369man-bx

-

Upload

cleto-delacruz-lopez -

Category

Documents

-

view

220 -

download

0

Transcript of 369man-bx

-

7/30/2019 369man-bx

1/298

GE Digital Energy

215 Anderson Avenue, Markham, Ontario, Canada L6E 1B3

Tel: (905) 294-6222, 1-800-547-8629 (North America)Fax: (905) 201-2098

Internet: http://www.gedigitalenergy.com

369 Motor Management Relay

Instruction Manual

369 Revision: 3.6x

Manual P/N: 1601-0077-BX

GE Publication Number: GEK-106288U

Copyright 2012 GE Digital Energy

GE Energy

*1601-0077-BX*

GE Digital Energy's QualityManagement System is

registered to ISO9001:2000

QMI # 005094UL # A3775

http://www.gemultilin.com/http://www.gemultilin.com/ -

7/30/2019 369man-bx

2/298

2012 GE Digital Energy Incorporated. All rights reserved.

GE Digital Energy 369 Motor Management Relay instruction manual for revision3.6x.

369 Motor Management Relay, is a registered trademark of GE Digital EnergyInc.

The contents of this manual are the property of GE Digital Energy Inc. Thisdocumentation is furnished on license and may not be reproduced in whole orin part without the permission of GE Digital Energy. The content of this manual isfor informational use only and is subject to change without notice.

Part numbers contained in this manual are subject to change without notice,and should therefore be verified by GE Digital Energy before ordering.

Part number: 1601-0077-BX (May 2012)

-

7/30/2019 369man-bx

3/298

1 TABLE OF CONTENTS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 13

GENERAL SAFETY PRECAUTIONS

The use of appropriate Safety shoes (Omega) safety gloves, safety

glasses and protective clothing are recommended during equipment

installation, maintenance and service of the equipment.

Failure to observe and follow the instructions provided in the equipment

manual(s) could cause irreversible damage to the equipment and couldlead to property damage, personal injury and/or death.

Before attempting to use the equipment, it is important that all danger

and caution indicators are reviewed.

If the equipment is used in a manner not specified by the manufacturer

or functions abnormally, proceed with caution. Otherwise, the

protection provided by the equipment may be impaired and can result

in impaired operation and injury.

Caution: Hazardous voltages can cause shock, burns or death.

Installation/service personnel must be familiar with general device test

practices, electrical awareness and safety precautions must be

followed. Before performing visual inspections, tests, or periodic maintenance on

this device or associated circuits, isolate or disconnect all hazardous live

circuits and sources of electric power.

Failure to shut equipment off prior to removing the power connections

could expose you to dangerous voltages causing injury or death.

All recommended equipment that should be grounded and must have a

reliable and uncompromised grounding path for safety purposes,

protection against electromagnetic interference and proper device

operation.

Equipment grounds should be bonded together and connected to the

facilitys main ground system for primary power. Keep all ground leads as short as possible.

At all times, equipment ground terminal must be grounded during

device operation and service.

In addition to the safety precautions mentioned all electrical

connections made must respect the applicable local jurisdiction

electrical code.

LED transmitters are classified as IEC 60825-1 Accessible Emission Limit

(AEL) Class 1M. Class 1M devices are considered safe to the unaided eye.

Do not view directly with optical instruments.

This product is rated to Class A emissions levels and is to be used in

Utility, Substation Industrial environments. Not to be used near

electronic devices rated for Class B levels.

This product requires an external disconnect to isolate the mains

voltage supply.

Ensure that the protective earth (PE) terminal is suited with a

recommended wire size of 10 awg minimum wire size.

CTs must be shorted prior to working on CT circuits on the 369.

-

7/30/2019 369man-bx

4/298

14 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

TABLE OF CONTENTS

-

7/30/2019 369man-bx

5/298

CHAPTER 1:

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 11

Table of Contents

1: INTRODUCTION ORDERING ........................................................................................................................................... 1-1

GENERAL OVERVIEW ........................................................................................................... 1-1ORDERING ............................................................................................................................1-2ACCESSORIES ....................................................................................................................... 1-3FIRMWARE HISTORY ............................................................................................................1-3PC PROGRAM (SOFTWARE) HISTORY ...............................................................................1-4369 RELAY FUNCTIONAL SUMMARY ................................................................................1-5RELAY LABEL DEFINITION ................................................................................................... 1-8

2: PRODUCT DESCRIPTION OVERVIEW ...........................................................................................................................................2-1GUIDEFORM SPECIFICATIONS ............................................................................................ 2-1METERED QUANTITIES ........................................................................................................ 2-2PROTECTION FEATURES ...................................................................................................... 2-2

ADDITIONAL FEATURES ....................................................................................................... 2-4SPECIFICATIONS ...............................................................................................................................2-5

INPUTS .................................................................................................................................. 2-5OUTPUTS ............................................................................................................................... 2-7METERING ............................................................................................................................. 2-8COMMUNICATIONS ..............................................................................................................2-9PROTECTION ELEMENTS ...................................................................................................... 2-10MONITORING ELEMENTS .................................................................................................... 2-13CONTROL ELEMENTS ........................................................................................................... 2-14ENVIRONMENTAL SPECIFICATIONS .................................................................................... 2-14LONG-TERMSTORAGE ......................................................................................................... 2-15APPROVALS/CERTIFICATION ...............................................................................................2-15

TYPE

TESTS

..........................................................................................................................2-16PRODUCTION TESTS ............................................................................................................2-16

3: INSTALLATION MECHANICAL INSTALLATION ..................................................................................................... 3-1MECHANICAL INSTALLATION ..............................................................................................3-1

TERMINAL IDENTIFICATION ......................................................................................................... 3-3369 RELAY TERMINAL LIST ................................................................................................3-3269 TO 369 RELAY CONVERSION TERMINAL LIST ........................................................ 3-5MTM TO 369 RELAY CONVERSION TERMINAL LIST ......................................................3-8MPM TO 369 RELAY CONVERSION TERMINAL LIST ......................................................3-9TERMINAL LAYOUT ..............................................................................................................3-10

ELECTRICAL INSTALLATION ......................................................................................................... 3-11

TYPICAL WIRING DIAGRAM ................................................................................................3-11TYPICAL WIRING .................................................................................................................. 3-11CONTROL POWER ................................................................................................................3-12PHASE CURRENT (CT) INPUTS ........................................................................................... 3-12GROUND CURRENT INPUTS ...............................................................................................3-13ZERO SEQUENCE GROUND CT PLACEMENT ....................................................................3-14PHASE VOLTAGE (VT/PT) INPUTS ..................................................................................... 3-14BACKSPIN VOLTAGE INPUTS ..............................................................................................3-15RTD INPUTS ......................................................................................................................... 3-16

-

7/30/2019 369man-bx

6/298

12 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

CHAPTER 1:

DIGITAL INPUTS ................................................................................................................... 3-16ANALOG OUTPUTS ..............................................................................................................3-17REMOTE DISPLAY ................................................................................................................. 3-17OUTPUT RELAYS .................................................................................................................. 3-18RS485 COMMUNICATIONS ................................................................................................3-19TYPICAL TWO-SPEED (LOW SPEED/HIGH SPEED) MOTOR WIRING ............................3-21TYPICAL MOTOR FORWARD/REVERSE WIRING ...............................................................3-23

REMOTE RTD MODULE (RRTD) ....................................................................................................3-25MECHANICAL INSTALLATION ..............................................................................................3-25ELECTRICAL INSTALLATION .................................................................................................3-27

CT INSTALLATION .............................................................................................................................3-28PHASE CT INSTALLATION ................................................................................................... 3-285 AMP GROUND CT INSTALLATION ..................................................................................3-29HGF (50:0.025) GROUND CT INSTALLATION ...............................................................3-30

4: USER INTERFACES FACEPLATE INTERFACE .................................................................................................................4-1DISPLAY ................................................................................................................................. 4-1LED INDICATORS ................................................................................................................. 4-1

RS232 PROGRAM PORT .................................................................................................... 4-2KEYPAD ................................................................................................................................. 4-2SETPOINT ENTRY .................................................................................................................. 4-3

ENERVISTA 369 SETUP INTERFACE .......................................................................................... 4-4HARDWAREAND SOFTWARE REQUIREMENTS .................................................................4-4INSTALLING ENERVISTA 369 SETUP .................................................................................4-4

CONNECTING ENERVISTA 369 SETUP TO THE RELAY ......................................................4-7CONFIGURING SERIAL COMMUNICATIONS ....................................................................... 4-7USINGTHE QUICK CONNECT FEATURE ............................................................................4-9CONFIGURING ETHERNET COMMUNICATIONS .................................................................4-9CONNECTINGTOTHE RELAY ..............................................................................................4-11

WORKING WITH SETPOINTS AND SETPOINT FILES ...........................................................4-13ENGAGINGA DEVICE ...........................................................................................................4-13

ENTERING SETPOINTS .........................................................................................................4-13FILE SUPPORT ......................................................................................................................4-15USING SETPOINTS FILES ..................................................................................................... 4-15

UPGRADING RELAY FIRMWARE .................................................................................................4-28DESCRIPTION ........................................................................................................................4-28SAVING SETPOINTSTOA FILE ............................................................................................4-28LOADING NEW FIRMWARE .................................................................................................4-28

ADVANCED ENERVISTA 369 SETUP FEATURES ...................................................................4-31TRIGGERED EVENTS .............................................................................................................4-31TRENDING .............................................................................................................................4-31WAVEFORM CAPTURE (TRACE MEMORY) ......................................................................... 4-33MOTOR START DATA LOGGER ...........................................................................................4-35DATA LOGGER ......................................................................................................................4-35

MOTOR HEALTH REPORT ................................................................................................... 4-41PHASORS ..............................................................................................................................4-41EVENT RECORDER ................................................................................................................4-43MODBUS USER MAP ...........................................................................................................4-44VIEWING ACTUAL VALUES ..................................................................................................4-44

USING ENERVISTA VIEWPOINT WITH THE 369 RELAY .....................................................4-46PLUGAND PLAY EXAMPLE .................................................................................................4-46

-

7/30/2019 369man-bx

7/298

CHAPTER 1:

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 13

5: SETPOINTS OVERVIEW ...........................................................................................................................................5-1SETPOINTS MAIN MENU ..................................................................................................... 5-1

S1 369 SETUP .................................................................................................................................... 5-5SETPOINT ACCESS ...............................................................................................................5-5DISPLAY PREFERENCES ....................................................................................................... 5-5369 COMMUNICATIONS ..................................................................................................... 5-6REAL TIME CLOCK ...............................................................................................................5-9WAVEFORM CAPTURE ......................................................................................................... 5-10DATA LOGGER ...................................................................................................................... 5-11EVENT RECORDS .................................................................................................................. 5-12MESSAGE SCRATCHPAD ...................................................................................................... 5-12DEFAULT MESSAGES ........................................................................................................... 5-13CLEAR/PRESET DATA .......................................................................................................... 5-14MODIFY OPTIONS ................................................................................................................5-15FACTORY SERVICE ...............................................................................................................5-15

S2 SYSTEM SETUP ............................................................................................................................ 5-16DESCRIPTION ........................................................................................................................ 5-16CT/VT SETUP ...................................................................................................................... 5-16

MONITORING SETUP ........................................................................................................... 5-19BLOCK FUNCTIONS .............................................................................................................5-23OUTPUT RELAY SETUP ........................................................................................................ 5-24CONTROL FUNCTIONS ........................................................................................................ 5-25

S3 OVERLOAD PROTECTION ....................................................................................................... 5-35DESCRIPTION ........................................................................................................................ 5-35THERMAL MODEL ................................................................................................................5-36OVERLOAD CURVES ............................................................................................................ 5-38OVERLOAD ALARM ..............................................................................................................5-48

S4 CURRENT ELEMENTS ............................................................................................................... 5-49DESCRIPTION ........................................................................................................................ 5-49SHORT CIRCUIT .................................................................................................................... 5-49MECHANICAL JAM ...............................................................................................................5-50

UNDERCURRENT .................................................................................................................. 5-51CURRENT UNBALANCE ....................................................................................................... 5-52GROUND FAULT ................................................................................................................... 5-53GROUND TRIP TIME EXTENSION ....................................................................................... 5-54

S5 MOTOR START/INHIBITS ......................................................................................................... 5-56DESCRIPTION ........................................................................................................................ 5-56ACCELERATION TRIP ............................................................................................................5-56START INHIBITS .................................................................................................................... 5-57BACKSPIN DETECTION ........................................................................................................ 5-58

S6 RTD TEMPERATURE ...................................................................................................................5-60DESCRIPTION ........................................................................................................................ 5-60LOCAL RTD PROTECTION ................................................................................................... 5-60REMOTE RTD PROTECTION ................................................................................................5-61

OPEN RTD ALARM ..............................................................................................................5-64SHORT/LOW TEMP RTD ALARM ....................................................................................... 5-64LOSSOF RRTD COMMS ALARM ....................................................................................... 5-65

S7 VOLTAGE ELEMENTS ................................................................................................................ 5-66DESCRIPTION ........................................................................................................................ 5-66UNDERVOLTAGE ................................................................................................................... 5-66OVERVOLTAGE ...................................................................................................................... 5-67PHASE REVERSAL ................................................................................................................. 5-68UNDERFREQUENCY ..............................................................................................................5-70

-

7/30/2019 369man-bx

8/298

14 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

CHAPTER 1:

OVERFREQUENCY ................................................................................................................. 5-71S8 POWER ELEMENTS ....................................................................................................................5-72

DESCRIPTION ........................................................................................................................5-72LEAD POWER FACTOR ........................................................................................................5-73LAG POWER FACTOR ..........................................................................................................5-74POSITIVE REACTIVE POWER ...............................................................................................5-74NEGATIVE REACTIVE POWER .............................................................................................5-75UNDERPOWER ......................................................................................................................5-77REVERSE POWER ................................................................................................................. 5-78

S9 DIGITAL INPUTS ..........................................................................................................................5-79DIGITAL INPUT FUNCTIONS ................................................................................................5-79SPARE SWITCH ..................................................................................................................... 5-81EMERGENCY RESTART .........................................................................................................5-82DIFFERENTIAL SWITCH ........................................................................................................5-82SPEED SWITCH ..................................................................................................................... 5-83REMOTE RESET ..................................................................................................................... 5-84

S10 ANALOG OUTPUTS .................................................................................................................5-85ANALOG OUTPUTS ..............................................................................................................5-85ANALOG OUTPUT SCALING CHANGE ...............................................................................5-86

S11 369 TESTING .............................................................................................................................5-88TEST OUTPUT RELAYS .........................................................................................................5-88TEST ANALOG OUTPUTS ..................................................................................................... 5-89

S12 TWO-SPEED MOTOR ..............................................................................................................5-90DESCRIPTION ........................................................................................................................5-90SPEED 2 OVERLOAD CURVES ............................................................................................5-90SPEED 2 UNDERCURRENT ..................................................................................................5-92SPEED 2 ACCELERATION .................................................................................................... 5-93

6: ACTUAL VALUES OVERVIEW ...........................................................................................................................................6-1ACTUAL VALUES MAIN MENU ...........................................................................................6-1

A1 STATUS ...........................................................................................................................................6-4

MOTOR STATUS ................................................................................................................... 6-4LAST TRIP DATA ................................................................................................................... 6-4DATA LOGGER ......................................................................................................................6-5DIAGNOSTIC MESSAGES ..................................................................................................... 6-5START BLOCK STATUS ........................................................................................................6-6DIGITAL INPUT STATUS ....................................................................................................... 6-6OUTPUT RELAY STATUS ...................................................................................................... 6-8REAL TIME CLOCK ...............................................................................................................6-8FIELDBUS SPECIFICATION STATUS .................................................................................... 6-8

A2 METERING DATA ........................................................................................................................ 6-9CURRENT METERING ...........................................................................................................6-9VOLTAGE METERING ...........................................................................................................6-9POWER METERING ..............................................................................................................6-10

BACKSPIN METERING ..........................................................................................................6-10LOCAL RTD .......................................................................................................................... 6-11REMOTE RTD .......................................................................................................................6-11OVERALL STATOR RTD ....................................................................................................... 6-12DEMAND METERING ............................................................................................................6-12PHASORS ..............................................................................................................................6-13

A3 LEARNED DATA ..........................................................................................................................6-15DESCRIPTION ........................................................................................................................6-15MOTOR DATA .......................................................................................................................6-15

-

7/30/2019 369man-bx

9/298

CHAPTER 1:

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 15

LOCAL RTD MAXIMUMS ..................................................................................................... 6-16REMOTE RTD MAXIMUMS .................................................................................................. 6-17

A4 STATISTICAL DATA ....................................................................................................................6-18TRIP COUNTERS ................................................................................................................... 6-18MOTOR STATISTICS .............................................................................................................6-19

A5 EVENT RECORD .......................................................................................................................... 6-21EVENT RECORDS .................................................................................................................. 6-21MODEL INFORMATION ........................................................................................................ 6-23FIRMWARE VERSION ........................................................................................................... 6-23

7: APPLICATIONS 269-369 COMPARISON .................................................................................................................7-1369 AND 269PLUS COMPARISON ................................................................................... 7-1

369 FAQS .............................................................................................................................................7-3FREQUENTLY ASKED QUESTIONS (FAQS) ........................................................................ 7-3

369 DOS AND DONTS ..................................................................................................................7-7DOSAND DONTS ...............................................................................................................7-7

CT SPECIFICATION AND SELECTION ........................................................................................ 7-10CT SPECIFICATION ...............................................................................................................7-10

CT SELECTION ..................................................................................................................... 7-11PROGRAMMING EXAMPLE ........................................................................................................... 7-13PROGRAMMING EXAMPLE ................................................................................................... 7-13

APPLICATIONS ................................................................................................................................... 7-19MOTOR STATUS DETECTION ..............................................................................................7-19SELECTIONOF COOL TIME CONSTANTS ........................................................................... 7-20THERMAL MODEL ................................................................................................................7-22RTD BIAS FEATURE ............................................................................................................7-23THERMAL CAPACITY USED CALCULATION ........................................................................ 7-24START INHIBIT ...................................................................................................................... 7-26TWO-PHASE CT CONFIGURATION .................................................................................... 7-28GROUND FAULT DETECTIONON UNGROUNDED SYSTEMS ........................................... 7-30RTD CIRCUITRY ................................................................................................................... 7-31

REDUCED RTD LEAD NUMBER APPLICATION .................................................................7-31TWO WIRE RTD LEAD COMPENSATION .......................................................................... 7-33AUTO TRANSFORMER STARTER WIRING .......................................................................... 7-33

8: TESTING TEST SETUP ......................................................................................................................................... 8-1INTRODUCTION ..................................................................................................................... 8-1SECONDARY INJECTION TEST SETUP ................................................................................8-2

HARDWARE FUNCTIONAL TESTING ......................................................................................... 8-3PHASE CURRENT ACCURACY TEST .................................................................................... 8-3VOLTAGE INPUT ACCURACY TEST ..................................................................................... 8-3GROUND (1 A / 5 A) ACCURACY TEST ............................................................................ 8-450:0.025 GROUND ACCURACY TEST ..............................................................................8-4

RTD ACCURACY TEST ......................................................................................................... 8-5DIGITAL INPUTS ................................................................................................................... 8-6ANALOG OUTPUTS ..............................................................................................................8-8OUTPUT RELAYS .................................................................................................................. 8-9

ADDITIONAL FUNCTIONAL TESTING ....................................................................................... 8-10OVERLOAD CURVE TEST ..................................................................................................... 8-10POWER MEASUREMENT TEST ............................................................................................ 8-11VOLTAGE PHASE REVERSAL TEST ...................................................................................... 8-11SHORT CIRCUIT TEST .......................................................................................................... 8-13

-

7/30/2019 369man-bx

10/298

16 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

CHAPTER 1:

APPENDIX: REVISIONS CHANGE NOTES ................................................................................................................................A-1REVISION HISTORY ..............................................................................................................A-1

WARRANTY .........................................................................................................................................A-7WARRANTY INFORMATION .................................................................................................A-7

INDEX

-

7/30/2019 369man-bx

11/298

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 11

369 Motor Management Relay

Chapter 1: Introduction

GE Energy

Introduction

1.1 Ordering

1.1.1 General Overview

The 369 Motor Management Relay is a digital relay that provides protection and

monitoring for three phase motors and their associated mechanical systems. A unique

feature of the 369 Relay is its ability to learn individual motor parameters and to adapt

itself to each application. Values such as motor inrush current, cooling rates and

acceleration time may be used to improve the 369 Relays protective capabil ities.

The 369 Relay offers optimum motor protection where other relays cannot, by using the

FlexCurve custom overload curve, or one of the f ifteen standard curves.

The 369 Relay has one RS232 front panel port and three RS485 rear ports. The Modbus RTU

protocol is standard to all ports. Setpoints can be entered via the front keypad or by using

the EnerVista 369 Setup software and a computer. Status, actual values and

troubleshooting information are also available via the front panel display or via

communications.

As an option, the 369 Relay can individually monitor up to 12 RTDs. These can be from the

stator, bearings, ambient or driven equipment. The type of RTD used is software selectable.

Optionally available as an accessory is the remote RTD module which can be l inked to the

369 Relay via a f ibre optic or RS485 connection.

The optional metering package provides VT inputs for voltage and power elements. It alsoprovides metering of V, kW, kvar, kVA, PF, Hz, and MWhrs. Three additional user

configurable analog outputs are included with this option along with one analog output

included as part of the base unit.

The Back-Spin Detection (B) option enables the 369 Relay to detect the flow reversal of a

pump motor and enable timely and safe motor restarting.

-

7/30/2019 369man-bx

12/298

12 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

ORDERING CHAPTER 1: INTRODUCTION

All 369 Relay options are available when ordering the relay from the factory. Field

upgrades are only available for the relay when the required hardware is installed in the

relay from the factory. Field upgrades are via an option enabling passcode available from

GE Multilin, which is unique to each relay and option. Any hardware modifications made to

the relay in the field will void the product warranty and will not be supported by GE Multilin.

1.1.2 Ordering

Select the basic model and the desired features from the selection guide below:

NoteNotes:

1. One Analog Output is available with the 369 base model. The other three Analog

Outputs can be obtained by purchasing the metering or backspin options.

The control power (HI or LO) must be specified with all orders. If a feature is not

required, a 0 must be placed in the order code. All order codes have 10 digits. The 369

is available in a non-drawout version only.

Examples: 369-HI-R-0-0-0-0-E: 369 with HI voltage control power and 12 RTD

inputs, and enhanced diagnostics

369-LO-0-M-0-0-0-E: 369 relay with LO voltage control power and metering

option, and enhanced diagnotics

2. Features available only in Enhanced option (E)

Enhanced faceplate with motor status indicators

Motor Health Report

Enhanced learned data

Motor Start Data Logger

Enhanced event recorder

Security audit trail events

Table 11:

369 * * * * * * *

369 | | | | | | | Base unit (no RTD)HI | | | | | | 50-300 VDC / 60-265 VAC control power

LO | | | | | | 20-60 VDC / 20-48 VAC control powerR | | | | | Optional 12 RTD inputs (built-in)

0 | | | | | No optional RTD inputsM | | | | Optional metering package

B | | | | Optional backspin detection (incl. metering)0 | | | | No optional metering or backspin detection

F | | | Optional Fiber Optic Port0 | | | No optional Fiber Optic Port

E | | Optional Modbus/TCP protocol interfaceP | | Optional Profibus-DP protocol interface

P1 | | Optional Profibus-DPV1 protocol interface

D | | Optional DeviceNet protocol interface0 | | No optional protocol interfaces

H | Harsh environment option0 | No Harsh environment option

E Enhanced diagnostics with Enhanced faceplate0 No Enhanced diagnostics with Basic faceplate

-

7/30/2019 369man-bx

13/298

CHAPTER 1: INTRODUCTION ORDERING

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 13

1.1.3 Accessories

EnerVista 369 Setup software: Setup and monitoring software provided free with each

relay.

RRTD: Remote RTD Module. Connects to the 369 Relay via a fibre optic or

RS485 connection. Allows remote metering and programming for up

to 12 RTDs.F485: Communications converter between RS232 and RS485 / fibre optic.

Interfaces a PC to the relay.

CT: 50, 75, 100, 150, 200, 300, 350, 400, 500, 600, 750, 1000 (1 A or 5 A

secondaries)

HGF: Ground CTs (50:0.025) used for sensitive earth fault detection on high

resistance grounded systems.

515: Blocking and test module. Provides effective trip blocking and relay

isolation.

DEMO: Metal carry case in which 369 is mounted.

FPC15: Remote faceplate cable, 15'.

1.1.4 Firmware History

Table 12: FIRMWARE HISTORY (Sheet 1 of 2)

FIRMWAREREVISION

BRIEF DESCRIPTION OF CHANGE RELEASE DATE

53CMB110.000 Production Release June 14, 1999

53CMB111.000 Changes to Backspin Detection algorithm June 24, 1999

53CMB112.000 Changes to Backspin Detection algorithm July 2, 1999

53CMB120.000 Capability to work with the Remote RTDmodule

October 15, 1999

53CMB130.000 Improvements to the Remote RTDcommunications January 3, 2000

53CMB140.000 Changes to Backspin Detection algorithmand improved RS232 communications March 27, 2000

53CMB145.000 Minor firmware changes June 9, 2000

53CMB160.000

Profibus protocol, waveform capture,phasor display, single analog output,

demand power and current, powerconsumption

October 12, 2000

53CMB161.000 Minor firmware changes October 19, 2000

53CMB162.000 Minor f irmware changesNovember 30,2000

53CMB170.000 Autorestart feature added February 9, 2001

53CMB180.000 Modbus/TCP feature added June 15, 2001

-

7/30/2019 369man-bx

14/298

14 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

ORDERING CHAPTER 1: INTRODUCTION

1.1.5 PC Program (Software) History

53CMB190.000 Number of Event Recorders increased to250; Hottest Overall RTD value addedNovember 23,2001

53CMB201.000Added Starter Failure, MWhrs as analogoutput parameter, and Motor LoadAveraging feature.

April 16, 2004

53CMB210.000Added support for variable frequencydrives; minor changes to Modbus TCP. November 5, 2004

53CMB220.000 Implementation of DeviceNet protocol andstarter operation monitor. April 11, 2005

53CMB230.000 Implemented Profibus DPV1, ForceOutputs and Protection Blocking.September 19,2005

53CMB240.000Custom Curve enhancement, increaserange from 0 to 32767 to 0 to 65534.

November 21,2005

53CMB250.000

Implementation of start control relay timersetting for reduced voltage starting,additional Modbus address added forstarts/hour lockout time remaining,correction to date and time Broadcastcommand Modbus addresses, fix forlatched resets with multiple local/remoteassigned relays, fix for repeated MotorStopped and Motor Running events.

April 28, 2006

53CMC310.000

Profibus loss of trip, trip contact seal inundervoltage auto restart, Motor HealthReport, Enhanced learned data, motorstart data logger, enhanced event recorder,security audit trail events, DeviceNetenhanced polling.

June 7, 2007

53CMC320.0002-speed motor feature, Dataloggerfeature, speed of last trip display, latchedtrip and alarm note.

March 20, 2008

53CMC330.000 Added Ethernet Loss of Comms Trip. May 7, 2009

53CMC340.000 Added DeviceNet Loss of Comms Trip. July 7, 2010

Table 12: FIRMWARE HISTORY (Sheet 2 of 2)

FIRMWAREREVISION

BRIEF DESCRIPTION OF CHANGE RELEASE DATE

Table 13: SOFTWARE HISTORY

PCPROGRAMREVISION

BRIEF DESCRIPTION OF CHANGES RELEASE DATE

1.10 Production Release June 14, 1999

1.20 Capability to work with the Remote RTD module October 15, 1999

-

7/30/2019 369man-bx

15/298

CHAPTER 1: INTRODUCTION ORDERING

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 15

1.1.6 369 Relay Functional Summary

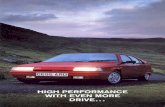

The front view for all 369 Relay models is shown below, along with the rear view showing

the Profibus port, the Modbus/TCP port, and the DeviceNet port.

1.30Capability to communicate effectively with version1.30 firmware January 3, 2000

1.40 Changes made for new firmware release March 27, 2000

1.45 Changes made for new firmware release June 9, 2000

1.60Profibus protocol, waveform capture, phasordisplay, single analog output, demand power andcurrent, power consumption

October 23, 2000

1.70 Changes made for new firmware release February 9, 2001

1.80 Changes made for new firmware release June 7, 2001

1.90 Changes made for new firmware release November 23, 2001

2.00 Changes made for new firmware release September 9, 2003

3.01 New features and enhancements August 16, 2004

3.11 Added support for firmware revision 2.1x November 16, 2004

3.20 Changes made for firmware revision 2.2x April 13, 2005

3.30 Changes made for f irmware revision 2.3x September 19,2005

3.40 Changes made for firmware revision 2.4x November 25, 2005

3.50 Changes made for firmware revision 2.5x May 15, 2006

3.70 Changes made for firmware revision 3.1x June 7, 2007

3.80 Changes made for firmware revision 3.2x March 20, 2008

3.90 Changes made for firmware revision 3.3x May 7, 2009

4.00 Changes made for firmware revision 3.4x July 7, 2010

Table 13: SOFTWARE HISTORY

PCPROGRAMREVISION

BRIEF DESCRIPTION OF CHANGES RELEASE DATE

-

7/30/2019 369man-bx

16/298

16 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

ORDERING CHAPTER 1: INTRODUCTION

FIGURE 11: Front and Rear View

840702BM.CDR

FIBER OPTIC DATA LINK ( F )For harsh enviroments and orhook up to RRTD

PROFIBUS-DP ( P )PROFIBUS-DPV1 ( P1 )

BACKSPIN DETECTION ( B )20mV to 480V RMS

3 x RS485 Ports3 Independent modbuschannels

1 ANALOG OUTPUT ( BASE UNIT )3 ANALOG OUTPUTS (M,B)

VOLTAGE INPUTS ( M )0-240V wye or delta VTconnections.

GROUND CT INPUTS5A, 1A and 50:0.25 taps

12 RTD INPUTS ( R )Field selectable type

CURRENT INPUTS3 Phase CT inputs5A, 1A, taps

CONTROL POWERHI: 50-300 VDC/60-265 VACLO: 20-60 VDC / 20-48 VAC

4 OUTPUT RELAYSProgrammable alarm and tripconditions activated byprogrammable setpoints,switch input, remotecommunication control

Customer AccessibleFuse

DIGITAL INPUTS

DISPLAY40 Character alpha-numericLCD display for viewingactual values, causesof alarms and trips, andprogramming setpoints

STATUS INDICATORSLEDs indicate if motor isstopped, starting, running,overloaded or locked out

HELP KEYHelp key can be pressed atany time to provide additionalinformation

KEYPADUsed to select the displayof actual values, causes ofalarms, causes of trips, faultdiagnosis, and to programsetpoints

Rugged, corrosion andflame retardent case.

STATUS INDICATORS

SERVICE LED

4 LEDs indicate when anoutput is activated. Whenan LED is lit, the cause ofthe output relay operationwill be shown on the display.

indicates that aself-diagnostic test failed, orthat the 369 is in Test Mode .

6

320

-

7/30/2019 369man-bx

17/298

CHAPTER 1: INTRODUCTION ORDERING

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 17

FIGURE 12: DeviceNet Model

FIGURE 13: Rear View (Modbus/TCP Model)

-

7/30/2019 369man-bx

18/298

18 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

ORDERING CHAPTER 1: INTRODUCTION

1.1.7 Relay Label Definition

1. The 369 Relay order code at the time of leaving the factory.

2. The serial number of the 369 Relay.

3. The firmware installed at the factory. Note that this may no longer be the currently

installed firmware as it may have been upgraded in the field. The current firmware revi-

sion can be checked in the actual values section of the 369 Relay.

4. Specifications for the output relay contacts.

5. Certifications the 369 Relay conforms with or has been approved to.

6. Factory installed options. These are based on the order code. Note that the 369 Relay

may have had options upgraded in the field. The actual values section of the 369 can

be checked to verify this.

7. Control power ratings for the 369 Relay as ordered. Based on the HI/LO rating from

the order code.

8. Pollution degree.

9. Overvoltage category.

10. IP code.

11. Modification number for any factory-ordered mods.

12. Insulative voltage rating.

CEg

INPUT POWER:

MODEL: 369-HI-R-B-F-P-0

MAXIMUMCONTACT RATING2 50 V AC 8 A R ES IS TI VE

1/4 HP 125 VAC 1/2 HP 250 VAC

SERIAL No: M53C07000001

FIRMWARE: 53CMC320.000

POLLUTION DEGREE: 2 IP CODE: 50X

50-300 VDC

60-265 VAC

485mA MAX.

50/60Hz or DCMOD:

12 RTDs:

BACKSPIN

FIBER OPTIC PORT

PROFIBUS

OPTIONS

INSULATIVE VOLTAGE: 2

NONEOVERVOLTAGE CATAGORY: II

1

7

2

8

3

9

4

10 11

6

12840350AB.CDR

UL

-

7/30/2019 369man-bx

19/298

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 21

369 Motor Management Relay

Chapter 2: Product Description

GE Energy

ProductDescription

2.1 Overview

2.1.1 Guideform Specifications

Motor protection and management shall be provided by a digital relay. Protective func-tions include:

phase overload standard curves (51)

overload by custom programmable curve (51)

I2t modeling (49)

current unbalance / single phase detection (46)

starts per hour and time between starts

short circuit (50)

ground fault (50G/50N 51G/51N)

mechanical jam / stall

two-speed motor protection

Optional functions include:

under / overvoltage (27/59)

phase reversal (47)

underpower (37)

power factor (55)

stator / bearing overtemperature with twelve (12) independent RTD inputs (49/38)

backspin detection

Management functions include:

statistical data

-

7/30/2019 369man-bx

20/298

22 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

OVERVIEW CHAPTER 2: PRODUCT DESCRIPTION

pre-trip data (last 40 events)

ability to learn, display and integrate critical parameters to maximize motor

protection

a keypad with 40 character display

flash memory

The relay is capable of displaying important metering functions, including phase volt-

ages, kilowatts, kvars, power factor, frequency and MWhr. In addition, undervoltage

and low power factor alarm and trip levels are field programmable. The communica-tions interface include one front RS232 port and three independent rear RS485 ports

with supporting PC software, thus allowing easy setpoint programming, local retrieval

of information and flexibility in communication with SCADA and engineering worksta-tions.

2.1.2 Metered Quantities

2.1.3 Protection Features

METERED QUANTITY UNITS OPTION

Phase Currents and Current Demand AmpsMotor Load FLA

Unbalance Current %

Ground Current Amps

Input Switch Status Open / Closed

Relay Output Status (De) Energized

RTD Temperature C or F R

Backspin Frequency Hz B

Phase/Line Voltages Volts M

Frequency Hz M

Power Factor lead / lag M

Real Power and Real Power Demand Watts M

Reactive Power and Reactive Power Demand Vars M

Apparent Power and Apparent Power Demand VA M

Real Power Consumption MWh M

Reactive Power Consumption/Generation Mvarh M

ANSI/IEEE

DEVICE

PROTECTION FEATURES OPTION TRIP ALARM BLOCK START

14 Speed Switch

27 Undervoltage M

37 Undercurrent / Underpower /M

38 Bearing RTD R or RRTD

46 Current Unbalance

47 Voltage Phase Reversal M

49 Stator RTD R or RRTD

-

7/30/2019 369man-bx

21/298

CHAPTER 2: PRODUCT DESCRIPTION OVERVIEW

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 23

50 Short Circuit & Backup

50G/51G Ground Fault & Ground FaultBackup

51 Overload 55 Power Factor M

59 Overvoltage M

66Starts per Hour/TimeBetween Starts

74 Alarm

81 Over/Under Frequency M

86 Lockout

87 Differential Switch

General Switch

Reactive Power M

Thermal Capacity Start Inhibit (thermal capacityavailable)

Restart Block (BackspinTimer)

Mechanical Jam

Acceleration Timer

Ambient RTD R or RRTD

Short/Low temp RTD R or RRTD

Broken/Open RTD R or RRTD

Loss of RRTDCommunications RRTD

Trip Counter

Self Test/Service

Backspin Detection B

Current Demand

kW Demand M

kvar Demand M

kVA Demand M

Starter Failure

Reverse Power M

Undervoltage Autorestart M or B

ANSI/IEEE

DEVICE

PROTECTION FEATURES OPTION TRIP ALARM BLOCK START

-

7/30/2019 369man-bx

22/298

24 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

OVERVIEW CHAPTER 2: PRODUCT DESCRIPTION

2.1.4 Additional Features

FIGURE 21: Single Line Diagram

FEATURE OPTION

Modbus/TCP protocol Ethernetinterface E

Profibus-DP rear communication port P

Profibus-DPV1 rear communicationport P1

DeviceNet protocol interface D

User Definable Baud Rate (1200-19200)

Flash Memory for easy firmwareupdates

Front RS232 communication port

Rear RS485 communication port

Rear fiber optic port F

RTD type is user definable R or RRTD

4 User Definable Analog Outputs

(0 to 1 mA, 0 to 20 mA, 4 to 20 mA) MWindows based PC program forsetting up and monitoring

-

7/30/2019 369man-bx

23/298

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 25

2.2 Specifications

2.2.1 Inputs

CONTROL POWER

LO range (nominal): .......................................DC: 24 to 48 V DC/AC (at 50/60 Hz)HI range (nominal): ........................................DC: 110 to 250 V DC

AC: 100 to 240 V AC at 50/60 Hz

Power:..................................................................nominal: 20 VA; maximum: 65 VA

Holdup:................................................................non-failsafe trip: 200 ms; failsafe trip: 100 ms

FUSE

T 3.15 A H 250 V (5 20 mm)

Timelag high breaking capacity

PHASE CURRENT INPUTS (CT)

CT input (rated):...............................................1 A and 5 A secondary

CT primary:........................................................1 to 5000 A

Range:

for 50/60 Hz nominal frequency: ......0.05 to 20 CT primary ampsfor variable frequency: ...........................0.1 to 20 CT primary amps

Full Scale: ...........................................................20 CT primary amps or 65535 A maximum

Frequency:.........................................................20 to 100 Hz

Conversion: ....................................................... True RMS, 1.04 ms/sample

Accuracy:

at 2 CT:............... .....................................0.5% of 2 CT for 50/60 Hz nominal freq.1.0% of 2 CT for variable frequency (for sinusoidalwaveforms)

at > 2 CT: ....................................................1.0% of 20 CT for 50/60 Hz nominal freq.3.0% of 12 CT or less for variable frequency (forsinusoidal waveforms)

PHASE CT BURDEN

PHASE CT CURRENT WITHSTAND

DIGITAL / SWITCH INPUTS

Inputs:..................................................................6 optically isolated

Input type:..........................................................Dry Contact (< 800 )

Function:.............................................................Programmable

PHASE CT INPUT (A) BURDEN

VA ()

1 A

1 0.03 0.03

5 0.64 0.03

20 11.7 0.03

5 A

5 0.07 0.003

25 1.71 0.003

100 31 0.003

PHASE CT WITHSTAND TIME

1 s 2 s continuous

1 A 100 CT 40 CT 3 CT

5 A 100 CT 40 CT 3 CT

-

7/30/2019 369man-bx

24/298

26 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

GROUND CURRENT INPUT (GF CT)

CT Input (rated):...............................................1 A/5 A secondary and 50:0.025

CT Primary: ........................................................1 to 5000 A (1 A/5 A)

Range: .................................................................0.1 to 1.0 CT primary (1 A/5 A)0.05 to 25.0 A (50:0.025)

Full Scale: ...........................................................1.0 CT primary (1 A/5 A)25 A (50:0.025)

Frequency:.........................................................20 to 100 HzConversion:........................................................True RMS 1.04ms/sample

Accuracy at 50/60 Hz:

for 1 A/5 A: .........................................1.0% of full scale (1 A/5 A)

for 50:0.025........................................0.07 A at

-

7/30/2019 369man-bx

25/298

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 27

BSD INPUTS (OPTION B)Frequency: ........................................................1 to 120 Hz

Dynamic BSD range: ....................................20 mV to 480 V RMS

Accuracy:...............................................0.02 Hz

Burden:...................... ..........................................>200 k

RTD INPUTS (OPTION R)

Wire Type: ..........................................................3 wireSensor Type: ..................................................... 100 platinum (DIN 43760), 100 nickel, 120 nickel,

10 copper

RTD sensing current: ....................................3 mA

Range:..................................................................40 to 200C or 40 to 392F

Accuracy:...............................................2C or 4F

Lead resistance:..............................................25 max. per lead for Pt and Ni type;3 max. per lead for Cu type

Isolation: .............................................................36 Vpk

2.2.2 Outputs

ANALOG OUTPUTS (OPTION M)

Accuracy:...............................................1% of full scale

Isolation:.............................................................fully isolated active source

OUTPUT RELAYS

This equipment is suitable for use in Class 1, Div 2, Groups A, B, C, D or Non-Hazardous

Locations only if MOD502 is ordered (for North America only).

Hazardous Location Class 1, Div 2 output rating if MOD502 is ordered: 240 V, 3 A max,

as per UL1604. The contact rating is only for Make and carry operations, and shall not

be used for breaking DC current.

PROGRAMMABLE

OUTPUT 0 to 1 mA 0 to 20 mA 4 to 20 mA

MAX LOAD 2400 600 600

MAX OUTPUT 1.01 mA 20.2 mA 20.2 mA

RESISTIVELOAD (pf = 1)

INDUCTIVELOAD (pf = 0.4)(L/

R 7ms)

RATED LOAD 8 A at 250 V AC8 A at 30 V DC

3.5 A at 250 V AC3.5 A at 30 V DC

CARRY CURRENT 8A

MAX SWITCHINGCAPACITY

2000 VA240 W

875 VA170 W

MAX SWITCHING V 380 V AC; 125 V DC

MAX SWITCHING I 8 A 3.5 A

OPERATE TIME

-

7/30/2019 369man-bx

26/298

28 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

Explosion Hazard Substitution of components may impair suitability for Class 1, Div 2.

Explosion Hazard Do not disconnect equipment unless power has been switched off

or the area is known to be Non-Hazardous.

2.2.3 Metering

POWER METERING (OPTION M)

EVENT RECORD

Capacity:.............................................................last 512 eventsTriggers:..............................................................trip, inhibit, power fail, alarms, self test,

waveform capture

WAVEFORM CAPTURELength:.................................................................3 buffers containing 16 cycles of all current and voltage

channels

Trigger position: ..............................................1 to 100% pre-trip to post-trip

Trigger: ...............................................................trip, manually via communications or digital input

MOTOR START DATA LOGGERLength: .......................................................... .....6 Buffers containing 30 seconds of motor start data.

Trigger: ...............................................................Motor Start Status.

Trigger position: .............................................1-second pre-trigger duration.Logging rate: ...................................................1 sample/200ms.

PARAMETER

ACCURACY

(FULL SCALE)

RESOLUTION

RANGE

kW 2% 1 kW 32000

kvar 2% 1 kvar 32000

kVA 2% 1 kVA 0 to 65000

kWh 2% 1 kWh 0 to 999

MWh 2% 1 MWh 0 to 65535kvarh 2% 1 kvarh 0 to 999

Mvarh 2% 1 Mvarh 0 to 65535

Power Factor 1% 0.01 0.99 to 1.00

Frequency 0.02 Hz 0.01 Hz 20.00 to100.00

kW Demand 2% 1 kW 0 to 32000

kvar Demand 2% 1 kvar 0 to 32000

kVA Demand 2% 1 kVA 0 to 65000

Amp Demand 2% 1 A 0 to 65535

-

7/30/2019 369man-bx

27/298

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 29

2.2.4 Communications

FRONT PORTType: ........................................................... ..........RS232, non-isolated

Baud rate: ......................................................... .4800 to 19200

Protocol:..............................................................Modbus RTU

BACK PORTS (3)Type: ................................................................. ....RS485

Baud rate: ................................................... .......1200 to 19200

Protocol:..............................................................Modbus RTU

36V isolation (together)

PROFIBUS (OPTIONS P AND P1)Type: ..................................................................... RS485

Baud rate:..........................................................1200 baud to 12 Mbaud

Protocol:..............................................................Profibus-DPProfibus-DPV1

Connector Type:..............................................DB9 Female

MODBUS/TCP ETHERNET (OPTION E)Connector type:...............................................RJ45

Protocol:..............................................................Modbus/TCP

DEVICENET (OPTION D)DeviceNet CONFORMANCE TESTED

Connector type:...............................................5-pin linear DeviceNet plug (phoenix type)

Baud rate: .......................................................... 125, 250, and 500 kbps

Protocol:..............................................................DeviceNet

Bus-Side Current Draw:...............................85mA (Typical), 100mA (Max)

FIBER OPTIC PORT (OPTION F)Optional use:.....................................................RTD remote module hookup

Baud rate: ......................................................... .1200 to 19200

Protocol:..............................................................Modbus RTU

Fiber sizes:...... ...................................................50/125, 62.5/125, 100/140, and 200 m

Emitter fiber type: ..........................................820 nm LED, multimode

Link power budget:

Transmit power: ...........................................20 dBm

Received sensitivity: ...................................30 dBm

Power budget: ...............................................10 dB

Maximum optical input power: ..............7.6 dBm

Typical link distance: ..... ..............................1.65 km

Note

Typical link distance is based upon the following assumptions for system loss. As actual

losses vary between installations, the distance covered will vary.

Connector loss: ..............................................2 dB

Fiber loss: ..........................................................3 dB/km

Splice loss: ........................................................One splice every 2 km at 0.05 dB loss/splice

System margin: ..............................................3 dB additional loss added to calculations to compensatefor all other losses

-

7/30/2019 369man-bx

28/298

210 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

FIELDBUS LOSS OF COMMUNICATIONPickup: .................................................................No communication

Time delay:........................................................0.25 to 10 sec in steps of 0.25 sec

Timing accuracy:...................................250 ms for Profibus300 ms for Ethernet250 ms for DeviceNet

2.2.5 Protection Elements

51 OVERLOAD/STALL/THERMAL MODELCurve Shape: ....................................................1 to 15 standard, custom

Curve Biasing: ..................................................unbalance, temperature, hot/cold ratio,cool time constants

Pickup Level: .....................................................1.01 to 1.25 FLA

Pickup Accuracy: ............................................as per phase current inputs

Dropout Level:..................................................96 to 98% of pickup

Timing Accuracy:.................. ..........................100 ms or 2% of total trip time

THERMAL CAPACITY ALARM

Pickup Level: .....................................................1 to 100% TC in steps of 1Pickup Accuracy: ............................................2%

Dropout Level:..................................................96 to 98% of pickup

Timing Accuracy:............................. ...............100 ms

OVERLOAD ALARMPickup Level: .....................................................1 .01 to 1.50 FLA in steps of 0.01

Pickup Accuracy: ............................................as per phase current inputs

Dropout Level:..................................................96 to 98% of pickup

Time Delay:........................................................0.1 to 60.0 s in steps of 0.1

Timing Accuracy:.................. ..........................100 ms or 2% of total trip time

50 SHORT CIRCUIT

Pickup Level: .....................................................2.0 to 20.0 CT in steps of 0.1Pickup Accuracy: ............................................as per phase current inputs

Dropout Level:..................................................96 to 98% of pickup

Time Delay:........................................................0 to 255.00 s in steps of 0.01 s

Backup Delay: ..................................................0.10 to 255.00 s in steps of 0.01 s

Timing Accuracy:............................................+50 ms for delays

-

7/30/2019 369man-bx

29/298

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 211

46 UNBALANCEPickup Level:..... ................................................4 to 30% in steps of 1

Pickup Accuracy: ............................................2%

Dropout Level:..................................................1 to 2% below pickup

Time Delay: .......................................................1 to 255 s in steps of 1

Start Delay:........................................................0 to 5000 s in steps of 1

Timing Accuracy:............................................500 ms or 0.5% of total time

50G/51G 50N/51N GROUND FAULTPickup Level: .....................................................0.10 to 1.00 CT for 1 A/5 A CT

0.25 to 25.00 A for 50:0.025 CT

Pickup Accuracy: ............................................as per ground current inputs

Dropout Level:..................................................96 to 98% of pickup

Time Delay: .......................................................0 to 255.00 s in steps of 0.01 s

Backup Delay: ..................................................0.01 to 255.00 s in steps of 0.01 s

Timing Accuracy:............................................+50 ms for delays

-

7/30/2019 369man-bx

30/298

212 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

Dropout Level:..................................................96 to 98% of pickup

Time Delay:........................................................0.0 to 255.0 s in steps of 0.1

Timing Accuracy:.......................... ..................100 ms or 0.5% of total trip time

47 PHASE REVERSAL

Pickup Level:...... ...............................................phase reversal detected

Time Delay:............................................... .........500 to 700 ms

81 UNDERFREQUENCYPickup Level: .....................................................20.00 to 70.00 Hz in steps of 0.01

Pickup Accuracy: ............................................0.02 Hz

Dropout Level:.............................. ....................0.05 Hz

Time Delay:........................................................0.0 to 255.0 s in steps of 0.1

Start Delay:........................................................0 to 5000 s in steps of 1

Timing Accuracy:.................. ..........................100 ms or 0.5% of total trip time

81 OVERFREQUENCY

Pickup Level: .....................................................20.00 to 70.00 Hz in steps of 0.01

Pickup Accuracy: ............................................0.02 Hz

Dropout Level:.............................. ....................0.05 Hz

Time Delay:........................................................0.0-255.0 s in steps of 0.1

Start Delay:.... ....................................................0-5000 s in steps of 1

Timing Accuracy:.................. ..........................100 ms or 0.5% of total trip time

55 LEAD POWER FACTOR

Pickup Level: .....................................................0 .99 to 0.05 in steps of 0.01

Pickup Accuracy: ............................................0.02

Dropout Level:..................................................0.03 of pickup

Time Delay:........................................................0.1 to 255.0 s in steps of 0.1

Start Delay:........................................................0 to 5000 s in steps of 1

Timing Accuracy:.................. ..........................300 ms or 0.5% of total trip time

55 LAG POWER FACTOR

Pickup Level: .....................................................0 .99 to 0.05 in steps of 0.01

Pickup Accuracy: ............................................0.02

Dropout Level:..................................................0.03 of pickup

Time Delay:........................................................0.1 to 255.0 s in steps of 0.1

Start Delay:........................................................0 to 5000 s in steps of 1

Timing Accuracy:.................. ..........................300 ms or 0.5% of total trip time

POSITIVE REACTIVE POWERPickup Level: .....................................................1 to 25000 in steps of 1

Pickup Accuracy: ............................................2%

Dropout Level:..................................................96 to 98% of pickup

Time Delay:........................................................0.1 to 255.0 s in steps of 0.1

Start Delay:........................................................0 to 5000 s in steps of 1

Timing Accuracy:.................. ..........................300 ms or 0.5% of total trip time

NEGATIVE REACTIVE POWER

Pickup Level: .....................................................1 to 25000 kvar in steps of 1

Pickup Accuracy: ............................................2%

Dropout Level:..................................................96 to 98% of pickup

Time Delay:........................................................0.1 to 255.0 s in steps of 0.1

Start Delay:........................................................0 to 5000 s in steps of 1

Timing Accuracy:.................. ..........................300 ms or 0.5% of total trip time

37 UNDERPOWER

Pickup Level: .....................................................1 to 25000 kW in steps of 1

Pickup Accuracy: ............................................2%

-

7/30/2019 369man-bx

31/298

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 213

Dropout Level:..................................................102 to 104% of pickup

Time Delay: .......................................................0.5 to 255.0 s in steps of 0.5

Start Delay:........................................................0 to 15000 s in steps of 1

Timing Accuracy:....................................... .....300 ms or 0.5% of total trip time

REVERSE POWER

Pickup Level:..... ................................................1 to 25000 kW in steps of 1

Pickup Accuracy: ............................................2%Dropout Level:..................................................96 to 98% of pickup

Time Delay: .......................................................0.5 to 30.0 s in steps of 0.5

Start Delay:........................................................0 to 50000 s in steps of 1

Timing Accuracy:....................................... .....300 ms or 0.5% of total trip time

87 DIFFERENTIAL SWITCH

Time Delay: .......................................................

-

7/30/2019 369man-bx

32/298

214 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

Pickup level:.......................................................1 to 50000 kvar in steps of 1

Pickup accuracy:.............................................2%

Dropout level:...................................................96 to 98% of pickup

Time delay:........................................................

-

7/30/2019 369man-bx

33/298

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL 215

POLLUTION DEGREE II

OVERVOLTAGE CATEGORY II

CLEANING

May be cleaned with a damp cloth.

INSULATION CLASS I

ALTITUDE: 2000 m (max)

2.2.9 Long-term storage

LONG-TERM STORAGE

Environment: ...................................................In addition to the above environmental considerations,the relay should be stored in an environment that is dry,corrosive-free, and not in direct sunlight.

Correct storage:..............................................Prevents premature component failures caused byenvironmental factors such as moisture or corrosivegases. Exposure to high humidity or corrosiveenvironments will prematurely degrade the electronic

components in any electronic device regardless of its useor manufacturer, unless specif ic precautions, such asthose mentioned in the Environmental section above, aretaken.

Note

It is recommended that all relays be powered up once per year, for one hour

continuously, to avoid deterioration of electrolytic capacitors and subsequent relay

failure.

2.2.10 Approvals/Certification

DeviceNet CONFORMANCE TESTED

Applicable Council Directive: According to:

CE compliance: Low voltage directive EN/IEC61010-1

EMC Directive EN50263 / EN61000-6-4

North America: cULus e234799 NOIV/NOIV7 Haz loc Class 1 Div2

cULus e83849 NKCR/7 C22.2 No14

UL508, UL1053

ISO: Manufactured under an ISO9001 registered quality program

-

7/30/2019 369man-bx

34/298

216 369 MOTOR MANAGEMENT RELAY INSTRUCTION MANUAL