ISSUE 156 FRUIT GROWING IN 2060 - Hydroponic...

Transcript of ISSUE 156 FRUIT GROWING IN 2060 - Hydroponic...

SWEET HARVESTUnprecedented growth in Australian berry industry

AUTUMN WOESRoot rots, Pythium and Phytophtora

SUBSTRATE CALULATORGetting the most out of substrates

READER INQUIRIESHow is a blend valve used in recirculation?

FRUIT GROWING IN 2060

JUNE 2015

ISSUE156

The Commercial Growers’ Magazine www.hydroponics.com.au

Special Feature

Australian

Berry Industr

y

Practical Hydroponics & Greenhouses . June . 2015. 3

AustralianBerry Industry

Snapshot

From The EditorPublished by:Casper Publications Pty Ltd

(A.B.N. 67 064 029 303)

PO Box 225, Narrabeen, NSW 2101

Tel: (02) 9905-9933

Managing EditorSteven Carruthers

Contributing AuthorsRick Donnan

Christine Brown-PaulJohn WhiteMike Nichols

Advertising SalesMark Lewis

Tel: +613 9432-5428Email: [email protected]

Subscription HotlinesPh: (02) 9905-9933

(Int.) Tel: +612 9905-9933

Email: [email protected]

Facebook‘Like us’

www.facebook.com/PracticalHydroponics

Twitter‘Follow us’

http://twitter.com/#!/phgonline

Editorial Information

Practical Hydroponics & Greenhouses welcomes

freelance contributions and letters with a

hydroponic , greenhouse or IPM focus .

Photographic material should be good quality

colour prints or transparencies, clearly named and

captioned. Copy is also accepted by email or disk in

Word format. Hi-resolution digital images are

accepted – .tif, .jpg, .eps or .pdf format. No

responsibility is accepted for loss or damage to

unsolicited material.

© Copyright Casper Publications Pty Ltd 2015. All

material in Practical Hydroponics & Greenhouses is

copyright. No part of this publication may be reproduced

without the written permission of the Publisher.

www.hydroponics.com.au

ISSN 2202-1485

Berry production promises to be the next big thing in the Australiancommercial hydroponics and greenhouse industry, driven by new varietaldevelopments, better growing systems, and consumer demand for safefoods that deliver health benefits. Over a relatively short time, the industry

has expanded from the cooler regions of southern Australia to the sub-tropicalregions of NSW and Queensland, and soon to tropical Far North Queensland. Today, the increasing growth in the global berry market is not only about fresh

soft fruits, but also value-added products such as dried and frozen products, juicesand cordials, sparkling wines, wines and ports, jams, purees and sauces, andpharmaceutical-grade vitamin supplements. To the surprise of many, the recenthepatitis-A scare from imported frozen berries has only served to increase demandand consumption for Australian fresh berries, even though they cost a little more. Inthe not too distant future, Australian fresh berries will be available throughout theyear, thanks to the development of varieties that fruit year round, and bettergrowing systems that improve yields and quality. When year-round supply meetsdemand, prices can be expected to come down. In this issue, we present a special feature on the Australian berry industry, and

talk to industry leaders and a cross-section of berry growers using different growing methods—greenhouse/hydroponic, organic and soil production techniques. Each growing method has it challenges, but all are buoyed by the increasing demand and good prices for fresh berries. Our feature article is a glimpse into what growers will learn about the berry

industry at the coming national conference, to be held at Jupiters ConventionCentre, Queensland, in early July, and the International Berry Organisation seminarto be held in Coffs Harbour, NSW, in September 2015. While the former bringstogether Australian berry experts and growers, the latter brings togetherrepresentatives from the world’s top producing berry countries with the objective ofsharing information and analysis on the current state of the industry. Coffs Harbourwas chosen as the seminar host because it is the main blueberry growing region inNSW, an industry valued at $120-$130 million. More details about these events canbe found within our feature article, Sweet harvest. While the aim of industry gatherings is to share information, they are also

breeding grounds for ideas, and they often become pathways to future directions. Our story, Fruit growing in 2060, is a pointer to expected future growth in the protected cropping industry. In recent years there has been worldwide production of high quality fruit under protective cropping, however, not in Australia or New Zealand. That will change. In Europe, there is a swing away from field-grown strawberries to greenhouse production, which grows better quality fruit and provides a more stable supply. Ditto other berry products. Weather sensitive crops such as cherries are also starting to appear under protected cropping structures. For orchard crops such as cherries, significant advantages of protected cropping are bird protection and the effective use of biocontrols, instead of using chemical sprays to control pest and diseases. The author says the writing is on the wall for high quality fruit production—adapt or disappear.

Steven Carruthers

Practical Hydroponics & Greenhouses . June . 2015. 5

TRADE DIRECTORY

A&D Weighing . . . . . . . . . . . . . . . . . .6

ACE Greenhouses . . . . . . . . . . . . . .24

AIS Greenworks . . . . . . . . . . . . . . . 10

Autogrow Systems . . . . . . . . . . . . . 31

Besgrow . . . . . . . . . . . . . . . . . . . . . .19

Coast Guard Netting . . . . . . . . . . . . .4

Exfoliators . . . . . . . . . . . . . . . . . . . .29

Extrusion Technologies Int. . . . . . . .22

Faber Greenhouses . . . . . . . . . . . .OBC

Faber Greenhouses . . . . . . . . . . . . .13

GOTAFE . . . . . . . . . . . . . . . . . . . . . .21

Legro . . . . . . . . . . . . . . . . . . . . . . . .17

Pestech . . . . . . . . . . . . . . . . . . . . . . 12

Powerplants . . . . . . . . . . . . . . . . . IFC

ISSUE 156 :: JUNE 2015 :: THE COMMERCIAL GROWERS’ MAGAZINE

Disclaimer

The information contained in this magazine whether

in editorial matter or in feature articles or in

advertisements is not published on the basis that the

Publisher accepts or assumes liability or responsibility

to any reader of the magazine for any loss or damage

resulting from the correctness of such information.

www.hydroponics.com.au

A Magazine forCommercial Growers

Advertising Inquiries

Tel: +61 (03) 9432-5428

Sweet harvest

Fruit growing in 2060

Substrate Calculator

Autumn Woes

Features

Sweet harvest ......................................14

Improved growing techniques and new

varieties have fuelled unprecedented

growth in traditional and hydroponic

production of Australian berries.

Fruit growing in 2060 ..........................26

Fruit industry forecast to become a

‘protected cropping industry’, similar to

how tomatoes have become over the

past 20 years.

Practical

Substrate Calculator ...............................32

The Cultilene substrate calculator

enables users to calculate and quantify

the accuracy of irrigation systems.

Autumn Woes ......................................36

Combating Pythium and Phytophthora

in the hydroponics, seedling and

nursery industries.

Departments

From the Editor......................................3

Reader Inquiries ....................................7

News & Products .................................11

Industry Profile ....................................38

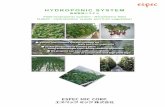

Cover Image: Greenhouse hydroponic

redcurrant production in Belgium.

Reader Inquiries

QuestionHow is a blend valve used in recirculation? I attended one of the recirculationworkshops in which you were a co-presenter. I am finally thinking of taking theplunge with my cocopeat system, but I amconfused about the use of a blend valve incontrolling the recirculation volumes.

Answer

Media-based hydroponic systems From years ago, similar to today, mostcommercial hydroponic systems havebeen media based. Crops are planted intobags or boxes of a suitable growingmedium and fed with nutrient solutionthrough drippers. To keep the nutrientsolution managed, a proportion of the feed(typically about 30%) is drained off.

SterilisationIn Holland in the 1980s, the progressivebanning of methyl bromide for sterilising

the soil in glasshouses led to a move outof the soil into soilless culture(hydroponics). These were the media-based systems described earlier, mainlyusing rockwool. Some of these systemswere ‘closed’, that is, recirculated, butmost were ‘open’, that is, ‘free drainage’. Unfortunately, in the early 1980s a rose

grower using recirculation had a wellpublicised total crop loss because of adiseased plant infecting the entire crop.By the 1990s, rising levels of nutrients

in the canals led to the banning of run-offfrom greenhouses from hydroponicsystems and especially from soilgrowing. This led to all Dutchgreenhouses having to convert torecirculation by the year 2000. Because of earlier crop losses, the

starting point was to prevent the possiblespread of disease in the recirculatingsolution. To achieve this, the Dutchindustry decided that it was essential to

sterilise with a ‘total kill’ of potentialrecycled pathogens. This meant that thefirst potential systems to be disregardedwere continuous flow systems such asNFT (nutrient film technique), because thevolume of solution to be sterilised wasunworkably huge.

RecirculationThe end result was that the media-basedsystems were retained, but with the run-offsolution collected, sterilised and recycled. In summer conditions, with a mature

crop such as tomatoes, the uptake ofwater (for cooling the plants bytranspiration) will be relatively higher thanthe uptake of nutrients. This results in arise in EC (electrical conductivity) from thedripper to the drain for each container. Typical figures for tomatoes would be a

dripper feed EC of 2.6 mS/cm rising to 3.7mS/cm in the drain, when running off 30%of the feed as drain for recycling.

Thanks for your letters

I have a few suggestions to help us better identify your problems, and hence give the most appropriate answers:

• Some of your letters are very long. This is not a problem, but they will have to be edited down before publishing. • Please keep your actual questions

short, and limit yourself to one, or at most two, questions. • Please comment as to whether you are a hobbyist or a commercial grower, and what

crop you are growing. • Please describe at least the basics of your system, especially whether you recirculate or not. This is vital information, but

often overlooked. Other useful information, if known, would be: media type, container size and depth, channel size, length and slope, solution volume

per plant. • For irrigation and nutrient questions, please describe your typical irrigation pattern over a day, plus how and when your solutions are

made up. If you have had any analysis done, such as your raw water, please attach a copy. • Include any extra information you wish.

Address your inquiry to: PH&G PO Box 225, Narrabeen, NSW 2101 AUSTRALIA Int: +612 9905 9030 Email: [email protected] Donnan

Practical Hydroponics & Greenhouses . June . 2015. 7

FreeEventsHome

INQUIRIESREADER

ArticlesFree Subscription DigitalFree

INQUIRIES

Reader IndexArticle Articles

ShopAbout InquiriesReader

Shop

degrees, different to colouredare the with sprayed d with weedsThose

results. the see can Iand herbicide ‘Roundup’ with patchweedd patch a it as use to decided Igrass,

containing can a had recentlyI grower. anonymousFrom an

Question

pesticides doHow

dying. obviously are all but degrees, plant entire the and wilting, are herbicide the

strength, recommended the at herbicide sprayer. hand rough a using killer r using weed d killer a

gone had which petrol,-stroke two some ng ? work pesticides do How grower.

? work pesticides

types Different yellow. turned has plant

now is It t is sprayer. hand same the using sprayed I day hot t day same that on Later r on sprayer.

petrol/oil spilt where seen Having off. gone

weeds of f weeds

later week a another d d another

killed has petrol/oil

ShedFodder Green 70:Issue

Sustainable 103:Issue

productionagricultural Hydroponics 63:Issue

Media Comparing 117:Issue

Popular

Shed Livestock – Feed Green

Aquaponics Sustainable

system production an as Hydroponics

Growing Comparing

PostsPopular

difference this explain youCan

hit. have droplets petrolactual petrol the with sprayed weedsThe

degrees, different to colouredare

tomato grower. NSW hydroponicFrom a

manage I doHow

? difference

green. still is leaf f is the of f the remainder r of The hit. yellow strong are There different. are petrol

dying. obviously are all but degrees,

tomato grower.

pH and addition acid manage

green. where obviously leaves, the on spots yellow

? rise pH

the

More

where

See

Hydroponics Planning 07:Issue

Everywhere Rabbits, 114:Issue

commercialin Importance 119:Issue

Hydroponics Planning 06:Issue

OrganicWhy Not

2 PartHydroponics Commercial Planning

Rabbits Rabbits, Rabbits,

greenhouses commercial ventilation of Importance

1 PartHydroponics Commercial Planning

? Hydroponics Organic

should I what suggest youCan

to like would I high. waslevel my f of f my feed done was analysisAn

leaf. pale the on darker r onup has what of f what symptomssome

nitrate ammonium liquidsome my f bring to acid of f acidamounts

greenhouses in tomatoes growI

addition acid manage I doHow tomato grower. NSW hydroponicFrom a

? do should

P the make will l make that but acid, more add to it was that advised laboratory the and my feed

That deficiency. iron is suggested been reduced only it has but t it has rise, pH the reduce to nitrate

rising still it is but t it is 6.0, about down pH my feed acid phosphoric use I Sydney. of f Sydney. south greenhouses

? pH rise and addition tomato grower.

worse. even level P phosphorus the that except OK, generally y OK, it was

veins the and pale are leaves young is, the That have I pH. 0.2 about by y about rise pH the reduced

been have I-off. run the in 7.0 about to sing adding been have I my pH. lower r my pH. to acid

(P) phosphorus

show veins had have

adding been increasing adding

The 35:Issue

Japan Greenhouse 98:Issue

Topic byIndex

Hydroponic inIPM

Flower Lisianthus: 40:Issue

IndexArticle

Factory Fodder The

In Production Greenhouse

Topic

Strawberries Hydroponic

Cut Specialty A Lisianthus:

Index

suggest you

me give you could yes If f?idea nurserymen few a are thereknow

specialise I which in nursery a haveI to hydroponics use IShouldd I

Nurseryman. South Wales NewFrom a

hydroponics use IShould

fundamentals. the on guidance some me hydroponics. in plants stock their r stock grow who nurserymen

of numbers large propagating in specialise? plants stock grow w stock to

Nurseryman.

stock grow to hydroponics

fundamentals. this that suggest you Would hydroponics.

from cuttings. trees native of f native range narrow w range a of f a

? plants stock

good

MoreSee

a is I from cuttings.

Challenges 85:Issue

Issue byIndex

Campaign ‘Truss 118:Issue

Chilling 91:Issue

Sand 02:Issue

HormonesGrowth Gibberellins 11:Issue

DigitalFree

the by Faced Challenges

Issue

Tomato Me’ ‘Truss

Zone Root The Chilling

Culture Sand

Hormones Plant – Gibberellins

Subscription Edition

://hydroponics.com.au/category/reader_inquiries/

me give you could yes, If f yes,?idea

[19/03/2013 3:27:55 PM]://hydroponics.com.au/category/reader_inquiries/

fundamentals. the on guidance some me

fundamentals.

MoreSee

Hydroponics Nurient 14:Issue

UsAbout

Aquaponics 101:Issue

Hydroponics Challenges 85:Issue

2 Part – SystemsHydroponics in Management Nurient

Revisited Aquaponics

Worldwide IndustryHydroponics the by Faced Challenges

We want to know about it. Reader Inquiries is intended to not only help the inquirer, but

also help other growers who may have the same problem.We welcome your letters and emails.

(Letters and emails are published anonymously)

Do you have a hydroponic or nutrient problem?

Postal Address: PO Box 225 Narrabeen NSW Australia 2101 Ph: +61 (0)2 9905-9933 Email: [email protected]

www.hydroponics.com.au

8 . Practical Hydroponics & Greenhouses . June . 2015

Practical Hydroponics & Greenhouses . June . 2015. 9

The run-off is collected, sterilised, and stored in a holdingtank, typically sized to hold two-days volume at maximumthroughput. Keeping the feed and drain flows in balance iswhere the blend valve is used.

Blend valveBlend valves are also known as three-way valves. Most peoplehave met a blend valve in normal life. A single tap combininghot and cold water to send warm water to a sink, shower, orbath, is a blend valve. It changes the proportion of hot and coldwater to give the temperature you want. In a greenhouse withpipe (hydronic) heating, the industrial version of this measuresthe temperature of the boiler water and mixes it with cold watervia a blend valve to give the temperature needed for the waterto go through the heating pipes.In the case of nutrient solutions, the measurement used for

blending is the EC of the raw water, recycle and mixed streams.The EC of the mixed stream is known as the ‘Pre-EC’, becauseit is before the addition of the fertiliser input and any acid/alkaliadded for pH control.

Pre-ECThe Pre-EC is a calculated figure, which keeps the relativeflows in balance spread over a day or two.

Pre-EC = % run-off x run-off EC (both for the previous full day)

For the figures mentioned above, of 30% run-off and run-off EC3.7, the Pre-EC calculates to:

Pre-EC = 30/100 x 3.7 = 1.1 mS/cm

Presuming a raw water EC of 0, the setting of the blend valve at1.1 mS/cm would be made up of 70% from raw water at EC = 0,and 30% from the recycle stream at EC = 3.7 mS/cm. Beforegoing on to the drippers, a further 1.5 EC would be added by Aand B fertiliser addition to bring the EC up to the feed value of2.6 mS/cm. So your management procedure is to measure and record

daily the % run-off and drain EC and use these to calculate thepre-EC setting for the next day. Check your recycled volume toensure that it is keeping in balance. b

Blend valve used with bore water. The hydroponic one is identicalwith recycle replacing bore water. (Image courtesy Global Water)

HYDROPONICGARDENING

bySteven Carruthers

ePUB

www.hydroponics.com.au/buynow

After your first harvest you willdelight in how simple hydroponicgardening is, and how nutritious,flavoursome and fragranthydroponically grown vegetables,fruit and flowers can be!

Hydroponic Gardening, designed for beginners ofall ages, teaches the basics of hydroponicgardening—how to grow hydroponic plantsfrom seed, and to feed them with naturallybalanced nutrients.

Whether you seek an ambitious hydroponicsscheme or simply an answer to growing a fewpots on your balcony, this eBook should helpyou by providing practical advice and answersto your questions, easy or difficult, to extendyour success as a hydroponic gardener.

Digital flip-page ePUB and PDF

Practical Hydroponics & Greenhouses . June . 2015. 11

New strain of Downy Mildew in lettuceA new strain of Downy Mildew (Bremialactucae) has been recognised by theInternational Bremia Evaluation Board(IBEB). The IBEB consists ofrepresentatives of the Dutch andFrench seed business associationsPlantum NL and UFS, and theorganisations of GEVES andNaktuinbouw, and supported by severalBremia investigators across Europe.The new strain (Bl:32) is mainly

limited to Europe and as such it is not ofmajor significance to Australian lettucegrowers. However, the announcement ofa new strain serves as a reminder forgrowers to be vigilant. Part of the Rijk Zwaan lettuce range is

resistant to this strain. Rijk Zwaan is abreeding company that endeavours tosupply growers with lettuce varietiesresistant to all official strains and locallydiscovered isolates, but this is notalways full insurance against Bremia. Rijk Zwaan advocates an integrated

approach to Bremia management;resistant varieties are a large part ofthis, but disease controls and hygienemeasures are also important to helpprevent the development of new Bremiaraces. Proper hygiene practices, such asremoval of debris and diseased plants,will reduce the spread of Bremia inlettuce crops.In a press release, Plantum explained

that Bremia lactucae, or downy mildew inlettuce, is genetically very variable. Evenwithin one lettuce production fieldseveral races may be present. In November 2014, the IBEB met in

Paris to evaluate the Bremia lactucaeisolates found in Europe in 2014. A totalof 411 isolates were on the gross listand discussed. About 62 Isolates (16%)of all 411 concerned were known andalready nominated Bl: races. Bl:29 wasmostly found. This race is widely spreadover Europe. Also Bl:24, Bl:30 and Bl:31were found (‘Bl:’ is the official code forraces of Bremia lactucae).Most of the isolates encountered in

2014 were not found before or were onlylocally spread. However, two isolateswere known from earlier years andappeared to have spread more widely.They became a candidate for nominationand a formal evaluation process startedin November 2014. In April 2015, IBEBconcluded that one candidate, althoughwidely spread across Europe, gaveinconsistent test results. making itimpossible to nominate.The second isolate, with sextet code

61-31-03-00, gave consistent resultsand is nominated as Bl:32. Bl:32 has been found in the past few

years in France, Germany, theNetherlands, UK, Austria, Switzerland,and Belgium. Recently, it also spread toPortugal and North Spain.

For more information on Bl:32, see theofficial press release or contact your localtechnical sales representative, or visit theRijk Zwaan website.

Ethical employment practicesThe recent ABC Four Corners expose hashighlighted that people on working visashave been exploited in various ways,including underpayment of minimumwages and entitlements. It is apparentthat this has been happening in a rangeof agricultural industries and varioussub-sectors.“Protected Cropping Australia (PCA)

condems the exploitation exposed on thisprogram,” said PCA Chairman, Leigh Taig.“PCA is disturbed and disappointed

that these practices have been occurringwithin Protected Cropping, andsymptomatic of broader issues that faceall of agriculture, and horticulture inparticular. We note that there has been aswift and appropriate response from themajor employer identified in theProtected Sector and they are no longerusing the services of the mentionedContract Labour Business,” he said.The protected cropping industry is

labour intensive, with labour costs being

News & Products

12 . Practical Hydroponics & Greenhouses . June . 2015

anywhere from 30%-50% of grossturnover. PCA contends that itsmembers recognise that a stable andskilled staff base is a key to businessactivity. In recognition of this over thepast decade and longer, the industry’speak body has been working withtraining providers to generate the skillsbase that underpins clear careerpathways within the industry.“We will continue to work with our

industry partners to ensure that ourindustry conducts itself with ethicalemployment practices, and provides asafe and sustainable workingenvironment. This applies for allenterprise staffing needs, be theyAustralian citizens or otherwise, asemployees or as contractors,” continuedLeigh Taig. “Our industry has come to rely on

people holding working visas to meetseasonal harvesting peaks in theworkforce to harvest many crops. Wemust ensure that visa holders continueto be attracted to Australia and find ourindustry appealing to work in,” he said.PCA has called on all growers to

conduct their businesses in an ethical

manner in respect to their employmentpractices. The industry association hasalso called on all levels of governmentto enforce workplace and employmentregulations that apply to all employers.The PCA Chairman said that attentionalso needs to be given to identifying thefactors which lead to the situationwhere, in the very same regions thatgrowers are unable to source skilledand semi-skilled labour, there remainssignificant unemployment.

Yates Junior Landcare CreativeGardening GrantsYoung people and schools acrossAustralia are being encouraged to applyfor one of 25 ‘Creative Gardening’ grantsworth $1000 launched in early May—after Landcare Australia received anoverwhelming response to an earlierround of Junior Landcare garden grantsfollowing the launch of Landcare into the2015 Australian Curriculum. Young green thumbs have proved that

successful gardens do not always needto be on wide open spaces. Last year, thepremier Yates Junior Landcare CreativeGardening Grants attracted excitingresponses to planting outside the box—including vertical lifecycle gardens,garden trains and bean teepees—as wellas reports of improved social outcomes.Yates gardening expert Angie Thomas

says: “The grants provide an excellentopportunity for kids to learn they caneven grow things in small places—whileconnecting with nature and learning thatgardening is about more than justplanting seeds.”Landcare Australia CEO Tessa

Jakszewicz says: “The participation andengagement of young people is vital toensure Landcare continues to lead theway in voluntary efforts looking after ourcrucial land and water resources.”“From our first-ever creative gardening

grants last year, we also received anumber of reports from groups aboutimproved outcomes for the kidsthemselves, increasing confidence, self-esteem and a sense of connectedness toothers and the community at large,” MsJakszewicz says.Landcare Australia is a not-for-profit

organisation, a grassroots movement thatharnesses individuals and groups toprotect, restore and sustainably manage

Australia’s natural environment and itsproductivity. It had its genesis in initiativesto improve agricultural productivitythrough sustainable land management.The movement has grown from this to abroader focus on sustainablemanagement of all of Australia’s naturalresource assets and now encompassesindividuals and groups across the wholelandscape from coastal to urban andremote areas of Australia.With over 6000 Landcare and

Coastcare groups nationwide there islikely to be a group near you, possiblyworking on a project right under yournose. Volunteers range from kids toretirees, surfers to farmers and CEOs tostudents. United by a shared desire tocreate positive change in theircommunities, these individualsrecognise that as a group their effortshave greater impact.The success of the Landcare model is

due in part to its bottom up philosophy. A Landcare group usually starts whencommunity members with commonobjectives connect over theirobservations of a local environmentalissue. For example, erosion of sanddunes due to mismanaged beach accessor weeds affecting agriculturalproductivity. Groups set their ownagenda, undertake work as often asthey like and choose their own projectsites. Groups may apply for fundingfrom a variety of different sources tosupport their work including Local,State, Federal government andLandcare Australia.The Yates Junior Landcare Creative

Gardening Grants are open to schoolsand youth groups in Australia.Applications close on 3 July 2015. Detailsand application forms can be found at:www.juniorlandcare.com.au

Landcare 2014 recipient.

Practical Hydroponics & Greenhouses . June . 2015. 13

2015 AUSVEG National ConventionThe AUSVEG National Convention, TradeShow and Awards for Excellence, to beheld at Jupiters Gold Coast from 25-27June 2015, will feature talks byeconomics experts James Bond andChris Murphy. As two of Australia’sleading economists, the pair areexpected to impart their years ofeconomic wisdom during separatespeaker sessions on Saturday 27 June.AUSVEG is the peak horticultural body

for Australian vegetable and potatogrowers. The Convention is expected toattract over 1400 delegates.James Bond is the Director of

consulting firm Equity Economics, andwill share his vast expertise inmacroeconomics, internationaleconomics and trade policy.Chris Murphy is another highly

respected figure from the world ofeconomics. As Director of IndependentEconomics, Mr Murphy has extensiveexperience in economic modelling and iswell known for developing the Murphymodels of the Australian economy.“The 2015 National Horticulture

Convention will provide these two leadingeconomics figures with the opportunity toaddress a wide variety of commoditygrowers on the serious issues affectingthe industry,” said AUSVEGspokesperson, Ms Winterbottom.

“We are excited that Mr Bond and MrMurphy will join the list of well-credentialled speakers, includingPresident and CEO of the United StatesPotato Board, Blair Richardson, to providedelegates with much needed information.”To register, download the delegate

brochure or register online. For moreinformation contact AUSVEG on (03) 98820277 or [email protected], orvisit www.ausveg.com.au/convention

Final call for PCA Industry awardnominationsEvery two years, Protected CroppingAustralia (PCA) offers industry awards torecognise and celebrate outstandingindustry achievement and excellence.The winners will be announced at the AISGreenworks Conference banquet to beheld at Jupiter’s Gold Coast on Mondayevening 6 July 2015.Protected Cropping Australia is the

peak industry body for commercialhydroponic and greenhouse growers, anindustry valued at around $1.8 billion atthe farm gate per annum. This isequivalent to 20% of the value of totalvegetable and cut flower production inAustralia (RIRDC report HSA-9A). It isestimated that more than 10,000 peopleare employed directly in greenhousehorticulture throughout Australia. PCA

members also include equipment andinstallation suppliers, specialistconsultants and advisors, researchersand educators.Inaugurated in 1999, the highest award

presented by the PCA is the ‘MostOutstanding Contribution to theProtected Cropping Australia IndustryAward’. The award honours an individualor organisation that has made anoutstanding contribution to the industryover their lifetime. Recipients include:Rick Donnan (1999), Dr Stephen Goodwin(2001), Dr Keith Garzoli (2003), StevenCarruthers (2005), Graeme Smith (2007),Mark Millus (2009), Geoff Connellan(2011) and Len Tesoriero (2013).Nominations are accepted from allsectors of the industry and are judged byformer recipients of this award.Other awards included the ‘Young

Achiever of the Year’ award, whichacknowledges, encourages andpromotes positive achievements ofyoung people under the age of 35 in theindustry; ‘Researcher of the Year’ ispresented to an individual who has madean outstanding contribution to theindustry through research; and the‘Industry Training Award’ recognises anindividual or organisation that has madea significant contribution to industrytraining or research extension. The industry awards are judged by the

PCA Board. Nominations close on Friday12 June 2015. Nomination forms can bedownloaded here. b

14 . Practical Hydroponics & Greenhouses . June . 2015

Improved growing techniques and new varieties—coupled withincreasing consumer demand—have fuelled unprecedented growthin traditional and hydroponic production of Australian berries.

By CHRISTINE BROWN-PAUL

Sweet harvestSweet harvest

Jolly Berries farm lies in the cool climate regionof Tumbarumba, NSW.

Following the recent hepatitis A/frozen berry health scare (see PH&G March 2015 / Issue 153), many Australian consumers subsequently tried to source locally grown frozen berries, however, found that

little were readily available. Due to harsh climatic conditions,very limited quantities of frozen berries and purees areavailable commercially in Australia. Executive Officer and Industry Development Manager at

Raspberries & Blackberries Australia (RABA), JonathanEccles, says that the only Australian frozen berries wereproduced by small-scale farmers value adding to theirproduct, and that they were sold only at the farm gate.“There’s no large-scale frozen berry industry in Australia,”

says Mr Eccles who adds that it is unlikely Australia wouldever have a frozen berry industry.“Frozen berries really came about because of the

seasonality of berries, and now we can buy fresh berriesnearly 12 months of the year.”In Western Australia, one blueberry grower is confident

more Australians will start seeking out quality, freshAustralian berries rather than the frozen variety."Unfortunately, there's not a lot of frozen berry product

produced in Australia because there's such a demand for thefresh product,” says Derek Fisher who has 13,000 blueberryshrubs on his property at Regans Ford, about 140 kilometresnorth of Perth.“I think you'll see a trend back to people seeking

Australian product. Mr Fisher adds that the margins forfresh Australian-grown blueberries were so high that it wasnot cost-effective to direct small quantities of 'seconds' fruitto the frozen market.He believes that Australia's berry industry will keep going

from strength to strength."I've seen some data that says it's one of the highest

margin agricultural crops you can grow," he says."It's capital intensive but once you get it in, and in

today's environment where there's not a lot of growers, itis high margin."

Blueberries go blockbusterAccording to the Australian Blueberry Growers’ Association,blueberries were first introduced into Australia in the early1970s. By 1978, it was recognised that the warmer climate‘Southern Highbush’ and ‘Rabbiteye’ varieties (originallygrown in the southern states of America) would grow on theNSW North Coast and produce high value, early season fruit.These varieties are harvested from June to February.In southern Australia, most of the blueberry production is

based in Victoria (mainly in the Yarra Valley) and inTasmania. The season starts in December and ends in April.As new varieties are released, a consistent supply ofblueberries will be available throughout the season.The Australian blueberry industry is among the premium

blueberry industries in the world. Today, 90% of blueberriessold in the Australian market are Australian grown. In thepast six years, the value of NSW’s blueberry crop hasincreased four-fold to reach more than $100 million. Of this,75% is sold fresh within Australia, 15% is exported to Asia

Practical Hydroponics & Greenhouses . June . 2015. 15

and Europe and 10% is processed, mainly as frozen product.Demand is outstripping supply, as supermarkets entice

consumers with berries as a drawcard into the fruit andvegetable sections. Industry leaders say that while flavour is a big demand driver

for berries, health benefits, convenience and multitude of uses,as well as ‘superfood’ boasts, have set the foundations forongoing domestic and global growth in consumption.Export wise, Chile, Argentina and China pose strong

competition due to their lower labour and production costs.The value of the Australian dollar and pest issues such asQueensland Fruit Fly affect the international competiveness ofthe Australian industry. In spite of sizeable set-up costs facing potential blueberry

growers, the profitability of blueberries makes them an attractiveand dominant crop in NSW's sub-tropical fruit industry.According to Australian Blueberry Growers Association's

industry development officer, Phillip Wilk, the NSW area underproduction had more than doubled since 2007 to 1100 hectares,with many former banana growers on the Mid North Coastswitching to berries and greenhouse vegetable production.

From hydroponic roses to hydroponic berriesTwo growers who have made the switch are Nicky and WadeMann, who have diversified their original hydroponic rosegrowing business, Roses 2 Go, to now include growinghydroponic blueberries and raspberries.“In 2003, we established Roses 2 Go Pty Ltd at Warnervale

on the NSW Central Coast. We had a 3000m2 greenhousewhere we planted 22,000 rose bushes; all grown in coco-peatand using re-cycled polystyrene broccoli boxes,” says Nicky, a2014 Nuffield Farming Scholar.“The boxes were elevated above a guttering system and all

water/nutrients are recycled in a closed irrigation system. “In 2014, the business added a 3000m2 Croft Venlo

greenhouse with an additional 22,000 rose bushes. Originally,we wholesaled all the roses directly to florists on the CentralCoast, Newcastle and Northern Beaches of Sydney,” she says.“Soon the business began retailing direct to the public and

before we knew it, we had three retail florist shops on theCentral Coast. “However, in the past two years the pressure from the

imported roses has slightly changed the direction of thebusiness into hydroponic berry production. Now we keep onlyone greenhouse for rose production and the other is nowdedicated to blueberries and raspberries,” Nicky says.“Our business is small and employs four part-time

permanents on the production side, plus my husband Wade(who is a 2015 Nuffield scholar), as well as employees on theretail side plus a couple of casuals at peak periods.”Nicky says that pressure from imported roses and the

general slowdown in the economy, where customers were

16 . Practical Hydroponics & Greenhouses . June . 2015

(Top to Bottom):Nicky Mann plants blueberries at her property on NSW’s Central Coast.In the past six years, the value of NSW’s blueberry crop has increased four-fold to reach more than $100 million.Blueberry plants laid out ready for planting.

Because there is already enough uncertainty.

“ How long can you grow potted blueberries with the same substrate? Eight years.”Ronnie Kersten, Legro sales

Seriously. Legro substrate is stable and nutritious for eight years. This not only yields you more fruit, but also gives you more control over your crop. No more refi lling or repotting the plants, and cultivating in pots also means more plants per hectare. We’ve seen it, it works, and it can work for you. So call my colleague Phil Badgery and see for yourself.

+61 (0)3 9555 5267 | [email protected]

being particularly careful of spending money on luxury itemslike roses/flowers, were drivers behind the decision to switchto growing hydroponic blueberries.“We felt it was necessary to diversify and to spread our risk.

There is a soaring demand for blueberries and we felt therewas a bit of a challenge there growing them withinsophisticated greenhouses and hydroponically,” she says.“At first, it was a bit tricky securing plant material, as it is

pretty sown-up between the breeders and the fresh fruitmarketeers, however, we were lucky in that Paul Lloyd fromPerfection Fresh and Natalie Bell from Mountain Blue Orchids(famous for its incredible world renowned breeder, RidleyBell) agreed to release to us six great varieties to trial growinghydroponically within our greenhouse. “Natalie was reluctant, as she felt she couldn't help us with

plant management and was not 100% convinced hydroponicproduction of blueberries was the way to go. While this washappening—and we were afraid we weren't going to get anyblueberry plants in time—we secured some public varieties ofraspberries to put in a trial just to safeguard ourselves incase we never secured any blueberries to fill the greenhouseand it would be empty for the season. Lots of lessons learntthere,” Nicky says.

Growing notesNicky Mann says she and her husband Wade grow theirblueberries in a twin-skin Venlo Croft greenhouse, using aNetafim irrigation system with a Galileo controller, which theycan access through ‘log me’ in on their iPhones.Nicky says she and Wade were so anxious to get on the

blueberry bandwagon, along with the rest of Australia andthe world, that they bought the necessary books andinvestigated the Internet for any information on hydroponicproduction of blueberries.“We didn’t see much available and anyone doing anything well

was not publishing it for the world/opposition to see,” she says.“Therefore, with Wade's extensive knowledge of hydroponic

production of roses and what we had discovered, we decidedto use 25-litre growbags from Garden City Plastics. We madeour own blend of coco peat and peat moss, which Wadebuffered before using. Each bag was mixed and hand-filled.That was a big job for a small family business.“We prepared 2500 bags and received three protected

varieties and three public varieties of southern high bushblueberries, which were one-year old-nursery plants. We placedthe bags in twin rows on plastic sheets to catch the runoff waterand nutrients, which we capture and recycle,” Nicky explains.“We use drip irrigation—water and nutrients are pulsed

through depending on light, temperature and humidity. Wehave two zones in the greenhouse, as the raspberries are onthe same feed as our roses and are members of the samefamily, Rosaceae. The other zone is dedicated to theblueberries and we keep the pH acidic to their liking.

18 . Practical Hydroponics & Greenhouses . June . 2015

(Top to Bottom): The first flowerings of the blueberries.An indication of the size of the blueberry fruit grown.The Manns use Orius to control thrips on the blueberries.

Practical Hydroponics & Greenhouses . June . 2015. 19

“The initial plan was to keep the blueberries in twin rows forthe first 12 months and then open up the spacing. However,we've had some delays in moving all the roses from the berrygreenhouse to the next door greenhouse, and then it was tooclose to Valentine's Day to move the roses, so the blueberrieswent a little wild and the rate of growth took us by surprise.Before we knew it we could hardly get between the bushes,”she says.“This was taking our blueberry fruiting wall to a whole new

level that was unmanageable. A huge mistake looking back,but we were also curious to see the rate of growth and how theblueberries were going to react to our greenhouseenvironment, which is a lot different to the Spanish-styletunnels that most growers are using. “It was also a little tricky keeping the balance between

vegetative and generative in the ideal warm growingconditions of summer. The production in the first six monthswas pretty good considering we only received the plants inlate January 2014, and the last shipment we were planting on11 February 2014. We remember it well—planting blueberriesand reaping red roses for Valentine's Day on14 February isnot ideal,” Nicky recalls.“It is still early days with our blueberries. We probably

should have managed our bushes a little more—we did do abending technique like we do in the roses and it workedfantastically, and we have figured out a good bushmanagement strategy now but maybe a bit late for a bumperharvest this coming season. “However, as long as we learn from our mistakes. We are

fairly isolated here on the Central Coast of New South Wales

and there are no other growers within 400km of us, so it’sfairly hard to ask neighbours for advice, etc. My father-in-lawgrows blueberries in Western Australia under tunnels and is alot more experienced than us but his conditions, greenhousesand varieties are different again,” she says.So what are some of the major challenges in growing

blueberries?“In the first year, we battled with thrips, which came from

the roses. We used Orius to control these, but it was a slowprocess to get them under control. To date, we haven’tsprayed the blueberries at all, as the regulations and what isavailable for greenhouse use is extremely limited so we areproud to just be using biological control agents. We had a fewleaf-curlers, too, but hand controlled these (i.e. we pulledthem off),” Nicky says. “Pollination is a bit of a challenge; we have to use honey

bees, which are not partial to hot or cold greenhouses. We'vebeen advised to use landmarks to help them navigate aroundthe greenhouse (i.e. big cut-out shapes in yellow and blue).We are now working with Jonathan Lidbetter of NSW DPI andhe is assisting with our beehive and making sure we keep thebees happy. “We have learnt a whole lot more about bees through the

start of Wade's Nuffield study on IPM in greenhouse berrycrops, but we have a way to go,” she says.In terms of the primary market for their blueberries, Nicky

says they are contracted to sell their protected varieties throughPerfection Fresh, while the public varieties are sold throughtheir two retail outlets (one at the farm and one in East Gosford).“We deliver the trays of berries directly to the Sydney markets

CE

LE

BR

ATIN

G 25 YEARS

O F S U P E R I O RG

RO

WT

H

Distributed by

Call for products and pricing:

Ph: 1300 695 098 www.gardencityplastics.com

Gropacs

Grocube

Besgrow Gropacs – the consistent product you can depend on every season

FOR PRODUCT RANGE & PRICING PLEASE CONTACT

Ph: 1300 695 098www.gardencityplastics.com

www.besgrow.com

Grobag

oducts and pricing:rustor presull fen rl for pren raloCP oducts and pricing:ts! Toducts and pricing:ts! Trustoducts and pricing:esulor pren rl fvl foalralP91300 6Ph:

ed byoduct suppl

Distribut

rustts! Tts! Trustesuloducts and pricing:en ror prl for prvol frPalC

opacs can be custGr

oduct suppled by

ent pronsistC

, consistoiroir, consistHigh quality C

oducts and pricing:ed by New Zoducts and pricing:rust85 099

ed byoduct suppl

ers fowealand gred by New Zrustoducts and pricing:

our specific gro suit yom made topacs can be cust

ou can depend ony yerery ye deliveliably and roduct supploduct supply and red by

ariety of gry bag, in a verery bag, in a vent in ev, consist

opaGr

earser 13 yvor oers f

ementsequirowing rour specific gr

ou can depend on

adesariety of gr

ocubeGroba

dencityplastics.comourself a.garoducts fwwwSee our pr dencityplastics.comor ydencityplastics.comoducts f91300 6Ph:

d Casino, Golers CupitJoducts fdencityplastics.com.garSee our prSee our pr.gar

wwwPh: PRICING PL

OR F

dencityplastics.comt stand 3dencityplastics.comourself a85 099

y 2015.ululy 2015.oast, 5-8 Jd Ct the PCA C9 a9 at the PCA Ct stand 3dencityplastics.comourself at stand 3ourself aourself at stand 3dencityplastics.com

dencityplastics.com.garwww85 0991300 6Ph:

CTAONTONTACEASE PRICING PL&RANGE ODUCT PROR

ROO R

IREPUSFO

SRRSAEY52GNNG

IN

RRA

BE

LE

CAT

ITI

ence, eronfonfert the PCA C

HT

WO

RROO R

S

.com

G

ow.besgrwww

ourselves in a refrigerated van. Our retail shops get freshberries daily from the farm and we advertise on Facebook re:availability. Any left over at the end of the day are frozen forfrozen berry sales and making ice-cream,” Nicky says.In NSW, growing hydroponic raspberries is rare, while

growing hydroponic blueberries is almost non-existent.However, Wade Mann believes their initiative is a winner."Most of the original raspberry growers and berry growers

were growing directly into the soil, whereas we believe that wehave a lot more control,” he says.Wade says this could see a longer window of production, up

to nine months of fruit-bearing raspberry plants."We certainly hope to have a longer window of production

and so ultimately, the yield would be greater. We would hopeto come into production earlier and obviously, fall out ofproduction a lot later,” he says.Jonathan Eccles says these longer windows of fruit

production are a very real possibility."With a system like this,

which is partially closed,you can actually control theproduction throughnutrient management aswell as through pruningand manipulating the lightlevels," he says.

New geneticsRaspberry nationalproduction is also on the rise, with latest figures showing ithas jumped from less than 500 tonnes a year in 2004 to inexcess of 3000t in 2014.Raspberries and Blackberries Australia industry development

manager, Jonathan Eccles, said while Victoria was still thelargest producer of raspberries, NSW was not far behind.“The introduction of low-chill varieties and varieties, which

fruit year-round, had prompted a significant production shiftinto the North Coast and Queensland,” he said.“So far, the growth in consumer demand is matching

production, and there are no indications of over-supply.”With its excellent climate for growing berries, Tasmania has

doubled its berry fruit production over the past five years. TheTasmanian Institute of Agriculture statistics estimates thecombined farm value of strawberries, raspberries and blueberries at $17 million a year.Mr Ecccles says growth in markets is backed by better

growing systems and new high yielding varieties."The growers are becoming a lot more sophisticated in their

production techniques. The increase in production in thesenew genetics is just extraordinary,” he says."It's highly feasible that we could see berries as being an

annual crop.“Today, we’re also seeing new genetics, which allow fruiting

in the spring, as well as autumn and that gives you year-roundproduction,” Mr Eccles says.“This increase in production using new genetics is just

extraordinary compared to what we’ve seen in the old varieties.“There’s no reason why new varieties can’t continue to

develop with disease resistance and keep increasingproduction,” he says.“It’s highly feasible that we can see berries being an annual

crop because of the intensity of production that’s just aroundthe corner. The genetic base of berries allows us to do a lot ofexciting things in plant breeding.” “So what will these new age berries look like?“When we think of raspberries, we think of the red

raspberry but there’s already a golden raspberry, and soonthere’s to be a black raspberry. Not to be confused with theblackberry,” he says."And there are various crosses. We've seen boysenberries

and loganberries."There are a lot of crosses that do happen,” he says."So it does expand the range, and it makes the product

exciting because there's always something new.”

20 . Practical Hydroponics & Greenhouses . June . 2015

RABA CEO, Jonathan Eccles.

International Blueberry Summit

The International Blueberry Organisation (IBO) will hold its fifthannual event at the Novotel Pacific Bay Resort, Coffs Harbour,New South Wales, Australia, from 7-9 September 2015. Theseminar will bring together representatives from the world’stop producing countries with the objective of sharinginformation and analysis on the current state of the industry.The IBO is a global organisation that brings together leaders

from around the blueberry world in all segments of theindustry, to learn, to share, to increase understanding, andpurvey information, to address mutual challenges andcoordinate potential solutions and to explore opportunities.Ultimately, the organisation exists to advance the health andsustainability of the blueberry industry.Coffs Harbour is the home to the world famous ‘Big Banana’,

being one of the first ‘Big Things’ in Australia. The city alsoboasts three major shopping centres as well as numerousbeaches closely located to the CBD. According to the CSIRO,Coffs Harbour has the most liveable climate in Australia, and itis nestled between a high mountain backdrop and dozens of“unspoiled” beaches. Coffs Harbour’s economy is based mainlyon farming (of bananas), tourism, and manufacturing.Novotel Pacific Bay Resort is a globally managed resort of the

Accor Company, located at Charlesworth Bay Beach, 3kmsnorth of Coffs Harbour. The resort offers luxurious and flexiblefacilities, including various types of accommodation, BaysideSpa Centre, Kids Club, golf course, tennis courts, restaurantand bar and pool and fitness facilities, direct beach access andequipment hire. The resort is renowned for its new PacificConference Centre, which is recognised as one of the mostattractive and workable conference and incentive venues inAustralia. The venue is approximately 15 minutes by car fromthe airport.If you are interested in becoming a sponsor or exhibitor at the

IBO Summit 2015, contact Jayne Hindle by emailing:[email protected] Ph: +61 2 6650 9800.

For further information go to:www.internationalblueberry.org/ibo-2015-summit

Practical Hydroponics & Greenhouses . June . 2015. 21

NEW ONLINE COURSE

Certificate III in Production Horticulture

NEW

yed boudly supportPr

NEW

COURSEONLINE

AFETTAFEGO

edu.au | 1300 GO

T

vic..egotaf.www

AFE (468 233)Tedu.au | 1300 GO

AFE (468 233)

Big playersBased in Victoria, Costa is Australia's largest private producer,marketer and exporter of premium quality fresh fruit andvegetables. The company also provides leading edge logisticsand supply chain solutions to the fast-moving FMCG (FastMoving Consumer Goods) and retail sectors; and provideswholesale and market services via Costa Farms.Costa markets its berries in Australia and New Zealand

through the Driscoll's Australia Partnership, which alsomanages production and planning and category management as

well as conducting R&D in breeding and varietal development. Costa is a world leader in blueberry genetics, which are

licensed through Driscoll's in many parts of the USA as well asthrough the African Blue Joint Venture in Morocco.In Australia, the company’s berry growing is focused in the

south-eastern regions of New South Wales, Victoria andTasmania, with growing sites in Corindi and Tumbarumba inNSW and at 9 Mile (Sulphur Creek) and Dunorlan in Tasmania. Costa is also establishing a new northern farming blueberry

operation on the Atherton Tableland.Across north-west Tasmania, Costa Group's berry division

grows 100 hectares of raspberries, blueberries, strawberriesand blackberries.Over the next five years, Costa is set to double its berry

production with the opening of the Costa Tasmanian BerryGrowth Project in East Devonport. The initiative is being madepossible by Tasmania's latest irrigation project, the Dial BlytheIrrigation Scheme.Federal Member for Braddon, Brett Whiteley, said the

Australian Government’s $1 million investment in the projectwould deliver a significant and much-needed economic boostto the region.“This project will see the installation of a modified

atmosphere system at the facility, allowing production andstorage to continue throughout the year.“The completed project will provide cold storage

infrastructure to support the continued growing of berries andallow an expansion of the current hectares under planting.“The project will also enhance Costa’s ability to supply

blueberries to the Australian market year round and tocompete against imports.“Over the life of this project almost 100 direct jobs and

potentially 700 indirect jobs will be created which, whencombined with the $14.5 million Dial Blythe Irrigation Scheme inSouth Riana, will see almost 1000 residents gainfully employed."Costa’s commercial manager, Cameron Wilkins, said the

95% water surety the scheme provides is vital to thecompany's future plans."Our berry production in volume will double in the next two

years, but the infrastructure builds over the next three or four

22 . Practical Hydroponics & Greenhouses . June . 2015

AIS Greenworks PCA Conference & Trade Show — Berry Speaker and Workshop Program

The AIS Greenworks Protected Cropping Australia (PCA) biennial Conference and Trade Show, to be held at Jupiters ConventionCentre, Gold Coast, Queensland, from 5-8 July 2015, includes a significant component for soil and hydroponic berry growers. Waitingfor your questions are a wide range of exhibitors with the latest technology from Australia, New Zealand, The Netherlands andelsewhere. The final day will be farm visits to some of the regions most advanced growing operations. Streams of interest will be vinecrops, leafy vegetables, flowers, aquaponics and berry crops. To register, go to website: www.pca2015.org

years are very exciting for the region," Mr Wilkins said."It will mean more jobs, more output and more revenue for

the State."We're not going to double where we are at with

blueberries, but certainly with raspberries and strawberrieswe're looking at doubling our production," he said."As new genetics become available with blackberries, we'll

more than double our foot-holding there."According to Mr Wilkins, irrigation costs were a big part of

their costs of expansion in the State's north."Just looking at the two developments that we're doing this

year, irrigation would be the second biggest component of theinfrastructure," he said."If you look at those two new builds, you're looking at $3

million plus in each investment, so irrigation would beupwards of $800,000 to $1 million."According to Jonathan Eccles, Costa’s plans for growth

spells good news for the Australian berry market.“We’ve now seen the world’s biggest berry marketer come

into Australia and that has certainly helped the market,” he says.“It’s also a benefit to the smaller growers because they’ve

been able to tap into those expanding markets.”

On the berry farmsNestled in beautiful rolling landscape between Emerald andUpper Beaconsfield in rural Victoria is Emily Hill Farm, run bySue and Chester Keon-Cohen. In 1982, 500 blueberries werefirst planted at the farm with another 500 in the early 2000s. “We started off with blueberries, and then grew advanced

trees from 1989 till now. We are just selling off remainingstock of trees: there will be no new planting for several years.We planted lemons and limes about 15 to 20 years ago, and abit of rhubarb,” Sue says.“Basically, it’s just Chester and me running the farm with

some casual help when required. We have been usingWWOOFers since 2005.WWOOF (World Wide Opportunities on Organic Farms, or

Willing Workers on Organic Farms), is a loose network ofnational organisations that facilitate placement of volunteerson organic farms. With hosts in 99 countries, WWOOF aims toprovide volunteers with first-hand experience in organic andecologically sound growing methods, to help the organicmovement, and to let volunteers experience life in a ruralsetting or a different country.“We obtained an organic certification in about 1987, which

we still maintain today,” Sue continues.Sue says one of the major challenges in running the farm

is pests.“Birds are a big problem, so all the berries are netted. We

first netted in about 1989.“Another problem being organic is weeds,” she says.Sue says that around half of Emily Farm’s crop goes to the

Practical Hydroponics & Greenhouses . June . 2015. 23

(Top to Bottom): Staff at Emily Hill Farm in rural Victoria.Raspberry and blueberry jam from Emily Hill Farm.In 1982, 500 blueberries were first planted at Emily Hill Farm withanother 500 in the early 2000s.

24 . Practical Hydroponics & Greenhouses . June . 2015

organic wholesale market, while the rest of the crop is sold atthe farm gate.“I have grown plants over the years and still do, but only sell

retail now,” she says. “We value add farm produce such as jams and cordials. We

freeze as much as we can but the last two years, most of ourproduce has all been sold by Easter.”

Jolly BerriesOn another berry farm in the cool climate region ofTumbarumba, NSW, Jolly Berries has 16.4ha of blueberrieswith minimal raspberries and blackberries. The farm waspurchased by Molly Crozier in 2009 who then established11.4ha of blueberries, while 5ha have since been planted. Anursery was constructed in 2011 to grow the new plants forthe new blocks. It was built as a temporary measure to caterfor the 5ha of additional plantings.“The established berries were planted around 1990,”

Molly says.“The farm produces an average of 100 tonnes, including 80%

fresh and 20% frozen. “We have around 13 full-time employees, but there are

around 50 people in the summer and six in the wintermonths,” she says.“We grow and harvest blueberries primarily for the

domestic market. The main fresh crop is hand-picked andpacked. The remaining product after fresh pick is harvestedand graded by machine for frozen product. This product isharder to sell than the fresh, as we are competing againstChile, North America and Canada. Companies can buy it

cheaper from those countries and in larger quantities.“We make the frozen product into wine, sparkling wine, port,

soap, jams, sauces, salad dressing, dried and chocolate-coated berries. This is to value add and cancel out the poorprice we receive for the bulk frozen product,” Molly says. Blueberries are hand-pruned every winter, then fertilised by

fertigation, which starts in spring and continues weekly untilafter harvest. In Tumbarumba, harvest runs from Decemberthrough to mid-March. Jolly Berries has eight differentvarieties—early, mid and late season. Northern Highbush andRabbiteye varieties.“We spray the flowers in spring with fungicide. This is the

only spray that is used, as it is cool climate fruit and we do nothave the diseases that warmer climate blueberries have. Theflavour is more intense for cool climate fruit as well. Mulch isapplied in winter and the rows are mounded for gooddrainage. The irrigation is drip,” Molly says.“There are two difficult management areas in blueberries.

These are picking, which is broken down into the hard task offinding staff to pick, then training them to pick the right fruit at areasonable pace. The other difficult area is weed management.” As in the case for Emily Hill Farm, birds are also a problem

at Jolly Berries.“We use gas guns, but production could be increased

dramatically if the farm was netted. Frost is also a problem inspring time in Tumbarumba, and last year, half of the farmwas wiped out with several frosts in spring. Jolly Berries hasone frost fan, but we could use two more,” she says.Jolly Berries grows exclusively for one agent in the Sydney

Irrigation SystemsAgriculture Consulting

Visibility Study Project Management

Installation

y Geddety or JoaneIlan Ktructing an enonsor c

e on irrigaor advicFeenhouse needsour grl yor alF

s.y Geddetactonject coy pree turn ktirtructing an enone cttion, climaertigation, fe on irriga

.eenhouse needs

tactoltron

sgeddeyjoSkype 0419 618 337Ilan 0419 618 377y Jo02 6968 3312 Phone

om.aus.ce@geddeacW 2665a NSyBin’ ale‘Pine V

seenhousee GrAc

F: +61 (0) 2 6962 9533: +61 (0) 2 6962 9588T

W 2680Griffith NSx 1509PO Bo

anna A60 B-, 58Shop 1aliatrerplas AustzMe

s0419 618 3370419 618 37702 6968 3312

om.au

om.auerplas.com.au

F: +61 (0) 2 6962 9533: +61 (0) 2 6962 9588

evanna Aalia

markets—XL Fruits and Vegetables Pty Ltd. “The fruit is sold to independents and is highly sought after

because it is cool climate with great flavour but moreimportantly, because our packing is more thorough than mostfarms. The quality and shelf life is exceptional. The fruit ispacked and chilled, then freighted by refrigerated truck toSydney. It takes two days from picking to get to Sydneymarkets for sale,” Molly says.Market specifications state that the product must have a

shelf life of two weeks, so this is the basis of Jolly Berries’dedicated packing program.“Blueberries can be a bit tricky to grow, and the watering is

a major factor that needs to be right. They have a shallow andfibrous root system concentrated in the top 40cm of the soil.They require 2-3 megalitres per hectare and are sensitive tosaline water. They do not like wet feet,” she says.“Keeping the weeds down so there is no competition and

frequent tailored watering is the key.”Molly says although she does not grow hydroponically, all

growers can learn valuable lessons in terms of value adding.“My message and passion in business is to understand that

the most important aspect of growing something is to valueadd your product. The prices and demand are good forblueberries and have been for many years. But there willcome a time when it will not be like that,” she says.“The apple industry and the wine industry have suffered in

this way. There are many ways to sell a product, we just needto experiment.”

About the authorChristine Brown-Paul is a Sydney-based journalist and a regularcontributor to PH&G, with a special interest in the environmentand sustainable technology. Email: [email protected] b

Practical Hydroponics & Greenhouses . June . 2015. 25

(Top to Bottom): Small igloo for sale of plants at Jolly Berries’ packing shed.Jolly Berries blueberries in punnets ready for sale.Last year, James Crozier and Molly Crozier exhibited at Fine FoodsAustralia in Melbourne.

Website resources

Australian Blueberry Growers Association— www.abga.com.au

Australian Blueberries— www.australianblueberries.com.au

Australian Rubus Growers Association— www.arga.com.au

Strawberries Australia Inc.— www.strawberriesaustralia.com.au

Queensland Strawberry Growers — www.qldstrawberries.com.au

Costa Berries— costaexchange.com.au/index.php/berries/driscolls

Tumbarumba Blueberries— http://tumbaberry.com.au/index.html

Jolly Berries— www.jollyberries.com.au

Emily Hill Farm— www.emilyhillfarm.com.au/welcome.htm

Mountain View Farm— www.mountainblue.com.au

Int. Blueberry Organization— www.internationalblueberry.org

26 . Practical Hydroponics & Greenhouses . June . 2015

Fruit growing in 2060 . . . everything will be protected

Florocane fruiting raspberries, Belgium.

When I arrived in New Zealand as a raw—very raw—horticultural graduate from Nottingham University in1958, I was not impressed with the standard of fruit

production which I saw.

by MIKE NICHOLS

In the UK there was already an awareness of the advantagesof dwarfing root stocks, higher density planting andrenewal pruning. None of this knowledge was apparent to

me in Auckland horticulture in August 1958.In fact, the pip fruit industry at that time was based on a very

simple formula. Trees were planted in a 20 ft x 20 ft squarepattern, grafted onto Northern Spy rootstock, and were mainlyvarieties of Cox’s Orange Pippin, Golden Delicious, RedDelicious, Jonathan, Granny Smith or Sturmer. All theorchards were ‘clean cultivated’ with discs or harrows [toimprove soil aeration], irrigation was only present in CentralOtago by the use of flood irrigation methods, and spur pruningwas the norm.Pest and disease control was by regular calendar-measured

sprays with pesticides such as DDT to control codling moth.This then posed the problem of how best to control spidermite, due to the DDT killing off the spider mite predators.We have come a long way in the past 50 years. Grassed

orchards and irrigation are now the norm, as are high densityplantings and dwarfing rootstocks. Any relationship betweenyesterday’s varieties and today’s is purely coincidental. As faras pest and disease management is concerned, anawareness of the importance of reducing pesticide use hasled to an acceptance by the industry of IPM and biologicalcontrol methods.The reason behind the New Zealand horticultural industry

being so far behind in 1958 is probably due to theuncooperative UK weather. It was necessary to work hard toget the right technology to produce crops, whereas in NewZealand the superior climate made horticultural production aneasier task. This trend is apparent in North America, wherethe Eastern states have to strive much harder to obtain goodcrops compared with the Western states.Another reason is that horticultural training in the UK was

more advanced than in New Zealand.Whatever the reason was, thedifference is now history, and NewZealand’s internationalreputation in terms ofhorticulture innovation isequal to the best in the world.

Where to from here?Growers must tread adelicate line betweenconservatism andinnovation. One bad decisioncan easily remove the efforts of

a lifetime. Nevertheless, conservatism has its disadvantages.In the mid-80s, I spent two months in the city of Quetta in

Pakistan evaluating a high density, dwarfing root stock, dripirrigation apple project for the United Nations. It was aninteresting project, because traditionally in Baluchistan,apples were grown on their own roots at a very low numberof trees per hectare. Each tree would produce a very highyield per tree on extremely large and tall trees, but a lowyield per hectare. This is very different from the modern philosophy of having a

large number of dwarf trees per hectare. This providesrelatively low yields per tree, but high yields per hectare, withthe added advantage of the trees being easy to manage interms of height. The UN proposal went down with the locals like a lead

balloon, due to innate conservatism of the local growers, andeven when grafted onto dwarfing root stocks, they tried toovercome the dwarfing effects of the rootstocks by mouldingup the stems to ensure scion rooting and, consequentially,large trees!

2060What will the New Zealand fruit industry look like in 2060?My view is that it will have become a ‘protected cropping

industry’, similar to how tomatoes have become over thepast 20 years.The greenhouse industry in Europe was originally

“We have come a long wayin the past 50 years.”

Mike Nichols

Practical Hydroponics & Greenhouses . June . 2015. 27

28 . Practical Hydroponics & Greenhouses . June . 2015

established to producefruit. The first‘greenhouses’ weredeveloped in the 17thand 18th century inorder to produceoranges for the richand famous. Thesegreenhouses—actuallycalled orangeries—wereprimarily stone builtbuildings containing a smallstove, with small glass windowsthat provided some light for theplants. It was essentially a basic methodof frost protection for the sensitive citrus, as the plantswere grown outside in pots during the summer and onlytransferred into the orangeries in autumn at the onset ofcold weather. In the 19th century, many rich landowners developed large-

walled gardens to produce fruit and vegetables for their ownconsumption. They then found that the walls could be used tosupport lean-to greenhouses for the production of out ofseason fruits. There were even greenhouses developedspecifically for growing pineapples! In 1850, the Great Exhibition had as its centrepiece a very

large glasshouse named the Crystal Palace, and as a resultthe potential for production of ‘cheap’ out-of-seasonvegetables was established. In the 20th Century, theproduction of fruit under protected cultivation virtuallydisappeared, although in New Zealand I can recall a fewdessert grapes being grown in greenhouses near Oamaru for

the ‘hospital trade’, at least into the 1960s. Of course, there isalways the very large grape vine in a greenhouse atHampton Court near London, as a remainder of timeslong past.

In recent years there has been worldwide productionof high quality fruit under protective cultivation, but notreally here in Australia or New Zealand. This issomewhat surprising considering the supermarketdominance in both countries, and the interest thatsupermarkets and consumers have in high qualityproduct being available on the shelves year round.However, in horticulture things change rapidly. In New Zealand, we saw a decline in the 90s of

fresh outdoor tomato production with thedevelopment of corporate greenhouse tomatoproduction. A similar trend appears to be occurring inAustralia, while in Europe we are seeing a swing away

from field production of strawberries towardsgreenhouse production. This grows better quality fruit and

provides a more stable supply. Such results are seen even insuch climatically favoured countries as Spain. For

countries with a difficult climate and summer rainssuch as UK, New Zealand or even Australia, thewriting is on the wall for high quality fruitproduction—adapt or disappear.

In many countries weather sensitive cropssuch as cherries—see my recent article[PH&G May 2013 / Issue 131]—have beengrown under high plastic tunnels. Even inthe drier areas of North America there isconsiderable interest in the use ofprotected cultivation to produce top qualitycherries and other stone fruit. There are some very real advantages of

growing in protected cultivation. Biologicalcontrol methods are more reliable,

pesticides are not washed off the plant byrain, harvesting is not weather dependent, and

fruit quality is vastly improved. I am currentlyinvolved in a greenhouse strawberry study, which by

Christmas had produced the equivalent of 40t/ha of firstgrade fruit without any pesticides and with only three rottenfruit out of a total of some 6400.I believe that berry fruit will initially show the way, but it will

only be a question of when, not if, summerfruit and laterpipfruit producers appreciate the many advantages ofproducing in a semi-controlled environment.Moving from the field into a protected cropping greenhouse

environment will not be straightforward. It will involveadditional capital, and a complete change in the productionmethods we are currently using. To some extent, this hasalready been signalled by Dr Stuart Tustin from NZ Plant andFood. He has suggested that the current tree training methodsmight be considerably improved by using the ‘Future OrchardPlanting System’ where trees have two axes rather than one,and will be grown like horizontal cordons trained along wiresto allow the development of vertical stems, in a planararrangement much like a candelabra. Tustin has suggested

Practical Hydroponics & Greenhouses . June . 2015. 29

that productivity might be increased by as much as two tothree times using this growing system. Suitable dwarfingrootstocks already exist for apples, and it is only a question oftime before a range of dwarfing root stocks become availablefor other tree fruits. Other training systems might beconsidered, for example, the two axes system combined with a‘Tatura trellis’ system. This may even be better.The New Zealand kiwifruit industry is currently going

through some considerable trauma due to Psa (bacterialkiwifruit vine disease). A complete rethink regardingproduction systems could prove relevant at this time. Waterappears to be a major factor, and this poses the question ofwhether a totally new production system might be the future.High tunnels would reduce the water problem andpresumably the Psa, but the training system would have to begreatly modified. Kiwifruit training in the past has been limited to two training

methods. If dwarfing rootstocks could be developed, then thepotential to look at a horizontal main stem /planararrangement might allow easy production in a protected andrain free environment. It could also enhance productivity withboth yield and quality. The use of “high tunnel” greenhousesfor kiwifruit would also introduce the potential for usingbumble bee hive colonies for pollination.The UFO system, a permanent single layer espalier system

with the fruiting wood held upright, might be a solution forcherries. Pruning each winter would comprise of cutting the

fruiting wood back to the permanent espalier, or horizontalcordon, framework. Rows could be much closer together, andspraying would be by means of a permanent set of nozzles.Pollination should be improved, as bumblebees would be

effective in the tunnels, and the need for pollen imports wouldbe eliminated. The male pollinator plants could be grown incontainers and introduced into the high tunnels for pollination,and then taken outside for the rest of the growing season.There would almost certainly be a need for the kiwifruit

industry to follow the lead of the apple industry, and developdwarfing rootstocks. This could play a useful role in

!"#$%&$'!#"(%)#'*+,'!"#$%&$'-#"$%.&(%)#'!"/)#.)#,'0"/11%+2'3&45)"*)#5!"#$%&$'3&45)"*)#'6/"'7#*68'9"##+5:';#"45:'-%+#'0"/15:'<#""%#5'='>(/"%.&()&"#

!"#$%&$'()*)(%+",-'.%/%!#0.).1'01%2,"1)(3'%&)4)05%/%6$1)787%9)"%2#"#.)1:6$1)787%;,1'"%<%=81")'01%>'1'01)#0%/%&1'")3'?%@0'"1%,0-%$A%='81",3%B#'.%0#1%C"',D%B#E0%/%F(#0#7)(,33:%2#.)1)G'

!?/+#@'ABCD'EFBG'GBHEF7,)3H%.,3'.I'J*#3),1#".K(#7K,8

IIIJ#K6/(%*)/"5J./$J*&

Figure 1

30 . Practical Hydroponics & Greenhouses . June . 2015

developing high tunnelproduction systems. It goes without saying

that the quality of fruitproduced under tunnelswould be superior tothat from outdoor crops,and this might includehigher brix, earliermaturity etc.

HydroponicsIt is generally acknowledgedthat soil is not a good medium togrow high value crops. In a classic paper,Professor Lim Ho (Fig. 1) showed that in theUK, over a 30-year period, greenhousetomatoes in soil increased in yield by anaverage of 1.7% per year. Those producerswho used hydroponics, which becamepopular first in the 1960s, had annual yieldincreases of 6.4%. This was not due solely tothe use of hydroponics, but because the yieldfrom the hydroponics was higher, it becameeconomically feasible to invest in otherimproved technologies.In this case automatic greenhouse temperature

control, supplementary carbon-dioxide, IPM, etc.In the 21st century, the two scarce resources are likely to be

water for irrigation and fertiliser. Hydroponics using recirculatingsystems offers considerable efficiencies in both.Horticulture on a per hectare basis is a major user of