Lower Up-Front Cost

+ Highest Efficiency+ Spectral Control+ Less Heat Load+ Long Bulb Life

Double Ended HID or LED/Induction

HVAC

Lighting

Grow Medium

Nutrients

Facility Type

8

grownetics.co | [email protected]

Grownetics Sensing & Crop Monitoring

9

Open Sensor Platform Mapped to Your GrowFlora™With Flora™ high-resolution crop sensing, one grower can monitor massive grow operations at a glance. It is the first open sensor platform designed to integrate any sensor on the market. Flora helps you monitor the micro-climates of your plant canopy in real time. In addition we offer sensing for every input to the plant and facility: reservoir, soil, light, and energy usage are just some of the things we can monitor. For a full list of current sensors please see our website.

Power Control& Monitoring

Fill Level Advanced PAR Sensor

EC pH

Air Temp Water TempDissolved Oxygen

Humidity CO2

Some of our Sensors

grownetics.co | [email protected] 10

Grownetics Full Facility Automation & Controls

Crop Directed Automation Integrate All Sub-SystemsAtmos™Atmos™ is the Grownetics crop directed automation and controls platform. It allows us to integrate all cultivation sub-systems into one control and monitoring platform that can then be controlled via strain-specific recipes. Have zone set points change depending on what is being grown in the zone. Update recipes in real time based on the latest batch analytics coming from the Optima™ Analytics and Reporting tools. Combined with energy monitoring we can also monitor all facility cultivation equipment.

Irrigation NutrientDosing

UniversalI/O

Platform

LED SpectrumHID Light

CO2 Dosing FansHVAC

Some of Our Control Options

grownetics.co | [email protected] 11

Grownetics Batch Management and Analytics

Batch Management Processing & AnalysisOptima™

Optima™ integrates batch management and individual plant tracking with our high resolution crop sensing.

Make the tedious process of data collection and correlation a thing of the past. Track every single plants environmental conditions from clone all the

way through harvest, dry, and cure. Review top producers historical data to optimize batch recipe’s every single harvest.

“If you can’t measure it, you can’t improve it.” - Peter Drucker

12

CCEA Grow Ops

Managing a CCEA Facility & Developing Best PracticesGrowing high quality Cannabis doesn’t have to be complicated but growing it at scale and continually improving quality and consistency can be. To keep things simple remember that all cultivation processes and systems should be aligned with the mission and goals of the company and brand. We built CropCircle, our enterprise cultivation suite (ECS) to help

commercial cultivators implement SOPs and continuously share improvements to recipe’s and workflows.

CCEA Facility Workflows & Tasks1.0 Cultivation & ProcessingBatch & Strain ManagementCrop MonitoringWorkflow Management

2.0 Pest MitigationMonitoring for susceptible climateMonitoring for plant health/stressRegular Cleaning & Checks

3.0 Quality Control & GMPTesting & Test DesignStatistical Quality ControlGood Manufacturing Practices Workload mgmtWorker Oversight

4.0 ComplianceIndividual Plant Tracking & ReportsRegular Self Audits

5.0 Human ResourcesHiring & TrainingCollaborative Cultivation Tools

6.0 Facility Monitoring & SecurityEquipment Monitoring & Regular MaintenanceSecurity SystemsSecurity On-Site

7.0 Logistics & Supply Mgmt Inventory & StockingPurchasing & Receiving

8.0 R&DBreeding Programs and Equipment/Systems Design

grownetics.co | [email protected] 13

REAL-TIME 3D CROP MONITORING CROP-DRIVEN AUTOMATION BATCH MGMT & ANALYTICS

Flora Atmos OptimaBe everywhere at once with our high-resolution crop sensor network. View all your data spatially on a real-time weather map of the micro-climates in your facility.

Our future-proof open middleware allows you to connect any sensor you desire. Temp, Hum, PAR, CO2, pH, EC, Dissolved Oxygen, Water Flow ... and many more.

Control you environment based on what’s going on in the canopy of your plants, not the thermostat on the wall. Control spectral recipes of LED lights for greater efficiency and faster harvests.

Integrate all facility sub-systems into the most powerful and dynamic CEA automation and hardware monitoring platform.

Optimize grow operations with batch management, individual plant tracking, full facility analytics, quality control, and audit scheduling.

Integrate task management into batch automation recipe’s for labor tracking.

Grownetics Enterprise Cultivation Suite

CropCircle Full CEA Facility Optimization, Process Automation, Task Mgmt, Real Time Multi Site

Monitoring & Analytics

Track every aspect of your commercial grow operations in one place. Track labor and tasks, automate processes and workflows. Share cultivation

recipes and best practices across multiple locations.

Custom reporting, supply chain management, product pre-sales with option for public facing wholesale website.

One platform, all sub-systems, real time monitoring, batch analytics, and crop driven automation

grownetics.co | [email protected] 14

Colorado University Research Group Entrepreneurial Solutions breaks down the savings and efficiency gains cannabis cultivators can expect to see when fully optimizing their facilities with Grownetics. The case study breaks down gains into

four main categories: Lighting/Energy, Water Usage, and Labor Costs. Read the full study at grownetics.co/news

90%

LIGHTING

DATA LOGGING

TOTAL SAVINGS ESTIMATE

WATER Grownetics enables water cost savings of 42%-94% when compared to an analog hand watered grow (using ASA Best Management Practices) and an automated grow without Grownetics. Furthermore, Grownetics is able to recapture and reuse 82% of the water in a typical hydroponic system.

Dynamic Supplemental Sunlight (DSS) System drops lighting energy cost by 87%-90% when compared to traditional High Pressure Sodium (HPS) grow lights.See more about DSS on page 16.

Cannabis growers spend approximately 30 hours per week logging and aggregating data. This amounts to roughly 4.5 hours per day. Growers could save almost 50% of the labor time and cost spent logging and aggregating data by using Grownetics.

With proper integration of the Grownetics system, growers could see significant labor cost savings regardless of the size of their operation. Assuming a harvest size of .75 lbs per plant and 5 harvests per year, the labor cost savings that Grownetics systems enable could account for a margin increase of 1.25%. Comparing labor cost savings to overall cost of production, Grownetics has the potential to deliver a 27.75% decrease in cost of production. Thesecalculations reflect an average $900 cost of production.

Grownetics can be easily implemented with grow operations of any size. The chart and table below show the possible savings that Grownetics enables for grow operations between 10,000-500,000 square feet.

LABOR SAVINGS

Grownetics Efficiency Study

Overall, the study concludes that cultivators can expect cost savings between $444K and $22 Million per year.

University of Colorado associated research team, Entrepreneurial Solutions releases Grownetics savings study

grownetics.co | [email protected] 15

Trends & New Technologies

+ High Efficiency+ Heating/Cooling/Dehum in One+ Tight Zone Climate Control

+ Cost Effective+ Redundant Failover Design+ Widely Available and Serviceable+ All in one Systems Available

Water based Chillers

Hybrid CEA Facilities+ Tight Environmental Controls+ Security+ Insulation+ Location and Logistics

+ High in Efficiency+ Purpose Built & Turnkey+ Mass Production Oriented+ Modular

+ Root Buffer+ Beneficial Bacteria+ Better Flavor

+ Tighter Feeding Controls+ Highly Automated+ Faster Growth

Minimal Living Soil Blend

+ Highest Efficiency+ Spectral Control+ Less Heat Load+ Long Bulb Life

LED

grownetics.co | [email protected] 16

Efficiency Spotlight: Grownetics & DSS Lighting

PAR Metersmeasure PPFD

provided by Solatubes

Climate SensorsAir Temp, Humidity, CO2 Levels

WiFi CameraSecurity, TimelapsesGrownetics

grow optimization& intelligence

real-timesensor data log

data syncs in cloudback-up, remote access,

analysis scripts

LED spectrum & intensity

dimmer control

PAR Meter

drops in available PAR outside triggerincreases in LED intensity to ensure

consistent canopy light saturation

LED LED

LED

Dimmeron-demand blackout

Amplifierfocus light on canopy

Collectorcaptures sunlight, absorbs IR (no heat transfer)

we bring full spectrum sunlight indoors

the future of sustainable indoor agriculture

Core System Overview

0.98 g / watt - total watts 1.76 g /watt - light watts

26.56 g / sq ft

Production Metrics1st Harvest

approaching 30 - 35 grams / sq ftapproaching 2-3 grams / watt - light watts

2nd Harvest

Sustain commercial production levels w/ 80% reduction in energy demand!

grownetics.co | [email protected] 17

Efficiency Spotlight: Grownetics & DSS Lighting

82% of water used was reclaimed

Water Used: 326.5 galWater Reclaimed: 268.0 gal

Plant: 9.26 gal

Water Metrics

8 wk flowering phaseASA BMPs suggests 160 gal/plant

2,500 sqft HPS vs SunGrown Indoor

Water (re)Use 100sqft 24 Grape Ape plants

630W LED LX602 lights = up to 630W/light. 50 LX602 remote controlled291 kW x 12 hr cycle ~ 92,160 kWh / year

DSS + LED Option

HPS Option

= 620,640 kWh SAVED / yearor $125,000 (@ $0.20/kWh)Drop your COGs without effecting yield or quality

1000W HPS lights w/ 100W Ballast = 1100W/light. 150 HPS lights = 165,000W or 165 kW, on/off only165 kW x 12 hr cycle

~ 712,800 kWh / year

Net Water Used: 58.5 gal

18grownetics.co | [email protected]

Grownetics Partners & Additional Resources

Full Cultivation Development Management and Consulting

CCEA Systems Consulting & Supply Chain Management

Efficiency Partners & Integrations

FALCON BRIDGE CONSULTING

urban-gro.com | [email protected] | 720.390.3880

precisioncultivationcompany.comjim@precisioncultivationcompany.com

falcon-bridge.com | [email protected]

spanishpeaksdevelopment.com

CCV Research

carrierwest.com | [email protected] | [email protected]

surna.com | [email protected] | 303.993.5271 heliospectra.com | [email protected]

ShiftCannabis.com [email protected] 1.866.744.3848

19

Notes & Next Actions