900/1400 GAS-FIRED SERIES - the Hooplacdn.thehoopla.com/risenabove/client/hotsy_parts/images... ·...

Transcript of 900/1400 GAS-FIRED SERIES - the Hooplacdn.thehoopla.com/risenabove/client/hotsy_parts/images... ·...

97-6574

SERIAL NUMBER:

DATE PURCHASED:

FOR SALES AND SERVICE, PLEASE CONTACT:

OPERATING INSTRUCTIONSAND PARTS MANUAL

Thank you for purchasing a Hotsy Pressure Washer. This manual covers the operation and mainte-nance of your pressure washer. All information in this manual is based on the latest product informa-tion available at the time of printing. Hotsy, Inc. reserves the right to make changes at any time withoutincurring any obligation.

Read instructions carefully before attempting to assemble, install, operate or service this pressurewasher. Failure to comply with instructions could result in personal injury and/or property damage!

900/1400GAS-FIRED SERIES

NOTE: This manual is intended for use with the following models only:

981SS 962SS 1424SS982SS 962SS-208 1425SS991SS 964SS 1452SS991SS-208 969SS 1452SS-208992SS 1411SS 1462SS992SS-208 1412SS 1462SS-208994SS 1421SS 1464SS995SS 1421SS-208 1469SS952SS 1422SS952SS-208 1422SS-208

®cLISTED ®

981SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 230Vac/60Hz/1Ph● Total Machine Amperage: 25 Amps● Machine Weight: 490 Lbs.● Shipping Weight: 550 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

982SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 230Vac/60Hz/1Ph● Total Machine Amperage: 25 Amps● Machine Weight: 490 Lbs.● Shipping Weight: 550 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

991SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 230Vac/60Hz/3Ph● Total Machine Amperage: 16 Amps● Machine Weight: 485 Lbs.● Shipping Weight: 545 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

991SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 208Vac/60Hz/3Ph● Total Machine Amperage: 18 Amps● Machine Weight: 485 Lbs.● Shipping Weight: 545 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

992SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 230Vac/60Hz/3Ph● Total Machine Amperage: 16 Amps● Machine Weight: 485 Lbs.● Shipping Weight: 545 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

992SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 208Vac/60Hz/3Ph● Total Machine Amperage: 18 Amps● Machine Weight: 485 Lbs.● Shipping Weight: 545 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

994SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 460Vac/60Hz/3Ph● Total Machine Amperage: 8 Amps● Machine Weight: 485 Lbs.● Shipping Weight: 545 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

995SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 2000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 5.0● Machine Voltage: 460Vac/60Hz/3Ph● Total Machine Amperage: 8 Amps● Machine Weight: 485 Lbs.● Shipping Weight: 545 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

952SS SPECIFICATIONS● Pump Volume At Pump Head: 3.8 GPM/228 GPH● Pump Pressure At Pump Head: 2300 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 6.2● Machine Voltage: 230Vac/60Hz/1Ph● Total Machine Amperage: 27 Amps● Machine Weight: 500 Lbs.● Shipping Weight: 560 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

952SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.8 GPM/228 GPH● Pump Pressure At Pump Head: 2300 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 6.2● Machine Voltage: 208Vac/60Hz/1Ph● Total Machine Amperage: 28 Amps● Machine Weight: 500 Lbs.● Shipping Weight: 560 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

962SS SPECIFICATIONS● Pump Volume At Pump Head: 3.8 GPM/228 GPH● Pump Pressure At Pump Head: 2300 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 6.2● Machine Voltage: 230Vac/60Hz/3Ph● Total Machine Amperage: 16 Amps● Machine Weight: 495 Lbs.● Shipping Weight: 550 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

962SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.8 GPM/228 GPH● Pump Pressure At Pump Head: 2300 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 6.2● Machine Voltage: 208Vac/60Hz/3Ph● Total Machine Amperage: 19.5 Amps● Machine Weight: 495 Lbs.● Shipping Weight: 550 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

964SS SPECIFICATIONS● Pump Volume At Pump Head: 3.8 GPM/228 GPH● Pump Pressure At Pump Head: 2300 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 6.2● Machine Voltage: 460Vac/60Hz/3Ph● Total Machine Amperage: 11.5 Amps● Machine Weight: 495 Lbs.● Shipping Weight: 550 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

969SS SPECIFICATIONS● Pump Volume At Pump Head: 3.8 GPM/228 GPH● Pump Pressure At Pump Head: 2300 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 6.2● Machine Voltage: 575Vac/60Hz/3Ph● Total Machine Amperage: 7 Amps● Machine Weight: 495 Lbs.● Shipping Weight: 550 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

1422SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 230Vac/60Hz/3Ph● Total Machine Amperage: 24 Amps● Machine Weight: 545 Lbs.● Shipping Weight: 605 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1422SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 208Vac/60Hz/3Ph● Total Machine Amperage: 24 Amps● Machine Weight: 545 Lbs.● Shipping Weight: 605 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

1424SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 460Vac/60Hz/3Ph● Total Machine Amperage: 12 Amps● Machine Weight: 545 Lbs.● Shipping Weight: 605 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1425SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 460Vac/60Hz/3Ph● Total Machine Amperage: 12 Amps● Machine Weight: 545 Lbs.● Shipping Weight: 605 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1411SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 230Vac/60Hz/1Ph● Total Machine Amperage: 34 Amps● Machine Weight: 550 Lbs.● Shipping Weight: 610 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1412SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 230Vac/60Hz/1Ph● Total Machine Amperage: 34 Amps● Machine Weight: 550 Lbs.● Shipping Weight: 610 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1421SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 230Vac/60Hz/3Ph● Total Machine Amperage: 25 Amps● Machine Weight: 545 Lbs.● Shipping Weight: 605 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

1421SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: LP Gas Fired, 350,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 208Vac/60Hz/3Ph● Total Machine Amperage: 24 Amps● Machine Weight: 545 Lbs.● Shipping Weight: 605 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18",

Height=50"

1462SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 8.2● Machine Voltage: 208Vac/60Hz/3Ph● Total Machine Amperage: 23 Amps● Machine Weight: 555 Lbs.● Shipping Weight: 615 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1464SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 7.5● Machine Voltage: 460VAC/60Hz/3Ph● Total Machine Amperage: 11 Amps● Machine Weight: 555 Lbs.● Shipping Weight: 615 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1469SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 8.2● Machine Voltage: 575VAC/60Hz/3Ph● Total Machine Amperage: 10 Amps● Machine Weight: 555 Lbs.● Shipping Weight: 615 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1452SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 8.2● Machine Voltage: 230Vac/60Hz/1Ph● Total Machine Amperage: 34 Amps● Machine Weight: 560 Lbs.● Shipping Weight: 620 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1452SS-208 SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 332,000 BTU/Hr.● Motor Hp: 8.2● Machine Voltage: 208Vac/60Hz/1Ph● Total Machine Amperage: 36.5 Amps● Machine Weight: 555 Lbs.● Shipping Weight: 615 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

1462SS SPECIFICATIONS● Pump Volume At Pump Head: 3.9 GPM/234 GPH● Pump Pressure At Pump Head: 3000 PSI● Burner Type: Natural Gas Fired, 350,000 BTU/Hr.● Motor Hp: 8.2● Machine Voltage: 230Vac/60Hz/3Ph● Total Machine Amperage: 22.5 Amps● Machine Weight: 555 Lbs.● Shipping Weight: 615 Lbs.● Exhaust Stack Size: 8"● Machine Dimensions: Length=45", Width=18", Height=50"

CONTENTS

697-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached tothe pressure washer. You should record both serial number anddate of purchase and keep in a safe place for future reference.

Introduction & Important Safety Information 7-8

Component Identification 9

Assembly Instructions 10

Installation Instructions 11-12

Operation Instructions 13-14

Shutdown Instructions 15

Storage 15

Maintenance 16

Troubleshooting 17-19

Exploded Views 20-21

Exploded View Parts List 22-23

Burner Assembly & Parts List 24-25

Pump Assembly & Parts List 26-27

Float Tank Assembly & Parts List 28-29

Control Panel & Parts List 30-31

Pump, Detail Exploded View & Parts List 32-34

Hose & Spray Gun Assembly & Parts List 35

Trigger Gun, Detail Exploded View & Parts List 36-37

Specifications 38

Wiring Diagrams 39-46

Warranty

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

7

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

INTRODUCTION & IMPORTANT SAFETY INFORMATION

Owner/User ResponsibilityThe owner and/or user must have an understanding ofthe manufacturer’s operating instructions and warningsbefore using this Hotsy pressure washer. Warning infor-mation should be emphasized and understood. If theoperator is not fluent in English, the manufacturer’s in-structions and warnings shall be read to and discussedwith the operator in the operator’s native language bythe purchaser/owner, making sure that the operator com-prehends its contents.

Owner and/or user must study and maintain for futurereference the manufacturers’ instructions.

This manual should be considered a permanentpart of the machine and should remain with it ifmachine is resold.

When ordering parts, please specify model andserial number.

IMPORTANT SAFETYINFORMATION

CAUTION: To reduce the risk ofinjury, read operating instruc-tions carefully before using.

1. Read the owner's manualthoroughly. Failure to follow in-structions could cause mal-function of the machine andresult in death, serious bodilyinjury and/or property dam-age.

2. Know how to stop the machine and bleed pres-sures quickly. Be thoroughly familiar with the con-trols.

3. Stay alert — watch what you are doing.

4. All installations must comply with local codes. Con-tact your electrician, plumber, utility company orthe selling distributor for specific details.

WARNING: Risk of asphyxiation.Use this product only in a wellventilated area.

5. Risk of explosion — do notspray flammable liquids or op-erate in an explosive location.Operate only where openflame or torch is permitted.

WARNING

RISK OFASPHYXIATION.

USE ONLY IN A WELLVENTILATED AREA.

WARNING

READ OPERATOR’SMANUAL

THOROUGHLY PRIOR TO USE.

WARNING

HIGH PRESSURESPRAY CAN PIERCESKIN AND TISSUES.

WARNING

KEEP WATER SPRAYAWAY FROM

ELECTRICAL WIRING.

WARNING: Keep water sprayaway from electrical wiring or fa-tal electrical shock may result.

6. To protect the operator fromelectrical shock, the machinemust be electrically grounded.It is the responsibility of theowner to connect this ma-chine to a UL grounded re-ceptacle of

proper voltage and amperage ratings. Do not spraywater on or near electrical components. Do nottouch machine with wet hands or while standing inwater. Always disconnect power before servicing.

7. Grip cleaning wand securely with both hands be-fore starting the cleaner. Failure to do this couldresult in injury from a whipping wand.

WARNING: High pressure streamof fluid that this equipment canproduce can pierce skin and itsunderlying tissues, leading to se-rious injury and possible ampu-tation.

8. High pressure developed bythese machines can causepersonal injury or equipmentdamage. Use caution whenoperat-

ing. Do not direct discharge stream at people, orsevere injury and/or death may result.

9. Never make adjustments on machine while in op-eration.

WARNING: High pressure spraycan cause paint chips or otherparticles to become airborneand fly at high speeds.10. Eye safety devices and foot

protection must be worn whenusing this equipment.

11. When the machine is working,do not cover or place in aclosed

space where ventilation is sufficient.

12. Do not operate with the spray gun in the off posi-tion for extensive periods of time as this may causedamage to the pump.

13. Protect from freezing.

14. Be certain all quick coupler fittings are secured be-fore using pressure washer.

15. Do not allow acids, caustic, or abrasive fluids topass through the pump.

16. Inlet water must be from a cold, fresh city water sup-ply.

WARNING

PROTECTIVE EYEWEARAND CLOTHING MUST

BE WORN.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

8

IMPORTANT SAFETY INFORMATION

17.To reduce the risk of injury, close supervision is nec-essary when a machine is used near children. Donot allow children to operate the pressure washer.This machine must be attended during opera-tion.

18. The best insurance against an accident is precau-tion and knowledge of the machine.

19. Do not operate this product when fatigued or un-der the influence of alcohol or drugs. Keep operat-ing area clear of all persons.

20. Do not replace LP tank while machine is running.Serious injury could result.

21. The LP models are designed to run on vapor pro-pane fuel. Do not use liquid fuel. Have a qualifiedserviceman install and service your equipment.

22. Never expose a spark or flame where there maybe unburned gas present.

23. Some gases are heavier than air and will spill outon the floor. Therefore always provide adequatespace and ventilation around these machines. In-stall the machine 18" above the floor.

24. Hotsy will not be liable for any changes made toour standard machines, or any components notpurchased from Hotsy.

25. Do not overreach or stand on unstable support.Keep good footing and balance at all times.

26. Follow maintenance instructions specified inmanual.

27. When making repairs, disconnect from electricalsource and shut off gas valve.

28. Turn burner off and cool to 100°F before turningmachine off.

29. Extinguish any open flame, and test all joints witha soap solution. If the odor persist, call your gassupplier immediately.

30. This machine must be attended during operation.

31. A draft hood shall be installed if this machine isgoing to be permanently installed and vented tothe outside of the building.

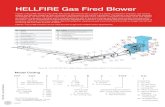

Example Of DownDraft DiverterFor Gas Fired

Machines

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

9

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

COMPONENT IDENTIFICATION

BurnerExhaust Vent

Thermostat

Pump switchHigh Pressure

Nozzle

Wand

High PressureHose

Detergent Bucket(not included)

ThermalRupture Disk

Burner Switch

Garden Hose(not included)

Trigger Gun

DetergentControl

Nozzles

Pump — Develops high pressure by pumping watervolume through nozzle.

Spray Gun — Controls the application of water anddetergent onto cleaning surface with trigger device. In-cludes safety latch.

Detergent Metering Valve — Controls detergent mix-ture.

Wand — Must be connected to the spray gun.

High Pressure Hose — Connect one end to waterpump discharge nipple and the other end to spray gun.

Pressure Nozzle — Inserted into wand quick couplerto develop pressure

Adjustable Thermostat — Prevents water tempera-ture from exceeding high temperatures. Is not used tomaintain constant temperature setting.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

10

ASSEMBLY INSTRUCTIONS

UnpackingUnpack carefully. Wear safety glasses or goggles whileunpacking, assembling or operating pressure washer. Ifthere are missing components or hidden damage imme-diately contact distributor or carrier concerning discrep-ancies.

1. Cut strapping band from pressure washer and pal-let.

2. Remove pressure washer from pallet.

Parts Included• Pressure Washer

• Pressure Hose

• Hose Hanger

• Wand

• Wand Holder

• Parts Box Containing:

■ Pressure Nozzles (3 ea.)

■ Trigger Gun

• Operating Instructions and Parts Manual

Tools Required• 10" Adjustable Crescent Wrenches (2 ea.)

• Blade Screwdriver

Pressure Hose, Wand and Wand Holder1. Use teflon tape on plumbing connections to prevent

leakage.2. Install pressure hose on machine as shown.

3. Assemble wand components as shown. Connectpressure hose to trigger gun.

NOTE: The nozzle is not to be installed at this time.

4. Make sure that all plumbing connections are tight.

Hose Hanger1. Install the hose hanger on the machine coil tank as

shown.

Quick Disconnect Plug Wand

QuickDisconnect

Trigger Gun

Pressure Hose

Hose Hanger

Pocket OnCoil Tank

Rupture Disk

Pressure Hose

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

11

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

INSTALLATION INSTRUCTIONS

Getting Started

IMPORTANT: Proper initial installation of equipmentwill assure more satisfactory performance, longerservice life and lower maintenance cost.

The pressure washer should be run on a level surface andin a protected area where it is not readily influenced byoutside sources such as strong winds, freezing tempera-tures, rain, etc. The pressure washer should be located toassure easy access for filling of fluids, adjustments andmaintenance. Normal precautions should be taken by theoperator to prevent moisture from reaching the pressurewasher. It is recommended that a partition be made be-tween the wash area and the pressure washer to preventdirect spray from the wand coming in contact with the pres-sure washer. Moisture reaching the equipment will reducethe pressure washer’s service life. All installations shouldcomply with the local codes covering such installations.

Venting

WARNING - RISK OF EXPLOSION: Do not spray flam-mable liquids or operate machine in areas where flam-mable vapors are present. Operate only where openflame or torch is permitted.

CAUTION - RISK OF ASPHYXIATION: Do not runmachine indoors or in an enclosed area without therequired venting, as exhaust fumes may be hazard-ous to your health.

CAUTION: Some gases are heavier than air and willspill out on the floor in the 2 to 3 minutes required forthe safety pilot valve to close off gas supply. There-fore, always provide adequate space and ventilationaround these units.

IMPORTANT: A draft diverter shall be installed.INSTALLER UNE HOTTE DE TIRAGE.

IMPORTANT: All venting must be in accordance withapplicable federal and state laws, and local ordi-nances. Consult local heating contractors.

IMPORTANT: Not suitable for connection to Type Bgas vent if the stack temperature exceeds 243°C(470°).

If the pressure washer is to be used in an enclosedarea, a flue must be installed to vent burner exhaust tothe outside atmosphere. Exhaust gases should not bevented into a wall, a ceiling, or into a concealed spacein a building. Be sure the flue is the same size as theburner exhaust vent on the pressure washer. Poor draftwill cause the pressure washer to soot and not operateproperly. When selecting the location for installation,beware of poorly ventilated locations or areas whereexhaust fans may cause an insufficient supply of oxy-gen. Proper combustion can only be obtained when thereis a sufficient supply of oxygen available for the amountof fuel being burned. If it is necessary to install themachine in a poorly ventilated area, outside fresh air

may have to be piped to the burner and a fan installedto bring sufficient air into the machine. Locate the pres-sure washer so that the flue will be as straight as pos-sible and protrude through the roof at a proper heightand location to provide adequate draft. This gas firedpressure washer must have a draft diverter installed inthe flue. A draft diverter will permit proper upward flowof exhaust flue gases.

Water SupplyConnect water supply hose to water inlet. The waterfaucet and supply hose must be capable of providing aminimum of 6.0 gallons per minute (GPM).

Fuel Supply

CAUTION: Have a qualified gas serviceman installand service your equipment.

WARNING: Gas line supply pressure must not ex-ceed 14 water column inches (.50 PSI).

IMPORTANT: Gas line must be provided with a shutoff valve.

IMPORTANT: The gas supply must be able to sup-ply a minimum of 525,000 BTU/HR at the machinesrated manifold pressure.

Consult building codes for installation requirements.For proper and safe machine operation, we recommendthat a licensed contractor be consulted for machineinstallation.

Natural Gas FuelHave a qualified gas serviceman install the natural gasfuel supply line to the machine.

On/OffSwitch

Outlet View

Line toPilot Light

ManifoldPressure

AdjustmentScrew Under

Cap

Inlet View

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

12

Gas ValveThe ideal incoming gas pressure is 11 w.c.i. (water col-umn inches) minimum 6 w.c.i., maximum 14 w.c.i. or 1/2 psig. The correct operating manifold pressure for natu-ral gas is 3.5 w.c.i. The operating manifold pressure forpropane gas is 11 w.c.i. The gas valve pressure regula-tor can be adjusted between 3 and 4 w.c.i. natural gasor 6 and 11 w.c.i.for propane.

The gas pressure coming out of the regulator and goingto the burner ring has been factory set. You should notreadjust the burner ring gas pressure. If you replaceyour gas valve, you will need to adjust the new valve.Refer to your machine’s specification plate for thecorrect pressure setting. Follow the installation and ad-justment instructions provided with your replacementvalve.

INSTALLATION INSTRUCTIONS

Electrical

WARNING: Make sure all switches and controlsare in the OFF position prior to connecting electricalsupply.

WARNING: DO NOT stand in water while connectingand disconnecting electrical supply.

WARNING: Always disconnect power before servic-ing your pressure washer.

IMPORTANT: Consult local building codes for exactelectrical requirements. Licensed contractors may berequired.

IMPORTANT: All wiring must be of proper voltage andamperage rating and conform to applicable codes.

IMPORTANT: This machine must be electricallygrounded. LA MACHINE DOIT ÊTRE MISE À LATERRE.

Grounding Instructions: Make sure all switches andcontrols are in the OFF position prior to connecting elec-trical supply. Do not stand in water while connectingand disconnecting electrical supply. If it should mal-function or break down, grounding provides a path ofleast resistance for electric current to reduce the risk ofelectric shock. The product must be connected to anappropriate power source that is properly installed andgrounded in accordance with all local codes and ordi-nances.

DANGER: Improper connection of the equipmentgrounding conductor can result in a risk of electro-cution. Check with a qualified electrician or servicepersonnel if you are in doubt as to whether theoutlet is properly grounded.

Extension Cords: Do not use extention cords with thisequipment.

WARNING: To reduce the risk of electrocution, keepall connections dry and off the ground.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

13

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

OPERATION INSTRUCTIONS

Before Starting1. Read all manuals provided with this pressure washer.

Become familiar with location and function of alloperating and safety controls.

WARNING: Check hoses, fittings, wand, trigger gunand fuel connections daily for signs of wear, cracksand looseness, and replace as required.

2. Connect water supply hose to the standard gardenhose connector. The water faucet and supply hosemust be capable of providing 6.0 GPM.

3. This machine was factory built for Natural Gas. Seeinstructions under Fuel Supply.

4. Check pump oil level.5. If detergents are to be used, only use detergents

intended for pressure washers. Follow instructionson the detergent container.

IMPORTANT: Before installing pressure nozzle on ini-tial start-up, turn on the water supply, start the pumpby pressing the pump ON switch, and hold the wandtrigger open until water appears at the end of thewand. Allow water to run from the end of the wanduntil clear to prevent the nozzle from clogging.

IMPORTANT: If the pressure washer has not beenused for an extended period of time, remove the pres-sure nozzle from the end of the wand and turn onwater supply, and start the pump by pressing thepump ON switch. Hold the wand trigger open and al-low water to run from the end of the wand until clear.

6. Install the pressure nozzle on end of wand, refer toillustration below.

IMPORTANT: The trigger gun provided with this pres-sure washer is equipped with a manual trigger lockto prevent accidental operation of the trigger gun, re-fer to figure above. The trigger lock should be usedwhenever the trigger gun is not in use.

IMPORTANT: On initial start-up or if maintenancehas been performed on the burner assembly, it willbe necessary to bleed the air from the gas line beforethe pilot will light.

7. If you are running the machine for the first time, orhave performed maintenance on the burner assem-bly, there will be air in the gas line. To bleed the airfrom the gas line run the pressure washer with pumpand burner switches on and thermostat on highestsetting. Squeeze the trigger of the trigger gun for 15seconds. If the burner has not ignited, release the

trigger for 5 seconds, then squeeze for 15 seconds.If the burner has not ignited after 10 tries, see theTroubleshooting Guide in this manual.

CAUTION: Have a qualified gas serviceman installand service your equipment.

DANGER: Never expose a spark or flame where theremay be unburned gas present.

DANGER: Some gases are heavier than air and willspill out on the floor in the 2 to 3 minutes required forthe safety pilot valve to close off gas supply. There-fore, always provide adequate space and ventilationaround these units.

To Start

WARNING: Risk of injection or severe injury - Keepclear of nozzle - DO NOT direct discharge stream atpersons - This machine is to be used only by quali-fied operators.

AVERTISSEMENT: RISQUE D’INJECTION ET DEBLESSURES GRAVES. SE TENIR À L’ÉCART DU JET.NE PAS DIRIGER LE JET DE SORTIE VERS D’AUTRESPERSONNES. CONFIER L’UTILISATION DE CEMATÉRIEL À UN OPÉRATEUR QUALIFIÉ.

WARNING: Wear eye, ear, hand, foot and skin protec-tion at all times while operating pressure washer.

WARNING: Before changing pressure nozzle, engagemanual trigger gun lock.

IMPORTANT: The water must be turned on before start-ing. Running the pump dry will cause damage andvoid warranty.

IMPORTANT: Do not allow the machine to run withtrigger of the trigger gun released for more than10 minutes at any one time or damage to pump mayoccur.

1. Turn ON water supply.2. Turn ON gas supply.3. Hold wand firmly, release trigger of trigger gun and

turn pump switch ON. Squeeze trigger of trigger gunand allow air to purge from system.

4. If HOT water is desired, adjust the thermostat to theproper temperature and turn burner switch ON.Squeeze trigger of trigger gun. The pilot will automati-cally light, quickly followed by the firing of the burnerring. When the trigger of the trigger gun is released orwhen the thermostat temperature setting is reached,the burner will automatically turn off.

IMPORTANT: If ignition or flame failure is experienced,discontinue use of pressure washer at once. Turn offburner and shut off fuel supply. Have cause of failurecorrected by an authorized service technician beforeuse of pressure washer is continued.

Manual Trigger Lock

Pressure Nozzle

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

14

OPERATION INSTRUCTIONS

To Clean

WARNING: Risk of injection or severe injury - Keepclear of nozzle - DO NOT direct discharge stream atpersons - This machine is to be used only by quali-fied operators.

AVERTISSEMENT: RISQUE D’INJECTION ET DEBLESSURES GRAVES. SE TENIR À L’ÉCART DU JET.NE PAS DIRIGER LE JET DE SORTIE VERS D’AUTRESPERSONNES. CONFIER L’UTILISATION DE CEMATÉRIEL À UN OPÉRATEUR QUALIFIÉ.

1. Insert detergent inlet line into container of mixeddetergent. Open detergent ON/OFF valve. Thedetergent will be pulled automatically into the sys-tem. Allow detergent to reach end of wand beforeproceeding to step 3.

2. Select pressure nozzle with spray pattern thatmatches your cleaning needs. Engage manual trig-ger lock and install selected nozzle.

3. Wash from the bottom to the top, using side to sidemotions. This washes away heavy dirt and allows thedetergent to soak as you work toward the top.

4. Do not wash at a 90° angle to the work (straight at it).This will allow water to splash back at you andreduces your cleaning power. Wash at a 30° to 60°angle to the work. This will allow the water to splashaway from you and the water will wash the dirt awayfaster and easier.

5. Use the width of the spray pattern to wash in a widepath. Overlap spray paths for complete coverage.Wash from side to side, using slow, steady motions.

6. The nozzle should be 12" to 24" from work, closerfor tough areas. Be careful on painted or delicatesurfaces, the pressure may damage surface if nozzleis too close.

7. Small parts should be washed in a basket and larger,lightweight parts should be clamped down so thepressure does not push them away.

8. Close the detergent ON/OFF valve to permit rinse.Always rinse with cold water after using detergents.Rinse from the top to the bottom to prevent deter-gent from dripping onto a rinsed area. For the bestresults, contact your Hotsy dealer to help you selectthe best detergent for your application.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

15

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

SHUTDOWN INSTRUCTIONS

To Stop1. If detergents were used, draw clear water through

the detergent line to purge detergent. Failure to doso may clog detergent injector valve.

2. If burner was used, turn OFF burner switch andallow pump to run cold water through coil for severalminutes.

3. Turn pump switch OFF.4. Turn water supply OFF.5. Squeeze trigger gun open to relieve system pres-

sure.6. Depress gas control knob slightly and turn to OFF

position.7. Turn off main shut-off valve on gas supply.

STORAGE INSTRUCTIONS

DANGER: Do not store flammable liquids (gasoline,diesel fuel, petroleum, solvents, etc.) near pressurewasher, or in non-ventilated areas.

IMPORTANT: Machine must be stored indoors.

1. Protect from freezing by storing in a heated area,or by flushing the system with antifreeze (use anautomotive engine antifreeze or windshield washersolvent to antifreeze). To flush the system fill the floattank with antifreeze and remove pressure nozzle fromwand. Start the machine and allow it to run until an-tifreeze runs from the end of the wand. Place wandinto float tank and circulate the solution through sys-

tem for several minutes. Open and close the triggergun several times to circulate antifreeze through theunloader valve system. Also draw antifreeze throughthe detergent inlet line to antifreeze the detergentsystem. For added protection after antifreezing, dis-connect the pressure hose from machine and removethe coil drain plug (refer to Component Identifica-tion illustration for location). After coil has drained,replace pressure hose and coil drain plug. If the pres-sure washer is not to be used for an extended lengthof time, it is recommended that the system be flushedwith antifreeze for rust protection.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

16

MAINTENANCE

WARNING: Unauthorized machine modification or useof non-approved replacement parts may cause per-sonal injury and/or property damage and will void themanufacturer warranty.

PumpUse Hotsy Pump Oil P/N 315068 for pump crankcase.Crankcase must be filled to the full mark on the dipstick orto center of sight glass window found on the rear of thepump. During the break-in-period, make sure the oil ischanged after the first 25 hours of operation. After that,replace oil every 3 months or 300 hours of operation, which-ever comes first.

Proper Pump Care:• Do not pump acids.

• Do not allow pump to run dry.

• Winterize if storing in freezing temperatures; referto Storage for details.

• Use a water softener on the water system if knownto be high in mineral content.

• Use only high quality detergents and follow manu-facturer’s mix recommendations.

• Flush the system with clear water immediately afterusing detergent solutions.

• Clean filter screen on detergent inlet line periodi-cally.

• Flush the pressure washer system with antifreezeif storing for an extended period of time; refer to Stor-age for details.

Pump MotorOn a yearly basis, oil pump motor per instructions on mo-tor nameplate.

NOTE: Some motors may be equipped with perma-nently lubricated bearings and will not require addi-tional lubrication.

Gas BurnerIt is recommended that the gas burner be serviced yearlyor as needed. Contact your local service center.

Relief Valve

WARNING: The relief valve on this pressure washerhas been factory set and sealed and is a field nonad-justable part. Tampering with the factory setting maycause personal injury and/or property damage, andwill void the manufacturer warranty.

Unloader Valve

WARNING: The unloader valve on this pressurewasher has been factory set and sealed and is a fieldnonadjustable part. Tampering with the factory set-ting may cause personal injury and/or property dam-age, and will void the manufacturer warranty.

Heating CoilCoil Descaling: In hard water areas, scale buildup withinthe heating coil will occur. Scale deposits will decrease thewater temperature rise and may eventually clog the heatingcoil. Contact your local service center when descaling isneeded.

Coil Desooting: Poor grades of fuel oil or inadequatecombustion air will cause heavy soot buildup on theoutside surface of the heating coil. These deposits willinsulate the coil. This will restrict the air flow through thecoil, further aggravating the soot buildup. Contact yourlocal service center when desooting is needed.

DipstickSight Glass(on Rear of Pump)

Oil Fill

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

17

PR

ES

SU

RE

WA

SH

ER

Trou

blesho

otin

g G

uid

eTROUBLESHOOTING

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Pressure washer willnot run.

Pump switch in OFF position. Place switch in ON position.

Power supply disconnected. Connect power supply.

Fuse blown or circuit breakertripped in electrical supply line.

Replace fuse or reset circuit breaker. Useonly circuits of adequate capacity.

Motor circuit overload tripped. Allow sufficient time for motor to cooldown. Place pump switch in ON position.

Pressure washer runs butwon't spray.

Trigger of trigger gun released. Squeeze trigger.

Water supply not turned on. Open water supply valve.

Clogged pressure nozzle. Clean pressure nozzle opening.

Inlet water screen clogged. Check screen and clean if necessary.

Pump sucking air. Fill the detergent container and check forloose hose clamps or fittings.

Low spray pressure atnozzle.

Inadequate water supply. Fully open faucet. Check for kinked ordamaged hose. Use 5/8" minimum hose.Check for debris clogging inlet screen.

Partially clogged or damagedpressure nozzle.

Clean or replace.

Air being drawn through detergentinlet line.

Refill detergent container. Ensure thatpick-up screen is fully immersed.

Uneven spray pattern. Partially clogged or damagedpressure nozzle.

Clean or replace.

Pressure washer will notproduce hot water.(continued)

Burner switch in OFF position. Place switch in ON position.

Gas valve switch in OFF position. Place switch in ON position.

Inadequate fuel supply. Check fuel supply.

Pump switch turned off. Pump must be running before burner willlight.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

T

rou

bles

ho

otin

g G

uid

e

18

TROUBLESHOOTING

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Pressure washer will notproduce hot water.(continued)

Inadequate water supply. Fully open faucet. Check for kinked ordamaged hose. Use 5/8" minimum hose.Check for debris clogging inlet screen.

Trigger of trigger gun released. Squeeze trigger. Water must be sprayingfor burner to light.

Thermostat set too low, or defective. Raise thermostat setting. Replace ifdefective.

Manual gas valve not open. Turn ON gas valve.

Defective gas valve. Replace gas valve.

Poor or no detergent flow. Inadequate detergent supply. Refill detergent container. Ensure thatpick-up screen is fully immersed.

Detergent screen or hose clogged. Clean. Always start with a clean detergentcontainer.

Clogged detergent injector checkvalve.

Clean check valve at detergent injector.

Poor cleaning. Improper detergent concentration ormixing.

Mix detergent per manufacturer's instruc-tions. Ensure that powdered detergentsare fully dissolved.

Wrong detergent for the application. Select appropriate detergent.

Rinsing with hot water. A final rinse with cold water will reducewater spotting.

Detergent valve not opening. Check that handle or knob is not slippingon shaft.

Unloader cycles whentrigger gun is opened orclosed.

Air in system. Open and close trigger gun several times.

Unloader defective. Replace if defective.

Water leak between unloadervalve and trigger gun.

Check fittings, hose and trigger gun forleaks. Repair or replace.

Burner smokes or hasobnoxious odor.

Stack restriction. See Venting under Installation.

Pressure relief valve leaking. Excessive pressure due todefective unloader valve.

Replace unloader valve.

Defective relief valve. Replace relief valve.

Dirty relief valve. Clean relief valve seat.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

19

PR

ES

SU

RE

WA

SH

ER

Trou

blesho

otin

g G

uid

eTROUBLESHOOTING

1800 GAS-FIRED SERIES OPTIONAL EQUIPMENT835525 Draft Diverter

When ordering from your dealer, please provide the following:

Model Number: _____________________Release:___________

Machine Serial Number: ________________________________

Component Part Number: _______________________________

Description: __________________________________________

IMPORTANTIf the pressure washer demonstrates other symptoms or the corrective actionslisted do not correct the problem, contact the local authorized Hotsy ServiceCenter. The Hotsy Service Center can be identified by visiting www.hotsy.com.

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

20

2

3

4

5

6

8

1

11

17

19

15

14,70

16,2126

25

24

27

754

12

1311

25

26

910 28

23

30

37

56

32

31

22

29

ForDetail SeeFloat Tank

Illus.

37

39

62

27

27

34

33

ForDetail See

BurnerAssy.

35

29

38

EXPLODED VIEW

59

60

20

66

61

60

65

57

26

OptionalHose Reel

See FloatTank Illus.For Detail

26

58

18

51

75

76

25 2671

77

78

80 79

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

21

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

40

57

26

26

58

41

49

52

72 30

26

25

ThermalSwitchOption

SeePump

Assy. forDetail

50

45

44

47

48

46

3637

42

55

To FloatTank

SeeControl

Panel Illus.for Detail

EXPLODED VIEW

43

72

30

2526

63

64

6768

73

7374

53

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

22

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 213034 Tob Hat, Weld Assy., 18” Hotsy Coil 1

2 873749 Insulation, Top Head, 18 OD x 1.8 ID, Fiberglass 1

3 860102 Ring, Insulation Retainer, 16” Top Hat 1

4 824115 Clip, Retaining U-Type 2

5 241098 Coil, Service Gas 900/1000 1

6 722417 Insulation, 30.75 x 59, Fiberglass 1

7 375513 Coil, SS, Tank, Weldment 1

8 861644 Hanger, Hose 1

9 914903 Label, Plate AL Hotsy 2

10 926598 Rivet, 1/8” x 1/4”, POP, AL 8

11 2-0008 Nipple, 1/2” Hex Steel 2

12 2-0052 Nipple, 1/2” JIC, 1/2” Pipe 1

13 2-0028 Elbow, 1/2”, 90° Female Pipe 1

14 2-00681 Bushing, 1/2” x 3/8”, Steel 1

15 2-10999 Block, Coil Discharge 1

16 2-00494 Plug, 1/2” Countersunk 1

17 2-3409 Rupture Disc Assy., 7000# 1

18 2-1019 Elbow, 3/8” Female, Brass 1

19 2-10862 Hose Barb, 3/8” Barb x 3/8” ML Pipe 1

20 4-02120003 Hose, 3/8” Push-On 45”

21 6-01271 Conduit, Flexo, Black 42”

22 95-07104320 Frame, Welded Assembly, Gas 1

23 95-07104307 Panel, 900/1400 Side 1

24 2-010381 Grommet, 2-1/8” x 2-7/8” x 7/16” Rubber 1

25 90-1000 Bolt, 1/4” x 1/2”, NC HH 17

26 90-4000 Washer, 1/4” Flat, SAE 23

27 2-01403 Bushing, 5/8” Snap 6

28 95-0710375584 Slider, Pump, Weldment 1

29 90-2001 Nut, 5/16” ESNA, NC 8

30 90-4001 Washer, 5/16” Flat, SAE 8

31 90-102746 Bolt, 1/2” x 5” NC HH Tap, All Thread 1

32 90-3096 Washer, 1/2” Flat, SAE 1

33 2-01401 Bushing, 1-3/8” Snap 1

34 95-07104306 Panel, Long Frame Cover 1

35 95-07104305 Panel, Small Frame Cover 1

36 90-2002 Nut, 3/8” ESNA, NC 4

37 90-4002 Washer, 3/8” SAE, Flat 12

38 90-4006 Washer, 5/16” x 1-1/4” Fender, SAE 4

39 90-1016 Bolt, 3/8” x 1” NC HH 4

40 95-07104308 Panel, Back Welded Assy. 1

41 95-07104330 Bracket, Unloader 1

42 95-07104301 Panel, Front 1

43 Motor, Please See Specifications Page

44 5-604040 Belt, BX40 2

45 Pump Pulley, Please See Specifications Page

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

23

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

46 Motor Pulley, Please See Specifications Page

47 5-5120220 Bushing, H x 22mm 1

48 Motor Bushing, Please See Specifications Page

49 95-07104313 Cover, Back Panel 1

50 95-07104309 Cover, Cabinet 1

51 2-9013 Clamp, 1/2” 1

52 2-00601 Elbow, 1/2” JIC x 3/8” Female, 90° 1

53 90-29980 Screw, #8 x 1/2”, Phillips, Zinc 2

54 11-10480 Label, Warning 1

55 11-0510 Label, Hotsy 900/1400 Control Panel 1

56 90-10343 Bolt, 10mm x 20mm, HH 4

57 90-1001 Bolt, 1/4” x 3/4” NC HH 4

58 90-2000 Nut, 1/4” ESNA, NC 4

59 4-02047727 Hose, 3/8” 2 Wire Pressure Loop 27”

60 90-100461 Screw, 1/4-20 x 1/2” Tri-Round, Black, Zinc 12

61 10-01002 Label, Natural Gas 1

10-01001 Label, LP (LP Option) 1

62 2-010381 Grommet, Rubber 1

63 6-051595 Strain Relief 1

64 6-0105 Cord, Service, 12/4 (962SS, 962SS-208,992SS, 964SS, 969SS, 991SS, 991SS-208,992SS-208. 994SS, 995SS, 1424SS, 1425SS,1464SS, 1469SS) 45”

6-0108 Cord, Service, 10/3 (952SS, 952SS-208,982SS, 981SS) 45”

6-0109 Cord, Service, 10/4 (1462SS, 1422SS-208,1422SS, 1421SS-208, 1421SS, 1462SS-208) 45”

6-0102 Cord, Service, 8/3 (1411SS, 1412SS, 1452SS,1452SS-208) 45”

65 2-0103 Grommet, Rubber, 1

66 10-09004 Label, Hot Water 1

67 95-07104328 Cover, Electrical Box 1

68 10-08021 Label, Disconnect Power Supply 1

69 90-1981 Screw, 4mm x 4mm, Panhead 1

70 2-2007 Nipple, 3/8” x 3/8” NPT 1

71 10-09003 Label, Cold Water Inlet 1

72 90-1006 Bolt, 5/16” x 3/4” NC, Grade 5 4

73 10-02028 Label, Exposed Label 2

74 9.800-049.0 Label, Detergent Warning 1

75 90-1808 Screw, 10/32” x 5/8” Phil Pan SS 1

76 90-017 Nut, 10/32” KEPS 1

77 95-07104337 Bracket, Transformer (969SS, 1469SS) 1

78 90-1007 Bolt, 5/16” x 1” NC, HH (969SS, 1469SS) 2

79 90-2001 Nut, 5/16” ESNA, NC (969SS, 1469SS) 2

80 90-4001 Washer, 5/16” Flat, SAE (969SS, 1469SS) 2

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

24

BURNER ASSEMBLY

29

45

20

13

1415

13

126

11

8

9

10

17

17

7

2

18

1918 16

19

1

19

26

21

2322

25

28

27

3

30

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

25

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

BURNER PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 95-0710200233 Angle, Gas Burner Bracket 1

2 Burner Ring, Please See Specifications Page

3 2-001681 Nipple, 3/4” x 9” Black 1

4 2-00293 Elbow, 3/4” Black, 90° 1

5 2-00151 Nipple, 3/4” x Close, Black 1

6 2-00163 Nipple, 3/4” x 2” Black 1

7 2-00166 Nipple, 3/4” x 3-1/2” Black Pipe 1

8 2-0037 Tee, 3/4” Black Pipe 1

9 2-00165 Nipple, 3/4” x 5” Black Pipe 1

10 2-00851 Cap, 3/4” Black Pipe 1

11 7-0150 Tubing, Aluminum, 600”/RL, 1/4” 10”

12 2-1116 Elbow, 1/4” Tube x 1/8” MPT, 90° 1

13 2-1072 Bushing, 1/4” x 1/8” Pipe 2

14 2-1117 Connector, 1/4” Tube x 1/8” MPT 1

15 2-3006 Valve, Ball, 1/4” Female x 1/4” Female 1

16 90-1010 Bolt, 5/16” x 1-3/4”, NC HH 1

17 90-19713 Screw, 5/16” x 3/4” Whiz Loc 2

18 90-4001 Washer, 5/16” Flat, SAE 6

19 90-20012 Nut, 5/16” Flange, Whiz Loc 3

20 7-700021 Valve, 3/4”, Natural Gas, 24V, 3.5 Honeywell 1

21 7-702371 Pilot, Ignitor, P, NG 1

22 95-07162025 Bracket, Pilot Light 1

23 90-1000 Bolt, 1/4” x 1/2” NC HH 2

24 90-4000 ▲ Washer, 1/4” Flat 2

25 90-199940 Screw, 10/32” x 1/4” HWH ROLOC, Z 2

26 90-10130 U-Bolt, 5/16” x 1”, Pipe 1

27 6-01353 Cable, Ignition, 60” 1

28 7-702320 LP, Conversion Kit (981SS, 991SS, 991SS-208, 994SS,1411SS, 1421SS, 1421SS-208, 1424SS) 1

29 95-07104332 Bracket, Gas Train 1

30 7-701511 Connector, Ignition Module 1

▲ Not Shown

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

26

PUMP PARTS LIST

PUMP ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 2-0053 Elbow, 1/2” JIC, 3/8”, 90° 1

2 5-3314 Unloader, LG, 3000 w/Knob 1

5-3228 Unloader, YVB9KMSS, W/S.S., Check Valve (Auto Start Option) 1

3 2-1060 Elbow, 1/2” JIC x 3/8”, 90° 1

4 2-0045 Tee, 3/8” Street 1

5 2-30051 Valve, 1/2” FNWTSC12, Brass, Swing Check 1

6 2-1062 Elbow, 1/2” JIC x 1/2”, 90° 1

7 2-1053 Nipple, 1/2” JIC x 1/2” MPT Pipe 1

8 2-1042 Tee, 1/2” Street 1

9 2-1105 Swivel, 1/2” JIC Female, Push-On 4

11

2

4

21

15

23

12

25

22

1

3

ToControlPanel

ThermalSwitchOption

18

17

16

9

27

10

242019

9

9

7

14

8

32

5

33

6

13

30

26

29

28

Auto StartOption

1

25

3

22

4

23

11

9

9

31

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

27

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

PUMP PARTS LIST

ITEM PART NO. DESCRIPTION QTY

10 4-02110000 Hose, 1/2” Push-On 20”

11 2-00601 Elbow, 1/2” JIC x 3/8” Female, 90° 1

2-00602 Elbow, 1/2” JIC x 3/8” Fem, 90° (Auto Start Option) 1

12 2-10897 Hose, Barb, 1/4” Barb x 3/8” ML Pipe, 90° 1

13 6-02165 Switch, Pressure, Black 1

14 2-0019 Nipple, 3/8” x 1/2” Hex, Steel 1

15 2-9040 Clamp, Hose, UNI .46 - .54 ST 1

16 2-0052 Nipple, 1/2” JIC, 1/2” Pipe 1

17 2-0028 Elbow, 1/2”, 90° Female Pipe 1

18 2-0008 Nipple, 1/2” Hex Steel 1

19 90-10343 Bolt, 10mm x 20mm, HH 4

20 90-4002 Washer, 3/8” Flat, SAE 4

21 4-02090000 Hose, 1/4” x 1/2” Braided Vinyl 36”

22 2-0079 Swivel, 1/2” JIC Female, 3/8” Male 1

23 2-00575 Elbow, 3/8” STL, Street, 45° 1

24 95-0710375584 Slider, Pump, Weldment 1

25 2-00493 Plug, 3/8” Allen Counter Sunk (Non-Thermal Option Only) 1

26 4-05135 Switch, Snap, 140° (Thermal Option) 1

27 2-1050 Plug, 1/2” JIC 1

28 6-0100 Cord, Service, SEO 16/2 (Thermal Option) 45”

29 2-1060 Elbow, 1/2” JIC x 3/8”, 90° 1

30 Pump, Please See Specifications Page

31 4-02110000 Hose, 1/2” Push-On, Fuel-Line 19.5”

32 4-02110000 Hose, 1/2” Push-On, Fuel Line 30”

33 2-1105 Swivel, 1/2” JIC Female, Push-On 1

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

28

FLOAT TANK ASSEMBLY

82

13

14

16

15

19

14

1

5

4 3

2

20

18

12

7

10

6

11

13

9

17

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

29

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

FLOAT TANK PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 2-01164100 Tank, Float, 2-1/2” Gallon, Blank 1

2 2-11041 Connector, 1/2” Anchor 1

3 2-3011 Valve, 1/2” Brass Float 1

4 2-0102 Ball, Float, Black Plastic 1

5 334934 Rod, 1/4” x 6, Threaded 1

6 90-4001 Washer, 5/16” Flat, SAE 2

7 95-07104333 Bracket, Hose Reel 1

8 2-10942 Swivel, 1/2” MP x 3/4” GHF w/Strainer 1

9 824096 Clip, 1.25 ID, RND 1

10 90-1006 Bolt, 5/16” x 3/4” NC, Grade 5 2

11 90-20231 Nut, Cage, 1/4” x 12 Gauge 2

12 90-200012 Nut, 1/4” Flange, Zinc 1

13 90-1001 Bolt, 1/4” x 3/4” NC HH 3

14 90-4000 Washer, 1/4” Flat, SAE 3

15 90-20012 Nut, 5/16” Whiz Loc 2

16 95-07104327 Bracket, Float Tank 1

17 698029 Hose Barb, 1/2” Barb x 1/2” MNPT 1

18 2-1105 Swivel, 1/2” JIC Female, Push-On 1

19 2-1906 Strainer, 1/2” Basket 1

20 4-02110000 Hose, 1/2” Push-On 30”

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

30

CONTROL PANEL ASSEMBLY

3916

15

7,8,9 43

5

29

10

18

17

13

12

11

1242

25

19

14

24

ToPump

38

1

26

33

22

20

2 3

4

2930

ReversedView

32

31 10

35

34

41

14

36

20

21

37

21

23

6

40

28

44

45

46

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

31

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

CONTROL PANEL PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 7-701510 Module, Ignition, Electronic Honeywell 1

2 784227 Meter, Hour, 24V AC 1

3 4-05095 Knob, Thermostat 1

4 875985 Switch, Rocker, 10A/250V/125V, 24 Volt 1(Auto Start/Stop Option) 2

5 875648 Relay, 24 Volt, DPST NO 2

6 6-0504004 Block, Terminal, 14 Pole 1

7 6-0507 Lug, Terminal Grounding, LAMA6-14-Q 1

8 90-1816 Screw, 8-32 x 1-1/4”, M PH PHD PL 1

9 90-200490 Nut, 8/32” Keps 4

10 90-29980 Screw, #8 x 1/2” Tek, Square Head, SS 6

11 921438 Valve, Metering, 1/4” Hose 1

12 2-9040 Clamp, Hose, UNI .46 - .54 ST 2

13 4-02090000 Hose, 1/4” x 1/2” Braided Vinyl 11 ft.

14 2-0103 Grommet, Rubber, Nozzle Holder 3

15 95-07104303 Stand-Off, E-Box 1

16 Contactor, Please See Specifications Page 38 1

17 Overload, Please See Specifications Page 38 1

18 Transformer, Please See Specifications Page 38 1

19 11-0510 Label, Hotsy, 900/1400 Control Panel 1

20 6-05152 Strain Relief, Straight, LQ Tite Small 2(Options) 3

21 6-05181A Locknut, 1/2” Conduit 2(Options) 3

22 6-051595 Strain Relief, Straight, LQ Tite Large 2

23 6-05181B Locknut, 3/4” 2

24 2-1905 Strainer, 1/4” Brass w/Check Valve 1

25 90-1815 Screw, 8-32 x 1/2”, M PH RDH PL 4

26 90-20012 Nut, 5/16” Flange, Whiz Loc 4

27 90-2001 Nut, 5/16” ESNA, NC 4

28 90-29980 Screw, #8 x 1/2” Tek, Square Head, SS 2(Auto Start/Stop Option) 3

29 6-02403 Fuse, FNM-6.25 1

30 Fuse, Please See Specifications Page 38

31 95-07104328 Cover, Electrical Box 1

32 10-08021 Label, Disconnect Power Supply 1

33 4-050952 Thermostat w/1 meter Capillary 1

34 4-050951 Plate, Thermostat 1

35 90-1980 Screw, 4mm x 6mm, Panhead 2

36 2-017 Bushing, Star 1

37 2-0148 Plug, 7/8” Hole 2(Options) 1

38 90-200490 Nut, 8/32” Keps 4

39 90-29980 Screw, #8 x 1/2” Tek, Square Head, SS 2

40 90-29981 Screw, #8 x 3/4” Tek, Zinc 2

41 2-01403 Bushing, 7/8” Snap 1

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

32

ITEM PART NO. DESCRIPTION QTY

42 4-02090000 Hose, 1/4” x 1/2” Braided Vinyl 3 ft.

43 6-021595 Rail, Din, 35mm (All Models Except 952SS,952SS-208, 1411SS, 1412SS, 1452SS,1452SS-208, 1426SS-208) 2”

44 6-036856 Timer, Delay, 60 Sec., 24V-5A (Thermal Option) 1

45 90-1816 Screw, 8/32” x 1-1/4” M, PH, PHD, PL (ThermalOption) 1

46 90-200490 Nut, 8/32” Keps (Thermal Option) 1

CONTROL PANEL PARTS LIST

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

33

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

PUMP - EXPLODED VIEW

10

8 6 2

14

15

13

14

16

17

18

19

20

21

22

23

24

26

28

27

29

31

32

33

34

21 1

0

21

36

37

30

38

39

40

41

42

43

45

46

23

25

47

48

35

29

11

12

13

44

9 7 5 3 1

4

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

34

PUMP - EXPLODED VIEW PARTS LIST

REF. NO. PART NO. DESCRIPTION QTY.

1 ★ Valve Seat O-Ring 6

2 ★ Valve Seat 6

3 ★ Valve Plate 6

4 ★ Valve Spring 6

5 ★ Valve Cage 6

6 926656 Manifold Plug O-Ring 6

7 915631 Manifold Plug 6

8 780560 Washer 8

9 612693 Manifold Stud Bolt 8

10 915630 Drain Plug 3/8” 3

11 780565 Copper Washer 2

12 884471 Manifold Housing 1

13 ▼◆ Support Ring 20 mm 6

14 ▼◆ V-Sleeve 20 mm 6

15 ▼ Intermediate Ring 20 mm 3

16 ▼ Pressure Ring 20 mm 3

17 ▼◆ Pressure Ring O-Ring 3

18 ▼❖ Plunger Seal 3

19 860361 Plunger Guide 3

20 835281 Oil Dipstick 1

21 855893 Gasket 3/8" 3

22 630670 Crankcase 1

23 926647 Bearing Housing O-Ring 2

24 867752 Closed-end Bearing Housing 1

25 867751 Bearing Housing 1

26 928637 Plunger Rod 3

27 827396 Crankshaft (HH400) 1

827392 Crankshaft (HHC500) 1

28 877249 Crank Shaft Key 8 x 25 mm 1

29 808400 Roller Bearing 2

30 926650 Crankshaft Seal 1

31 691820 Crankcase Cover Gasket 1

32 630671 Crankcase Cover 1

33 735313 Crankcase Cover Allen Screw 5

34 858431 Sight Glass 3/8" 1

35 735312 Allen Screw 6

36 780564 Spring Washer 6

37 928641 Connecting Rod Assembly 3

38 914139 Connecting Rod Pin 3

39 926692 Connecting Rod Pin Snap Ring 6

40 ✤ Copper Spacer 3

41 ✤ Ceramic Plunger Sleeve 20 mm 3

42 ✤ Copper Spacer 3

43 ✤ Teflon Ring 3

44 ✤ Plunger Bolt O-Ring 3

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

35

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

PUMP - EXPLODED VIEW PARTS LIST

REF. NO. PART NO. DESCRIPTION QTY.

45 ✤ Plunger Assembly Bolt 3

46 944783 Shim 2

47 780561 Washer 8

48 735317 Hex Screw 8

REPLACEMENT PARTS

▼ 753014 Complete Seal Packing Kit 3

✤ 877656 Ceramic Sleeve Kit 3

★ 877648 Complete Valve Assembly Kit 6

❖ 877655 Plunger Seal Kit 1

◆ 877654 Seal Packing Kit 1

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

36

HOSE & TRIGGER GUN ASSEMBLY

HOSE & TRIGGER GUN ASSEMBLY PARTS LIST

5

42

1

3

3

6,7,8

ITEM PART NO. DESCRIPTION QTY

1 860447 Trigger Gun, Hotsy 1

2 915786 Nipple, 1/4" x 1/4" NPT ST Male 1

3 826169 Coupler, 1/4" Female, Brass 2

4 878917 Wand, Side Grip, 35.5” w/Couplers 1

5 4-02033450C Hose, 1/2" x 50', 1 Wire, 3/8" MSWBE 1

6 799001 Nozzle, 4.5 Red (1400 Series) 1

799003 Nozzle, 5.5 Red (981SS, 982SS, 991SS,991SS-208, 992SS, 992SS-208, 994SS,995SS) 1

799002 Nozzle, 5.0 Red (952SS, 952SS-208, 962SS,962SS-208, 964SS, 969SS) 1

7 799013 Nozzle, 4.5 Yellow (1400 Series) 1

799015 Nozzle, 5.5 Yellow (981SS, 982SS, 991SS,991SS-208, 992SS, 992SS-208, 994SS,995SS) 1

799014 Nozzle, 5.0 Yellow 952SS, 952SS-208, 962SS,962SS-208, 964SS, 969SS) 1

8 799025 Nozzle, 4.5 White (1400 Series) 1

799027 Nozzle, 5.5 White (981SS, 982SS, 991SS,991SS-208, 992SS, 992SS-208, 994SS,995SS) 1

799026 Nozzle, 5.0 White 952SS, 952SS-208, 962SS,962SS-208, 964SS, 969SS) 1

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

37

PR

ES

SU

RE

WA

SH

ER

OP

ER

ATO

R’S

MA

NU

AL

TRIGGER GUN ASSEMBLY

12

34

56

78

910

1110 15

1213

14

16

21

22

21

2320 19

18 17

24

TRIGGER GUN ASSEMBLY PARTS LIST

ITEM PART NO. DESCRIPTION QTY.

1 817320 Valve Cap 1

2 ✪ Valve Cap O-Ring 1

3 ✪ Valve Seat Spring 1

4 ✪ Valve Spring 1

5 ✪ Ball 1

6 ✪ Valve Seat 1

7 ✪ Valve Seat O-Ring 1

8 812801 Valve Body 1

9 ✪ Plunger Guide Seat O-Ring 1

10 ✪ Plunger Guide Backring 2

11 ✪ Plunger Guide O-Ring 1

12 ✪ Plunger Guide 1

13 ✪ Plunger Rod 1

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

OP

ER

ATO

R’S

MA

NU

AL

P

RE

SS

UR

E W

AS

HE

R

38

TRIGGER GUN ASSEMBLY PARTS LIST

ITEM PART NO. DESCRIPTION QTY.

14 ✪ Plunger Seat 1

15 914141 Trigger Pin 1

16 860495 Left Gun Shell 1

17 735316 Phillips Screw 6

18 914142 Trigger Lock Pin 1

19 960271 Trigger 1

20 881941 Trigger Lock Lever 1

21 936460 Inlet Pipe Seat 2

22 914285 Inlet Pipe 1

23 851190 Inlet Fitting 1

24 860496 Right Gun Shell 1

Replacement Parts✪ 877471 Trigger Gun Repair Kit

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

39

PR

ES

SU

RE

WA

SH

ER

Sp

ecification

sSPECIFICATIONS

Con- Trans- Pump Motor Motor Gas LP

Model Motor tactor Overload Former Pump Pulley Pulley Bushing Burner Pilot ValveConv. Fuse (2)

981SS 5-1052M 6-4015 6-5013 6-602013 5-1857 5-40508001 5-40504701 5-511113 7-70111 7-702371 7-700021 7-7023206-02299

982SS 5-1052M 6-4015 6-5013 6-602013 5-1857 5-40508001 5-40504701 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

991SS 5-10109 6-4012 6-5011 6-602013 5-1857 5-40508001 5-40504701 5-511113 7-70111 7-702371 7-700021 7-7023206-02299

991SS-208 5-10106 6-4012 6-5011 6-602013 5-1857 5-40508001 5-40504701 5-511113 7-70111 7-702371 7-700021 7-7023206-02299

992SS 5-10109 6-4012 6-5011 6-602013 5-1857 5-40508001 5-40504701 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

992SS-208 5-10106 6-4012 6-5011 6-602013 5-1857 5-40508001 5-40504701 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

994SS 5-10109 6-4003 6-5009 6-602014 5-1857 5-40508001 5-40504701 5-511113 7-70111 7-702371 7-700021 7-7023206-02295

995SS 5-10109 6-4003 6-5009 6-602014 5-1857 5-40508001 5-40504701 5-511113 7-7011 7-702371 7-700021 N/A 6-02295

1411SS 5-10142 6-4020 6-5015 6-602013 5-1857 5-40508001 5-40504701 5-511138 7-70111 7-702371 7-700021 7-7023206-02299

1412SS 5-10142 6-4020 6-5015 6-602013 5-1857 5-40508001 5-40504701 5-511138 7-7011 7-702371 7-700021 N/A 6-02299

1421SS 5-10145 6-4012 6-5012 6-602013 5-1857 5-40508001 5-40504701 5-511138 7-70111 7-702371 7-700021 7-7023206-02299

1421SS-208 5-10141 6-4015 6-5013 6-602013 5-1857 5-40508001 5-40504701 5-511138 7-70111 7-702371 7-700021 7-7023206-02299

1422SS 5-10145 6-4015 6-5013 6-602013 5-1857 5-40508001 5-40504701 5-511138 7-7011 7-702371 7-700021 N/A 6-02299

1422SS-208 5-10141 6-4015 6-5013 6-602013 5-1857 5-40508001 5-40504701 5-511138 7-7011 7-702371 7-700021 N/A 6-02299

1424SS 5-10145 6-4006 6-5010 6-602014 5-1857 5-40508001 5-40504701 5-511138 7-70111 7-702371 7-700021 7-7023206-02295

1425SS 5-10145 6-4006 6-5010 6-602014 5-1857 5-40508001 5-40504701 5-511138 7-7011 7-702371 7-700021 N/A 6-02295

952SS 5-10404 6-4020 6-5014 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

952SS-208 5-10403 6-4020 6-5014 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

962SS 5-10405 6-4012 6-5011 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

962SS-208 5-10407 6-4015 6-5012 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

964SS 5-10405 6-4006 6-5008 6-602014 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02295

969SS 5-10406 6-4003 6-5008 6-602012 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02295

1452SS 5-1085 6-40210 6-5015 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

1452SS-208 5-1079 6-40210 6-5015 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

1462SS 5-1086 6-4015 6-5012 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

1462SS-208 5-1088 6-4020 6-5014 6-602013 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02299

1464SS 5-1086 6-40090 6-5010 6-602014 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02295

1469SS 5-1087 6-4006 6-5010 6-602012 5-1807 5-40509001 5-40503601 5-511113 7-7011 7-702371 7-700021 N/A 6-02295

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

W

irin

g D

iag

ram

40

900/1400 3 PH W/ELECTRIC IGNITION

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

WA

RR

AN

TY

Wirin

g D

iagram

41

900/1400 3 PH W/ELECTRIC IGNITION & THERMAL SHUTDOWN

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

W

irin

g D

iag

ram

42

900/1400 3 PH W/ELECTRIC IGNITION & AUTO START

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

WA

RR

AN

TY

Wirin

g D

iagram

43

900/1400 3 PH W/ELEC IGN, THERM SHUTDOWN & AUTO START

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

W

irin

g D

iag

ram

44

900/1400 1 PH W/ELECTRIC IGNITION

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

WA

RR

AN

TY

Wirin

g D

iagram

45

900/1400 1 PH W/ELECTRIC IGNITION & THERMAL SHUTDOWN

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

W

irin

g D

iag

ram

46

900/1400 1 PH W/ELECTRIC IGNITION & AUTO START

97-6574 • HOTSY 900-1400 GAS FIRED • REV. 10/05

PR

ES

SU

RE

WA

SH

ER

WA

RR

AN

TY

Wirin

g D

iagram

47

900/1400 1 PH W/ELEC IGN, THERM SHUTDOWN & AUTO START

WARRANTYHOTSY LIMITED WARRANTY:

Hotsy products are warranted by the Hotsy Corporation (Hotsy) to be free of defects in material andworkmanship under normal use, for a period of ONE YEAR from the date of the original purchase.Items that fail due to normal wear such as o-rings hoses, seals, quick couplers, nozzles, gunjets, etc. ordamage resulting from neglect, abuse, tampering, or modification are not covered under this warranty.Hotsy will at its option repair or replace any part covered by this warranty which is defective undernormal use for one year at no charge for parts or labor. All defects must be verified by an authorizedHotsy service location. This warranty is not transferable.

EXCEPTIONS TO THE ONE YEAR WARRANTY FOR PARTS ONLY ARE:Hotsy Pumps: SEVEN YEAR Warranty (LIFETIME Brass Manifold Warranty-

Even Against Freezing) General Pumps: FIVE YEAR Warranty

Heating Coils: FIVE YEAR Warranty

LIMITATION OF LIABILITY:To the extent allowable under applicable law, Hotsy liability for consequential and incidental damagesis expressly disclaimed. Hotsy liability in all events is limited to, and shall not exceed, the purchaseprice paid for the equipment. Hotsy liability is limited to repair or replacement of defective parts only, atthe option of the Hotsy Corporation.

WARRANTY DISCLAIMER:Hotsy has made a diligent effort to illustrate and describe the product in this literature accurately;however, such illustrations and descriptions are for the sole purpose of identification, and do notexpress or imply a warranty that the product is merchantable or fits a particular purpose, or that theproduct will necessarily conform to the illustrations or descriptions.

PRODUCT SUITABILITY:Many states and localities have codes and regulations governing sales, construction, installation, and/or use of products for certain purposes, which may vary from those in neighboring areas. Whileattempts to assure that its products comply with such codes, it cannot guarantee compliance andcannot be responsible for how the product is installed or used. Before purchase and use of a product,please review the product application, and national and local codes and regulations, and be sure thatthe product, installation, and use will comply with them.

PROMPT DISPOSITION:Hotsy will make a good faith effort for prompt correction or other adjustments with respect to anyproduct which proves to be defective within limited warranty. For any product believed to be defectivewithin limited warranty, contact dealer from whom product was purchased. Dealer will give additionaldirections. If product was damaged in transit to you, file claim with freight carrier.

The Hotsy Corporationwww.hotsy.com1-800-525-1976

97-6574 • Rev. 10/05