AA-SM-005-002 Bolted Connections - 2- Bolt Bending

description

Transcript of AA-SM-005-002 Bolted Connections - 2- Bolt Bending

~#temp

READ MEAuthor:R. AbbottTotal Report Pages:Check: Report:Date:Revision:Section Number:Sheet NameIMPORTANT INFORMATIONReport Title:Section:

IMPORTANT INFORMATION

About us:

XL-Viking was created to make working with Microsoft Excel easier and more efficient. XL-Viking started as an internal group at Abbott Aerospace Inc. developing Excel tools to increase productivity, reliability and quality of engineering applications. XL-Viking was establised as a seperate company in 2014.

Established in 2008, Abbott Aerospace helps people develop new aircraft structure and systems and make modifications to existing structure and systems. We do all types of aircraft - Part 23, Part 25, Civil, Military, Prototype, Experimental - and have extensive experience with composite laminate material selection, process control, manufacture, design, substantiation and certification.

We have made these spreadheets available through XL-Xiking and have helped in developing the Xl-Viking add-in.

About the Abbott Aerospace Analysis Spreadsheets:

Our in-house structural analysis toolbox is our collection of spreadsheets. The sheets that we make freely available are a small proportion of the sheets that we have developed for our own use.

They are intended to be used by engineers. They are not protected software packages and can be changed in every way by the user.

All of our spreadsheets are provided 'as is' with no warranty or guarantee explicitly given or implied. You may these spreadsheets at your own risk. The Author will nor be liable for data loss, damages, loss of profits or any other kind of loss while using or misusing these spreadsheetsWe have made every reasonable effort to remove all errors but some may still exist and all analysis work should be thoroughly checked. If you do find errors plese notify us at:

Proprietary information:

The spreadsheets contain no proprietary information from outside of Abbott Aerospace Inc. If you think that we have used proprietary information inappropriately please let us know.

Abbott Aerospace Inc. and XL-Viking grants the user the right to use, modify, reproduce and redistribute these spreadsheets. We just ask that if possible you maintain a credit naming Abbott Aerospace Inc./XL-Viking as the source.

Our analysis spreadsheets in general do not use Visual Basic routines and the outcome of the analysis in the spreadsheets rely solely on native Excel functions. The display of the math in these sheets rely on the XL-Viking add-in and the spreadsheets will not display correcly if the add-in is not installed.

To find out more about the Xl-Viking Add-in:www.XL-Viking.com

Find out more about the Design and Analysis services provided by Abbott Aerospace:www.abbottaerospace.com

&"Arial,Bold"ABBOTT AEROSPACE INC. PROPRIETARY INFORMATION&"Arial,Regular"Subject to restrictions on the cover or first page

StressAuthor:R. AbbottTotal Report Pages:3Page TitleSubSubSubFigTableRunning CountsTotal Sheet Pages:3Check: Report:AA-SM-005-002NoNoTitleTitleTitleNoNoTotal Title No:0Date:20/10/2013Revision:IRTotal Sub No:0Section Number:Sheet NameBOLT BENDINGTotal Sub No:0Report Title:STANDARD SPREADSHEET METHODTotal Sub No:0Section:Total Fig No:0Total Table No:0Author:R. AbbottDocument Number:AA-SM-005-002Check: Revision Level :IR1Date:20/10/2013Page:1 of 31Title:STANDARD SPREADSHEET METHODBOLT BENDING

References:Michael Niu - "Airframe Stress Analysis & Sizing", Chapter 6.4 E.F. Bruhn - "Analysis & Design of Flight Vehicle Structures", para. D1.14

P =2000NFastener Loadt =6.00mmLug 1 Thicknesst =10.00mmLug 2 Thicknessg =3.30mmGap or Clearance Between the Lugs

Moment Arm:b =t / 2 + t / 4 + g6 / 2 + 10 / 4 + 3.3b =8.80mmMax. Bolt Moment:MMAX =0.5 b P0.5 8.8 2000MMAX =8800NmmAllowable Moment:MALL =25000Nmm

MSBEND (incl 1.15 fitting factor) = MALL / MMAX - 1 = 25000 / (8800 1.15) - 1 =1.47

If you see errors on this spreadsheet it is because you do not have the XL-Viking Plugin, to find out more:www.XL-Viking.comAuthor:R. AbbottDocument Number:AA-SM-005-002Check: Revision Level :IR1Date:20/10/2013Page:2 of 32Title:STANDARD SPREADSHEET METHODBOLT BENDING

Method taking into account the geonetry of the lug

References:Michael Niu - Airframe Stress Analysis & Sizing, 9.8

Refer to previous section.

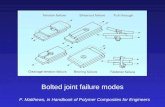

As the bolt bends, the stress distribution acting on the inner lug tends to peak ratherthan form an even distribution; thus, a weak bolt can cause a lug to fail at a smaller load than that predicted by standard methods. Peaking also results in a lower moment arm, thus causing lower bending moment in the bolt.The reduction factor, g, depends on the geometry of the lug, and is shown in the figure below.

(PU)MIN is the smaller of PBRU or PTU for the inner lug, and the FTU is the ultimate tensile strength of the lug material for the grain direction parallel to the bolt hole.

If you see errors on this spreadsheet it is because you do not have the XL-Viking Plugin, to find out more:www.XL-Viking.comAuthor:R. AbbottDocument Number:AA-SM-005-002Check: Revision Level :IR1Date:20/10/2013Page:3 of 33Title:STANDARD SPREADSHEET METHODBOLT BENDING

P =2000NFastener Loadt =6.00mmLug 1 Thicknesst =10.00mmLug 2 ThicknessD =6.35mmFastener Diameterg =3.30mmGap or Clearance Between the LugsFTU =427.0MPaUltimate Tensile Strength of the Inner Lug Materiale =12.70mmEdge DistanceP =10000NSmaller of PBRU or PTU for the Inner Lug

ABR =D tABR =6.35 10ABR =63.5mm2Bearing Area of the Inner Lug, ABR = D t2

r =(e / D - 0.5) (D / t)r =(12.7 / 6.35 - 0.5) (6.35 / 10)r =0.95

x =P / (ABR FTU)x =10000 / (63.5 427)x =0.37

Note: The chart has not been digitized. For any values of r less or equal to 0.55, the reduction factor g should be read from the attached chart.

g =0.18Reduction FactorBending Moment Arm:b =t / 2 + g t / 4 + gb =6 / 2 + 0.184 10 / 4 + 3.3b =6.76mmMax. Bending Moment:MMAX =0.5 b PMMAX =0.5 6.76 2000MMAX =6761NmmAllowable Moment:MALL =25000NmmMSBEND (incl 1.15 fitting factor) = MALL / MMAX - 1 = 25000 / (6761 1.15) - 1 =2.22

If you see errors on this spreadsheet it is because you do not have the XL-Viking Plugin, to find out more:www.XL-Viking.com

![Bolted Connections[1]](https://static.fdocuments.in/doc/165x107/54e7f8c84a7959704f8b46b8/bolted-connections1.jpg)