4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

-

Upload

chandana-kumara -

Category

Documents

-

view

217 -

download

0

Transcript of 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

1/10

ON THE BEARING RESISTANCE OF BOLTED CONNECTIONS

Primo Moe, Darko BegUniversity of Ljubljana, Faculty of Civil and Geodetic Engineering

[email protected], [email protected]

ABSTRACTThe paper presents 48 tests on the connections with bolts in bearing. Single

bolts connections as well as the connections with up to six bolts positioned in thedirection of loading were testes in order to obtain the evidence on bolt bearingdeformation capacity and resistance. Several connection configurations includingconnection with bolts in single shear were tested. The bolt bearing resistance and theconnection resistance are compared to Eurocode 3 design rules. Moreover, thenumerical parametric study on 114 single bolt connections is presented. The results

of the study are compared to the Eurocode bearing resistance formula, as well as tothe new bearing resistance formula that is based on the results of high strength steelbolt bearing connections.

1 INTRODUCTION

In recent years the authors of this paper have studied the bolt bearingconnections made of high strength steel (Moe & Beg, 2010, 2011). The studyrevealed that the bearing resistance formula as defined in Eurocode (CEN, 2005)lacks interpretation for certain cases. It is defined by mean bearing stress in order tolimit deformations and it is referred as an ultimate check. However, Eurocode doesnot prescribe the limit deformation. Since even a significant hole elongation is not anultimate limit state in a strict sense, Eurocode formula is conservative if compared tothe maximum bearing resistance. Such conservativeness of the Eurocode bearingformula was shown by several researchers. The current definition of bolt bearingresistance is appropriate, if the bolt bearing deformation capacity is known.Unfortunately, these data are not available (see Table 6.1 in EN 1993-1-8). Eurocodealso defines the resistance of a group of fasteners (Chapter 3.7 in 1993-1-8) as thesum of the bearing resistances of the individual fasteners under certain conditions.Obviously the summation should be considered at the same bearing deformationlevel, but Eurocode gives only the maximum bearing resistance and not also thebearing deformation level. Moreover, it also does not provide the distribution of

bearing forces on bolts in connection with several bolts. It is usually assumed that thedistribution is uniform. On the contrary, the tests of high strength steel connectionshave shown that it may be very unequal. Due to the conservativeness of theEurocode bearing formula or due to unequal distribution of bearing forces, anoverload may result in the failure of bolts that are considered as non-ductile failures.

An extensive test programme of bolt bearing connections of differentconfigurations was performed in order to provide answers to the open issues. Due tothe limitations of the tests, the finite element simulations are necessary to completethe test results, to obtain additional data and to expand the connection database.

2 TEST PROGRAMME

The test programme covered tension splices with up to six bolts positioned inthe loading direction (42 tests) as well as splices with two bolts in a row, positioned

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

2/10

perpendicular to loading direction (6 tests). The connection geometries are given inTable 1. Besides the connections with bolts in double shear, also the connectionswith bolts in single shear (denoted by letter s) were tested. The selected platethicknesses for the fabrication of the connections were 8, 12 and 16 mm in gradeS235. Special attention was devoted to the actual material strengths in order to

obtain tensile splices with similar strengths of the inner and outer plates. Thestandard tensile tests showed that all used steels were very ductile with ultimate-to-yield stress ratio higher than 1.4 and with strain at fracture exceeding 35 %. Theultimate tensile strength was in the range of 400 MPa to 450 MPa for all steel plates.The packing plate was installed between the outer plates of the connections withbolts in double shear. They had the same thickness as the inner plate. The outerplates and the packing plates were welded together to form a fork into which theinner plate and bolts with washers were inserted, forming the splice connection. Thefork (two outer plates) was denoted by MF and the inner plate was denoted by M.Bolts M16, M20 and M24, all 10.9, in standard holes were used. They were not underinvestigation, thus they were designed accordingly.

Table 1. Connection geometries. The number in the name after M stands for thenumber of bolts in a connection (exp. M508 5 bolts)

Name e1/d0p1/d0e2/d0p2/d0d0

[mm]b

[mm]t

[mm]Bolt Name e1/d0 p1/d0 e2/d0 p2/d0

d0[mm]

b[mm]

t[mm]

Bolt

M101 1.23 1.23 26 64 12 M24 M404 1.23 2 2 22 88 16 M20

M102 1.5 1.23 26 64 12 M24 M405 1.23 3 3.86 22 170 16 M20

M103 2 1.23 26 64 12 M24 M405h As M405, holes shifted so that end bolt activates first

M104 1 1.5 26 78 12 M24 M405s 1.23 3 3.86 22 170 8 M20

M105 1.23 1.5 26 78 12 M24 M405t 1.23 3 3.86 22 170 16 M20

M106 1.5 1.5 26 78 12 M24 M406 1.23 3 2 22 88 16 M20

M107 2 1.5 26 78 12 M24 M407 1.5 3 3.86 22 170 16 M20

M108 2.5 1.5 26 78 12 M24 M408* 2 3 3.86 22 170 16 M20

M109 1 1.5 18 54 12 M16 M409* 2.5 3 3.86 22 170 16 M20M110 1.22 1.5 18 54 12 M16 M501 1.5 2 3.86 22 170 16 M20

M111 1.5 1.5 18 54 12 M16 M502 1.5 2 2.41 22 106 16 M20

M112 2 1.5 18 54 12 M16 M502s 1.5 2 3.86 22 170 8 M20

M113 2.5 1.5 18 54 12 M16 M504 1.23 3 3.86 22 170 16 M20

M201 1.5 2.41 2.41 22 159 12 M20 M504t 1.23 3 3.86 22 170 16 M20

M202 2.5 2.41 2.41 22 159 12 M20 M505 1.23 3 2.41 22 106 16 M20

M203 1.5 1.23 3.68 22 135 12 M20 M505t 1.23 3 2.41 22 106 16 M20

M204 2.5 1.23 3.68 22 135 12 M20 M506 3 3 3.86 22 170 16 M20

M205 1.5 1.5 3 22 132 12 M20 M506s 3 3 3.86 22 170 8 M20

M206 2.5 1.5 3 22 132 12 M20 M507 1.23 4 3.86 22 170 16 M20

M401 2 2 3.86 22 170 16 M20 M508 2 4 3.86 22 170 16 M20

M402 3 2 3.86 22 170 16 M20 M508h As M508, holes shifted so that 2nd bolt activates first

M403 4 2 3.86 22 170 16 M20 M602 1.23 3 3,86 22 170 16 M20M403h As M403, holes shifted so that end bolt activates first M602t 1.23 3 3,86 22 170 16 M20

M403s 4 2 3.86 22 170 8 M20 M602th As M602t, holes shifted so that last bolt activates first

* 3 bolts

Two options of the connections with bolts in double shear were considered. Inthe first the thickness of both outer plates was equal to the thickness of the innerplate (equal axial strength and stiffness of inner and outer plates). In the secondoption the thickness of the outer plates was twice larger than the thickness of theinner plate. The second option is denoted by letter t. All connections with one andtwo bolts had cover plates that were twice stiffer and stronger than the inner plate.The functional fabrication tolerances were simulated at specimens designated by

letter h, where bolt holes were shifted by 4 mm (twice the bolt hole clearance). Thus,only one bolt was carrying the bearing load for the first 4 mm of hole elongation and

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

3/10

after that the remaining bolts activated. The geometry of the specimens wasdesigned to cover different failure types and different distributions of bearing forcesbetween bolts. The range of pitches, end and edge distances were selectedaccording to EN 1993-1-8 from the minimum allowed distances to the most commonones. For the connections with more than 3 bolts the edge distance e2was limited to

85 mm due to the strength of the material and the capacity of the testing machine.The tests were carried out at a prescribed displacement rate of 2 mm/min on a testingmachine with the capacity of 1 MN. A relative displacement between the inner andthe cover plates was measured by two inductive displacement transducers (IDT). Infive tests, the bolts were instrumented with a strain gauge embedded in a hole alongthe bolt shank (on bolt head side) to measure the axial deformation of the bolt. Allmeasuring devices were connected to an external universal recording unit. The boltswere hand tightened to achieve firm contact between plates and to ensure that theload was transferred primarily by the bearing and not by friction.

3 TEST RESULTS

Table 2 gives information about connections experimental resistance, type offailure and resistances calculated according to EN 1993-1-8 (bearing, net cross-section and block tear resistance).

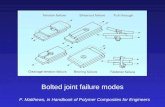

shear failure shear/splitting failure from shear to cross-section failure net cross-section failure

block shear sigle bolt tear out end splitting failure (only 3 bolts!)

necking of the net cross-section curling of the plateFigure 1. Failure modes

The most typical failure modes were observed at single bolt connections (seeFigure 1). The failure, commonly referred to as shear failure, was observed at the

connections with edge distance e2at least equal to or larger than end distance e1,while the end distance was e1 1.5d0. This failure was characterized by large hole

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

4/10

elongation, a distinctive response curve with long yield plateau and a fracture in theshear plane. The hole elongation was the result of plastic transformation of thematerial in front of the bolt due to high bearing pressures. The failure of M106resembles the splitting failure, where the plate in front of the bolts splits or bursts outdue to high tension stress in the direction perpendicular to the loading on the free

edge of the plate in front of the bolt. Another typical failure was net cross-sectionfailure. The hole elongation mainly developed due to necking of the net cross-section. The transition from the shear failure to the net cross-section failure was verysharp, similarly as at the high strength steel connections. The failures at the transitionbetween failure modes almost reach the net cross-section resistance, which is themaximum possible resistance for a defined width of the connection, and are typifiedwith the highest hole elongation due to the bearing pressures and the necking of thenet cross-section.

The specific failure of the connections with 2 bolts positioned perpendicular toloading is block shear failure (also referred to as block tear failure). The common typeof block shear was observed at M201 (Figure 1) and M202 with both bolts tearing

from the plate. M203 (Figure 1) and M204 fractured at the shorter edge of the netcross-section, showing resistance lower than net cross-section resistance anddeveloping deformations also in the shear plane. Thus, they present a special caseof the block shear failure of a single bolt, similar to the block shear of eccentricallyconnected angle (see Figure 3.8 in EN 1993-1-8).

Figure 2. The response curves for selected connections

The connections with more than 3 bolts positioned in a row in the direction of

loading performed as expected. The bearing deformation capacity ensured thedistribution of bearing forces on all bolts without significant reduction of theresistance. The connections noted with letter hwere designed to transfer the loadwith a single bolt bearing for the deformation of 4 mm (twice the hole clearance)before all the remaining bolts started to bear. If the resistance of the plate in bearingwas underestimated in a way that it was smaller than the shear resistance of the bolt,the bolt would fracture in shear at low loading, before the load was distributed amongall bolts. The response curves of the connections with several bolts (see Figure 2)differ from those of single bolt connections (see Figure 6). The first part of the curveis distinctively linear with a constant slope. It is followed by a short plateau, gainingplastic stiffness, and continues with a gradually decreasing slope to the displacement

equalling up to 1.5 times the bolt diameter (if the net cross-section failure does notprevail). The fracture opened quickly after the maximum resistance had been

0

200

400

600

800

1000

0 5 10 15 20 25 30 35 40

Force[k

N]

Displacement [mm]

M401

M403s

M403

M403h

M404

M408

M507

d0/6 = 3.67 mm

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

5/10

achieved. Figure 2 also suggests that d0/6 may correspond to an acceptable holeelongation in the serviceability limit state. The same limit was discussed for highstrength steel connections (Moe & Beg, 2010). The reduction of the ultimateresistance at this displacement is in relation to ratio fu /fy.

In case of net cross-section failure all hole elongations remain equal to the

point, where the net cross-section fully yields. From that point on, the displacement isincreasing mainly on account of necking, while the bearing pressure on boltsincreases until the ultimate strength of the net cross-section is reached. The holeelongations outside the net cross-section do not need to increase much. Therefore,the deformation at the maximum resistance is less than 1.5 dfor M404 in Figure 2.

In case of end bolt tear out (end splitting failure) all hole elongations have toremain equal until the splitting fracture. This situation results in an increase of bearingpressures on all bolts. If the end distance e1 is much smaller than the pitch p1,unequal distribution of bearing forces between bolts occurs (different bearingpressure stiffness, equal displacement). This situation could result in accidental boltfracture, since equal distribution of bearing forces is assumed in the design.

Fortunately, mild steel grades have high fu /fyratio that acts as a fuse. With a properdesign of the connection it triggers yielding of the net cross-section and thus allowshigh accumulation of plastic deformations in the net cross-section, preventing thesplitting failure. The statement is correct only if the strain hardening of the plate inbearing is higher than in tension (in the net cross-section). This was confirmed in thetests (see MF507 in Figure 1). The connection M507 had small end distancee1 = 1.23d0, but large pitchp1 = 4d0. It can be clearly seen in Figure 1 that yielding ofthe net cross-section prevented the tearing out of the end bolt.

110 kN

360 kN

414 kN

Figure 3. M405s at differentlevel of resistance

Figure 4. M403s at 424 kN

Four tests were performed on connections with four or five bolts in singleshear. Soon after the force was applied to the connection, the plates bended and thebolts rotated to allow load transfer from one plate to another along the shortest path.Therefore, the bolts were subjected also to tension not only to bearing. There was noeccentricity due to clamping of the connection. Figure 3 illustrates the connectionM405s at different levels of resistance. The test of M403s was stopped due toexcessive curling of the plates. Figure 4 presents the connection M403s just beforeunloading at 424 kN (curling failure), not reaching the maximum resistance or fracture(Figure 2). Nevertheless, the connections reached their full capacity as their twinconnection with bolts in double shear.

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

6/10

Table 2. Test results and various resistances according to Eurocode

Name

Experiment EN 1993-1-8

Failure typeFmax[kN]

Averageforce

per bolt[kN]

edge bolt inner boltFb

[kN]

Fnet[kN]

Veff[kN]

Criticalcheckk1

b

Fb[kN]

k1

b

Fb[kN]

singleboltconnections

M101 shear 151 151 0.72 88 88 174 bearing

M102 net 192 192 0.87 107 107 174 bearingM103 net 202 202 1.16 143 143 174 bearing

M104 shear 125 125 0.83 102 102 239 bearing

M105 shear 164 164 1.03 126 126 239 bearing

M106 shear 197 197 1.25 153 153 239 bearing

M107 net/bearing 283 283 1.67 204 204 239 bearing

M108 net 279 279 2.08 255 255 239 net

M109 shear 84 84 0.83 68 68 165 bearing

M110 shear 104 104 1.02 83 83 165 bearing

M111 shear 129 129 1.25 102 102 165 bearing

M112 net/bearing 182 182 1.67 136 136 165 bearing

M113 net 188 188 2.08 170 170 165 net

2bol

ts

perpend

icul

artoloa

ding

M201 block shear 359 180 1.25 128 255 528 254 block shear

M202 block shear 493 246 2.08 213 425 528 349 block shear

M203 block shear (single) 348 174 0.87 89 177 418 259 bearingM204 partial net 455 228 1.45 148 295 418 354 bearing

M205 shear 353 176 1.25 128 255 404 320 bearing

M206 net 469 235 2.08 213 425 404 415 net

4bolts(exceptM408,M4093

bolts)

M401 end split 861 215 1.67 224 1.04 140 727 894 bearing

M402 net 902 225 2.50 336 1.04 140 951 894 net

M403 net 941 235 2.50 319 1.04 133 904 850 net

M403h net 1000 250 2.50 358 1.04 149 1015 955 net

M403s curling 429 107 2.50 168 1.04 70 475 447 net

M404 net 431 108 1.02 137 1.04 140 554 399 net

M405 end split 965 241 1.02 147 1.88 269 831 955 bearing

M405h end split 898 224 1.02 147 1.88 269 831 955 bearing

M405s end split/curling 449 112 1.02 69 1.88 126 389 447 bearing

M405t net 989 247 1.02 147 1.88 269 953 955 bearing

M406 net 428 107 1.02 137 1.88 252 778 399 net

M407 end split /net 1000 250 1.25 179 1.88 269 896 955 bearingM408 end split 877 292 1.67 239 1.88 269 747 955 bearing

M409 net 925 308 2.08 266 1.88 239 771 850 bearing

5bolts

M501 end split/net 933 187 1.25 160 1.04 133 718 850 bearing

M502 net 598 120 1.25 176 1.04 147 792 532 net

M502s net 449 90 1.25 90 1.04 75 403 477 bearing

M504 net 943 189 1.02 131 1.88 239 979 850 net

M504t net 1000 200 1.02 147 1.88 269 1222 955 net

M505 net 537 107 1.02 137 1.88 252 1030 507 net

M505t net 621 124 1.02 147 1.88 269 1222 542 net

M506 net 926 185 2.50 336 1.88 252 1426 894 net

M506s net 469 94 2.50 168 1.88 126 713 447 net

M507 end split /net 930 186 1.02 137 2.50 336 1281 894 net

M508 net 934 187 1.67 224 2.50 336 1454 894 net

M508h net 930 186 1.67 224 2.50 336 1454 894 net

6bolts

M602 net 915 153 1.02 137 1.88 252 1281 894 net

M602t net 1041 174 1.02 147 1.88 269 1491 955 net

M602th net 1000 167 1.02 147 1.88 269 1491 955 net

* the capacity of the testing machine was reached

On the horizontal axis of Figure 5a the bearing forces per bolt according toEurocode are plotted. The vertical axis illustrates the average bearing force as aresult of the test (see Table 2). The connections where the net cross-section is thecritical check are not included. The results are very scattered with low correlationcoefficient equalling 0.53. Most of the results are on the safe side (above the dottedline), except the bearing forces on the inner bolt (all for the end splitting failure).Figure 5b compares the Eurocode critical check (net cross-section, block tear andsum of bearing resistances) to the experimental resistance. Eurocode values ofresistances are always higher than the experimental ones. The sum of bearingresistances per bolt was calculated differently, for two connection configuration. For

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

7/10

the basic configuration two edge bolts were assumed and for the configuration withstiff outer plates (denoted by letter t) one bolt was considered as the edge bolt andthe remaining as inner bolts.

a) b)Figure 5. Test results versus resistances according to EN 1993-1-8

4 NUMERICAL ANALYIS

4.1 Comparison to experiments resultsSingle bolt connections were modelled in the finite element environment

ABAQUS v6.10 . They were modelled by deformable steel plate and rigid tube thatpresented the bolt. A hard surface-to-surface contact formulation in the normal

direction was defined between the bolt shank and the bolt hole on the plate. Theplate was meshed by linear brick finite elements with eight nodes and withincompatible modes (C3D8I). These elements were selected due to their enhancedbending behaviour. Moreover, they also preserve constant volume at largedeformations. Additionally, 6-node linear triangular prisms C3D6 were used only tocomplete the mesh. The structural steel was modelled as an elasticplastic material,where plasticity was considered as a polygonal approximation of the stressstraincurve, obtained from the standard tensile tests.

Figure 6. Comparison of numerical responsecurves and experimental ones

Figure 7. Comparison of numericaland experimental results

For the application in the FE model the engineering material curves were thentranslated to the form of logarithmic strain and true (Cauchy) stress. Youngs

y = 1.1836xR = 0.5292

0

70

140

210

280

350

0 70 140 210 280 350Averageforceperbolt[kN]-test

Bearing force per bolt [kN] (EN 1993-1-8)

more than 2 bolts - edge bolt

1 bolt

2 bolts

more than 2 bolts - inner bolt

y = 1.0969xR = 0.9694

0

250

500

750

1000

0 250 500 750 1000

Experimentalresistance[kN]

min (Fb; Fnet; Veff) [kN] (EN 1993-1-8 )

0

50

100

150

200

250

300

0 5 10 15 20 25

Force

[kN]

Displacement [mm]

M104 test M104 Abaqus

M106 test M106 Abaqus

M107 test M107 Abaqus

y = 1,0411x

R = 0,987

0

100

200

300

0 100 200 300Experimentalresults[k

N]

Abaqus results [kN]

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

8/10

modulus was taken as E= 210000 MPa and Poissons ratio as = 0.3.The tests of single bolt connections were numerically simulated in order to

obtain reliable numerical results. As a consequence, the models could be used forthe parametric study. In Figure 6 the experimental and numeric response curves forsingle bolt connections with different failure mechanisms are presented. M104, M106

and M107 have constant edge distance e2, while end distance e1is increasing. It maybe observed that the numerical results are in great agreement with the experimentalones. A difference is noticeable at M107 that failed in net cross-section. Similarobservations are observed at the response curves for the remaining connections.Figure 7 compares maximum resistances between the numerical simulations and thetests. The correlation coefficient is 0.987 the regression coefficient 1.04. If theconnections with net cross-section failures are excluded, the correlation coefficient is0.997 and the regression coefficient drops to 1.001. It may be concluded that theresults obtained by the presented numerical model are reliable.

4.2 Numerical parametric study

The numerical parametric study was performed in order to obtain the boltbearing forces for single bolt connections. The study included 114 connections. Thegeometries of the connections in the study as well as the normalized maximumresistanceFmaxand the displacement at Fmaxare presented in Table 3.

Table 3. The results of the numerical parametric study

S235fy= 313 Mpafu= 425 Mpa

Normalized max. bearing force Fmax/(d t fu) Displacement at max. bearing force [mm]

M16d= 16 mm. d0= 18 mm

M24d= 24 mm. d0= 26 mm

M16d= 16 mm. d0= 18 mm

M24d= 24 mm. d0= 26 mm

e1/d0 e2/d0plate thickness t[mm] plate thickness t[mm]

8 12 16 8 12 20 8 12 16 8 12 20

1.2

1.2 1.26 1.26 1.26 1.22 1.23 1.54 7.3 7.3 7.3 10.7 11.1 11.01.5 1.29 1.29 1.30 1.26 1.26 1.58 7.6 7.4 7.5 11.1 10.8 10.8

2 1.36 1.37 1.37 1.32 1.33 1.66 7.8 7.7 7.7 10.6 10.3 10.8

3 1.39 1.39 1.40 1.35 1.35 1.70 6.9 7.0 8.0 10.3 10.2 10.1

5 1.39 1.40 1.40 1.35 1.35 1.70 7.3 7.6 7.5 9.9 10.2 9.9

1.5

1.25 1.67 1.66 1.66 1.62 1.63 2.03 10.5 11.4 11.2 14.8 16.2 15.4

1.5 1.65 1.65 1.65 1.60 1.61 2.01 9.1 9.1 9.2 14.3 13.3 14.3

2 1.71 1.71 1.72 1.67 1.67 2.09 9.2 9.5 9.5 13.6 13.8 14.7

3 1.79 1.79 1.80 1.74 1.74 2.18 9.6 9.6 9.8 13.2 13.9 13.2

5 1.80 1.80 1.80 1.75 1.74 2.19 9.8 9.8 9.9 13.0 13.9 13.2

2

1.5 2.21 2.21 2.20 2.16 2.15 2.69 14.1 13.9 13.6 21.2 21.4 22.1

2 2.21 2.21 2.20 2.16 2.16 2.69 11.9 11.9 12.0 18.4 18.9 18.2

3 2.33 2.33 2.32 2.28 2.26 2.84 14.7 14.4 14.3 20.4 17.6 20.1

5 2.38 2.38 2.37 2.32 2.32 2.89 13.2 13.2 13.1 19.5 19.0 18.5

3

1.5 2.29 2.32 2.35 2.19 2.21 2.81 10.2 10.9 11.6 13.2 13.8 15.5

2 3.02 3.03 3.02 2.95 2.76 3.71 20.2 22.1 23.5 26.4 17.1 30.0

3 3.09 3.09 3.09 3.00 2.80 3.76 18.7 20.9 22.4 24.5 16.2 26.8

5 3.21 3.20 3.22 3.14 2.83 3.95 18.5 19.3 22.2 25.7 15.7 29.5

7 3.23 3.22 3.24 3.16 2.84 3.96 18.4 19.8 22.4 25.5 15.6 29.2

The varying parameters were bolt diameter, plate thickness, end distance e1 andedge distance e2. For the selected normalized end distances e1 /d0 = 1.2, 1.5, 2, 3the normalized edge distance e2 /d0 was varied. The minimum selected edgedistance was the distance where the bolt bearing force was approximately equal tothe net cross-section resistance. For the edge distances e2lower than the minimum

selected, the net cross-section resistance check is critical (see Figure 8b the netcross-section is fully yielded). The edge distance was increased until the bolt bearing

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

9/10

force converged to the upper limit (see Figure 8a, c). The maximum resistance inTable 3 is normalized by tensile strength, plate thickness and bolt diameter. Thedisplacement at Fmaxpresents the bolt hole elongation.

The results seem to be highly reliable for e1 /d02. This may be concludedfrom the comparison of the numerical simulations to the experiments presented in the

previous chapter. For the end distance e1 /d0= 3 and the edge distances e2 /d03the analysis stopped at the plateau, reaching its maximum force. The problempresented the 12 mm thick plates with bolt M24 for e1 /d0= 3 and e2 /d03. Forthese connections the analysis stopped before reaching the maximum force due toconvergence difficulties. The whole study was repeated with the material model thatincluded damage initiation and damage evolution, but the results did not changemuch. It is expected that the bearing pressure has an upper limit due to tearing of thematerial in front of the bolt. Therefore, for the connections with large end and edgedimensions (e1 >>d0and e2 >>d0) the bearing pressure is limited by fracture of thematerial or bolt shear failure. According to this study it appears that the bearingstress limit is about 3fu.

a) response curves for M16, t = 16 mm b) connection M16, t = 8 mm, e1/d0= 2,e2/d01.5 at max. resistance

c) connection M16, t = 8 mm, e1/d0= 2, e2/d05 at max. resistanceFigure 8. The response curves of the connections with bolt M16 and 16 mm thick

plate a) and Mises stress field for two selected connections

5 NEW DESIGN RULE

The ultimate bearing stress is presented as k1 k2 fu, where coefficients kiare

linear functions of end to edge distance ratio e1/e2 and normalized edge distancee2/d0. Written in mathematical language, it follows:

0

60

120

180

240

300

360

0 10 20 30

Force

[kN]

Displacement [mm]

e1/d0 = 3

e1/d0 = 2

e1/d0 = 1.2

-

8/12/2019 4_P. Moze, D. Beg_On the Bearing Resistance of Bolted Connections

10/10

1 2 max 1 2max ; max ; 2.9b,new u uF k k k d t f k k d t f (1)

1 11 11 12

2 2

min ; min 1.3 ; 1.9e e

k k ke e

, (2)

2 2

2 21 22

0 0

1

0.9 4

e e

k k kd d (3)

The formulation on the new formula is based on the results of the tests ofsingle bolt connections made of steel S690 (Moe & Beg, 2010). The mainassumption is that the resistance of the shear planes (Ashearfu/3) in front of the boltand the net cross-section resistance (Anetfu) are equal. Thus, net cross-sectionfailure becomes a function of the ratio e1/e2and the edge distance e2and it occurswhen the ratio e1/e2= 1.43 for e2/d0= 1.2 and converges to the ratio e1/e2equalling1.7 for large edge distances. This is considered in coefficient k1. The upper limit ofk1= 1.9 defines net cross-section failures (e1/e2= k12/k11= 1.9/1.3 = 1.46). Theaddition to the formula presented in Moe and Beg (2010) is the upper limit kmax = 2.9

of the product k1 k2. Some further test are planned to confirm this upper limit. Figure 9illustrates the results of the new formula without an upper limit and limited tokmax = 2.9. Figure 9b compares the bearing resistance calculated according to thepresented rule (filled triangles) and to Eurocode (circles) to the numerical results. Itcan be seen that the presented rule has higher correlation coefficient equalling 0.99and quite lower regression coefficient.

a) without upper limit of the new formula b) the new formula is limited to kmax = 2.9

Figure 9. The Eurocode bearing formula and the new formula compared to the

numerical results

ACKNOWLEDGMENTS

Financial support from Slovenian Research Agency under post-doctoralresearch project Z2-4172 is gratefully acknowledged.

REFERENCES

CEN. (2005). Eurocode 3: Design of steel structures - Part 1-8: Design of joints. In EN 1993-1-8. Brussels: European Committee for Standardisation.

Moe, P., & Beg, D. (2010). High strength steel tension splices with one or two bolts. Journal

of Constructional Steel Research, 66(8-9), 1000-1010.Moe, P., & Beg, D. (2011). Investigation of high strength steel connections with severalbolts in double shear. Journal of Constructional Steel Research, 67(3), 333-347.

Eurocode bearing formulay = 1,2466xR = 0,9227

New formulay = 1,0197xR = 0,9713

0

140

280

420

560

700

0 140 280 420 560 700

Numericalres

ult[kN]

Theoretical value [kN]

Eurocode bearing formula

New formula

Eurocode bearing formulay = 1,2466xR = 0,9227

New formulay = 1,0729xR = 0,9912

0

140

280

420

560

700

0 140 280 420 560 700

Numericalres

ult[kN]

Theoretical value [kN]

Eurocode bearing formula

New formula

![Bolted Connections[1]](https://static.fdocuments.in/doc/165x107/54e7f8c84a7959704f8b46b8/bolted-connections1.jpg)