Achieving "Optimum " S&OP Results with CDFR, ABB

-

Upload

innovation-enterprise -

Category

Health & Medicine

-

view

30 -

download

0

description

Transcript of Achieving "Optimum " S&OP Results with CDFR, ABB

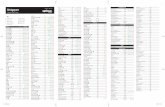

Achieving “Optimum” S&OP Results with

CPFRJanuary 27, 2011

2

Agenda

Who is Optimum NutritionNeed for CPFR in the S&OP

ProcessImplementing CPFRGoal of CPFRRoadblocks to successOvercoming roadblocksFinal ThoughtsQuestions

3

Optimum Nutrition (ON) is a dominant force in the sports nutrition industry with the highest quality products available in health food stores, specialty stores, gyms and progressive retailers everywhere

ON was founded in 1986 by two brothers in Chicago , IL Optimum Nutrition, Inc. (ON) is now a wholly owned subsidiary of

Glanbia, a leading international cheese and nutritional ingredients group based in Ireland

ON has two brands of nutritional supplements◦ Optimum Nutrition

◦ American Body Building

ON is the only sports nutrition company to manufacture items in every product category:◦ Protein Powders◦ Nutritional Bars◦ Ready-to-drink Sports Beverages◦ Vitamins

Optimum Nutrition’s History

4

Significant growth in any industry drives the industry leaders to initiate change in order to be successful…

The Sports Nutrition Industry, until recently, was not truly focused on forecasting, collaboration or the Supply and Operations Planning Process

ON recognized that in order to continue their success and support their growth initiatives, change had to occur in these areas

Need for CPFR in the S&OP Process

5

Collaborative Planning, Forecasting and Replenishment practice is the basis for achieving Optimum results from your Supply and Operations Planning Process

This collaboration must take place with both internal and external customers in order to drive results through to the S&OP process

Implementing CPFR

6

Collaborative planning and forecasting must first

begin with the demand planning function at both the

supplier and trade partner

The baseline forecast is created at the customer level

by sku to drive improved forecast accuracy

◦ Input internally from the sales and marketing functions are

key

Trade Partners and Suppliers must then openly share

Implementing CPFR

forecasting information in order to begin

the collaboration process

7

Implementing CPFR Supplier best practices:

Monthly in depth forecasting meeting with top trade

partners looking at a rolling 6 month forecast with a focus

on the next 90 days

Weekly meetings with top trade partners where possible

in order to react to changes more quickly

Compare both forecasts and manage the exceptions and

discuss any new information from both parties

New products

Promotional calendars

Supply constraints

8

Goal of CPFR is to create a more accurate forecast in order to

drive a better S&OP process

The timely handoff from the demand planning function to the

supply planning function is critical

Speed is of the essence: the quicker you can alert the supply

planning group to changes, the more success you will have in

Goal of CPFR

altering your production schedules

Helping people understand the goal of

the CPFR process is in the end to

increase fulfillment rates, improve

customer satisfaction, increase

manufacturing efficiencies and

decrease inventory DOH

9

Under developed demand planning function both at the

supplier and trade partner level

Under developed supply planning function

◦ Supply Planning vs Manufacturing?

Sales team not familiar with the collaborative planning

and forecasting model

◦ Forecasting viewed as a waste of time

Trade Partners not familiar with the collaborative planning

and forecasting model Weak S&OP process not supported by business

Potential Roadblocks to Success

10

Make sure that the demand and supply planning functions have the right team in order to drive change both internally and externally with trade partners

Help the internal sales team understand the importance of the process by demonstrating what improved forecasting can do to their sales and fulfillment levels

Help trade partners understand the importance of the process by demonstrating that improved forecasting can have a positive impact on increasing fill rates, improving out of stocks and driving sales

Implement a very detailed S&OP process◦ Weekly “mini” S&OP meetings◦ Monthly S&OP Meeting

Over communication is a good thing

How to overcome Roadblocks

11

In order to develop a great S&OP process it must first begin with a solid forecast

At least try something Monthly S&OP meetings are great, but in this industry

weekly meetings are critical to success Over communicate Goal of all good S&OP processes:

◦ Establish and achieve DOH targets while exceeding trade partners needs!!

Final Thoughts

12

QUESTIONS/DISCUSSION?