Bolted Connector HV

-

Upload

aziz-jamaludin -

Category

Documents

-

view

246 -

download

2

description

Transcript of Bolted Connector HV

-

Bolted Connectors for High Voltage Accessories Installed on UndergroundTransmission Lines

ByWolfgang B. Haverkamp, Raychem, Member IEEE/PES

Thomas McKoon, Georgia Tech / NEETRACM. Wilck, Raychem, Member VDE

Abstract: Splicing conductors in high voltage undergroundcable requires special skills and tools. For instance,techniques in use today include soldering, welding andcompressing. A new generation of connectors was designedand developed incorporating shear-bolts to simplifyinstallation. The application of the connectors is independentof conductor design, construction and material, and can beused on solid or stranded conductors.

The authors describe the design with respect to the differentrequirements, developmental steps, and final qualificationprocess incorporating various international standards. Thesestandards focus on product performance verification andoperational limits.

Keywords: Conductor, Connector, Aluminum, Emergencytemperature, Installer skill, ANSI C119.4, VDE 0220, IEC1238-1, HV splice, Long term stability

I. Introduction

Besides the appropriate selection of the cableaccessory for XLPE insulated transmissioncables, the connector technology is essential withrespect to stability and performance underoperation.

The problem of splicing large aluminumconductor transmission cable leads to revisitingthe existing connector techniques like soldering,welding and compression.

Soldering two conductors together requireshigh jointer practice and good knowledge of theselected materials like solder, flux and conductormetal. A soldered connection has limitedoperation temperatures, which reduces thenetwork usage capability.

.

In particular, when utilities optimize theirnetwork with regard to cost and usage, thenetwork will carry heavier loads. As aconsequence, the conductor will run at highertemperatures. Fig.1 demonstrates the possiblecost benefit per annum.

Fig 1 cost benefits per annum depending on conductor temperature

II. Why bolted connectors for HV-splices?

Commonly used in the past werecompression type connections and connectionsmade by the exothermic welding process.

Both systems have significantdisadvantages, particularly for large conductorsizes.

Compression connections are long, and a lotof material is required to restore the insulation

-

system along the connector. Heavy andexpensive hydraulic tools are required for theinstallation. To make those tools available for asmall number of connections or, for repairs, isvery costly. Furthermore, compressionconnectors have to be tailored to the conductorchamber and conductor construction, e.g. solid,stranded, stranded compact.[4] For example, theconductor diameter of an 800mm conductor canvary by about 20%, when comparing a solidconductor with a stranded conductor.Additionally, the exact cable data are oftenunavailable beforehand.

Currently available compression ferrules aredesigned for 90C continuous conductortemperature and limited emergency @ 110C.Temperatures up to 130C require special designand tooling.

The major physical behavior, which makessplicing aluminum conductors with compressionferrules critical, has been extensively covered inseveral papers [1,2]. Behaviors like cold flowand creep under mechanical and thermal stress,in addition to rapid surface oxidation, are contra-productive and require additional engineeringeffort to extend the dimensional limitations.

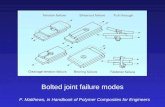

Fig 2 shows various compression shapes. InEurope the hexagonal type is commonly used, inFrance, Italy and Scandinavia deep indenttechniques are preferred [3].

Fig 2 Different compression shapesa. Indentation, b. Deep-indent, c. Multiple-indentd. Flat-indent, e. Round-indent, f. Hex-compression

The exothermic welding process (Cadweld)is critical when used in humid environments and

requires good ventilation of the working spacefor safety reasons. To dress the welds for furtherjointing work is very time consuming. Whenusing this process on longitudinally water-blocked cables, the cleaning of each individualstrand is essential. To guarantee a goodconnection, x-ray control of the finishedconnection is advisable.

III. RequirementsCables and accessories are designed to

serve for a period of min. 40 years. During itslifetime the cable line is exposed to varyingconductor temperatures between ambient andmaximum for XLPE conductor temperatureswhich can be as high as 90C and 130C foremergency conditions. Short circuits of 40kAmay occur, which can raise the conductivetemperature up to 250C for 1 sec. Mechanicalforces of the connection are caused bytemperature variation and movement of the backfilling when cables are buried directly.Installation reliability has to be taken intoconsideration. Therfore, the design of a modernconnector system must exclude jointerdependency on all quality influencing steps.

IV. SpecificationsSpecifications have to cover the

requirements in the form of elevated Design andType tests.

Several specifications try to adjust fieldexperience with laboratory tests enabling acomparison of different connector technologies.They aim to qualify connectors for the sameapplications. A comparison of commonly sizedconnector specifications is given in Table 1.

The major differences between the IEC / VDEand the ANSI Specifications are as follows:

1) ANSI does not require short circuit tests.

2) ANSI specifies conductor temp. for heatcycling. IEC / VDE specify the connectortemp.

-

3) ANSI requires only half the number of heatcycles.

In 1971 the first specification VDE 0220 forconnectors in power cable had been issued inGermany. In conjunction to a mandatory testtime interval the sample current was adjusted toreach the required test temperature at the hightemperature part of the connector.

IEC 1238-193.08Class A

VDE 0220Part 2 0.4 78

ANSI C119.4 - 1991

CompressionConnectorsup to 300 mm

Class A, tensionClass 3

No. of heatcyclesTemperatures

1000Tc = 100CConnectortemperature

1000Tc = 100CConnectortemperature

500Tc = 90C + 32kConductor temp.

Shortcircuit test

Tc =250270Cconductor-temp.t = 1 sec6 times

Tc =250270Cconductor-temp.t = 1 sec3 times

not required

--

Mechanicalload

= 40N/mmfor AL = 60N/mmfor Cubut max.20.000N

= 40N/mmfor AL = 60N/mmfor Cu

5% of rated breakingstrength of conductor

No. ofsamples tobe tested

6 6 4

Major passcriteria

T Tcon cmax max

Resistancefactor ratio:

= kk0

15.

T Tcon cm ax m ax

Resistancefactor ratio:

= kk02 0.

T Tcon cmax max

Variation ofconnectionResistance max. 5%of average of allmeasurements

Abreviation: Tc = Conductor Temperature; Tcon = ConnectorTemperature

Table 1 Comparison of relevant specification

The IEC 1238-1 is a good basic specification;however, for short circuit tests the requirementsare unrealistically high for large conductor sizes.The typical 1 sec. short circuit currents in 69 kVcable networks are reported with approx. 40 kA.

In accordance with IEC 1238, the 1 sec.conductor temp. of 250 270C is required. Fora 1000mm Cu conductor, 120 kA for 1 sec. are

required. Even with the allowed 5 sec. timeextension 54 kA are still required. A restrictionto 40 kA max. for 1 sec. and a reduction to 3high current tests would be more realistic.

The French spec refers to thermal energy(It), which is categorized for LV = 10kAs, MV= 100kAs and HV = 800kAs [5,6]. This ismore realistic and refers to short circuit valuesless than 30kA per 1 second.

In order to evaluate the long-term enduranceof any connector system the individualspecifications refer to a reference conductor testprocedure. Based on the relation to connectormass and dimensions two reference pointsmonitoring the temperature were introduced todetermine the aging aspects of conductor and testspecimen. At the same time the start upconnector resistance factor k - equation (1) - isestablished as the relation of reference conductorresistance to the connector contact resistance.

resistanceconductor = Rresistanceconnector =R

factor resistanceconnector start = k

(1) 1

con

c

0

=con

c

RRk

The k-factor is correlated to the individualdata obtained from the measurements during thetest sequence, where the variance is determinedin the equation (2)

factor resistance connector start =kfactor resistance connector final =k

ratiofactor resistance =

(2) 5.1

0

0

=kk

Depending on the connectors maximumoperation temperature, the test current in the test

-

loop needs to be raised, so that the connectortemperature reaches the maximum designoperation temperature. In this case the referenceconductor temperature will be beyond the maxconnector temperature. A typical test cycle isgiven in Fig 3.

Fig 3: Current cycle profile according to IEC 1238-1

In addition to the connector tests, it has to beproven that the connector harmonizes with thecable splice. An acceptance test used inRaychem is shown in Table 2

Sequence Test Requirement

1) Determination of the k-valueafter installation of the connector

2) Partial discharge extinguishing voltage DEV

-

Fig 5 Installation of EPPA 047

VI. Testing

As described in Table 1, various connectortest programs are necessary to establish thedatabase for the performance of the designedconnectors.Solid Al conductor 400mmtype EPPA 047

The test program was carried out inaccordance to VDE 0220, part 1a 4.78.

In table 3 the test sequence refers to aconductor temperature of 90C minimum at anAC current of I = 870A for 1000 cycle withcurrent 2h /2h on/off.

No Test Date Results

1 Voltage drop Uo 25.11.88 Uo = 1.7mV AV

2 250 load cycles 2/2 h --- ---

3 Voltage drop U1 06.02.89 U1 = 1.66mV AV

4 250 load cycles 2/2 h --- ---

5 Voltage drop U2 29.03.89 U2 = 1.65mV AV

6 Short circuit test 40 kA, 1 sec,

performed 3 times

05.04.89 U3 = 2.1mV AV

7 Voltage drop U4 06.04.89 U4 = 2.05mV AV

8 250 load cycles 2/2 h

9 Temperature measurement 28.04.89 T = 96.6C

10 Voltage drop U5 28.04.89 U5 = 2.1mV AV

11 Tensile strength 05.05.89 24kN (req.16kN min).basis S=0.04kN/mm

12 Load cycling 2/2 h, 1120 A,

130C conductor temperature

Since10.05.89

Status per April 5,1994: passed 9.123cycles (36.492 h), nofailure.

Test is ongoing

Table 3

The data perform to the requirements of voltage drop variance less 15%increase and voltage drop less than 50% increase after short circuit @40kA per 1s (1600kAs)

Comments: After completing the test and successfully

passing the mechanical pulling test the loadcycling was continued for more than 36,492hours, without change of the electrical stability.

Solid Al conductor 800mm type EPPA 047

Table 4 describes the test requirement toVDE 0220 part 2 04.78 carried on 6 connectorsrun in parallel and Table 5 describes theextension of the former test. The connectortemperature was ramped up to 100C-conductortemperature and kept for 10 minutes on thistemperature. This plateau accelerates the agingprocess, which is also implemented in the IEC1238-1 08/93 (see table 3).

Results: The total test performed more than 2,806

cycles including test sequence no. 23 with stablevoltage drop and k-factor

-

No. Test sequence Requirements1. Voltage drop over the

connector andconductor

Basic measurement

2. Load cycling 208 cycles3. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 1

4. Load cycling 416 cycles5. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 1

6. Load cycling 506 cycles7. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 1

8. Short circuit 3 Shots at 46 kA 1sec.9. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 7

10. Load cycling 722 cycles11. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 9

12. Load cycling 1064 cycles13. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 9

Table 4 Tests requirements in accordance with VDE 0220 part 2 04.78connector test 800mm Al solid

No. Test sequence Requirements14. Load cycling 1564 cycles15. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 9

16. Load cycling 2194 cycles17. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 9

18. Load cycling 2500 cycles19. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 9

20. Short circuit 3 Shots at 63 kA 1sec.21. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 9

22. Load cycling 2806 cycles23. Voltage drop over the

connector andconductor

increase of voltage drop 15 %measurement of Point 21

Table 5 Extended connector test of EPPA 047 800mm Al solid

Fig 6 Load cycling of connector 800mm Al solid Cycle time 30Min-10Min-30Min

Stranded Al conductor 2000kCM Based on PECOs request, a test program

was designed and carried out for Raychem Corp.to evaluate the thermal characteristics of theRaychems type EPPA bolted splice connectorfor use on 2,000 kcM 127 strand Al conductor.The test program has followed ANSI C119.4,1991. The specification is the AmericanNational Standard for Connectors for Usebetween Aluminum-to-Aluminum or Aluminum-to-Copper Bare Overhead Conductors. Thisstandard establishes the current carrying,resistance and tensile performance requirementsfor connectors used for continuous service undernormal operating conditions. The basic testsinclude Current Cycle Tests and MechanicalTests.

The heat cycling tests, depending on thecurrent carrying class of the connector, consistsof either 500, 250, or 125 cycles for the electricalclass of connector tested. The classes are ClassA, Class B and Class C respectively. Themechanical tests, depending on the tensile classof the connector are Class 1 full-tension, Class 2medium-tension, and Class 3 minimum-tension.Acceptable values are 95, 40 and 5 per-cent ofthe rated breaking strength (RBS) of theconductor respectively. (See also table 3)

-

The heat cycling requirements are that theconnector must operate at a temperature coolerthan that of the control conductor at all times.The temperature and resistance values of theconnectors must also be stable throughout theentire test.

These tests were conducted at the GeorgiaInstitute of Technologys National ElectricEnergy Testing, Research, and ApplicationsCenter, NEETRAC, located in Forest Park,Georgia, USA.

Fig 7 Voltage drop change over load cycling including two short circuitsdetails see table 5

Test set up

The test loop consisted of four connectorsjoined in a series loop with welded equalizers.The welded equalizers provide an equipotentialplane to assure that all strands are in contact witheach other for resistance measurements and alsoprevent the thermal influence of one connector toanother.

Prior to assembly of the test loop, theconductor ends that were to be inserted into theconnector were mechanically cleaned with a wirebrush to remove any oxide build-up on theconductor strands. The conductor used in thisevaluation was 2000 kCMIL, 127 strand, allaluminum conductor (AAC). Oxide inhibitorwas not applied to the strands because theconnectors were pre-filled by the manufacturer.

Fig 8 Test set up at GA. TECH / NEETRAC, ForestPark,Georgia,USA

Each connector is supplied with eightaluminum shear type bolts. This design bolteliminates the need for special tooling such as atorque wrench. The conductors were inserted,and starting at the center of the connector,tension was taken up on the bolts in accordancewith manufacturers instructions with a box typespanner wrench. After all bolts were tensioned,and a snug fit was established, the bolts weretensioned again, from the center of the connectoroutward, until the bolt head sheared.

The conductors were three feet in lengthfrom the edge of the connector to the equalizer inaccordance with ANSI C119.4, 1991. Thecontrol conductor was six feet in length. Eachend of the series loop was attached to an accurrent loading transformer and thermocoupleand resistance leads were attached.

The current was adjusted, during the firstthree cycles, to achieve a steady-statetemperature rise of 100 degrees Celsius, aboveambient air temperature, on the controlconductor. The required current averagedapproximately 1,804 amperes. ANSI C119.4requires that the connectors be subjected to 500cycles with each cycle consisting of a currentON period of two hours and a current OFFperiod of equal duration. However, for this testthe connectors were allowed to run for 647cycles. During the current OFF period theconnectors were allowed to return to ambient

L o a d c y c l i n g o f b o l te d c o n n e c to rs 8 0 0 m m s o l i d A l c o n d u c to r

- 3 0 .0 %

- 2 0 .0 %

- 1 0 .0 %

0 .0 %

1 0 .0 %

2 0 .0 %

3 0 .0 %0 5 0 0 1 0 0 0 1 5 0 0 2 0 0 0 2 5 0 0 3 0 0 0

cy cle no .

vari

ance o

f volt

age d

rop i

n [

s a m p le 1s a m p le 2s a m p le 3s a m p le 4s a m p le 5s a m p le 6

-

temperature. Ambient temperature averaged 24degrees Celsius over the duration of the test.

Temperature measurements of theconnectors and the control conductor were takenat the end of each heating cycle with the currenton. Type T, sub-miniature, stainless steelsheathed thermocouples were used to monitorthe temperature of the connectors and controlconductor. Three, 0.033 inch diameter, 0.025inch deep holes were drilled into the body ofeach connector for thermocouple installation.The thermocouples were located in the currenttransfer path where the highest temperatureswere anticipated. The control conductor wasmonitored with two thermocouples located in thecenter of the six-foot length.

Fig 9 2000 kcM 127 strands and Connector with thermocouples

Resistance measurements were taken atcycle zero, to obtain and initial resistance value,and then at cycles 25, 50, 75, 100, 125, 165, 205,250, 325, 405, and 500 in accordance with ANSIC119.4, 1991. Additional resistancemeasurements were taken at cycles 580 and 647.Resistance measurements were made across eachconnector, from equalizer to equalizer, after theconnectors had returned to ambient temperature.The connector temperature was recorded witheach set of resistance measurements to allow forthe correction of measured resistance values to20 degrees Celsius. The corrected values wereused to evaluate the resistance performance ofeach connector.

Results: The connections made with the EPPA

connectors performed well in the 500 cycle,current cycle test. On average, in the maximumtemperature test, the connectors ran 17 degreesCelsius cooler than the control conductor. ANSIC119.4, 1991 requires that to pass the maximumtemperature test, the connectors must operate at atemperature lower than that of the controlconductor.

In the resistance stability test, all connectorsperformed well and met all requirements forresistance stability. On average, the connectorsresistance values were 59 micro ohms. Passingcriteria is 56 to 62 micro ohms.

Examples of resistor and temperature profileare presented in fig 10 and fig 11.

Fig 10 Resistance profile over cycle

Fig 11 Temperature profile over cycle

Raychem 72kV HV Splice Type EPPA 047-42/72-180 Connector #2 Resistance

45

50

55

60

65

70

0 100 200 300 400 500 600

CYCLES

Minimum ResistanceMaximum Accepatble ResistanceResistance

Raychem 72kV HV Splice Type EPPA 047-42/72-180

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700

CYCLES

0

20

40

60

80

100

120

140

CONNECTOR #2 Maximum Temperature

AmbientTC#1TC#2TC#3Control Conductor

-

VII. Experiences and Conclusions

The bolted type connector productintroduced in the late 80s has been extended tothe a wide range of cable conductor applicationsas solid Al, stranded Al and Cu, which reinforcethe versatility of the connector design. Utilityexpectations, with respect to installer skill andshortened length of HV splices, are addressedand fulfilled.

More than 18,000 systems were installedworldwide using the above-described boltedconnector. No failures have been reported todate.

The presented results prove the long-termstability of the connector type.

VIII Future

Beyond the successfully passed ANSIC119.4 specification, the remaining 2000kcMconnector samples at NEETRACs laboratorywill be kept under test for further evaluation andstudy.

IX. References[1], M.D. Charneski, F.W. Bond Jr., R.R. Borowski,G.L. Winkler Use of polymeric electrical joint compoundin aluminum compression connectors for joiningaluminum, and copper to aluminum, power cables,CH1399-5/80/0000-0320, 1980 IEEE

[2], Louis Lam, Richard Morin Specification,performance, testing and qualification of extra-heavy-dutyconnectors for high-voltage applications, 0-7803-3522-8/96, 1996 IEEE

[3], R. Battle, D. Clarke, M. Demko, M.P. GarnerThe waterproofing of insulation piercing connectors forlow voltage aerial bundled cable

[4], Klaus Frster Kabelgarnituren anStarkstromkabeln, Elektrizittswirtschaft, Jg.85 (1986),18

X. Biography

Wolfgang B. Haverkamp graduated from theUniversity of Essen, Germany with a Masters ofScience Degree in Electrical- and PowerEngineering in 1966.His employmentexperiences included the Siemens A.G. , KaiserAluminium and Chemical Corporation.In 1980 he joined Raychem GmbH, ElectricalProducts Division in Ottobrunn, Germany. Hisareas of responsibility have included managingprojects on cable accessory development, theirapplications and product management. He iscurrently Technical Manager for CableAccessories in Ottobrunn, Germany. He is aWorking Group Member of IEEE/ICC.

Manfred H. Wilck received his EngineeringDegree in 1959.After 12 years of experiencewith Kabelmetal in Hannover in Cable NetworksDesign and Cable Accessories Development, hejoined Raychem GmbH in 1971. He has been theManager of the Cable Accessories Departmentfor several years. He is a Working GroupMember in VDE and CENELEC.

Thomas L. McKoon is a ResearchCoordinator and Principal Investigator atGeorgia Institute of Technologys NationalElectric Energy Testing, Research andApplications Center (NEETRAC) in Forest Park,Georgia, USA. He holds a degree in MechanicalTechnology from Carroll Tech, Carrollton, GA.He has an extensive background in electricalconnectors which are used throughout theelectric utility industry. He is a member ofANSI C119.4 subcommittee, and is chairman ofthe Working Group on Testing. He is a memberof ANSI C119.1 subcommittee on SealedInsulated Underground Connectors.