A R a L Coli & M Kasem - NISCAIRnopr.niscair.res.in/bitstream/123456789/24533/1/IJFTR 31...Indian...

Transcript of A R a L Coli & M Kasem - NISCAIRnopr.niscair.res.in/bitstream/123456789/24533/1/IJFTR 31...Indian...

I ndian Journal of Fibre & Texti le Research Vol . 3 1 , September 2006, pp. 387-393

Structural and functional characteristics of yarns manufactured by different pneumatic spinning systems

A R iva" , L Coli & M Kasem I nstituto de Investigaci6n Text i l de Terrassa CINTEXTER), Un iversidad Pol i tecnica de Catalufia, Spain

Revised received 2 J April 2005; accepted R lillie 2005

The structural and functional properties of yarns manufactured by two pneumatic spinning systems, namely pneumatic wrapping spinn ing by false twist and pneumatic spinn ing by real wrapping twist, have been studied and compared to those of the yarns manufactured by conventional ring spinn ing. These properties are assessed by determining apparent diameter. yarn deformation, yarn evenness, hairiness, neps, average apparent twist, tenacity, elongation, twist v ivacity, elongation due to untwist-backtwisting and residual shrinkage. The real wrapping twist pneumatic spinn ing system produces yarns that have a less pronounced corkscrew structure than those produced by false twist pneumatic spinning. However, the yarns produced by real twist spinning show some characteristics of i rregularity and dynamometric characteristics that situate them in an inferior position to yarns produced by conventional r ing spinn ing.

Keywords: Cotton, Corkscrew structure, Pneumatic spinn ing, Polyester, Ring spinning, Wrapping fibre. Yarn

IPC Code: I nl. C I .8 00 1 H i l l i S

1 Introduction

Of the various spinning systems uti l ized to manufacture yarns, pneumatic spinning allows one of the quickest speeds of production. Nevertheless, the yarns manufactured by pneumatic spinning are characterised by a particular structure, i n which a core of paral lel fibres is bound by wrapping fibres . This structure is peculiar and responsible for the difference between the physical properties of these yarns and those of the yarns manufactured by conventional ring spinning or open-end spinning (rotor) systems.

The yarns manufactured by pneumatic spi nning have a corkscrew type structure that is more or less pronounced depending on the quant i ty of wrapping fibres and on their tension around the core fibres. The regularity and other structural characteristics of the pneumatic yarns depend on a number of variables in the spinning process .

I n this paper, the structural and functional properties of yarns manufactured by two pneumatic spinning systems (pneumatic wrapping spinning by false twist and pneumatic spinning by real wrapping twist) have been studied and compared to those of the yarns manufactured by the conventional ring spinning. I - 1 2 These properties are assessed by

"To whom all the correspondence should be addressed. E-mai l : [email protected]

determining the parameters, such as apparent diameter, yarn deformation, yarn evenness, hairiness, neps, average apparent twist, tenaci ty, elongation, twist v ivacity, elongation due to untwist-backtwisting and residual shrinkage.

2 Materials and Methods

2.1 Materials

The yarns used in the study were of three types. Two types of yarns were manufactured using two different pneumatic spinning systems and the third type was obtained using the conventional ring spmnmg.

The two pneumatic spinning systems used were as follows:

( i ) Pneumatic wrapping spinning by false twist , hereafter refened to as HZNtf.

( i i ) Pneumatic spinning by real wrapping twist, hereafter refened to as HZNtrz .

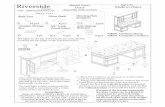

The fundamental difference between the two systems is the manner in which they twist the wrapping fibres. The pneumatic wrapping spinning system (HZNtf) (Fig. I ) cons ists of a tandem twistdetwist air jet. The types of air jets which are now used to impart transient (false) twist in the pneumatic wrapping-spinning system have the disadvantage that the spun yarn takes the characteristical form of a

388 I N DIAN J . FIBRE TEXT. RES., SEPTEMBER 2006

1 2

Fig. I�Murata MJS technique ( I -draft i ng roller, 2-del ivcry roller, 3-suction nozzle, 4-false twist nozzle, 5-compressed air, 6-fibre and 7-yarn)

R 3 4

2

Fig. 2�New technique ( I -draft roller, 2-dc l i very roller, 3-tw ist ing nozzle, 4-false twist m in i-spindle, 5-comprcssed a i r, 6-fibre, 7-yarn and 8-dust and free fibres suction)

corkscrew and shows a rough touch which negatively influences the properties of the end product. Thi s effect i s particularly felt i n the case of h igh qual i ty woven and kni tted fabrics. On try ing to weigh out the low twisting power of the spinning air jets by air overpressure, the excess of flows degradates the quality of the yarns . Thi s fact, together with high hairiness more considerable in 1 00% cotton spun yarns, negat ively influences the properties of the end product and thus the appl ication of these yarns is I imited. 1 3- 1 9 A Murata MJS 802 spinn ing frame was ut i l ized to implement this spinning system.

The HZNtrz system (Fig. 2) i s able to produce real twist yarns ; it is basically composed of a false twist min iature spindle and a special air jet, responsible for the aspiration of s l ivers from the drafting roller (R), for releasing the ends of fibres corresponding to the group of fibres transient twisted by the false twist min i-spindle (4) and for twist i ng them (real twist) on the nucleus. When the yarn loses the false twi st, after going through the false twist mini -spindle, the twisting of fibres wrapping the nucleus is reinforced. All along the spinning zone, the fibres and the yarn are guided by special ducts connected to a vacuum

Table I �Average fibre length and evenness of the s l ivers

Composi t ion Average fibre Evenness Neps '

% length, m m Uster C Y % neps/g

CO PES

1 00 27.5 3 . 84 I I 75 25 28 .5 4.46 9 50 50 30.0 4.49 9 25 75 3 1 .7 3 .57 7

1 00 34.8 2.95 4

pump to prevent the contamination of dust and fluff in the working envi ronment. The yarns produced wi th this system have a structure almost l ike that of a conventional yarns, where the fibres covering the nucleus have real twist and only the fibres i nside remain wi thout torsion, as described earl ier.20. 2 1

A prototype studied at the I nsti tute of Textile Research of Terrassa ( INTEXTER) was ut i l ized to i mplement this spinning system. The yarn obtained using conventional ring spinning are referred to as RS.

Cotton/polyester blend yarns ( 1 5 tex) were spun on each of the spinning systems i n the ratios 1 00:0, 75 :25, 50:50, 25:75 and 0: 1 00. The raw materials used were extra-long Egyptian cotton (CO) and 1 .3/38 Br polyester (PES) .

The spi nning was done in an INTEXTER pilot plant. The s l ivers of al l the composi tions were made by three passes through a modified Ingolstadt (Shubert-Salzer) drawing frame. From the resulting s l ivers, the evenness of the s l iver and the average fibre length were determined.

The average fibre length was determined as per the DIN Standard 53808 (ref. 22) using Afis (Uster) equipment.23 The evenness of the s l ivers was obtained using an Uster Evenness Tester I I I 23 following the ASTM Standard D 1 425 (ref. 24).

The characteristics of the resulting sl ivers are given in Table I .

2.2 Methods

2.2. 1 Apparent Diameter and Yam Deformation

To determine the apparent diameter and the yarn deformation of the wrapped yarns, a unique methodology was developed. The yarn was taken under constant tension over a glass sl ide to faci l itate a continuous observation of i ts s tructure. The diameters de and d; were measured in the tested yarns by means of optical and electronic microscopy, where the hairi ness can be easi ly d iscarded optically (Fig. 3) .

One hundred measurements were made for each type of yarn. The average apparent diameter,

RIV A I:l al. : STRUCTURAL & FUNCTIONAL CHARACTERISTICS OF YARNS 389

Fig. 3--Structure of the HZNtrz yarn

necessary to study the yarn deformation, was measured in the areas of l i ttle deformation. The coefficient of yarn deformation was determined using the following relat ionship:

d - d D = e i

e d

where De i s the coefficient of deformation (0 < De > I ) ; dc, the maximu m diameter of the yarn ()..I.); di, the minimum diameter of the yarn ()..I.); and d, the average apparent diameter of the yarn in non-deformed areas ()..I.) .

The closer the value of De to one, the greater i s the deformation of the result ing yarn, which wi ll have a more pronounced "corkscrew" structure. On the other hand, as this value approaches zero, the yarn shows less deformation and is more cylindrical . Figure 4 i l lustrates the meaning of the parameters indicated above.

2.2.2 Yam Evelllless, Hairilless alld Neps

The yarn evenness was determined with an Uster Evenness Tester I I I 23 as per the ASTM Standard D 1 425 (ref. 24). The hairiness and neps were analysed using the method i ncorporated i n the evenness tester, which gives a value corresponding to the total hairiness and the number of neps.

2.2.3 Average Apparellt Twist

The average apparent twist of the yarns was determined using the Zweigle 0-3 1 2 S Automatic Digital Twist Counter, fol lowing the DIN Standard 53832 for twi st-backtwist ing.25

2.2.4 Tellacity alld Elongatioll

Uster Automatic Dynamometer was used to determine the tenac i ty and elongation of the yarns, fol lowing the ASTM S tandard 02256 (ref. 26) . Each yarn was tested 1 00 times and the average was taken .

2.2.5 Twist Vivacity

Twist vivacity i s the tendency of a yarn to twist as a consequence of the twist caused by the spinning process. The method to determine the twist vivaci ty

Fig. 4-Wrapped yarns (a) with l i ttle deformation and (b) with pronounced deformation

entai ls determining the twist produced in a thread after it is plied and hung with a small weight and left to twist until it stabi l ises. The backtwisting was determined following the ISO 206 1 (ref. 27).

2.2.6 Elongatioll due to Ulltwist-Backtwisting Effect

This parameter was determined from the elongation curve that results from the untwist-backtwisting of the yarn . The method is based on the hypothesis that the lesser the degree to which the thread exhibits a corkscrew structure, the greater i s the compensation for fibri llar twist ing in the group of fibres that make up the nucleus of the wrapped yarn. For this reason, the elongation curve yields i nformation on the structure of this type of yarn. The process fol lowed to determine the elongation curve is as fol lows:

The average apparent twist was measured using an automatic twist counter and following the usual procedure. Subsequently, the elongation produced in the yarn at the following four different moments of backtwisting was measured:

• When half (50%) of the apparent twist of the yarn had unwound.

• When all ( 1 00%) of the apparent twist of the yarn had unwound.

• When half (50%) of the apparent twist of the yarn had backtwisted.

• When all ( 1 00%) of the apparent twist of the yarn had backtwisted and the yarn had reached its in i ti al length.

390 I N DIAN J . F IBRE TEXT. RES. , SEPTEMBER 2006

The average apparent twist of the yarns along with the elongation curves was determined using a Zweigle D-3 1 2 S Automatic Digital Twist Counter following the untwist-backtwisting method as per the DIN Standard 53832 (ref. 25).

2.2. 7 Residual Shrinkage

This parameter was observed by determining the contraction undergone by the yarns after being boiled in distilled water. The testing method was based on determining the length of a 2620 tex hank, prior to and fol lowing hydrothermal treatment, by suspending a 497 g weight from it for 30 s . The procedure used was as follows :

Acclimate the hanks to a standard relative temperature and humidity for a min imum of 24 h prior to the test.

Determine the in i tial length of the hanks while they sustain a weight of 479 g for 30 s .

Carry out the aforementioned shrinkage test. To avoid the hanks becoming tangled during the boi l ing process, they were introduced longitudinally into i ndividual pouches made of Marquisette fabric . The boi l ing time was 30 min . The hanks were subsequently allowed to cool till they reached an approximate temperature of 50° C .

Centrifuge the hanks for 3 m in , dry them at 30-40° C and then suspend them for 2 h under forced ventilation.

Re-accli mate the hanks.

Re-measure the length of the hanks in the same conditions indicated before.

Calculate the shrinkage using the following formula:

Ini t ial length - Final length 1 00 Shrinkaae (%) = x t:> Initial length

3 Results and Discussion

3.1 Apparent Diameter and Yarn Deformation

The results obtained for these parameters are shown i n Table 2. While i n all the cotton/polyester blends the apparent diameters of the HZNtf yarns are smaller than the HZNtrz yarns, the significant differences do not exist among the different blends.

It can be clearly observed that for all the cotton/polyester blends the deformation produced by the HZNtrz system is less than that of the HZNtf yarns. This reflects the difference that exists between the two spinning systems; in the HZNtrz system, as a consequence of not generating false twist, the wrapping fibres are submitted to less tension than i n the HZNtf which subsequently diminishes the corkscrew effect and, therefore, yarn deformation. Consequently, the structure of the HZNtrz yarns is closer to that of the yarns produced by conventional ring spinning.

The yarns with 50 :50 CO/PES blend ratio show a sl ightly higher degree of deformation for both the spinning systems. For the HZNtf system, the 1 00% polyester thread shows the lowest degree of deformation, whi le in the HZNtrz system the 75 :25 CO/PES yarns show the lowest degree of deformation.

The differences in deformation between samples of different cotton/polyester blends can be attributed to sl ight, inherent variations i n tension during the spinning process that stem from spinning different compositions of materials .

3 .2 Yarn Evenness, Hairiness and Neps

Table 3 shows the results for yarn evenness and Table 4 the results for hairiness and the number of neps for 5 different cotton/polyester blends studied.

The yarns produced by the three spinning systems show CY Uster values within the 25th percentile of the Uster Standard. The HZNtf yarns yield lower values, i .e . they have a lower percentage of

Tablc 2-Apparcnt d iameter (0) and yarn deformation (Dc)

Composi t ioll, o/(J HZNtrz system HZNtf systcm

CO PES 0 CV % De 0 C V % De

� � � �

1 00 2 1 . 8 42.83 0.448 1 8 .2 42. 1 4 0.63 1

75 25 22.6 37.34 0.277 1 8.4 34.83 0.6 1 1

50 50 22.2 34. 1 1 0.450 1 7.4 33.94 0.745

25 75 22.0 42.92 0.352 1 8 .4 33.54 0.590

1 00 22.2 4 1 .03 0.33 1 1 8 .2 35 .25 0.5 1 8

RIVA 1'1 {[t . : STRUCTURAL & FUNCTIONAL CHARACTERISTICS OF YARNS 39 1

Table 3-Yarn evenness propert ies

Composit ion Uster Thin places (-50%) Thick places (+50%)

% CV % 1 1 1 000 III 1 1 1 000 III

CO PES HZNtrz HZNtf RS HZNtrz HZNtf RS HZNtrz HZNtf RS

1 00 1 4.6 1 2 .55 1 3 .9 I S 4 1 0 44 4 34

75 25 1 5 . 1 7 1 2 .53 1 4.47 3 1 2 1 2 47 5 28

SO SO 1 5 .89 1 2 . 6 1 1 5 .47 59 6 1 2 89 1 4 47

25 75 1 5 .92 1 3 .82 1 5 .76 64 8 45 47 26 67

1 00 1 7 .64 1 4. 1 1 1 6 . 6 1 69 20 86 89 1 6 80

Table 4-Neps and hairi ness of the yarns

Composition %

Neps ( +200%) 1 1 1 000 III

Hairi ncss (h ) (J Hairi ness

CO PES HZNtrz HZNtf RS H ZNtrz HZNtf RS HZNtrz HZNtf RS

1 00

75 25

SO so 25 75

1 00

29

3]

42

1 7

1 3

I S 1 3

28

40

\ I

9 3.85

1 6 3 .8

1 0 3 .89

25 4.0 1

5 4.4 1

4 .33 4.06 1 .07 1 .24 0.9

4.23 3 .89 1 .02 1 . 1 0 .85

3 .96 3.44 0.99 1 .03 0.76

3.78 3 . 83 1 .04 0.94 0.85

3 .74 4.62 I . 00 0.82 1 .06

Table .'i-Average apparent twist and dynamometric propert ies of the yarns

Composit ion. %

CO PES

1 00

75 25

so so

25 75

1 00

Average apparent twist twistS/ill

HZNtrz HZNtf

374.2 472.9

1 92.4 392.0

1 83 .4 4 1 4. 7

1 77 .8 408.4

1 1 2 .3 464.5

Valucs in parentheses are CV%.

HZNtrz

1 5 .04

(9.97 )

1 4.94

( 1 0.73)

1 6.38

( 1 2 .45 )

22.5 I

( 1 3 . 1 4)

24.84

( 1 4 .59)

i rregularity. I t i s also these yarns that have a smaller i ncidence of thin and thick parts.

The HZNtrz yarns have the highest Uster coefficients of variation, and are thus less even. They also have the highest number of th i n and thick parts. So, the HZNtrz yarns have less corkscrew structure but simultaneously are more i rregular because along the yarn length more thi n and thick places exist (Fig. 5) .

The yarns obtained by pneumatic spi nning show higher numbers of neps than the conventional yarns; the values for the HZNtrz yarns are s l ightly h igher than those for the HZNtf yarns.

Though the values for hairi ness are general ly around 25% l imi t of the Uster S tandard, a few samples sl ightly exceeded i t . D ifferences between the spinning systems were not observed.

Tenacity Elongation cN/tex %

HZNtf RS HZNtrz HZNtf RS

1 6.42 26.82 3 .8 3 .58 4 .77

( 1 0.37) (9 .68) ( 1 0.05) ( 1 3 .48) (7 .6 1 )

1 7 .65 24.84 4.33 3 .75 5 .2

(9 .34) (9 .68) ( 1 1 .(8) ( 1 1 .54 ) (7 .29)

1 7 .44 2 1 . 1 4 6.92 4.72 5.47

( 1 0.73) (9 .53) ( 1 7 .3 1 ) ( 1 3 .76) ( 1 0.54)

20.28 23 .99 1 0.36 7 .02 9.76

( 1 1 .9 1 ) ( 1 4.92) (9.49) ( 1 3 .94) ( 1 6 .03)

23.49 3 1 .29 1 0.04 9 . 1 2 1 2 .35

( 1 3 .89) ( 1 4.86) (9 .57 ) ( 1 0.89) (7 .76)

a

b

Fig . .'i-Corkscrew and evenness (a ) yarn without corkscrew but with bad evenness and ( b) yarn with corkscrew but with good evenness

3.3 Average Apparent Twist, Tenacity and Elongation

The results obtained are shown i n Table 5. The HZNtf yarns un iformly show h igher twist values than the HZNtrz yarns. The yarns obtained by pneumatic spinning have lower tenac i ty values than the yarns

392 INDIAN J. FIBRE TEXT. RES., SEPTEMBER 2006

produced by conventional ring spinning, as expected. The inferior tenacity of pneumatic yarns with respect to conventional yarns is a well-known fact and represents one of the main disadvantages of this type of yarn . There were no differences worthy of mention between the two pneumatic spinning systems.

The i ncrease in polyester fibre percentage i ncreases the tenacity of the yarns produced on pneumatic spinning systems. There is a sl ight loss in tenacity of conventional yarn as the polyester percentage is i ncreased to 50%; the tenac i ty however increases on further i ncrease i n polyester content.

For the yarns obtained by pneumatic spinning, the elongation values are lower than those obtained by conventional yarns ; the HZNtf yarns have the lowest values . Thi s behaviour can be explained by their yarn structure; in the case of the HZNtf yarns, there exists a smaller chance of sliding of fibres i n the nucleus of the yarn .

3.4 Twist Vivacity of Threads

The values of twist v ivac ity (Table 6), somewhat higher in the HZNtf yarns, indicate that these yarns have a greater tendency to backtwist than the HZNtrz yarns. Once again, the values for this parameter i ndicate that the structure of the HZNtf yarns has areas where the wrapping is very pronounced.

3.5 Elongation due to Ulltwist-Backtwistillg Effect

Table 7 shows that the values obtai ned for elongation due to the untwist-backtwisting effect are greater in the HZNtf yarns for all the cotton/polyester

Table 6-Average twist vivacity of the yarn

Composition, % Twist v i vacity, twistS/ill

CO PES HZNtrz HZNtf

1 00 20.7 30.6

75 25 25.0 39.6

50 50 1 9. 1 49.8

25 75 1 8 .2 49.9

1 00 29.4 49.8

blends, which indicates that these kind of yarns have a more pronounced corkscrew structure than the HZNtrz yarns .

Coherent elongation values were obtained for the 1 00% polyester and 25 :75 cotton/polyester yarns . The values i ncrease when the yarn approach the total unwound and then decrease to zero once the yarn had completely backtwisted. In other cases, the behaviour was somewhat anomalous. One should take note that as the yarns did not show a uniform twist, the moment at which the yarn was completely untwisted cannot be determined wi th exactitude (even if the apparent twist had been determined previously). Thus, it i s possible for the yarns to begin to twist again w ithout reaching zero twist, and for this reason they have a smaller length at the end of the test than at the beginning; thi s explains why i n some cases negative elongation values are obtained.

3.6 Residual Shrinkage

The values for residual shrinkage are shown in Table 8. I t can be observed that the HZNtrz yarns show less shrinkage than the conventional yarns and that the HZNtf yarns exhibit more shrinkage. The reason behind thi s behaviour is again the HZNtf yarns' thread composition, which is characterised by a strong wrapping configuration.

This behaviour is explained by the fact that inside a hank the areas of HZNtf yarns that have a corkscrew structure are more l ikely to be compacted.

The HZNtrz yarns have a higher apparent diameter than the HZNtf yarns, though they have an identical count (number of fibres per section). Thus, the porosity of the HZNtrz yarns is greater than that of the HZNtf yarns .

Furthermore, there i s a greater incidence of yarn deformation in the HZNtf yarns than i n the HZNtrz yarns, which causes the former to be more l iable to suffer shrinkage.

The 1 00% cotton yarns had the least shrinkage throughout. Bearing in mind the fact that the polyester

Table 7-Elongation due to the untwi st-backtwisting effect

Untwist- Elongation, % backtwisting

1 00% CO 75:25 CO/PES 50:50 CO/PES 25:75 CO/PES 1 00% PES % HZNtrz HZNtf HZNtrz HZNtf HZNtrz HZNtf HZNtrz HZNtf HZNtrz HZNtf

0 0 0 0 0 0 0 0 0 0 0

-50 0.24 0.27 0.08 0.2 1 0.08 0.82 0. 1 1 0.32 0.08 0.47

- 1 00 0.36 0.39 0. 1 0 0.32 0.08 0.45 0.22 0.56 0. 1 2 0.80

50 0.2 1 0.36 -0.02 0. 1 1 -0.07 0.32 0.2 1 0.52 0. 10 0.74

1 00 -0.50 0.02 -0.48 -0.39 -0.44 -0.36 0.00 0.00 0.00 0.05

RIV A et al. : STRUCTURAL & FUNCTIONAL CHARACTERISTICS OF YARNS 393

Table 8--Residual shrinkage

Composition, % Residual shrinkage, %

CO PES HZNtrz HZNtf RS

100 1 .73 2.07 2.30

75 25 1 .93 4.4 1 3 .03

50 50 2.34 4.89 3 .60

25 75 2.27 4.96 3.20

1 00 2.4 1 4.33 2 .54

yarns had not been thermofixed beforehand, it stands to reason that the polyester and the cotton/polyester blend yarns should exhibit a greater degree of shrinkage.

4 Conclusions 4.1 The real wrapping twist pneumatic spinning

system gives rise to yarns that exhibit less yarn deformation and have a sl ightly greater apparent diameter than the yarns produced by the false twist spinning system.

4.2 The yarns obtained by the real twist pneumatic system (HZNtrz) exhibit less evenness although have a greater number of thin and thick places which exceed in both measures the corresponding values for the HZNtf yarns . The HZNtrz yarns also have a h igher number of neps.

4.3 The average apparent twist is greater in the HZNtf yarns than in the HZNtrz yarns for all the blends studied.

4.4 The dynamometric behaviour of the yarns produced by both pneumatic spinning systems is very s imi lar and logically worse than that of the yarns produced by conventional ring spinning.

4.5 The HZNtrz yarns have less twist v ivaci ty than the HZNtf yarns.

4.6 The elongation due to untwist-backtwisting is greater in HZNtf yarns than that in HZNtrz yarns.

4.7 The shrinkage produced by hydrothermal treatment is less in HZNtrz yarns than in HZNtf yarns.

It can be concluded that the real wrapping twist pneumatic spinning system produces yarns that have a less pronounced corkscrew structure than those produced by false twist pneumatic spinning. However, the yarns produced by real twist spinning show some characteristics of irregularity and dynamometric characteri stics that si tuate them in an

inferior position to yarns produced by conventional ring spinning.

References 1 Artz P, Messmer R & Maide H, Text Prax Int, 4 ( 1987) 363. 2 Salhotra K R, Indian J Fibre Text Res, 17 ( 1 992) 255. 3 Coll-Tortosa L, Chemiefasem Text Illd, 27 ( 1 977) 422. 4 Garcia E, Hilarura Ileumatica par falsa tarsi6n: relacioll elltre

los parametros de hilatura y las propiedades al usa de los tejidos, Ph.D. thesis, Un iversidad Politecnica de Cataluiia. Barcelona, Spain, 1 993.

5 Krause H W, Mellialld Textilber, 68( I ) ( 1 987) 7. 6 Mori S, U S Pat 5,2 1 1 ,00 1 (to Murata Kikai Kabushiki Kaisha,

Kyoto, Japan), 1 8 May 1 993. 7 Nishimura S, U S Pat 4,827,7 10 (to Murata Kikai Kabllshiki

Kaisha, Kyoto, Japan), 9 May 1989. 8 Mori S, U S Pat 5, 193,335 (to Murata Kikai Kabushiki Kaisha,

Kyoto, Japan), 16 March 1 993. 9 Deno K, U S Pat 5,528,895 (to Murata Kikai Kabushiki

Kaisha, Kyoto, Japan), 25 June 1 996. 1 0 Lawrence C A & Baqlli M A , Text Res J, 6 1 (3) ( 199 1 ) 123. 1 1 Uematasu I, Text Prax lilt, 4 1 ( 1986) 1057. 12 Kasem M H M, Aportaci61l tecllalogica a l pracesa de hilatllra

lIeulIlatica par tarsioll real de ZUllchado, Ph.D. thesis, Universidad Politecnica de Cataluiia, Barcelona, Spain, 1 999.

1 3 Artzt P , H i latura por chorro de aire de mezclas de fibras celul6sicas diversas, Tech Text IlIf, 35( 1 ) ( 199 1 ) 29.

14 Chasmawala R J, Hansen S M & Jayaraman S, Text Res J, 60(2) ( 1 990) 6 1 .

1 5 Coli L & Garda E, Bal Infexter. 9 6 ( 1989) 86. 16 Wang K Y & Jordan G, Melliand Textilber, 65(6) ( 1 984) 374. 1 7 Nakayama T, Yamagata S & Asano T, The New Spinlling

Techllology of Fasciated Yams, paper presented at the 22nd I nternationale Chemiefaseltagung, Dornbirn, 8 - 10 Juny 1983.

1 8 Coli L , Garcia E & Galvan F , Mellialld Textilber, 73(3) ( 1992) 220.

1 9 Artzt P, Dal lmann H & Shou Tsai I , Text Prax lilt, 41 (5) ( 1986) 509.

20 Feuerlohn H, Coli L, Roig F, Weide T, Tornero J A & Schulze 0, U S Pat 6,209,304 (to W Schlafhorst AG&Co, Germany), 3 April 200 1 .

2 1 Feuerlohn H , Coli L , Roig F , Weide T, Tornero J A & Schulze 0, U S Pat 6,3 14,7 14 (to W Schlafhorst AG&Co, Germany), 13 November 200 I .

22 DIN Stalldards DIN 53808 (Deutshes Institut fUr Normllng e.V., Berl in), 2003.

23 Uster Afts Catalogue - N. -L & D. -T (Zel lweger Uster AG, Uster, Switzerland), 1 994.

24 ASTM Stalldards ASTM 01425 (ASTM International, West Conshohocken, PAl, 1 996.

25 DIN Standards DIN 53832 (Deutshes Institut fUr Normung e.V., Berl in).

26 ASTM Stalldards ASTM 02256 (ASTM International, West Conshohocken, PAl, 2002.

27 ISO St(lIldards ISO 2061 (International Organisation for Standardization, Geneva), 1 995.

, .