(a) (b) 11 PFG NMR plot

Transcript of (a) (b) 11 PFG NMR plot

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

In-situ NMR-based methodology for screening and optimisation of

heterogenised organocatalytic systems

Previous research track record

Principal Investigator (PI) – Dr Carmine D’Agostino (CDA) is a chemical engineer, with a BEng

(XXXX) and MEng (XXXX) from the XXXXXX, and was awarded his PhD (supervised by Prof.

XXX) from the University of Cambridge (XXXX) for NMR techniques to study sustainable

manufacturing of fine chemicals using heterogeneous catalysis on the project TSB (TP/7/ZEE/6/I/

N0262B). This was followed by postdoctoral positions as research scientist, during which he

delivered on several strategic UK catalysis projects, including the EPSRC CASTECH (EP/

G011397/1) project on sustainable catalytic technologies and Johnson Matthey (JM) industrial

projects on developing heterogeneous catalysts. He then was awarded a prestigious Junior

Research Fellowship (JRF) by Wolfson College, University of Cambridge, and took up a position

as teaching fellow in the same institution, successfully supervising two PhD projects on

spectroscopic studies of heterogeneous catalytic systems. He has also worked in the oil and

refining industry (companies ENI and Technip) both as planner and process engineer, gaining

skills in project management and interfacing with the chemical industry. In February XXXX, CDA

was appointed as Lecturer in the School of Chemical Engineering and Analytical Science at the

University of Manchester within the Catalysis and Porous Materials research group.

CDA’s primary research area is in catalysis and porous materials, with specific focus on key

phenomena that lie at the heart of catalysis, such as diffusion, adsorption and reactivity in porous

catalysts, by developing novel NMR protocols that exploit pulsed-field gradient (PFG) NMR and

NMR relaxation techniques, together with other spectroscopic tools. The PI has published 54 peer-

reviewed papers (h-index = 14, over 890 citations), winning prizes for top quality and highly cited

papers, and a book chapter in Handbook of Green Chemistry (Wiley-VCH), currently in production.

CDA has a proven track record of delivering high-quality scientific work in the areas of

heterogeneous catalysis and physical chemistry of porous materials.1-22 His previous work on

diffusion in porous media highlights the experimental approach to investigate and quantify mass

transport in porous catalysts in order to identify key features of the pore structure that determine

catalyst behaviour. Using diffusion NMR techniques combined with T1 NMR relaxation he was able

to reveal new insights into the unusual behaviour of enhanced diffusion of polyols confined in

porous materials, highlighted in a publication on the Journal of Physical Chemistry C (2012).4 In a

work on the catalytic oxidation of propylene glycol over AuPt/C catalyst, using NMR diffusion

techniques the PI demonstrated the importance of rate of diffusion transport inside the catalyst

porous matrix and how this affects catalyst behaviour, which posits that presence of micropores

causes particular problems in

terms of catalyst deactivation

(Figure 1). This paper conferred

a prize for ‘Highest Quality

Paper’ featuring on the front

cover of Catalysis Science &

Technology (2014).8

Adsorption is also a key

aspect in dictating catalytic

behaviour in catalyst pores. PI

demonstrated for the first time

the ability of T1 and T2 NMR

relaxation to non-invasively

quantify adsorption of liquids in

0

1

2

3

4

5

6

0 0.2 0.4 0.6 0.8 1

Ds

low [

m2 s

-1]

x 1

01

1

Pore volume [cm3 g

-1]

Fresh catalyst

1st run catalyst

4th run catalyst

Din

mic

rop

ore

s [

m2

s-1

]

10

-11

Pore volume [cm3 g-1]b-factor

0.001

0.01

0.1

1

0 5 109

1 1010

1.5 1010

2 1010

Micropore diffusion

NM

R s

ign

al

PFG NMR plot

(a) (b)

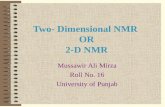

Figure 1. (a) PFG NMR plot from which it is possible to extract diffusion coefficient in the micropores of the AuPt/C catalyst. (b) Values of micropore

diffusion coefficients plotted as a function of pore volume after each reuse of

the catalyst. Adapted from D’Agostino et al. (2014).8

EPSRC Reference: EP/S019138/1 Page 1 of 8EPSRC Reference: EP/S019138/1 Page 1 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

heterogeneous catalysts. The findings

showed a relationship between NMR

relaxation measurements and

energetics of adsorption of molecules

over catalyst surfaces (Figure 2), and

were highlighted by the European

Journal of Chemistry (2014).7

The snapshots presented above

have then set the basis for the

application of these experimental

protocols in real-working catalysts,

showing the ability to identify key

parameters that determine the catalyst

behaviour including solvent,3, 5, 14 type of

substrate5 and metal particle size.18

Faraday Discussion - Complex Molecular

Surfaces and Interfaces (2017)20 highlighted

PI’s recent work on these NMR protocols and

their ability to quantify molecular dynamics of

molecules confined in porous materials

whose surface was modified by

immobilisation of organic species (Figure 3).

PI’s expertise and proven track record in

reaction and NMR studies of fluids in porous

materials puts him in an advantageous

position to explore and validate new ways of

exploiting NMR methods to design and optimise organocatalyst immobilised on solids.

Coupling traditional catalyst screening with NMR methods (i.e., spectroscopy, diffusion and

relaxation) it will be possible to achieve a comprehensive picture of the physico-chemical

behaviour of chemical reactions occurring over organocatalysts immobilised in porous structures;

this includes reactivity, molecular transport and surface effects, which have so far been largely

unexplored but are thought to play a crucial role in the heterogenisation of homogeneous catalysts

over solid supports.23

PI will collaborate with Prof. Armando Carlone (AC) at the Università de L’Aquila in Italy, an

expert in homogeneous organocatalysis and organic synthesis with high impact work in the area,24-

27 including implementation of such processes at the commercial scale. This collaboration will bring

organic chemistry expertise, which will lead to a powerful synergy with PI’s expertise in physical

chemistry of solid catalysts. The outstanding facilities of PI’s School at the University of

Manchester to study liquid-phase catalysis and the possibility to interact with Prof. Chris Hardacre,

a world-leading catalyst scientist, will provide the optimal environment for catalyst preparation,

characterisation and testing. The state-of-the-art NMR facilities managed by Prof. Gareth Morris in

the School of Chemistry will support the part of the project for the in-situ NMR spectroscopy,

diffusion and relaxation. The industrial relevance of the proposal is highlighted by the support

provided by Johnson Matthey (JM), a world-leading catalyst and chemical company. PI has

previously collaborated with JM to produce novel work14 resulting in the implementation of new

tools for quality control of catalytic materials. JM will provide both materials to be used in the

project as well as industrial facilities and expertise that will enhance significantly the impact of this

proposal in the business sector, hence speeding up commercial and IP exploitation of the research

outcomes in terms of development of new characterisation methodologies and catalysts.

(from TPD)

(fro

mN

MR

)

TiO2 anatase

TiO2 rutile

γ-Al2O3

SiO2

ZrO2

θ-Al2O3ETTe 21Surf

Theory Experiments(a) (b)

Figure 2. (a) Interaction between water and an oxide surface. The ratio of NMR relaxation times, T1/T2, is theoretically related to an activation energy of interaction, ΔE. This relationship was

experimentally verified in a recent set of experiments, whose main

results are shown in (b). Adapted from D’Agostino et al. (2014).7

Hydroxyl groupsAliphatic chains replacing

hydroxyl groups

Changes in T1 NMR relaxation times of adsorbed methanol

Solid support

Figure 3. Replacement of hydroxyl groups of solid surfaces

with alkyl chains affects the molecular dynamics of the probe species, methanol, which can be probed using T1 NMR relaxation times. Adapted from D’Agostino et al. (2017).

20

EPSRC Reference: EP/S019138/1 Page 2 of 8EPSRC Reference: EP/S019138/1 Page 2 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

Description of proposed research

Summary

The goal of this proposal is to develop and validate an in-situ Nuclear Magnetic Resonance (NMR)-

based screening and optimisation methodology for heterogenised organocatalytic systems, able to

monitor and evaluate catalyst activity, transport and surface interactions at a pore-scale level in

such functionalised materials. Batch reaction studies combined with in-situ 1H and 13C NMR

spectroscopy, diffusion and relaxation techniques will give new and exclusive insights into these

systems by providing quantitative data on intra-pore kinetics, diffusion and adsorption, which will

be able to direct catalyst formulation and reaction design by evaluating the controlling interactions

and mass transport phenomena of the various reactant/solvent/product species within the pores of

the heterogenised catalytic system, hence aid selection of optimal reaction parameters such as

choice of suitable solvents, solid supports, pore size and type of linker to immobilise the

organocatalyst on support. The validation of this methodology in heterogenised organocatalysis will

be a significant step forward towards effective screening and development of these materials,

which can be expanded to other related technologies using functionalised porous materials.

Background

Homogeneous organocatalysis is a key technology in the manufacturing of many fine chemicals,

including drugs and other high-value specialty chemicals.28 It has the advantage of usually being

highly active and selective under mild conditions and with well-defined reaction mechanisms. The

major drawback of this technology is in the laborious and expensive procedures needed to

separate the catalyst from the reaction products which, in many cases, is unfeasible or may lead to

catalyst degradation with consequent waste of valuable material.29

In the past decades much effort has gone into the immobilisation of organocatalytic

functions onto solid supports, through a process called heterogenisation. The basic idea, shown in

Figure 4, is to immobilise the soluble organocatalyst onto a solid support, usually through covalent

bonding, hence making the catalyst insoluble, with significant benefits in terms of: (i) easier catalyst

handling, separation and work-up; (ii) easier catalyst recovery and reusability; (iii) possibility to run

continuous processes in packed bed reactors, hence more process flexibility. This directly leads to

improvements in process operations and sustainability by reducing waste of materials and energy

consumption, due to laborious distillation procedures, often used in homogeneous catalysis.29

Figure 4. Difference between (a) traditional homogeneous catalysts, whereby the catalytic function (X) enabling a

reaction A+B→C is in homogeneous solution and (b) heterogenised catalysts, whereby the same catalytic function (X) is

immobilised over a solid surface, which makes the catalyst insoluble and hence easy to separate and recycle.

One of the challenges that has slowed down or hindered development and implementation of

this technology is the lack of understanding and ability to measure key physico-chemical aspects of

these systems. In particular, the role of mass transport and adsorption phenomena, which become

crucial factors once the homogeneous catalytic function is immobilised over high surface area

nanoporous supports, onto the catalyst performance remains unclear and unexplored. 23 This is

due to the lack of ability so far to comprehensively investigate and accurately quantify the influence

Solid

X

X

X

X X

A+B C(a) (b)

Soluble homogeneous catalyst(X)

X

X

X

X

A + B C

X

Insoluble heterogenised catalyst (Solid-X)

EPSRC Reference: EP/S019138/1 Page 3 of 8EPSRC Reference: EP/S019138/1 Page 3 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

of such phenomena at a pore scale level. Indeed, most of the work done in the area has focused

on the conventional approach of characterising the bare heterogenised solid catalyst, and then

analysing the bulk fluid surrounding the catalyst particles during reaction to assess the catalytic

performance; a large gap remains on the behaviour of the various reaction species in direct contact

with the catalyst surface inside the pore space, including diffusion transport within the pore

structure and fluid/solid surface interactions of the various reactive species, products and solvents.

In this project, this gap will be closed by combining reaction studies with in-situ 1H/13C NMR

techniques to evaluate kinetics, diffusion and adsorption inside the pores functionalised with the

organocatalytic function. NMR T1/T2 relaxation measurements will provide new quantitative data on

molecular dynamics and adsorption of reactive species, products and solvents confined in the pore

space containing the immobilised organocatalytic function, allowing to quantify solvent and product

inhibition in different catalytic systems and hence direct the selection of important reaction

parameters such as choice of suitable solvents and solid supports. Pulsed-field gradient (PFG)

NMR will be able to quantify diffusion transport and hence elucidate the effect of textural properties

(pore size, tortuosity and surface area) and type of linker (linking the organocatalytic function to the

support) on accessibility of reactants and products to the pore space. The validation of such NMR

techniques, which give accurate and quantitative data with a relatively short acquisition time, will

provide a new toolkit for boosting screening and optimisation of this class of catalytic materials.

National Importance

Catalysis is a key technology for the UK industry, enabling creation of new chemical processes and

addressing many issues related to economy and sustainability. The decision to maintain

investments in this area highlights the long-term commitment of the EPSRC, which has explicitly

stated the “needs to nurture early career researchers and future leaders”. Methodological

advances in the technology of heterogenised organocatalysts will boost and help developing more

rapidly such materials, making the technology more viable, hence improve significantly

manufacturing of fine chemicals, providing more sustainable routes, lower environmental impact

with better use of available resources and less energy intensive processes as well as hazard

reduction; at the same time new screening tools will be validated, which can be extended to similar

classes of materials, i.e., functionalised porous materials. The outcome of this proposal will be very

relevant to the UK chemical industry as it will boost the development of a technology that is still

under-exploited, with potential of improving significantly economic and environmental sustainability.

This project fits well in the current UK activities in catalysis, and aims at developing an area,

heterogenised organocatalysis, that complements some of the major established activities in

catalysis funded by the EPSRC, such as “The UK Catalysis Hub”. The topic of this proposal lies

also in the area of sustainable manufacturing of fine chemicals through innovating technologies

and aligns well with the EPSRC research theme of “Manufacturing the Future”; the collaboration

with Johnson Matthey will enable a direct interaction with the industry, making the proposal directly

relevant to the chemical business and further developing its outcomes at a commercial scale.

Academic Impact

The academic impact will be broad and significant. The primary impact of this proposal will be in

developing a methodology for a rapid and effective screening of heterogenised organocatalysts,

which will lead to a significant advance in knowledge and way of developing this class of catalysts,

complementing very well the current UK landscape of homogeneous and heterogeneous catalysis;

indeed it will be able to bridge further the gap between these two different sub-disciplines. There

will be however, a much broader reach as in addition to catalysis, this proposal will bring together

aspects of organic chemistry, porous materials, surface science and spectroscopy, leading to new

knowledge in these areas, which will be promoted and made available to the scientific community

in the UK and internationally by conferences, seminars and publications in high-quality academic

EPSRC Reference: EP/S019138/1 Page 4 of 8EPSRC Reference: EP/S019138/1 Page 4 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

journals as well as magazines such as the The Chemical Engineer and The Catalyst Review,

which provide key global information to business strategy development in the catalytic process

industry. In addition, PI intends to exploit his IChemE membership and affiliation to the Catalysis

Special Interest Group (SIG) in order to promote the research outcomes in events and workshops.

Research ideas and objectives

The central idea of this proposal is in coupling batch reaction studies with in-situ multi-technique 1H/13C NMR to quantify for the first time transport, adsorption and kinetics in heterogenised

organocatalytic systems at a pore-scale level, hence validate and use these data to direct a

rational catalyst and process design. An overview is shown in Figure 5, highlighting the approach

and objective, which can be summarised as:

OBJECTIVE: Validate the use of an in-situ NMR methodology as a new toolkit to speed up and

optimise heterogenised organocatalytic reaction systems.

HOW: Determine the structure/activity/stability relationship of these materials; evaluate quantitative

data on intra-pore kinetics, diffusion and adsorption using in-situ NMR spectroscopy, diffusion and

relaxation techniques, respectively; unravel the key links diffusion/adsorption/catalyst performance.

Figure 5. Schematic of the approach and objective of the proposed research project.

Batch reaction studies and 1H/13C NMR spectroscopy will enable to achieve in-situ

reaction monitoring directly inside the pore space, allowing quantification of kinetics, conversion

and selectivity for different catalyst formulations. The effect of homogeneous catalyst loading to

immobilise over the support, which remains unexplored, will also be investigated; whilst low loading

may lead to a lower reaction rate, a high loading may lead to self-aggregation of the immobilised

species with loss of activity. Hence, an important outcome of these studies will be the identification

of an optimal load that maximises product yield, and how the choice of support, linker and pore

size influence such loading. In addition, it will be possible to detect reaction products/by-products

trapped inside catalyst pores, which cannot be detected by conventional analysis of bulk fluid.

Using NMR relaxation it will be possible for the first time to investigate liquid/solid surface

interactions in these catalysts. For example, the role of the support and how this affects the activity

of the immobilised organocatalyst remains puzzling; using this technique it will be possible to

understand how the support affects molecular dynamics and surface interactions of reactive

species, products and solvents, hence understand key phenomena such as solvent and product

inhibition, which impact significantly the performance of these catalysts. The outcome of these

measurements will help identify the key links between catalyst performance and surface

interactions as probed by NMR relaxation, hence develop a method for optimising solvent and

support selection.

Diffusion is another issue arising when organocatalysts are immobilised over nanoporous

structures and its effect has not yet been elucidate. Diffusion studies by pulsed-field gradient

NMR spectroscopy(reactivity)

NMR relaxation(surface interactions)

PFG NMR(mass transport)

Batch reactionstudies

Immobilisation of organocatalystover solid supports

Reactor-scale studies

Pore-scale studies

Catalyst synthesis and structural characterisation

Solid

X

X

X

X X

A+B C

Applications forcatalyst screening and optimisation

OBJECTIVE: In-situ NMR protocol validation

EPSRC Reference: EP/S019138/1 Page 5 of 8EPSRC Reference: EP/S019138/1 Page 5 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

(PFG) NMR will enable to identify diffusion limitations, quantify the effect of various linkers on

accessibility of reactant molecules to the pore space, quantify the ability of reaction products to

diffuse out of the catalyst and hence find the optimal textural properties of the porous matrix.

Studies in fresh and reused catalysts will aim at understanding the deactivation process

and its effect catalyst reusability, molecular transport and adsorption, hence identify the key

parameters for a more robust catalyst formulation. Altogether, it will be ultimately possible to

identify and quantify the key factors that determine catalyst behaviour and validate a new

methodology for a comprehensive, robust and rational catalyst and process design.

Novelty and relevance

Immobilisation of organocatalysts onto porous supports has previously been achieved but so far

the lack of understanding of key phenomena such as diffusion limitations inside the pore space,

self-aggregation and changes in surface interactions of reactive species and solvents with the pore

surface have hindered significantly the development in terms of catalyst formulation and process

optimisation.23 With the proposed approach, unlike most of the previous studies, which have

focused on obtaining kinetic data on the analysis of the bulk fluid, it will be possible for the first

time to have a much closer look at the reaction as it happens directly in the catalyst pores,

providing new and exclusive insights by accessing novel and quantitative information on intra-pore

kinetics, molecular dynamics, mass transport as well as interactions of molecules with the catalyst

surface (Figure 6), leading to an accurate evaluation of solvent and product inhibition and how the

support affects these properties. The validation of these methods for heterogenised catalytic

systems will therefore lead to new applications of NMR techniques that go beyond purely

homogeneous or heterogeneous systems, enabling to gain new fundamental insights on aspects of

crucial importance for improving the design of efficient heterogenised catalysts, hence improve

sustainability in the manufacturing of fine chemicals. This is very relevant to the current efforts at a

global level in enabling new, more sustainable catalytic technologies for chemical manufacturing.

Programme and methodology

To achieve the objective of the project, the model

reactive system under investigation will be the

asymmetric aldol condensation reaction between

aldehydes with different substituent groups (R) and

hydroxyacetone over proline-immobilised catalysts, a

versatile organic synthesis for the formation of C-C

bond (Figure 6). This is a benchmark organic reaction

with wide applications in the fine chemical and drug

synthesis and proline is one of the “privileged

scaffolds” for catalysing organic synthesis; hence the

system is ideal to test and validate the proposed

methodology and extend its applications to a broad

range of reactive systems. The proposal is structured

in the following Work Packages (WP).

WP1. Synthesis and characterisation of proline-immobilised catalysts

Description: This part of the project involves the synthesis of proline-immobilised catalysts using

different mesoporous supports, SiO2, TiO2, Al2O3 and ZrO2, which are low-cost, readily available

and offer large surface areas and high mechanical stability; in addition, they can be easily extruded

to form pellets, which are the privileged catalyst form used in industry. The synthesis is described

in Figure 7. The heterogenisation involves a first step (Step 1) whereby different linkers (specified

in the figure) are attached to the 4-OH-proline organocatalyst. In a subsequent step (Step 2) the

modified organocatalyst is then anchored via the linker to the solid support by covalent bonding.

Figure 6. Reactive system to investigate.

adsorption

diffusion

kinetics

Lin

ker

Heterogenizedorganocatalyst

Heterogenizedorganocatalyst

Porous support

solvent

?

EPSRC Reference: EP/S019138/1 Page 6 of 8EPSRC Reference: EP/S019138/1 Page 6 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

Figure 7. Immobilisation scheme of the organocatalyst onto the support via the linker.

DELIVERABLES: DLV1.1. Successful preparation of organocatalysts confirmed by NMR and

mass spectrometry (MS). DLV1.2. Successful immobilisation of the organocatalysts on support

and characterisation by solid-state NMR, IR, Raman, XPS, N2 adsorption, SEM, TEM, PXRD.

MILESTONES: MS1.1. Successful synthesis of the soluble organocatalyst for homogeneous

phase reaction tests in WP2. MS1.2. Successful synthesis of immobilised organocatalysts for

heterogenised catalyst reaction tests in WP2.

WP2. Catalytic reaction studies using batch reactors and in-situ 1H/13C NMR monitoring

Description: The heterogenised catalysts synthesized in WP1 will be tested in batch reactors,

using established bulk analysis, such as GC and HPLC, and using in-situ 1H and 13C NMR

spectroscopy. The in-situ NMR approach has never been used to study such reactive systems and

will allow for the first time to monitor reaction kinetics and product distribution directly inside the

catalyst pores. By exploiting the inherent wide chemical shift range of 13C NMR it will be possible to

overcome issues arising from 1H NMR peak overlap, where this occurs, that may be present when

fluids are confined in porous materials. NMR studies will be able to reveal also the presence of

species trapped inside the pores, hence not easily detectable with conventional analysis of the bulk

fluid. These studies will be conducted in glass NMR tubes at ambient pressure and mild

temperatures. A wide range of parameters is going to be explored, aiming at representing a variety

of fine chemical and pharmaceutical synthetic routes and reaction conditions, which include: (a)

aldehyde substituent group (from purely aliphatic to groups containing nitrogen or oxygen); (b)

support (SiO2, TiO2, Al2O3 and ZrO2) and linker (different length and chemical structure); (c) solvent

(apolar, polar aprotic polar and polar protic); (d) pore size of the support (from few to hundreds of

nm); (e) loading of homogeneous catalyst to be immobilised.

Reusability tests will be carried out to identify the most stable formulation (support/linker/pore

size/loading). Catalyst activity will be benchmarked against the same reactions carried out in a

homogeneous phase using the non-supported organocatalyst. Deactivation will also be assessed.

DELIVERABLES: DLV2.1. Batch and in-situ 1H/13C NMR catalytic tests of soluble organocatalysts

(before immobilisation). DLV2.2. Batch and in-situ 1H/13C NMR catalytic tests of different

heterogenised catalyst formulations in different solvents; benchmarking against the non-supported

organocatalyst. DLV2.3. Assessment and characterisation of catalyst deactivation pattern.

MILESTONES: MS2.1. Relationship between catalyst structure with reactivity and stability

determined. MS2.2. Catalyst deactivation and reusability pattern determined.

WP3. NMR diffusion and relaxation studies

Description: In order to understand the catalyst behaviour determined in WP2, T1,T2 and PFG

NMR relaxation will be used to quantify surface interactions and diffusion of chemical species in

supports and heterogenised catalysts. PI’s previous work demonstrated the ability to study

adsorption in catalyst pores by using the T1/T2 ratio, a robust, non-invasive indicator of

adsorbate/adsorbent interactions.7 The PI’s previous work showed the ability of this indicator to

Support

Lin

ker

Step 1 Step 2

Support

Organocatalytic function

Linker a Linker b Linker c

EPSRC Reference: EP/S019138/1 Page 7 of 8EPSRC Reference: EP/S019138/1 Page 7 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Case for Support

quantify solvent inhibition and use this knowledge to optimise solvent and material selection in

purely heterogeneous catalytic systems. 3,5,14 The validation of the technique in the area of

heterogenised organocatalysts will be invaluable as by quantifying for the first time surface

interactions of the various reactants, products and solvents in these materials, it will be possible to

study competitive adsorption, quantify the degree of solvent and product inhibition, evaluate the

currently unknown effect of the support on molecular adsorption and hence determine the optimal

selection of solvent and support that enhance the chemical reaction at the surface. In addition, it

will also be possible to study the effect of the support material on adsorption of reaction products

and hence understand which support reduces product inhibition. Diffusion NMR techniques will be

used to understand the effect of pore size on mass transport of substrates and products,

estimating the effect of pore diffusion on reaction rate by using methods such as the Weisz–Prater

criterion, which will be possible by combining reaction kinetic data with the diffusion coefficients

determined by NMR measurements. In addition, it will also be possible to assess the effect of

linkers on accessibility to pore space. Such data will lead to an optimal choice of suitable linkers

and pore structures that ensure a high surface-to-volume ratio but at the same time with pore sizes

large enough to avoid diffusion limitations of reactants and products.

DELIVERABLES: DLV3.1. Quantification of liquid/surface interactions of reactive species,

products and solvents in supports and catalysts byT1/T2 NMR relaxation. DLV3.2. Quantification of

molecular diffusion for reactive species, products and solvents as a function of catalyst pore size

and linker dimensions using PFG NMR. DLV3.3. Quantification of transport limitations by combing

kinetics and diffusion data. DLV3.4. T1/T2 and PFG NMR measurements in recycled catalysts.

MILESTONES: MS3.1. Relationship adsorption/transport/reactivity determined - Validation of NMR

spectroscopy, relaxation and PFG NMR techniques achieved. MS3.2. Evolution of surface and

pore structure after catalyst reuse determined.

Project management activities

PI (15% of time) will oversee the whole range of activities, from catalyst synthesis to reaction and

NMR studies supported by a PDRA (100% of time). Most of the work will take place at the

University of Manchester at the PI’s School and the School of Chemistry, liaising with Prof. Gareth

Morrison for the use of the NMR facilities. PI will manage project activities. The PDRA will visit

Prof. Armando Carlone in Italy, where they will carry out further research activities on organic

synthesis. Visits to Johnson Matthey (JM) will also be arranged for the PDRA to use their

characterisation facilities, including a bench-top NMR spectrometer, and interact with industrialists

working on catalyst development. The PDRA progress will be monitored with quarterly reports and

updates, ensuring project tasks are delivered and milestone achieved.

References 1. Mantle, M. D., et al., J. Phys. Chem. C 2011, 115 (C), 1073-1079; 2. Akpa, B. S., et al., Journal of Catalysis 2012, 289,30-41; 3. D'Agostino, C., et al., Chemistry-a European Journal 2012, 18 (45), 14426-14433; 4. D'Agostino, C., et al., The Journal of Physical Chemistry C 2012, 116 (16), 8975-8982; 5. D'Agostino, C., et al., Chemistry - A European Journal 2013, 19 (35), 11725-11732. 6. Al-Khattaf, S., et al., Catal. Sci. Technol. 2014, 4, 1017-1027; 7. D'Agostino, C., et al., Chemistry - A European Journal 2014, 20, 13009-13015; 8. D'Agostino, C., et al., Catalysis Science & Technology 2014, 4 (5), 1313-1322; 9. Haider, M. H., et al., Chemistry – A European Journal 2014, 20 (6), 1743-1752; 10. Ralphs, K., et al., Catalysis Science & Technology 2014, 4 (2), 531-539; 11. McManus, I., et al., Journal of Catalysis 2015, 330, 344-353; 12. Wilkinson, S. K., et al., Journal of Catalysis 2015, 330, 362-373; 13. D'Agostino, C., et al., Catalysis Science &Technology 2016, 6, 1661-1666; 14. D'Agostino, C., et al., Catalysis Science & Technology 2016, 6 (21), 7896-7901; 15. Zhu, Q. Y., et al., Chem. Eng. J. 2016, 306, 67-76; 16. Zhu, Q. Y., et al., Chem. Eng. J. 2016, 306, 1223-1233; 17. D'Agostino, C., et al., RSC Advances 2017, 7 (57), 36163-36167; 18. D'Agostino, C., et al., ACS Catal. 2017, 7 (7), 4235-4241; 19. D'Agostino, C., et al., Microporous and Mesoporous Materials 2017; 20. Robinson, N., et al., Faraday Discuss. 2017, 204, 439-452; 21. Bräuer, P., et al., RSC Advances 2017, 7 (83), 52604-52613; 22. Brauer, P., et al., Phys. Chem. Chem. Phys. 2018, 20, 4250-4262; 23. Hübner, S., et al., Adv. Synth. Catal. 2016, 358 (1), 3-25; 24. Carlone, A., et al., Chemical Communications 2006, (47), 4928-4930; 25. Carlone, A., et al., Angew. Chem. Int. Ed. 2007, 46 (24), 4504-4506; 26. Carlone, A., et al., Angew. Chem. Int. Ed. 2007, 46 (7), 1101-1104; 27. Wilson, M. R., et al., Nature 2016, 534, 235; 28. Beller, M., New Avenues to Efficient Chemical Synthesis: Emerging Technologies, Springer, 2007; 29. Cole-Hamilton, D. J.; Tooze, R. P., Catalyst Separation, Recovery and Recycling: Chemistry and Process Design, Springer, 2006.

EPSRC Reference: EP/S019138/1 Page 8 of 8EPSRC Reference: EP/S019138/1 Page 8 of 8Case For SupportCase for Support

EPSRC New Investigator Award – Carmine D’Agostino Pathways to Impact

In-situ NMR-based methodology for screening and optimisation of

heterogenised organocatalytic systems

Impact Summary

The stakeholders benefiting from this proposal include: (i) Industry and the commercial sector, in

particular companies involved in the catalyst business as well as fine chemicals, including the

pharmaceutical sector; (ii) Outreach and engagement of scientific community; (iii) Environmental

policy and the wider public; (iv) Scientists and engineers building up skills and knowledge.

The objectives of the impact and the pathway activities to reach them are detailed below; some of

the timeline implementations of such activities, including industrial visits, are also outlined in the

Work Plan.

(i) Industry and the commercial sector

Objective: Actively involve the commercial sector in developing and exploiting the outcome of the

proposal in terms of methodological approach and exploitation of key research findings to address

current challenges in the area of heterogenised organocatalysis; assess the feasibility of follow-up

studies to boost industrial exploitation.

What will be done: The support and close interaction with Johnson Matthey (JM) is a key part that

will enable such objective to be achieved. The PI has a well-established collaboration with the JM

Technology Centre in Reading, which will continue during the project. The company is enthusiastic

about the potential outcomes of the research and as such fully supports the project by providing

industrially relevant raw materials, expertise, equipment, industrially-driven guidance and directions

as well as being involved in the industrial exploitation of the outcomes of this proposal. The JM

centre has also got in-house bench-top low-field NMR facilities, which will be used during the

PDRA visit for a proof-of-concept validation of the NMR results obtained from the academic high-

field NMR facilities, which will in turn enable development and transfer of technology and know-

how from academia to industry, with benefits for the commercial sector. Review meetings involving

the company will be arranged to make sure the objectives of the collaboration are achieved and at

the same time remain within the domain of interest of the industrial sector as well.

The project will also exploit the link with the pharmaceutical sector by reaching out to companies

such as AstroZeneca, GSK, Pfizer, which regularly visit the School during industrial advisory board

meetings, which will be a great opportunity to further increase the industrial impact of the proposal

by inviting company representatives to the workshop that is part of this project. The project will also

use the network and links of Prof. Armando Carlone with the fine chemical business sector in order

to broaden the outreach of the proposal to companies within and outside the UK. The support of

the IChemE through the Catalysis Special Interest Group (SIG) will provide further links to industry

and enable technology transfer.

Costs: The budget to enable such impact is estimated to be £1.2k, mostly to cover the visits of PI

and PDRA to the JM Technology Centre in Reading.

(ii) Outreach and engagement

Objective: Maximise the visibility and achievements of the project to the scientific community in

various areas of science and technology.

What will be done: The project is highly multidisciplinary in nature and will cover various areas,

from organic to physical chemistry, from catalysis to spectroscopy. Knowledge and findings of the

project will be disseminated though peer-reviewed publications on prestigious journals as well as

UK and international conferences, including: (i) the EUROMAR, which is the major NMR

conference in Europe; (ii) the UKCC, which is the main UK catalysis event; (iii) the UK

ChemEngDay, which is a major event in the area of Chemical Engineering across the UK and

beyond; (iv) the ICC, which is a major international event in the area of catalysis. Seminars across

the University as well as in Italy, exploiting the network of Prof. Armando Carlone, will also be

EPSRC Reference: EP/S019138/1 Page 1 of 2EPSRC Reference: EP/S019138/1 Page 1 of 2Pathways to ImpactPathways to Impact

EPSRC New Investigator Award – Carmine D’Agostino Pathways to Impact

organised with a particular emphasis on introducing the new methodology being developed to the

organic and synthetic chemistry community. A workshop on the project will be organised with the

support of the IChemE Catalysis Special Interest Group (SIG) through advertising and promoting

the event via email, website and social media, advice on organisation and management, logistic

support and contacts with the scientific community.

Costs: The cost for such activities is estimated to £9.5k, which covers the attendance of the UK

and international conferences and events as well as the organisation of the workshop.

(iii) Environmental policy, public engagement and the wider society

Objective: Make the public aware of technological developments in this area of catalysis that will

decrease waste of energy and materials as well as improve health and safety in working

environments.

What will be done: The PI will leverage the strong network within the School in the areas of

sustainability, corporate responsibility and circular economy, which are closely related to the

objective of the proposal. Among the various activities, we propose final year research projects for

Masters students within the School on life cycle analysis on the topic covered by the proposal,

which will be able to give a further insights onto the environmental impact of the work as well as

make young engineers aware of the potential of this technology to improve process sustainability

and innovate manufacturing in the chemical industry.

In order to reach the wider public, the project will engage with University of Manchester’s outreach

and public engagement activities, including the delivery of presentations at the Science,

Technology, Engineering and Maths (STEM) events within the University of Manchester as well as

use of social media of both the School and the University for promoting research and innovation

carried out by academics within the School. The outreach of the project outcomes will also be

strengthened by using IChemE channels, including promotion through the IChemE Catalysis

Special Interest Group (SIG), which the PI is part of.

Costs: The cost for such activities is estimated to £7.7k, which accounts for approximately 5% of

the PI and PDRA time to be dedicated to such activities.

(iv) Training and skill development

Objective: Building individuals with outstanding scientific vision and R&D industrial knowledge

and skills.

What will be done: The PDRA working on this project will closely interact during the project with a

broad range of disciplines and leading scientists in such discipline. The PDRA will visit the external

collaborator in Italy (Month 5) to carry out organocatalysis reaction studies under his guidance.

The PDRA will have day-to-day interaction with leading catalyst researchers in the School; he/she

will use routinely the NMR facilities in the School of Chemistry and attend their weekly group

seminars. In addition, the collaboration with JM will give fundamental research insights from and

industrial perspective and visits to the JM Technology Centre will certainly help in achieving this.

The PDRA and PI will visit JM facilities several times during the project (Months 7-8 and12).

A set of skills, (experimental, analytical, project and interface management skills) and knowledge

(spectroscopy, organic and physical chemistry, engineering and materials science) will be

transferred to the other people involved in this project, including Masters and PhD students, who

will be able to interact with the PDRA during the project. This will be possible by the arrangement

of suitable student research projects aiming at supporting the work of the PDRA.

Costs: The budget to enable such impact is estimated to be £4.5k, which include visits to JM and

to the external collaborator in Italy as well as consumables for Masters student’s projects

supporting the PDRA activities.

Total cost of impact activities: £22.9k, which accounts for 10% of the total project budget.

EPSRC Reference: EP/S019138/1 Page 2 of 2EPSRC Reference: EP/S019138/1 Page 2 of 2Pathways to ImpactPathways to Impact

EPSRC New Investigator Award – Carmine D’Agostino Justification of Resources

In-situ NMR-based methodology for screening and optimisation of heterogenised

organocatalytic systems

Justification of Resources

Staff - directly incurred posts

A post-doc research associate (PDRA) with previous research experience in physical chemistry

and catalysis will be hired to work with the PI for the whole duration of the project. The PDRA,

supported by the PI and the external collaborator, Prof. Armando Carlone, will dedicate 100% of

his/her time to carry out all the experimental work required for the success of the 18-month

research project, from catalyst synthesis and testing to the NMR studies. The total cost of

the PDRA is £XXk.

TOTAL COST: £XXk

Staff - directly allocated posts

The PI will dedicate 15% of his time for the whole 18-month duration of the project, which is going

to be split into 10% (0.5 day per week) for research supervision and 5% (overall 1 day per

month) for impact and networking activities, for a cost of £XXk.

TOTAL COST: £XXk

Travel and subsistence

The project will involve travel activities that will enable exchange of scientific knowledge,

dissemination of the work as well as increasing its impact.

Funding is requested for attending the following conferences:

(i) The PI to attend the European Magnetic Resonance Meeting (EMAR), which will be held in

Berlin (Germany) in August 2019 (approximately, registration fee £600, accommodation £600,

flight £200, extra £100, total £1.5k);

(ii) The PI to attend the UK Catalysis Conference (UKCC) in January 2020, which will be held

within the UK (approximately, registration fee £400, accommodation £200, transport £100, extra

£50, total of £0.75k);

(iii) The PDRA to attend the UK ChemEngDay (UKCED) in March 2020, which will be held within

the UK (approximately, registration fee £400, accommodation £200, transport £100, extra £50,

total of £0.75k);

(iv) The PDRA to attend the International Congress on Catalysis (ICC), which will be held in San

Diego (USA) from the 14th to the 19th of June 2020 (approximately, registration fee £700,

accommodation £800, flight £800, extra £200, total of £2.5k).

Funding for the following project trips is also requested:

(i) The external collaborator, Prof. Armando Carlone, to visit the University of Manchester in April

2019 and June 2020 to supervise and carry out work on initial and final project activities,

respectively, with a two-week period for each visit (approximately, flight £2×200, accommodation

£2×1400, extra £2×400, total of £4k );

(ii) The PDRA to visit Prof. Armando Carlone at the Università degli Studi dell'Aquila in Italy in July

2019 for a period between two to four weeks to carry out part of the project activities

(approximately, flight £200, accommodation £1400, extra £400, total of £2k);

EPSRC Reference: EP/S019138/1 Page 1 of 2EPSRC Reference: EP/S019138/1 Page 1 of 2Justification for ResourcesJustification of Resources

EPSRC New Investigator Award – Carmine D’Agostino Justification of Resources

(iii) The PI and PDRA to visit the Johnson Matthey Technology centre in Sonning Common,

Reading, UK, during October/November 2019 for a couple of days for project management and

review activities (approximately, transport £2×100, accommodation £2×100, extra £2×50, total of

£0.5k) and the PDRA to visit again in March 2010 for a week to carry out experimental work,

including catalyst characterisation activities (approximately, transport £100, accommodation £500,

extra £100, total of £0.7k).

TOTAL COST: £12.7k

Other directly incurred costs

A consumables budget is requested for:

(i) General lab consumables and chemicals, including reagents, solid supports, catalysts and

catalyst precursors, fittings and parts for reaction set-up, estimated to £12k,

(ii) Access and use of SEM, TEM and XPS characterisation, estimated to £8.7k;

(iii) Organisation of the workshop at the University of Manchester which includes £0.6k

refreshments, £0.6k for flight and accommodation of external collaborator from Italy, £0.5k for JM

partner from the UK, £3×0.6 k to cover travel and accommodation of external speakers from

UK/EU, extra £0.5, for a total cost of £4k.

TOTAL COST: £24.7k

Other directly allocated costs

The project requires 2 out of 18 months dedicated to NMR measurements, 12% of the total time,

and an NMR technician is requested for specialised support, including cryogenic refills and

maintenance of the two spectrometers (one for the solid-state NMR characterisation of the catalyst

and another for the in-situ NMR studies of the reactive systems). The total cost of the technician is

£XXk. Estates-laboratory and other indirect costs for a total of £XXk.

TOTAL COST: £XXk

TOTAL COST OF THE PROJECT: £232.3k (RC contribution is 80%, equal to £185.8k)

EPSRC Reference: EP/S019138/1 Page 2 of 2EPSRC Reference: EP/S019138/1 Page 2 of 2Justification for ResourcesJustification of Resources

M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12 M13 M14 M15 M16 M17 M18

WP1. Catalyst synthesis/characterisation

▪ Literature review on organocatalyst preparation and immobilisation

proceduresPDRA

/PI

▪ DLV1.1. Preparation/characterisation of the organocatalyst in the

soluble form (NMR and mass spectrometry)▪ DLV1.2. Immobilisation/characterisation of organocatalyst on supports

(SS NMR, IR, Raman, XPS, N2 ads, SEM/TEM, XRD)PDRA/PI

WP2. Batch and in-situ1H/

13C NMR reaction studies

▪ Literature review on heterogenised organocatalysis and in-situ NMR

spectroscopy in catalysisPDRA/PI

▪ DLV2.1. Batch and 1H/

13C in-situ NMR homogeneous catalytic tests of

soluble organocatalyst before immobilisation

▪ DLV 2.2. Batch and 1H/

13C in-situ NMR catalytic tests of different

heterogenised catalyst formulations▪ DLV2.3. Assessment and characterisation of deactivation pattern for

different immobilised organocatalyst formulationsPDRA/PI

WP3. NMR diffusion and relaxation studies

▪ Literature review on NMR relaxation and diffusion in porous materials

and functionalised surfacesPDRA/PI

▪ DLV3.1. T 1/T 2 NMR relaxation measurements of reactants, products

and solvents in pure supports and different catalyst formulationsPDRA/PI

▪ DLV3.2. PFG NMR measurements: Effect of pore size and type of

linker on molecular diffusion and accessibility to the pore spacePDRA/PI

▪ DLV3.3. Quantification of diffusion limitations by combining kinetics

and diffusion dataPDRA/PI

▪ DLV3.4. T 1/T 2 and PFG NMR relaxation measurements in collected

reused and recycled catalyst samplesPDRA/PI

Project management activitiesVisits▪ Visits of external collaborator to the University of Manchester, UK AC AC

▪ Visits to the Università degli Studi dell'Aquila, Italy PDRA

▪ Visits to Johnson Matthey (JM) Technology Centre, UK PI/PDRA PDRA

Journal submissions (JS) JS1 JS2 JS3

Conferences PI PI PDRA PDRA

IChemE workshop (WS) WS

MS1.1 : Successful synthesis of organocatalysts for tests in WP2

Review: Review meeting with JM/external collaborator

Work Packages (WP)Months (Starting date 1

st March 2019)

PI: Principal Investigator PDRA: Post Doc Research Associate AC: External collaborator, Prof. Armando Carlone

PDRA/PI

/AC

PDRA/PI

/AC

PDRA/PI

/AC

MS1.2 : Successful synthesis of immobilised organocatalysts for tests in WP2

DLV : Deliverable MS : Milestone

MS3.1 : Link adsorption/transport/activity determined - NMR methods validation MS3.2 : Surface/structure evolution in recycled catalysts determined

Journal submissions (JS): JS1 to ACS Catalysis JS2 to Microporous and Mesoporous Materials JS3 to Angewandte Chemie International Edition

Conferences: EMAR: European meeting on NMR UKCC: UK Catalysis Conference UKCED: UK ChemEngDay ICC: International Congress on Catalysis

MS2.1 : Relationship between catalyst structure, reactivity and stability determined MS2.2 : Catalyst deactivation/reusability pattern determined

Report: PDRA project report WS: IChemE workshop

MS1.1

MS1.2

MS2.1

MS2.2

MS3.1

MS3.2

EPSRC Reference: EP/S019138/1 Page 1 of 1WorkplanWorkplan

Organisation where the Grant would be held

Project Title [up to 150 chars]

Start Date and Duration

Applicants

Objectives

List the main objectives of the proposed research in order of priority [up to 4000 chars]

EPSRC

Polaris House, North Star Avenue, Swindon, Wiltshire,

United Kingdom SN2 1ET

Telephone +44 (0) 1793 444000

Web http://www.epsrc.ac.uk/COMPLIANCE WITH THE DATA PROTECTION ACT 1998

In accordance with the Data Protection Act 1998, the personal data provided on this form will be processed by EPSRC, and

may be held on computerised database and/or manual files. Further details may be found in the guidance notes

New Investigator AwardPROPOSAL

Document Status: With Council EPSRC Reference:

New Investigator Award

Organisation The University of ManchesterResearch Organisation

Reference:NMR-MESOHOS

Division or DepartmentChem Eng and Analytical

Science

In-situ NMR-based methodology for screening and optimisation of heterogenised organocatalytic systems

a. Proposed start

date01 March 2019

b. Duration of the grant

(months)18

Role Name Organisation Division or Department How many hours a

week will the

investigator work

on the project?

Principal Investigator Dr Carmine D'AgostinoThe University of

Manchester

Chem Eng and Analytical

Science5.64

Heterogenised organocatalysis represents a viable technology for the production of many fine chemicals and

pharmaceuticals, which could be used as an alternative route to more established processes exploiting homogeneous-

phase catalysis. The advantages of this technology are in: (i) easier catalyst handling, separation and work-up; (ii) easier

catalyst recovery and reusability; (iii) possibility to run continuous processes in packed bed reactors, hence more process

flexibility. This would improve significantly process sustainability by reducing energy consumption and waste of material.

Despite such benefits, this technology has remained under-exploited due to a series of challenges that are related to the

poor understanding of the hetero-homogeneous behaviour of these materials. In particular, the role of mass transport and

adsorption, which become crucial factors once the homogeneous organocatalytic function is being immobilised over high

surface area nanoporous solid supports, onto the catalyst performance remains unclear and unexplored and this is due to

the lack of ability so far to comprehensively investigate and accurately quantify such phenomena occurring at a pore scale

level.

8EP/S019138/1 Page 1 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Summary

Describe the proposed research in simple terms in a way that could be publicised to a general audience [up to 4000 chars].

Note that this summary will be automatically published on EPSRC’s website in the event that a grant is awarded.

Academic Beneficiaries

Describe who will benefit from the research [up to 4000 chars].

The objective of this project is to develop and validate the use of an in-situ NMR methodology as a new toolkit able to

monitor kinetics, diffusion and adsorption in heterogenised organocatalytic systems. This will provide new quantitative data

and exclusive insights into the physico-chemical behaviour of these reactive systems, which will enable to evaluate the

controlling interactions and mass transport phenomena of the various reactant/solvent/product species within the pores of

the heterogenised catalytic system, hence aid selection of optimal reaction parameters such as choice of suitable solvents,

solid supports, pore size and type of linker to immobilise the organocatalyst onto the support.

The validation of these methods for heterogenised catalytic systems will also lead to new applications of NMR techniques

that go beyond purely homogeneous or heterogeneous systems, enabling to gain new fundamental insights on aspects of

crucial importance for improving the design of efficient heterogenised catalysts, hence improve sustainability in the

manufacturing of fine chemicals, as well as in the more general area of functionalised solid materials.

The goal of this proposal is to develop and validate an in-situ Nuclear Magnetic Resonance (NMR)-based screening and

optimisation methodology for heterogenised organocatalytic systems, able to monitor and evaluate catalyst activity,

transport and surface interactions at a pore-scale level in such functionalised materials. Batch reaction studies combined

with in-situ 1H and 13C NMR spectroscopy, diffusion and relaxation techniques will give new and exclusive insights into

these systems by providing quantitative data on intra-pore kinetics, diffusion and adsorption, which will be able to direct

catalyst formulation and reaction design by evaluating the controlling interactions and mass transport phenomena of the

various reactant/solvent/product species within the pores of the heterogenised catalytic system, hence aid selection of

optimal reaction parameters such as choice of suitable solvents, solid supports, pore size and type of linker to immobilise

the organocatalyst on support. The validation of this methodology in heterogenised organocatalysis will be a significant

step forward towards effective screening and development of these materials, which can be expanded to other related

technologies using functionalised porous materials.

The outcome of this project will contribute to maintain and further enhance the UK leading position in the field of catalysis.

Indeed, the validation of new methodologies to screen and optimise the design of poorly understood systems such as

heterogenised catalysts is crucial to boost this challenging but much sought-after technology that, if implemented on a

larger scale, could potentially improve significantly chemical manufacturing by reducing energy consumption and waste,

hence improve the sustainability of processes. Sitting across homogeneous and heterogeneous catalysis, this discipline will

be of interest to researchers working in both these areas and will actually contribute to bridge the gap between them. The

interaction with Prof Chris Hardacre, with his large research group, and the large pool of academics in the School working

in the area of catalysis and porous materials, will certainly be an outstanding platform for mutual exchange of knowledge

and generation of new ideas in this area of catalysis, which, together with the major involvement of the School in the UK

Catalysis Hub, will contribute to ensure that the benefits of this proposal will be delivered to a broad audience both

nationally and internationally. The networking with other leading catalyst scientists, including Prof. Graham Hutchings, who

has a long-standing collaboration with the PI, will also further enhance the spread of the new knowledge generated in this

project. The final outcome will also be relevant in the biotechnology area, whereby enzyme immobilisation over solids for

bio-catalysis applications is a very active area of research, which will benefit from the methodology validation proposed in

this project.

This project will look at development and validation of new spectroscopic protocols for in-situ catalyst screening and

characterisation under working conditions, hence it will also appeal those working in reaction engineering and

spectroscopy. The interaction with the group of Prof. Gareth Morris, a leading NMR scientist in the School of Chemistry, will

8EP/S019138/1 Page 2 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Impact Summary

Impact Summary (please refer to the help for guidance on what to consider when completing this section) [up to 4000 chars]

allow the project to deliver benefits in terms of expanding and developing new NMR tools in the area of heterogenised

catalysis, hence advancing the exploitation of NMR techniques to study materials with a new approach. The participation to

the weekly NMR Seminars and the central role of Prof. Morris group in the UK NMR Discussion Group will be a great

opportunity to present new results and directions of the research project to the NMR community.

The project contains a strong organic chemistry component, hence it will be able to reach those working in organic

synthesis and fine chemicals and provide them with new tools to use and exploit in such disciplines, thus enabling

methodological advances in the area. The collaboration with Prof. Armando Carlone from the Università degli Studi

dell'Aquila in Italy, with extensive academic and industrial expertise in organic chemistry, will ensure that such benefits are

delivered to the organic/fine chemistry communities at an international level.

Besides active collaborations, a further way to make sure that the research, together with the data, materials and

developed protocols, reaches a broader audience, will be by dissemination of the work in peer-reviewed publications in

areas covered by the research project, attendance of important international conferences such as the EUROMAR and the

ICC, and important UK events in the area of chemical engineering and catalysis such as the ChemEngDay, the UKCC and

the UK NMR Discussion Group as well as the support and involvement of the Institution of Chemical Engineers (IChemE)

with the Catalysis Special Interest Group (SIG) for organising a workshop towards the end of the project.

The project will benefit stakeholders with impact in the following areas: (i) Industry and commercial sector; (ii) Outreach and

engagement of scientific community; (iii) Environmental policy and the wider society; (iv) Training and skill development.

(i) Industry and commercial sector

Heterogenised organocatalysts, if properly implemented on an industrial scale, will contribute to reduce current costs to

industry associated with the use of homogeneous catalysts, by reducing material and energy costs associated to expensive

separation procedures and catalyst loss/disposal. In addition heterogenised organocatalysts can be used in packed-bed

reactors for continuous operation, increasing productivity, allowing easier process control and decreasing maintenance

level. The industrial exploitation will be maximised by a close collaboration with Johnson Matthey (JM), a leading catalyst

and chemical company, which is fully supporting the proposal and will provide industrially relevant raw materials, technical

expertise and guidance for industrial exploitation. Using the strong links of the PI's School with important pharmaceutical

companies, such as AstroZeneca, GSK and Pfizer, with a high interest in fine chemicals, it will be possible to involve the

wider industrial community.

(ii) Outreach and engagement of scientific community

The project covers various scientific areas, which will benefit several communities from organic to physical chemistry, from

catalysis to spectroscopy; hence it represents a great opportunity for cross-disciplinary exchange of knowledge, which will

be enabled by attending various UK and international conferences; visits and seminars across the UK and internationally

through the network of external collaborator Prof Armando Carlone; organising a dedicated workshop supported by the

IChemE Catalysis Special Interest Group (SIG).

(iii) Environmental policy and the wider society

This project will have a positive impact on both environment and the wider society. Developments in the area of

heterogenised organocatalysts will be able to address many societal issues related to the chemical industry, such as

reduction of waste and energy consumption, efficient use of resources as well as a decrease in the environmental footprint

of chemical processes. The strong expertise of the PI's School in sustainability and corporate responsibility will provide an

ideal platform for enhancing such impact. The project will reach people beyond those directly involved in it, including

undergraduate students, through organisation of satellite research projects on sustainability and life cycle analysis of these

8EP/S019138/1 Page 3 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Summary of Resources Required for Project

Other Support

Details of support sought or received from any other source for this or other research in the same field.

processes; the wider public will be reached using the links and social media of the University for public engagement. The

IChemE channels will be used to further promote project outcomes.

(iv) Training and skill development

The inter-disciplinary nature of the project will develop highly skilled scientists, who will gain a broad range of skills and

knowledge. The people involved on this project will deal with a variety of disciplines, including materials science, catalysis,

organic chemistry and spectroscopy, hence will acquire a broad set of skills as well as a multi-perspectives approach to

scientific problems. The interaction with leading academics from different areas, most notably catalysis, NMR and organic

synthesis, will contribute in developing important interface management and communication skills, which is paramount in

the current scientific and technological landscape, whereby projects are often highly multi-disciplinary. The collaboration

with JM will also benefit by providing the possibility to interact with the commercial sector, carry out research work in

industrial facilities as well as developing important skills required by the industry. Hence, the project will develop highly

skilled scientists with a broad range of knowledge, which will benefit the whole UK economy and R&D sector.

Financial resourcesSummary

fund headingFund heading

Full economic

Cost

EPSRC

contribution

% EPSRC

contributionDirectly

IncurredStaff 80

Travel &

Subsistence80

Other Costs 80Sub-total

Directly

AllocatedInvestigators 80

Estates Costs 80Other Directly

Allocated80

Sub-total

Indirect Costs Indirect Costs 80

Exceptions Other Costs 0.00 0.00 100Sub-total 0.00 0.00

Total 232285.27 185828.22

Summary of staff effort requestedMonths

Investigator 2.75Researcher 18Technician 0Other 0Visiting Researcher 0Student 0Total 20.75

Other support is not relevant to this application.

8EP/S019138/1 Page 4 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Staff

Directly Incurred Posts

Applicants

EFFORT ON

PROJECT

Role Name /Post Identifier Start Date

Period

on

Project

(months)

% of Full

TimeScale

Increment

Date

Basic

Starting

Salary

London

Allowan

ce (£)

Super-

annuation

and NI (£)

Total cost on

grant (£)

Researcher PDRA 01/03/2019 18 100 N/A 01/08/2020 0Total

Role Name

Post will

outlast

project

(Y/N)

Contracted

working week as a

% of full time work

Total number of hours to be

charged to the grant over

the duration of the grant

Average number of

hours per week

charged to the

grant

Rate of

Salary

pool/banding

Cost estimate

Principal

InvestigatorDr Carmine D'Agostino Y 100 372 5.6

Total

8EP/S019138/1 Page 5 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Travel and Subsistence

Other Directly Incurred Costs

Other Directly Allocated Costs

Research Facilities/Existing Equipment

Research Council Facilities

details of any proposed usage of national facilities

Human Participation

Animal Research

Destination and purpose Total £

Within UKtravel, accommodation and living expenses for two visits of 1-2 weeks

each4000

Outside UK One international conference each for PDRA and PI 4000Within UK One UK conferences each for PDRA and PI 1500Outside UK Visit of PDRA to external collaborator in Italy 2000Within UK Visits of PI and PDRA to company (UK) 1200

Total £ 12700

Description Total £General chemicals and consumables 12000Organisation of workshop 4000

Total £ 16000

Description Total £Pool staff costs 6606Infrastructure Technicians

Total £ 9258

Description Total £MCF-XPS - Near Ambient Pressure - 40 hours 6954MCF/EM-IN HOURS-SEM 2 - Sigma - 20 hours 616MCF/EM-IN HOURS-TEM 1-Talos F200X - 20 hours 1131

Total £ 8701

Research Council Facilities are not relevant to this application.

Would the project involve the use of human subjects? Yes No✔

If yes, would equal numbers of males and females be used? Yes No✔

Would the project involve the use of human tissue? Yes No✔

Would the project involve the use of biological samples? Yes No✔Would the project involve the administration of drugs, chemical agents or vaccines

to humans?Yes No✔

Will personal information be used? Yes No✔

If yes, will the information be anonymised and unlinked? Yes No✔

Or will it be anonymised and linked? Yes No✔

Will the research participants be identifiable? Yes No✔Please provide details of any areas of substantial or moderate severity:

Would the project involve the use of vertebrate animals or other organisms

covered by the Animals (Scientific Procedures) Act?Yes No✔

8EP/S019138/1 Page 6 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Animal Species

Please select any other species of animals that are to be used in the proposed research.

Genetic and Biological Risk

Approvals

If yes, what would be the maximum severity of the procedures?Mild or non-

recoveryModerate

Severe

Please provide details of any areas which are Moderate or Severe:

Does the proposed research involve the use of non-human primates? Yes ✔No

Does the proposed research involve the use of dogs? Yes ✔No

Does the proposed research involve the use of cats? Yes ✔No

Does the proposed research involve the use of equidae? Yes ✔No

Fish Sheep

Rabbit Rat

Amphibian Poultry

Cow Mouse

Reptile Guinea Pig

Pig Other Rodent

Bird Other Animal

Would the project involve the production and/or use of genetically modified animals? Yes ✔ No

If yes, will the genetic modification be used as an experimental tool, e.g., to study the function of

a gene in a genetically modified organism?Yes ✔ No

And will the research involve the release of genetically modified organisms? Yes ✔ No

And will the research be aimed at the ultimate development of commercial or industrial

genetically modified products or processes?Yes ✔ No

Would the project involve the production and/or use of genetically modified plants? Yes ✔ No

If yes, will the genetic modification be used as an experimental tool, e.g., to study the function of

a gene in a genetically modified organism?Yes ✔ No

And will the research involve the release of genetically modified organisms? Yes ✔ No

And will the research be aimed at the ultimate development of commercial or industrial

genetically modified products or processes?Yes ✔ No

Would the project involve the production and/or use of genetically modified microbes? Yes ✔ No

If yes, will the genetic modification be used as an experimental tool, e.g., to study the function of

a gene in a genetically modified organism?Yes ✔ No

And will the research involve the release of genetically modified organisms? Yes ✔ No

And will the research be aimed at the ultimate development of commercial or industrial

genetically modified products or processes?Yes ✔ No

8EP/S019138/1 Page 7 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

Other Issues

OTHER INFORMATION

Reviewers

Reviewers

Reviewers

Have the following necessary approvals been given by:The Regional Multicentre Research Ethics Committee

(MREC) or Local Research Ethics Committee (LREC)?Yes No

Not

required✔

The Human Fertilisation and Embryology Authority? Yes NoNot

required✔The Home Office (in relation to personal and project

licences, and certificates of designation)?Yes No

Not

required✔

The Gene Therapy Advisory Committee? Yes NoNot

required✔

The UK Xenotransplantation Interim Regulatory Authority? Yes NoNot

required✔Administration of Radioactive Substances Advisory

Committee (ARSAC)?Yes No

Not

required✔

Other bodies as appropriate? Please specify.

Are there any other issues of which the

Council should be aware?No

Provide details of what they are and how they would be addressed [up to 1000 characters]

1 Name Division or Department Email AddressOrganisation

2 Name Division or Department Email AddressOrganisation

3 Name Organisation Division or Department Email Address

8EP/S019138/1 Page 8 of Date Saved: 29/06/2018 09:37:00

Date Printed: 29/06/2018 09:39:07Proposal original proforma document

The University of Manchester School of Chemical Engineering and Analytical Science Oxford Road Manchester M13 9PL, UK

18th June 2018

Dear Sir/Madam,

My name is Carmine D’Agostino and I am a new Lecturer in the School of Chemical

Engineering and Analytical Science at the University of Manchester within the Catalysis and

Porous Materials research group, which I joined in February 2018. I have a background in

chemical engineering at the interface with chemical and materials science. My primary

research area is in catalysis and porous materials, with specific focus on key phenomena

that lie at the heart of catalysis, such as diffusion, adsorption and reactivity in porous

catalysts, by developing novel NMR protocols that exploit pulsed-field gradient (PFG) NMR

and NMR relaxation techniques, together with other spectroscopic tools. I have a rich

scientific track record with 54 peer-reviewed papers (h-index = 14, over 890 citations),

included invited contributions, awards of prizes, including a Young Scientist Award and a

Junior Research Fellowship (JRF) from Wolfson College, University of Cambridge, and

several other recognitions, including prizes for top quality and highly cited papers, as well as

a book chapter in the Handbook of Green Chemistry (Wiley-VCH), currently in production. I

have also experience in project management of research projects having previously

supervised several PhD projects to successful completion.

I would like to respectfully submit the following project proposal for the EPSRC New

Investigator Award scheme on:

In-situ NMR-based methodology for screening and optimisation of heterogenised

organocatalytic systems

Heterogenised organocatalytic systems, whereby a homogeneous organocatalyst is being

immobilised over a solid surface, hold a great potential to innovate manufacturing in the

chemical industry as they can potentially combine the benefits of both homogeneous

catalysis, such as high activity and selectivity, with those of heterogeneous catalysis, such as

ease of catalyst separation, recycle and possibility to operate in fixed-bed reactors and

simplify process operations. However, implementation of such processes on a larger scale

has so far been hindered by a series of challenges related to these materials, such as lower

activity and selectivity compared to their homogeneous counterpart as well as catalyst

stability and other issues related to heterogenisation, such as introduction of mass transport

and adsorption related issues once the homogeneous catalyst is immobilised over a solid

surface.

The first step in order to address these challenges is in a critical evaluation of the key

physico-chemical phenomena related to these materials and their influence of their

performances. In this context, research progress in this area has been scarce and most of