ACI STRUCTURAL JOURNAL TECHNICAL PAPER … · · 2016-08-12Flexural Behavior of One-Way Concrete...

Transcript of ACI STRUCTURAL JOURNAL TECHNICAL PAPER … · · 2016-08-12Flexural Behavior of One-Way Concrete...

ACI STRUCTURAL JOURNAL TECHNICAL PAPER Title no. 95-S32

Flexural Behavior of One-Way Concrete Slabs Reinforced by Fiber Reinforced Plastic Reinforcements

by Craig R. Michaluk, Sami H. Rizkalla, Gamil Tadros, and Brahim Benmokrane

Fiber Reinforced Plastic (FRP) reinforcements are currently used for special concrete structures in areas sensitive to magnetic fields and severe environmental conditions which accelerate corrosion of the steel reinforcements, and consequently leads to deterioration of the structure. This paper presents test results of eight one-way concrete slabs reinforced with glassfiber, carbon-fiber and conventional steel reinforcements. The slabs were tested under static loading conditions to determine their flexural and shear limit states, including the behavior prior to cracking, cracking, ultimate capacities and modes offailure. Based on this investigation, design recommendations and guidelines are proposed.

Keywords: cracks; concrete; failure; fiber; flexural; glass; plastic; slab

reinforcements.

INTRODUCTION Parking structures and bridge decks are prime examples of

structures subjected to severe environmental conditions, leading to the deterioration of the main structural concrete components due to corrosion of steel, and consequently, a reduced serviceability. Significant fluctuation of the temperature and use of salt for deicing accelerates the corrosion process of the steel reinforcements. In Canada, it is estimated that the cost of repairing parking Structures is in the range of four to six billion dollars. 1 The estimated repair cost for existing highway bridges in U.S. is over 50 billion dollars, and one to three trillion dollars for all concrete structures.2

Excessive corrosion problems also exist in Arabian Gulf countries.3 The exterior of reinforced concrete structures in these countries are subjected to an extremely aggressive environment due to the high temperatures and humidities. Presence of shrinkage and flexural cracks allows intrusion of the salt-laden condensation, contaminated rain water, oxygen, and carbon dioxide gases. This mixture of chemicals and moisture eventually penetrates to the level of steel reinforcement and accelerates their corrosion rates. Many techniques have been studied to delay the corrosion rates. These include cathodic protection systems4 and the use of galvanized or epoxy coated rebars.5 Long term efficiency of these systems is still uncertain.6 Eniineers are currently exploring the use of fiber reinforced plastics (FRP) as a promising solution for the corrosion problem. FRP is non-corrosive, mag-

ACI Structural Journal/May-June 1998

netically neutral and has a high ~trength-to-weight ratio. Although there is a tremendous diversity of the available glass-fiber reinforced plastic (GFRP) bars, no general information, nor clear specifications specifically address their behavior as reinforcements for concrete structures.

This paper presents one phase of an extensive program to study the flexural behavior of concrete slabs reinforced by GFRP reinforcements. These are also used as reinforcements for beams and grouted rock anchors.?

RESEARCH SIGNIFICANCE The paper presents unique experimental results of eight

prototype one-way concrete slabs reinforced by three different FRP materials tested under static loading conditions up to failure. The research describes the various limit states behavior including modes of failure due to variation of the slab thickness and the reinforcement ratio. The behavior of concrete slabs reinforced by GFRP is compared to slabs reinforced by carbon fiber reip.forced plastic (CFRP) bars and steel reinforcements. The information gathered throughout this investigation is valuable for future development of design guidelines for one-way concrete slabs reinforced by FRPbars.

MATERIAL CHARACTERISTICS Although GFRP bars possess the lowest tensile strength in

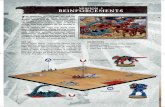

comparison to other available FRP reinforcements, they have the advantage of being the least expensive, 1 along with their noncorrosive, magnetically neutral and high strengthto-weight ratio? characteristics. Therefore, GFRP reinforcements are an excellent candidate for reinforced concrete structures subjected to aggressive environmental conditions and for those sensitive to magnetic fields. Figure 1 shows the material characteristics of the three types of reinforce-

ACI Structural Journal, V. 95, No.3, May-June 1998. Recdved September 9'.1996, and reviewed under Institute publication policies.

Coprnght © 1998, Amencan Concrete In.shtute. All rights reserved, including the makinll of COPieS ~nless peTI?lsslO!lls obtamed from the copyright proprietors. Pertinent diSCUSSIOn wlll be pubhshed m the March-April 1999 ACI Structural Journal if received by November 1, 1998.

353

Craig R. Michaluk received his BSc in civil engineering and his MSc in structural engineering from the University of Manitoba. He is presently employed with Scouten and Associates Engineering Ltd., Prince George, British Columbia, Canada.

Sami H. Rizkalkl, FACI, received his MSc and PhD from North Carolina State University. He currently serves as president of the Canadian Network of Centers of Excellence on Intelligent Sensing for Innovative Structures (ISIS Canada) in Winnipeg, Manitoba. He is also a Fellow of ASCE, CSCE, and EIC, as well as a member of ACI Committee 550, Precast Concrete, and Chairman of ACI Committee 440, FRP Reinforcement. Additionally, he serves as chief editor of the FRP International Newsletter. and is a member of the editorial board of the ASCE lournal of Composites for Construction.

ACI member Gamil Tadros received his PhD in 1970 from the University of Calgary, Alberta, Canada. He is a structural engineering consultant involved primarily with bridge design and construction. He has published extensively in the field of bridge design and construction, along with receiving numerous awards. He is also a member of ASCE, CSCE, PC1, and IABSE.

ACI member Brahim Benmokrane is a professor of civil engineering at the University of Sherbrook, Quebec, Canada. He is currently a project leader in the Canadian Network of Excellence on Intelligent Sensing for Innovative Structures. His research interests include the application of advanced composite materials and FRP reinforcements in civil engineering structures, design of FRP reinforced concrete structures, bond and durability of FRP reinforcements, rehabilitation and strengthening of structures using FRP tendons and anchorage, and smart FRP structures using fiber optic sensors. He is a member of ACI Committee 440, FRP Reinforcement.

ments used in· this program, including GFRP, CFRP, and steel. Table 1 provides their fundamental mechanical properties.

The GFRP rods are manufactured by pultration of E-glass continuous fibers and thermosetting polyester resin. To enc hance the bond characteristics, the surface is wrapped by helically glass fiber strands and covered by a mixture of a known grain size of sand and polyester resin.?

The CFRP reinforcement used in this test program is an 8 mm (5/16 in.} diameter CFRP bar produced by Mitsubishi Chemical, Japan. The CFRP bars are fabricated using continuous coal tar pitch-based continuous fibers and epoxy resin.8 Figure 2 shows the particular GFRP and CFRP bars used in the investigation.

The measured average compressive strengths of the concrete used for the slabs ranged from 60.0 MPa (8600 psi) to 66.3 MPa (9600 psi) at the time of testing, with a maximum aggregate size of 14 mm (1/2 in.).

EXPERIMENTAL PROGRAM The eight prototype one-way concrete slabs, reinforced by

three different reinforcement materials, tested in this program are given in Table 2. Five specimens were reinforced by GFRP bars, two were reinforced by conventional steel bars, and one was reinforced by CFRP bars. The three slabs reinforced by CFRP and steel reinforcements are used as control specimens to compare the behavior of the slabs reinforced by GFRP bars.

The length and width of all the slabs were 3500 mm (11.5 ft) and 1000 mm (3.28 ft), respectively, with a clear span of 3000 rom (10 ft), which was kept constant throughout the study. The two thicknesses of slabs were ·150 rom (6 in.) and 200 rom (8 in.) according to the requirements of the Canadian Design Code, CAN3-A23.3-M94.9 A concrete cover of 38 mm (1.5 in.) was used for the longitudinal reinforcements. Initially, the slabs were (jesigned to achieve the classical three modes of failure, including: rupture of the reinforcements; simultaneous rupture of the reinforcements

354

2000

1800

1600

1400

;c 1200

~ 1000 ~ Steel ~ 800

600

400

200

0 0 2 3 4 5 8

StraiD {%I

Fig. I-Material characteristics of the GFRp, CFRp, and steel reinforcements

Fig. 2-GFRP and CFRP reinforcements

9

and crushing of the concrete; and crushing of the concrete while the reinforcement remains elastic. This was accomplished by using reinforcement ratios less, equal, and more than the balanced reinforcement ratio Ph for the slabs, respectively. After completion of testing the 150 mm (6 in.) thick slabs, the program was revised for reasons related to the observed modes of failure, which will be discussed later.

Schematic and view of the test set-up used are shown in Fig. 3(a) and 3(b), respectively. A 1000 kN (225 kips) closed-loop MTS actuator was used to apply the load through a spreader beam system as shown in Fig. 3(b). The slabs were simply supported at each end along the entire width.

The slabs were instrumented to measure the applied load, midspan deflections, strains in the extreme compression fibers of the slabs, strains in the reinforcements, strains in the concrete at the level of reinforcements, crack widths within the constant moment zone, and bond slippage at both ends of the specimens.

The slabs were initially loaded at a slow rate of 0.6 mm/min. e/128 in.lmin) up to initiation of cracks. After cracking, the rate of applied load was increased to 1.2 mm1min el64 in.lmin) up to failure.

TEST RESULTS Flexural behavior

In general, all the slabs reinforced by GFRP bars exhibited linear behavior prior to cracking, followed by development

ACI Structural Journal/May-June 1998

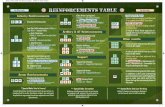

Table 1-Tensile properties of the reinforcements Ultimate stress, MPa (ksi)

Reinforcement material Guaruanteed

GFRP-690

reinforcement7

CFRP-reinforcementS

1970

Steel-rebar 400

• Standard deviation t Yield stress :j: Yield strain

Average value 0* n

692 (100) " 19.4 (2.8)

2250 (326) -

435 (62.9)t 4.08 (0.61)

Table 2-Details of the test specimens

Thickness, "mm Reinforcement Mark no.

Steel S-150-T

1-150-A 150

GFRP 1-150-B

I~150-C

Steel S-200-T

1-200~A

200 GFRP 1-200-C

CFRP LL-200-C

• _ Area of reinforcements p-" bd

(l RP E t Ph = _[_p)_c • _c_u -

0Fu Ecu + EFu

eFu=C1FjEF ecu = .003

Bar diameter, mm(in.)

15M (0.6)

12.7 (0.5)

15.9 (0.62)

15.9 (0.62)

10M (0.4)

9.5 (0.4)

15.9 (0.62)

8.0 (0.31)

of sudden, wide and deep cracks, accompanied by large deflections. Test results and observed mo~es of failure for the slabs tested in this program are given1n Table 3. The loaddeflection behavior of the 150 mm (6 in.) thick slabs reinforced by three reinforcement ratios of GFRP and one slab reinforced by steel reinforcements are shown in Fig. 4. For the two slabs reinforced by the same reinforcement ratio, S-150-T and I-150-C, the slab reinforced by GFRP bars exhibits a significant reduction in stiffness after the initiation of the first crack in comparison to the slab reinforced by steel reinforcements. This behavior is attributed to the low elastic modulus of GFRP bars in comparison to steel reinforcements. All the slabs reinforced by GFRP reinforcements exhibit significantly wider crack widths and depths in comparison to the slab reinforced with steel reinforcements. Since the slabs were tested under a stroke control condition, initiation of new cracks is reflected by large reductions in the load resistance, as shown by the step-wise behavior in Fig. 4. The ratio of drop in the load resl>tance due to initiation of the first crack, LlP, to the cracking load, Per' is given for all the tested slabs in Table 3. The large values of the ratio LlPIPcr

ACI Structural Journal/May-June 1998

Ultimate strain, percent Elastic modulus, GPa (ksi)

Average Average value "on* value 0* n

1.767 0.047 41.3 (5975) 1.25 (181)

I

1.3 - 147 (21,300) -

0.246* 0.001 177 (25,670) 1.3 (189)

Predicted mode of

No.ofbaFS p,* percent p/pbt failure

5 .962 0.23 Yield

4 .487 0.66 Rupture of rebars

4 " .764 0.99 Balanced

5 .955 1.25 Crushing of concrete

6' .390 0.09 Yield

5 .230 0.31 Rupture of rebars

6 .774 1.01 Crushing of concrete

6 .303 0.87 Crushing of concrete

for the slabs reinforced by GFRP bars, in comparison to the slabs reinforced by steel, is due to the low elastic modulus of GFRP.

Slabs I-150-A and I-150-B failed due to rupture of the reinforcements. Slab I-150-C was over-reinforced and expected to fail by crushing of the concrete before rupture of the reinforcem~nts. However, the failure was due to shear of the GFRP bars at a major crack located outside the constant moment zone, as shown in Fig. 5. Behavior of Slab S-150-T, reinforced by steel reinforcements, was typical as shown in Fig. 4. The reduction in the stiffness after cracking was followed by yielding, reflected by the measured large deflections, and failure due to the crushing of the concrete in the compression zone at a location within the constant moment· zone of the slab.

Based on the behavior described above, the experimental program was revised to test only two 200 mm (8 in.) thick slabs reinforced by GFRP bars, Slabs I-200-A and I-200-C. These slabs were designed to fail by the two extreme failure modes of rupture of the GFRP reinforcements and crushing of the concrete respectively. Along with a control slab rein-

355

r - - - - I Sreelframc I :..---supporttng the actuator

I Steel frame

Two LVDT'a urc slab deflection

l' • - .. i

Prcsu-cd Floor ;1 AnchOr

: ~teslob 35m long

1.7S

I !supporting the slabs : r_LV.!-'DT ...... '7to"'me7""':;.:SI=:lJc"--_ I oonc_1b'ain ... - -,

LVDT 10 monitor the ... pport movement

~ ________ 3.000 _______ -+_

Fig. 3(a)-Schematic of the test set up

Fig.3(b)-Testsetup

~ ." 01 c

...:l

150 140 130 120 110 100 90

80 70 60

50 40 30 20 10 0

0 10 20 30 40 50 60 70 80 90 100' 110 120 130

Deflection [mmJ

Fig. 4-Load-deflection at mid-span of the 150 mm (6 in.) thick slabs

forced by steel reinforcements, a fourth 200 mm (S in.) thick slab reinforced by CFRP reinforcements, was included in the program.

The load-deflection behavior of the two 200 mm (S in.) thick slabs, I-200-A and I-200-C, reinforced by GFRP, and the slab reinforced by steel, S-200-T, are shown in Fig. 6. Slab I-200-A failed by rupture of the GFRP reinforcements due to flexure in the maximum m<fment zone. Slab I-200-C failed by shear of the GFRP bars at a major diagonal crack

356

located outside the constant moment zone, as shown in Fig. 7. The steel reinforced slab, S-200-T, failed, as predicted, by crushing of the concrete in the compression zone, after yielding of steel.

The load-deflection behavior of three slabs reinforced by similar reinforcement ratios using GFRP, CFRP and steel reinforcements, are shown in Fig. S. The slab reinforced by CFRP reinforcements, LL-200-C, failed at a load level 27.S percent higher than the nominal strength of the slab. Failure was due to slipping of the reinforcement at one end of the slab at an equivalent bond stress of 4.6 MPa (667 psi). This value is similar to the values measured by tests conducted at the University of Manitoba, 10 and is less than the flexural bond strength of steel reinforcements. As evident in Fig. S, the ultimate load was significantly higher than the other two slabs, due to the relatively high tensile strength of the CFRP bars in comparison to the GFRP and steel reinforcements, as given in Table 1. Based on the measured load at failure, the calculated tensile stress of the CFRP bars was apporximately 3000 MPa, which is well above the manufactured guaranteed ultimate tensile strength value of 1970 MPa, given in Table 1, and used in the original design ofthe slab. These values are in agreement with measured values obtained in an independent study conducted at the University of Manitoba. 11 It should be noted that prior to failure, all the FRP reinforced slabs gave an ample warning effect through large deflections and extensive cracking.

Crack patterns Crack patterns of the 150 mm (6 in.) thick slabs reinforced

by GFRP and steel reinforcements are shown in Fig. 9. Averaged measured first crack widths and spacings for all slabs tested in this prognun are given in Table 4. The averaged first crack widths for the 150 mm (6 in.) thick slabs reinforced by GFRP reinforcements was in the range of 1.0 mm (0.04 in.), which is significantly higher than the allowable value of 0.33 mm (0.013 in.) specified by the Canadian Design Code, CAN3-A23.3-M94.9 The first crack widths, WIF, of the slabs reinforced by GFRP reinforcements are compared to the first crack widths, W Is' of the slabs of simi-

ACI Structural Journal/May-June 1998

Fig. 5( a)-Shear of the reinforcements of Slab /-J50-C

Fig. 5(b )-Close-up of the crack at the left end of Slab I-J50-C

160

140

120

~ 100

-c:s 80 as j

60

40

20

0

0

S-200-T

p.-0390%

20 40 60 80 100 120 140 160 180 200 220 240 Deflection [mm]

Fig. 6-Load-deflection at mid-span of the 200 mm (8 in.) thick slabs reinforced by GFRP and steel reinforcements

lar thickness and reinforced by steel in Table 4. Results indicate that the large crack widths in the slabs reinforced by GFRP bars are almost 19 times those developed in the steel reinforced slab. The larger crack widths also result in a large crack spacing of 242 mm (9.5 in.) for the 150 mm (6 in.) thick slabs reinforced by GFRP reinforcements within the

ACI Structural Journal/May-June 1998

Fig. 7( a)-Failure of Slab /-200-C

Fig. 7(b)-Close-up of the shear failure of Slab /-200-C

280 260 240 220 200

[ 180 160

"C 140 as 120 j

100 80 60 40 20 0

0

LL-200-C

Pr- 0303%

S-200-T p.-(lJ90%

20 40 60 80 100 120 140 160 180 200 220 240 Deflection [mm)

Fig. 8-Load-deflection at mid-span of the slabs with similar reinforcement ratios of GFRp, CFRp, and steel reinforcements

constant moment zone, which is about 2.3 times that observed for the similar slab reinforced by steel reinforcements. Since no slippage of the GFRP reinforcements was observed at the two ends of the slabs, it appears that the large spacing of the cracks is due to a loss of bond of the GFRP reinforcements to the concrete between the cracks. This could

357

Table 3-Test 'results

Predicted Measured Ultimate ultimate ultimate load deflection

Pcr> kN !'J.P!P cr' t load, kN Pult,kN ' tiult,mm Predicted Observed Slab (kips) . percent (kips) (kips) (in.) failure.mode failure mode

S-150-T 40.6 8.1 107.2' 109.6' 29.0' Yield of Yield of

(9.10) (24.04) (24.58) (1.14) rebars rebars

1-150-A 24.1 4904 73.6 60.6, 103.6 Rupture of Ruptnreof (5040) (16.51) (13.59) (4.08) rebars rebars

I-150-B 32.9 49.5 109.5 8004 125.7 Balanced Ruptnreof

(7.38) (24.56) (18.03) (4.95) tebars

1-150-C 27.0 36.7 135.9 74.6 101.1 Concrete Shear (6.06) (30048) (16.73) (3.98) crushing

S-200-T 79.0 9.1 111.7' 101.6' 10.3' Yield of Yield of (17.72) (25.05) (2:f.78) (0041) rebars rebars

1-200-A 43.9 49.9 77.5 47.1 28.3 Rupture of Ruptnreof ~9.85) (17.38) (10.56) (1.11) • rebars rebars

1-200-C 44.0 34.3 246.5 158.1 80.8 Concrete Shear (9.87) (55.28) (35046) (3.18) crushing

LL-200-C 51.0 1904 202.8 259.1 118.8 Concrete . Bond (11.44) (45048) (58.11) (4.68) crushing

• Values at yiel!Jing t !'.P is the step-wise drop in the applied load after initiation of the first crack

Table 4--Crack widths and spacing

WIF or Wls' mm Slab p, percent (in.)

S-150-T 0.962 0.063 (0.0025)

1-150-A 00487 U85 (0.047)

I-150-B 0.764 1.180 (0.046)

I-150-C 0.955 1.190 (0:047) ------

S-200-T 0.390 0.090 (0.0035)

1-200-A . 0.230 1.310 (0.052)

I-200-C 0.774 I 0.562 (0.022)

LL-200-C 0.303 0.506 (0.020)

be triggered by possible debonding of the outer spiral layer of the glass fiber wrapped around the core of this particular GFRP reinforcement.

This debonding phenomenon was observed during testing of reinforced concrete tension specimeps using the same GFRP reinforcement at the University of Manitoba.12 as shown in Fig. lO(a). I These tension specimens consisted of a single GFRP bar embedded in concrete subjected to axial load using two cantilever ends. as shown in Fig. lO(b). Separation and breaking of the deformations from the GFRP bar surface during tension tests was also reported by others.13

Crack patterns of the 200 mm (8 in.) thick slabs reinforced with GFRP. steel. and CFRP reinforcements are shown in Fig. 11. Similarly. the crack spacing for slabs reinforced with GFRP bars was significantly larger in comparison to slabs reinforced by CFRP and steel reinforcements. The average first crack widths for the two slabs reinforced by GFRP bars. I-200-A and I-200-C. were 1.310 mm (0.052 in.) and 0.562 mm (0.022 in.). respectively. These values exceed the allowable value of 0.33 mm (0.013 in.) specified by the Canadian De,sign Code. CAN3-A23.3-M94.9 The width of the first crack for slab'I-200-A. reinforced bylaFRP reinforcements. is over 14 times those observed in the steel reinforced slab. S-200-T. which has a similar reinforcement ratio. Once

35S'

.' scF and scs' mm wlF!wls (in.) scF1scs

1.0 97 (3.82) 1.0

18.8 231 (9.09) 204

18.7 273 (10.75) 2;8

18.9 223 (8.78) 2.3

1.0 119 (4.69) 1.0

14.6 283 (11.14) 204

6.2 236 (9.29) 2.0

5.6 220 (8.66) 1.8

again. this behavior is obviously due to the low elastic modulus of GFRP reinforcements in comparison to the elastic modulus of the steel reinforcements and possibly due to loss of bond of these particular GFRP bars.

Mode of failure All under-reinforced slabs. I-200-A. I-150-B and I-150-A.

failed by rupturing of the GFRP bars within the constant moment zone. The measured concrete strains at the level of the GFRP reinforcements and the reading of strain gauges attached to the GFRP bars were lower than the expected ultimate strain value. resulting in lower ultimate moment load resistances of these slabs. as given in Table 3. Typicalloadstrain at the level of reinforcements. measured by six DEMEC point stations and two electrical strain gauge.s attached to each GFRP bar within the constant moment zone. is shown in Fig. 12. The results indicate that rupture of the GFRP reinforcements occured. at strain levels lower than the ultimate strain levels achieved in the tension tests. This behavior suggests that the sudden impact caused by the transfer of tensile forces from the concrete to the GFRP bars at the time of cracking. created a localized rupture of the fibers. impeding the GFRP reinforcements to achieve their ultimate tensile strengths. Using the measured ultimate loads and strain

ACI Structural Journal! May-June 1998

Fig. 9-Crack patterns for the 150 mm (6 in.) thick slabs

Fig. 1 O( a )-Debonding of outer wrapping of the GFRP bar

compatibility, the percentage of the ultimate tensile stresses ofthe GFRP bars to the nominal values, CJFexplCJFu, for slabs I-200-A, I-ISO-A, and I-1S0-B were 76.8 percent, 9S.4 percent, and 81.0 percent, respectively. The load-deflection behavior for the three mentioned slabs are presented in Fig. 13 in ascending order with respect to their bar diameters and percentage of reinforcements. All three slabs exhibit fairly linear behavior after the initiation of crllcking, as evident by the load-deflection envelope. As the bar diameter increased from 9.S mm e/8 in.) to 12.7 mm (1/2 in.), and consequently the reinforcement ratio, the immediate drop of the load resistance t1P due to the initiation of cracks significantly reduced, as shown in Fig. 13(a) and 13(b). This resulted in a reduction of the impact effect of the load transferred from the concrete in tension to the GFRP and consequently reduces the possibility of localized fracture of the fibers. This was evident by the increase of the ratio of the measured stress of GFRP at failure to the tensile strength, CJexp ICJFu ' from 76.8 to 9S.4 percent. Reduction of t1PIPcr by increasing of the percentage of reinforcements is typical for the two slab thickness used in this study. It was also noticed that increasing the bar diameter from 12.7 mm (1/2 in.) to IS.9 mm (5/8 in.), reduced the ratio CJexplCJFu from 9S.4 to 81.0 percent, as given in Fig. 13(b) and 13( c). This behavior could be attributed to the fact that GFRP bars are made of tholtsands of layers of glass fibers and the interlaminate shear lag could lead to a possible unstressed central region of the GFRP bar when subjected to

ACI Structural Journal/May-June 1998

Fig. lO(b)-Concrete tension specimen

Fig. II-Crack patterns of the 200 mm (8 in.) thick slabs

tensile forces at the outer surface of the bar, as shown in Fig. 14. These characteristics lead to a reduction of the ultimate tensile strength of larger diameter GFRP bars in comparison to small diameters using the same type and percentage by volume of fibers. This phenomenon is reported by others14

for GFRP reinforcements.

These findings lead to the development of the following proposed equation to evaluate the general strength of FRP reinforcements T in terms of the cross-sectional area AF and ultimate tensile strength, CJFu' of specific sizes of dFRP bars.

[kN] (1)

The factor ~1 accounts for the reductions in the strengths due to the increase of the diameter in comparison to the specific size of bar manufactured using the same type of fibers and percentage of fibers by volume. The factor ~2 is related to the percentage of FRP reinforcements ratio used in a given concrete member. Evaluation of ~1 could be determined using pure tension tests of various diameters of FRP bars manufactured using the same type of fibers and percentage of fibers by volume. Evaluation of ~2 requires performing flexural tests of concrete members using the same diameter of FRP bars and various percentages of reinforcement.

359

360

70

60

50

-~ 40 -"CI ell

~ 30

20 -l-

10 DEMEC stations Side A

at reinf. level SideB

0

0 0.2 0.4 0.6

7~gcs

•• 1. ¢ 321 4 S 6 DEMEC

poinls

0.8 1

Strain [%] 1.2

P.It""60.6 kN

--s.G. (TYP.~ -.-STAI ___ STA2 ~STA3 -o-STA4 -C-STA! --6-STA6

1.4 .1.6

Fig. 12-Measured strain of the GFRP and the concrete at the level of reinforcement for slab /-/50-A

90 80

70

~ 60 50

~ 40 GIl

~ 30

20

10· 0

0

Loacl-Delled1on Envelope

Slab: i-200-A d,-9.5mm p,-O.l30% pFip.-O.l!)

(J,.., -76.8%orv

10 20 30 40 "50 60 70 80 90 100 110 120 130

Deflection [mm]

Fig J3( a)-Load-deflection curve of Slab /-200-A

90 80 70

..-. 60 ~ ..... 50

" 40 CC

~ 30

20 10 0

0

/

Loacl·Defleet1on Envelope

Slab: 1-150-A "-11.7mm Pr-o.487% .

pr/p.-o.61

0, ... - ~4%Oh

10 20 30 40 50 60 70 80 90 100 110 120 130

Deflection [mm]

Fig. J3(b )-Load-deflection curve of Slab /-J50-A I

ACI Structural Journal/May-June 1998

...-.

~ "c:I = Q

~

90 80 70 60 50 40 30

20 10 0

Slab: 1-150-B d.-15.9nun PF= 0.764%

P~P.-0.93

(Jp.., - 81.0%(JFu

0 10 20 30 40 50 60 70 80 90 100 110 120 130 Deflection [mm)

Fig. i3( c )-Load-deflection curve of Slab i-150-B

Actual stresses due to shear lag

Applied Load

Tension

Area of neglible stress due to interlaminate

shear lag

Assumed stress in the bar

Fig. i4-Possible stress distribution across a section of FRP reinforcements

Shear strength of slabs reinforced by GFRP bars The two slabs reinforced by GFRP originally designed to

fail by crushing of the concrete, 1-150-C and 1-200-C, failed in shear due to rupture of the GFRP bars at a major crack within the flexural-shear location. These failures deemed to be premature, since the measured ultimate shear loads of 37.3 kN (8.4 kips) and 79.1 kN (17.7 kips) for Slabs 1-150-C and 1-200-C, respectively, were significantly lower than shear capacities predicted by the Canadian Design Code.9

The Canadian Design Code equation, Eq. (2), predicts shear capacities of 169.0 kN (37.9 kips) and 250.2 kN (56.1 kips) for the aforementioned slabs respectively using unity for the factors 'A, and <Pc .

CSA CAN3-A23.3-M94 [SI]:

[N] (2)

ACI Structural Journal/May-June 1998

Fig. i5-Close-up of the shear rupture of the GFRP bar at the crack of Slab i-150-C

Close up of the shear rupture of the GFRP bars at the cracks is shown in Fig. 15. The measured crack widths, in both slabs, prior to failure was approximately 15 mm (9/16 in.), and extended vertically along the entire depth of the slab, providing a compression zone depth of approximately 15 nun e/16 in.). The large width and depth of the cracks virtually eliminates any shear resistance that could be provided along the cracks due to aggregate interlocking and allows for only a very small shear resistance within the reduced compression zone. As a result, the remaining shear resistance was provided mainly by the dowel action of the GFRP bars across the cracks, causing the premature failure as described previously.

The dowel strength of the GFRP reinforcements is estimated to be within the range of 7.5 percent to 13.8 percent of the ultimate tensile strength, based on the experimental results of slabs 1-150-C and 1-200-C. This range is close to the value of 8.7 percent, obtained from pure dowel strength tests performed on the same GFRP bars at the University of Man-itoba. 15 •

The measured ultimate shear capacities of Slabs 1-150-C and 1-200-C were also compared to the ACI Design Code16

[Eq. (3) and (4)], the Japanese Society of Civil Engineers (JSCE) Design Code 198417 [Eq. (5)], the recommendation by Machida18 for the JSCE Design Code 1996 [Eq. (6)], and

361

fD Urunodified o Modified 1 I!IlIModified 2

1.4

1.2

) 0.8

0.6

0.4

0.2

0

CSA ACI 11.3.2.1 ACI 11.3.1.1 JSCE Machida CEB-FIP

v c equations

Fig. 16-Comparison of V c and the proposed modification for V c' slab /-150-C

the Comite Euro-Intemational du Beton and Federation Intemationale de la Pn!contrainte (CEB-FlP) Design Code19

[Eq. (7)]. The.results are presented in Fig. 16 and 17 for the 150 rom (6 in.) and 200 rom (8 in.) slabs,respectively.

ACI Clause 11.3.2.1 [SI]:

where

ACIClause 11.3.1.1[SI]:

v = (Jl'c)b d c 6 W

JSCE 1984 [SI]:

where

~d = 1/1001 d - 1 ;;::: 0

~p = ,)100p - 1 ~ 0.73

[N] (3)

/

[N] (4)

[kg] (5)

(d in [cm])

(Mo = decompression moment; Md = applied moment at

362."

f~

section)

2 [kg/cm ]

Machida (JSCE 1996) [SI]:

where

~d = 1/100/ d ~ 1.5 (d in [cm])

f~

CEB-FIP [SIJ:

where

2 [kg/cm]

[N]

(6)

(7)

'tRd = 0.00842(f~ - 50) + 5 (for f~;;::: 50 MPa)

K = 1.6·- d;;::: 1.0 (d in [m])

p ;;:::0.02

Figures 16 and 17 show that all the shear capacity equations significantly overestimate the shear capacities of Slabs 1 -150-C and 1-200-C. Due to the large difference in the elastic modulus values of GFRP reinforcements E F and steel rebars Es used in Eq. (2)-(7), it is proposed to modify all these equations to include a factor of the ratio of the two elastic

ACI Structural Journal/May-June 1998

II Unmodifl~' eM<.>difitdl l ..

II Moditi~ .~.

A.Olll.3.1.l

V c equ~tiQns

Fig. 17-Comparison of V c and the proposed modification for V c' Slab /-200-C

modulii EF/Es' The modification can also be introduced as a factor affecting only the reinforcement ratio p. The two proposed methods are discussed in the following sections.

Method i-Since the shear capacity equation Vc is based on the shear strength contributions from the concrete in the compression zone, the aggregate interlock along the crack and the dowel action of the longitudinal reinforcement, the first modification method, labeled Modification 1 on Fig. 16 and 17, considers the ratio Ep/Es as a multiplication factor to the entire shear capacity based on Eq. (2)-(7).

Method 2-The second modification method, labeled Modification 2 on Fig. 16 and 17 and based on Machida's approach,18 considers only the reduction in shear capacity due to the effect of the elastic modulus on the reinforcement ratio. Modification 2 is represented by Eq. (8)-(13). It should be noted that for the equations that do not include the reinforcement ratio parameter, the proposed Modification 1 is identical to Modification 2. /

CSA CAN3-A23.3-M94 (Modified 2) [SI): '(no change)

[N) (8)

ACI Clause 11.3.2.1 (Modified 2) [SI):

[N) (9)

ACI Clause 11.3.1.1 (Modified 2)[SI]: (no change)

[N) (10)

Act Struetural Journal/May-June 1998

JSCE 1984 (Modified 2) [SI):

[kg] (11)

where

f3 p = 100p(~:) - 1 $ 0.73

Machida (JSCE 1996) (Modified 2) [SI):

(12)

where

f3 p = JI00P(~:) $ 1.5 CEB-FIP (Modified 2) [SI):

[N) (13)

The measured ultimate shear loads for slabs I-150-C and I-200-C are compared to the predicted values based on the two proposed modifications in Fig. 16 and 17,respectively. The comparison indicates that the proposed Modification 1 is better since it is conservative for all test slabs. Machida's18 approach, used in Modification 2, was found to overestimate several slabs, as shown in Fig. 16 and 17.

SUMMARY AND CONCLUSIONS Eight one-way reinforced concrete slabs, with clear spans

of 3000 mm (10 ft), were tested under static loading conditions: Five slabs reinforced by GFRP bars; two reinforced

with conventional steel rebars; and one slab reinforced with CFRP bars. Behavior of ~e specimens prior to and after cracking was monitored, including midspan deflections, crack widths, and spacing. Based on these experimental results, the following conclusions may be made:

1.) Behavior of the FRP reinforced slabs throughout the testing was bilinearly elastic until failure. Stiffness of the slabs reinforced by GFRP reinforcements is significantly reduced after initiation of cracks in comparison to slabs reinforced by steel and CFRP bars. .

2.) The slab behavior exhibited adequate warning prior to failure through large and deep cracks, accompanied by large deformations for slabs reinforced by GFRP bars. Crack widths and deflections of slabs reinforced by GFRP reinforcements are significantly larger than comparable slabs with the same percentage of reinforcement using steel and CFRP reinforcements. This is due to the low elastic modulus of GFRP bars in comparison to steel rebars, and the debonding of the outer deformation of this particular bar used in this study.

3.) For the under-reinforced slabs designed to fail by rupture of the reinforcements, the GFRP bars did not reach the ultimate strain based on pure tension tests of the bars. This behavior could be attibuted to the localized failure of the fibers at the crack, due to the sudden transfer of tensile forces from the concrete to the GFRP bars at the crack. Increasing the diameter of th" GFRP bars could aslo magnify the effect of the inerlaminate shear lag phenomenon and consequently reduce ultimate tensile stress of the GFRP bar.

4.) Heavily reinforced slabs with GFRP reinforcements could fail in shear by rupture of the GFRP reinforcements at a crack within the maximum shear-flexural zone. The measured dowel strengths of the GFRP bars is estimated to be 7.5 to 13.8 percent that of the ultimate tensile strength.

5.) The shear capacity provided by all the current code equations signifcantly over-estimate the shear capacity of the slabs reinforced by GFRP bars. It is proposed to modify the current code equations for shear by introducing the ratio of the elastic modulii of GFRP and steel, E FIE s ' as .a multiplier.

6.) Further research should be pursued prior to allowing the use of GFRP as reinforcement for reinforced concrete slabs.

ACKNOWLEDGMENTS The writers gratefully acknowledge the financial support provided by

Pultrall Inc. and Mitsubishi Chemical for providing the materials used in the test program. Financial support provided by the Natural Sciences and Engineering Council of Canada and the Canadian Network of Centres of Excellence on Intelligent Sensing for Innovative Structures (ISIS Canada) made it possible to conduct the test program. Special thanks are extended to S. Sparrow, E. Lemke; and M. McVey for their assistance in testing and fabricating the specimens.

NOTATION a shear span AF cross-sectional area of FRP reinforcements As cross-sectional area of steel reinforcements bw width of slabs (b) d depth to center of reinforcllJlents, measured from the extreme

compression fiber of concrete ([rom] for Japanese equations, [rom] for the rest)

db diameter of reinforcement

364.<

EF Es Fe g Mu Per til'

Pull seF ses WIF

Wis

Ve

VU (XI

~

~I ~

~d -'

~r ~n l'1u1t eeu eFu $e K

A. P Pb PFmin=

crexp =

crFu =

crFexp = 'tRd =

elastic modulus of FRP in tension elastic modulus of steel in tension compressive strength of concrete cylinders acceleration due to gravity (9.810 mls2)

factored ultimate moment cracking load step wise drop in load after initiation of first crack ultimate load average crack spacing for FRP reinforced specimens average crack spacing for steel reinforced specimens aV(lrage first crack width for FRP reinforced specimens at load Per average first crack width for steel reinforced specimens at load Per concrete contribution of the shear capacity of a reinforced concrete member factored ultimate shear load factor to define rectangular stress block in compression zone. 0.85-.0015f 'c 3 0.67 factor to define rectangular stress block in compression zone. 0.97-.0025f 'c 3 0.67 material factor for the diameter effect on FRP bars material factor for the general behavior of a specific FRP bar type in concrete shear factor for d in JSCE Design.Codei7

shear factor for r iIi JSCE Design Code i7

shear factor for. axial applied loads in JSCE Design Code17

midspan deflection at ultimate load strain in concrete at ultimate compression stress (0.003) ultimate tensile strain in FRP reinforcements concrete material factor (0.60) shear factor for d in CEB-FIP Design Codel9

concrete type factor (1.0 for normal) reinforcement ratio (AF or As / bd) balanced reinforcement ratio minimum reinforcement ratio for GFRP reinforced concrete members stress at failure based on the measured strain at failure ultimate tensile strength of FRP tensile stress achieved in FRP at a given stage shear factor for concrete str~mgths in CEB-FIP Design Codel9

CONVERSION FACTORS

645.1 rom2

645.1 rom2

4.448kN . 6.895MPa 9.81 MPa

1 in. 645.1 rom2

1 kip 1 ksi 1 kglrom2

REFERENCES 1. Bedard, C:, "Composite Reinforcing Bars: Assessing Their Use in

Construction," Concrete International, V. 14, No.1, Jan. 1992, pp. 55-59. 2. Fickelhom, M., "Editorial," Materials and Structures, RILEM, V. 23,

No. 137, Sept. 1990, pp. 317. 3. Makhtouf, H. M.; Ahmadi, B. H.; and AI-Jabal, J., "Preventing Rein

forced Concrete Deterioration in the Arabian Gulf," Concrete Intel7Ultional, V. 13, No.5, May 1991, pp. 65-67 ..

4. Howell, K. M., "Corrosion of Reinforced Concrete Slab Foundations," Materials Performance, Dec. 1990, pp. 15-19.

5. Yeomans, S. R., "Performance of Black, Galvanized, and EpoxyCoated Reinforcing Steels in Chloride-Contaminated Concrete," Corro-sion, V. 50, No.1, Jan. 1994, pp. 72-81. ..

6. Clarke, J. L., Alternative Materials for the Reiriforcemf(nt and Prestressing of Concrete, Blackie Academic & Professional, an import of Chapman & Hall, 1993,204 pp.

7. Chaallal, 0., and Benmokrane, B., "Physical and Mechanical Perf orman~e of an Innovative Glass-Fiber-Reinforced Plastic Rod for Concrete and Grouted Anchorages," Canadian Journal of Civil Engineering, V. io, No.2, 1993, pp. 254-268.

8. Mitsubishi Kasei, Leadline Carbon Fibre Rod Technical Data, Japan, Dec. 1992, 50 pp.

9. Canadian Standards Association (CSA), Design of Concrete Structuresfor Buildings (CAN3-A23.3-M94), Rexdale, Ontario, Canada 1994.

ACI Structural Journal/May-June 1998

10. Domenico, N., Mahmoud, Z.,and Rizkalla, S., "Bond Properties of CFRP Prestressed ~einforcements,'1 Proceedings, CSCE Annual Conference, May 1996.

11. Abdelrahman, A. A., Serviceability of Concrete Beams Prestressed by Fibre Reinforced Plastic Tendons, Ph.D .. Thesis, Dept. of Civil and Geological Engineering, University of Manitoba, Winnipeg, Manitoba, Canada, Oct. 1995.

12. Clegg, A., and Markos, S., Tension Stiffening of Concrete Reinforced by FRP, Undergraduate TheSis, Dept. of Civil and Geological Engineering, University of Manitoba, Winnipeg, Manitoba, Canada, April 1995.

13. Malvar, L. J., "Tensile and Bond Properties of GFRP Reinforcement Bars," ACI Materials Journal, V. 92, No.3, May-June 1995.

14. Malvar, L. J., "Grip Effects in Tensile Testing of FRP Bars," Second FRP International Symposium, Non-Metallic (FRP) Reinforcements for Concrete Structures, Ghent, Belgium, August 1995, pp. 108-11S.

/

IS. Grieef, S., ISQROD GFRP [')owel Bars in Concrete PCIIlements, MS Thesis, Dept. of Civil and Geologic3I Engineering, University of Manitoba, Winnipeg, Manitoba, Canada, May 1996.

16. American Concrete Institute (ACI), Building Code Requirements for Reinforced Concrete (ACI 318M-89) and Commentary ACI-318R M-89, Detroit, Michigan, U.S.A~, June 1990.

17. Japan Society of Civil Engineers (JSCE), "Concrete Library," International No.4, Tokyo, Jap311, December, 1984,329 pp.

18. Machida, A., "Desiguing Concrete Structures With Continuous Fiber Reinforcing Materials,"Dept. of Civil and Environmental Engineering, Saitarna University, Urawa, Saitama 338, Japan, 1996, pp. 1-13.

19. Cornite f!,uro-International du Beton and Federation de la Precontrainte, CEB-FIP Model Code for Concrete Structures, Third Edition, CEB, Paris, France, 1978,348 pp.

365

![«Heading» - City Planning Books | Architecture Books - … · Web viewBRITISH REINFORCED CONCRETE ENGINEERING COMPANY, LTD, THE B.R.C. Reinforcements London, 1918. [30913] 172 indexed](https://static.fdocuments.in/doc/165x107/5b5b41677f8b9a55388df078/heading-city-planning-books-architecture-books-web-viewbritish-reinforced.jpg)