3111 Old Lincoln Highway Trevose, PA 19053-4996 USA TEL ...G3 Towing Bridle Assembly 07357 G4 Towing...

Transcript of 3111 Old Lincoln Highway Trevose, PA 19053-4996 USA TEL ...G3 Towing Bridle Assembly 07357 G4 Towing...

General Machine Products Co., Inc. 3111 Old Lincoln Highway Trevose, PA 19053-4996 USA TEL: 215-357-5500 FAX: 215-357-6216 E-MAIL: [email protected] WEB: http://www.GMPtools.com

GMP reserves the right, without notice, to make changes in equipment design or components as progress in engineering or manufacturing methods may warrant. All contents ©2005 GMP

General Machine Products Co., Inc. 3111 Old Lincoln Highway Trevose, PA 19053-4996 USA TEL: 215-357-5500 FAX: 215-357-6216 E-MAIL: [email protected] WEB: http://www.GMPtools.com

GMP reserves the right, without notice, to make changes in equipment design or components as progress in engineering or manufacturing methods may warrant. All contents ©2005 GMP

GMP G Lasher

15

G61

G62 G69

G63 G70

G65

G66

G67

G64

G60

G59

G58

G57

G56

G54

G55

G53G68

G75G74

G72

G73

G71

G45

G48

G52

G51 G50

G47G46

G46

G49

G45

G84G78

G81

G80G79 G76

G77

G83

G82

Table ofcontents

Read me first! . . . . . . . . . . . . . . . . . . . 3Important precautions . . . . . . . . . . . . 4Check your machine first . . . . . . . . . . . . . . . . . . . . . . . . 4Use the proper safety equipment . . . . . . . . . . . . . . . . . . 4Use the bridle assembly at pole transfers. . . . . . . . . . . . 4

About your G Lasher . . . . . . . . . . . . . 5Cable capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Lashing wire magazines and capacities . . . . . . . . . . . . . 7Adjustable rear gates and cable lifter . . . . . . . . . . . . . . . 7Front gate and pulling eye . . . . . . . . . . . . . . . . . . . . . . . 8Strand tensioning mechanism . . . . . . . . . . . . . . . . . . . . 8Automatic brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using your G Lasher. . . . . . . . . . . . . . 8Preparing a lashing wire coil. . . . . . . . . . . . . . . . . . . . . . 9Placing the lasher on the strand . . . . . . . . . . . . . . . . . . 10Transferring the lasher around a pole or other obstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Instructions for over-lashing . . . . . . . . . . . . . . . . . . . . 11Lubrication advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Repairs and maintenance . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix: Parts summary . . . . . . . . 13

2

GMP G Lasher

3

Read me first!

This manual covers the care, operation and maintenanceof your GMP model G Cable Lasher, which you can use tolash cables from about 21⁄2 in. up to 5 in. (125 mm) dia. tosuspension strand, or smaller cable sizes to an existinglashed cable and strand (a process called “over-lashing”). This machine is intended for use ONLY by properly trainedjourney linespeople or other craftspeople under the DIRECTsupervision and responsibility of those individuals.As such, this manual’s scope is specifically limited to the machine’s functions, and no attempt is made todescribe the proper procedure for placing and lashing aerial cable plant.We cannot be held liable for any direct or indirect con-sequences arising from use of the product by any indi-viduals not already properly trained in its use. If you would like information about professional trainingprograms, call us for details.

14

G2

G1

G5G5

G6

G8

G7 G9

G11

G12

G10

G13G15

G14

G22G27

G27

G28

G29

G32

G32

G38

G38

G31G41

G42

G40

G39

G43

G44

G33

G35

G26

G34

G37

G25 G24 G23

G36

G20

G21

G19 G18

G17G16

G3

G4

G30

GMP G Lasher

4

Importantprecautions

The proposed cable run should be pre-surveyed to deter-mine the terrain and field conditions that will be encoun-tered in the lashing operation. Among those factors to beconsidered (not by limitation) are:(a) vehicle & pedestrian safety (b) condition of poles, anchors, guys and strand (c) proper bonding and grounding of strand

and attachments (d) obstructions such as trees, limbs and

drop wires (e) clearances and separations on poles shared by

other utilities (f) clearances over roads, driveways, walkways

and crossings Protect your work site with advance warning devices atstrategic points to warn traffic and pedestrians of theobstruction in the area. Check your machine first! Prior to using the machine, check that it is in good repair,that all of the parts and mechanical assemblies are intactand in good working order. If the machine has not beenproperly maintained it may well be unsafe to use and poseunnecessary risk to the user. GMP Lashers can be profes-sionally repaired and/or overhauled at the factory withquick turnaround and minimal downtime. Use the proper safety equipment! Before working aloft, inspect all your climbing and safetyequipment to make certain it is in good repair. And whileyou are aloft, ALWAYS wear a body belt with a safetystrap securely attached to help prevent you from falling. Also, you should always raise and lower your lasher onlywith a proper aerial handline (such as our 68590 or08192) or a truck lift. Use the bridle assembly at pole transfers! When transferring the lasher around a pole or otherobstruction, use the bridle assembly as a tether to preventdamage to the machine in case it is dropped. This alsoallows you to concentrate on your own safety first ratherthan the safety of the machine.

13

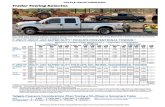

G1 Gear Housing 05475G2 Gear Housing Cover 05525G3 Towing Bridle Assembly 07357G4 Towing Bridle Stop Bolt 09007

Towing Bridle Stop Nut 03569G5 Strand Drive Wheel 05486G6 Strand Drive Wheel Nut 03039G7 Pulling Eye 13398G8 Top Roller Assembly Screw 03305

Top Roller Assembly Washer 16005G9 Top Roller Assembly 15192G10 Pulling Eye Screw 16041

Pulling Eye Nut 02854G11 Clamping Washer 05485G12 Rear Strand Drive Shaft 07363

(shaft, gears & bearing)G13 Front Strand Drive Shaft 07364

(shaft, gear & bearing)G14 Ratchet Pawl Spring 03037G15 Rubber Sleeve 03041G16 Steel Guide 05502G17 Shoulder Screw 05527

Shoulder Nut 03272G18 Ratchet Brake Pawl 07346G19 Idler Gear 05496G20 Oilite Bearing 03056G21 Idler Gear Shaft 03038G22 Clamping Nut 03030G24 Ratchet Brake Collar 05531G25 Ratchet Brake Copper Latch 05532G26 Tru-Arc Ring #50 03277G27 Drive Shaft 05510G28 Collar 05535G29 Timing Gear 25224G30 Drive Shaft Gear Assy. 07362G31 Spring Screw 03040G32 Towing Bridle Pivot 05501G33 Spacer 05534G34 Stop Pin 09463G35 Retaining Ring Screw 03291

Retaining Ring Lockwasher 03260G36 88013 Bearing 03054G37 Bearing Retainer Rings

3 ea. required 030242 ea. required 030251 ea. required 24825

G38 Tru-Arc Ring #125 09447G39 Towing Bridle Spring 05530G40 Pivot Retaining Ring 15220G41 5-40 x 3⁄4 Filister Screw 17677G42 5-40 x 5⁄8 Flathead Screw 09442G43 Strand Lifter Assembly 07302G44 10-24 x 5⁄8 Filister Screw 03298G45 Wire Coil Door Assembly 07305G46 Door Pulley 14413G47 Door Pulley Bearing 09435G48 Door Release Spring 24991G50 Handle 05506G51 1⁄4 x 20 Flathead Screw 03271G52 .065 in. Wire Pulley 15622G53 Front Plate Assembly 15163G54 Left Lock 03121G55 Right Lock 03120G56 10-24 x 1⁄2 Filister Screw 03298G57 Locking Bolt 07580G58 Locking Bolt Spring 03089G59 Locking Bolt Retainer 03090G60 Locking Bolt Retainer Nut 03087G61 Rotor Body 05474G62 Ring Gear 05491G63 1⁄4-20 x 1 Allen Screw 17542G64 Spacer 05481G65 Strand Roller w/Bearings 26076G66 Strand Roller Shaft 05495G67 1⁄4-20 x 1 Flathead Screw 03271G68 Rear Plate Assembly 07307G69 Swing Bolt Spring 03078G70 Swing Bolt Assembly 07547G71 Front Bearing Ring 05478G72 Rear Bearing Ring 05479G73 6-32 x 3⁄8 Filister Screw 03293G74 Ball Bearing 88038 26051G75 Eccentric Screw 03091G76 Wire Guide Assembly 07312G77 10-24 x 7⁄8 Filister Screw 03300G78 Front Cable Lifter Assembly 07319G79 Hex Head Screw 03375G80 10-24 x 1-1⁄8 Filister Screw 09440G81 10-24 x 3⁄4 Filister Screw 03299G82 Side Roller Assembly 15191G83 10-24 x 3⁄4 Filister Screw 03299G84 Rear Lifter Assembly 07310

GMP G Lasher

About yourG Lasher

12

Note: Do not set the lasher vertically on the rear gate toavoid damage to the spring catches.1. Remove the four screws holding the gear housing

cover and remove the cover.2. Position the lasher with the gear housing facing to the

right and the rear gate to the left.3. Remove the three #10-25 filister head screws which

will allow the complete strand tension roller assemblyto drop out through the bottom of the gear housing.

4. Reinstall the gear housing cover and your G lasher is now capable of over-lashing cable(s) up to thecapacity of the machine.

Note: Be sure to save the parts. To reinstall simply reversethe above procedure.When placing the lasher into its case, have the front cablelifter assembly open and put the rotor assembly in thelocked position. Keep the lasher in the carrying case at alltimes when not in use. Lubrication advice The gears of the G Lasher are lubricated at the factory witha specially formulated graphite-based lubricant. This lubri-cation will last indefinitely provided that the gear housingis left unopened and uncontaminated by solvent or debris. If, during the course of your G Lasher’s service life, it isever returned to the factory for repair and reconditioning,it will receive a thorough cleaning during disassembly andwill be freshly relubricated as it was when new. Do notattempt to lubricate the gears as improper lubrication cancause eventual slippage due to lubricant flowing to othersurface areas during operation. The only parts whichshould require occasional lubrication with S.A.E. 10 or 20motor oil, are the threads of the rear cable lifter and hingesto keep them operating freely. Wipe off any excess oil.Repairs & maintenance From time to time it may be necessary to make minor fieldrepairs; the following list of parts will prove helpful inordering what you need. However, nobody can give yourlasher as thorough a check-up as the people who builtit...GMP. Our experienced technicians will check everydetail, thoroughly clean and re-lubricate your machine andput your lasher back in like-new shape within 10 workingdays, guaranteed. Just call the factory for full details onour lasher maintenance program.

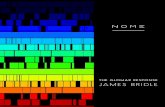

Look at your G Lasher for a moment. You will see it consists of a rotating drum supported on a carriage; thestrand and cable pass through this carriage during the lashing operation.As you look at the carriage, you will see it also has a forward direct gear drive mechanism, cable and strandrollers, front and rear gates, various pulling eyes and ananti-backroll brake. The major components are made of heat-treated, high-strength aluminum alloy, bronze, stainless or zinc-platedsteel. Sealed aircraft-type, dust-proof ball bearings are onall shafts and the drum, with other moving parts mountedon Oilite bushings. At about 71 lbs. (32 kgs) without wire, your machine’sweight and features give it an optimal strength-to-weightratio for the heavy-duty work of lashing large telephonecable(s) or electrical distribution cables.Cable capacities The G Cable Lasher can be used for securing aerial cablefrom about 21⁄2 in. up to 5 in. (65 - 125 mm) diameter tosuspension strands from 3⁄8 in. to 3⁄4 in. (9 -19 mm) diame-ter with a spiral lashing of .065 in. (1.65 mm) stainlesssteel lashing wire. (A modification for .045 in. / 1.1 mmstainless steel wire is also available.) The G Lasher has the capability of lashing any number of cables to a singlesuspension strand provided that the entire diameter of thecable bundle not exceed 5 in. (125 mm).

5

Underside of Lasher

Towing Bridle

StrandTensioning

Roller (closed)

Strand DriveWheels

Front Gate and Latch

Rear StrandRoller

Rear CableLifter inclosed position

GMP G Lasher

6

Cable LifterAdjusting Knob

Cable LifterAdjusting Knob

Vertical Cable Rollers

HandleStrand Tensioning RollerLever in closed position

Spring Lock Rear Cable Lifter and Release Knob Spring Lock

7. Pull out sufficient lashing wire for termination andclamp the lashing wire to the strand at least 12 in. (30 cm) behind the lasher.

8. Close the front gate assembly. Remove the tow linesnap hook from the strand and attach the snap hookto the other tow eye of the lasher.

9. The lasher is now prepared to lash cable. Transferring the lasher around a pole or other obstruction

1. Before transferring around a pole, temporarily termi-nate the lashing wire near the pole with a lashing wiregrip, pull out sufficient wire for the final terminationand the cut.

2. Open the front gate all the way.3. Move the lasher forward or backward along the strand

until the drum locks.4. Attach one of the lasher bridle snap hooks to a lasher

towing eye on the front of the machine. Now pass thebridle under the strand, past the obstruction and attachthe other snap hook to another lasher pulling eye.

5. Press down the strand tension roller lever and turn itclockwise to disengage it from the strand.

6. Raise the lasher from the strand and transfer themachine to the strand in the next span following theinstructions beginning in step 5 of the preceding section.

Instructions for over-lashingWhen lashing a cable or cables to an existing cable thesame procedure is followed with one exception. The strandtension roller assembly should be removed so as not tointerfere with existing lasher cable. This is a simple proce-dure which should only be attempted while on the groundand working on a suitably stable work surface.

11

GMP G Lasher

Lashing wire magazines & capacities The lasher has two magazines for loading of lashing wire;each can hold a coil of .065 in. x 450 ft. (1.65 mm x 137 m)wire. Note: .045 in. x 1200 ft. (1.1mm x 365 m) coils maybe used as an alternate. Each magazine has two rollers forguiding and tensioning wire during lashing. The wire coilsare held stationary in the magazines, with the wire feedingfrom the center of the coil eye through a throated hole andover a guiding roller; it is then threaded around the rollersand wound onto the cable/strand bundle.Your lasher can use a single wire or two wires simultane-ously (often called “double-lashing”) wherever extrastrength is desired. Unlike other machines, the balance ofa GMP lasher is not adversely affected by the amount ofwire loaded in either magazine. There are two rubber strand drive wheels mounted in theforward part of the machine in the drive housing andgeared directly to the rotatable drum. A smaller trailerwheel located in the rear of the carriage supports the rearend of the lasher on the strand. Maximum traction is pro-vided by forcing the strand into the groove of the two rub-ber drive wheels by means of a tensioning device actuatedthrough a system of levers. This feature provides uniformtraction regardless of the angle between the pulling lineand the strand. Adjustable rear gates & cable lifter The rear cable lifter rollers are adjustable vertically toaccommodate cables of various diameters and are held inthe open position by a spring catch on each side. To openthe rear cable lifter loosen the bottom knurled knob suffi-ciently to swing free. Swing both gates open until thespring catches are engaged. DO NOT force the gates openpast the point of engagement of the spring catches toavoid deforming the springs.To adjust the rear cable lifter, open the rear cable lifter,and loosen the bottom knurled knob sufficiently to swingfree. Raise or lower the cable lifter rollers on each side byturning the knurled knobs at the top of each verticaladjusting screw until the desired height is obtained.Observe that the rollers are in proper alignment and swingthe bottom knurled knob up into the closed position andtighten securely.

10

Placing the lasher on the strand 1. Open the rear cable lifter, adjust it to its lowest

position and close it.2. The strand tensioning roller assembly should be in the

open position, placed against the side of the aluminumhousing. This is done by depressing the lever projectingup through top of cover of gear unit and turning itclockwise to the open position.

3. Attach a handline to the strand and to the lasher handle and raise the lasher to the strand by means of the handline.

4. With the machine at the required height, open the rearcable lifter past the spring lock and place the lasher onthe strand. Also, attach one of the snap hooks on thelasher tow bridle (rope) to a pulling eye and the otherhook to the strand as a tether.

5. Engage the strand tension roller assembly by pressingthe lever all the way down and turning it counterclock-wise, allowing it to rise. When the strand tension rollerassembly is in the engaged position, the end of its sup-porting casting is engaged in the grooved guide on theinside of the gear housing.

6. Raise the cable to the strand (by hand), close rear cable lifter and let the cable rest on the rollers.Estimate the amount the rollers should be raised to elevate the cable to within 1⁄4 in. (6 mm) of thestrand. Lift the cable slightly (by hand), open thecable lifter, lower the cable clear of the opening andturn the adjusting knobs on top of the threaded postsuntil the lifter is raised the desired amount. Raise thecable (by hand) and close the lifter.

7

GMP G Lasher

8 9

Front gate & pulling eye The front cable lifter or gate is opened by releasing a latch.When in the open position, this locks the drum automati-cally when its cable slot registers with the slots in the car-riage. The drum is free to revolve when the front cablelifter is closed. The rear cable lifter is held in the openposition by means of spring catches on each side. There are two pulling eyes located forward of the frontcable lifter. These eyes also function as the connectionpoint for the towing bridle when used as a tether to pre-vent the lasher from being accidentally dropped whiletransferring around a pole or other obstruction. Strand tensioning mechanism The strand tensioning mechanism works through a systemof levers. When engaged and locked under the strand, itprovides uniform traction through a wide range of pullingline and strand angles.Automatic brake The anti-backroll brake is a ratchet device which operatesautomatically when the lasher stops and tension is removedfrom the towing line, and is released when towing isresumed. It is not necessary to maintain tension in the tow-ing line when the lasher is not in motion. The automaticbrake will be released when the towing eye assembly ispressed toward the rear of the lasher. To move the lasherbackwards, first clamp the lashing wire to the strand. If thelasher is within reach, release the brake by pushing backagainst the towing assembly. If it is not within reach andthe towing line is attached to the towing eye assembly,release the brake by pulling back on the towing line. Whenthe towing line is attached to one of the pulling eyes on thefront of the gear housing a separate line attached to thetowing eye assembly may be used to release the brake.

As we stated in the beginning of this book, you shouldNEVER operate a lasher unless you’ve been properlytrained in advance, or are being directed by a properlytrained linesperson who is responsible for your work.However, you should find this section of the book helpfulin remembering the right sequence of steps to take inusing your lasher.

Using yourG Lasher

Preparing a lashing wire coil1. Remove the lasher from its case. Remember! It weighs

71 lbs. (32 kgs).2. Cut and remove the coil binding holding the looped end

of the wire at the coil eye or center (inside end) of coil.3. Cut and remove two opposite bindings. Do not cut the

other two bindings.4. Pull out the looped end of the wire until the first turn

is tight against the binding, and cut off the loop. Pullout about 12 in. (30 cm) of wire from the inside of thecoil. The loose end should come out of the face side of the coil.

5. Cut off the loop on the outside end of the lashing wireto prevent snarling.

6. If the coils are installed aloft, see that the strand ten-sion roller is engaged under the strand, the rear cablelifter is closed, the front cable lifter is open and therotating drum locked.

7. Loosen the wing nut on the cover latch and open thelatch. The cover will open automatically.

8. Place the coil in the magazine. The top side of the coil should be toward the open side of the magazine.Position the coil with the two coil bindings in therecesses. Feed the free (inside) end of the wire fromthe center of the coil through the throat in the coverand over the grooved pulley in the hinged cover of the magazine.

9. Close the cover, latch, and tighten the wing nut untilthe cover contacts the coil lightly.

10. Cut the two remaining bindings and remove them.11. Tighten the wing nut as far as it will go by hand.

Do not use pliers.12. Thread the lashing wire around the snubbing pulleys

in the direction indicated by the arrows and thenthrough the wire guide roller.

13. The front lifter of the lasher should be left open andthe drum in the locked position as the machine wasremoved from the lasher case.

GMP G Lasher

8 9

Front gate & pulling eye The front cable lifter or gate is opened by releasing a latch.When in the open position, this locks the drum automati-cally when its cable slot registers with the slots in the car-riage. The drum is free to revolve when the front cablelifter is closed. The rear cable lifter is held in the openposition by means of spring catches on each side. There are two pulling eyes located forward of the frontcable lifter. These eyes also function as the connectionpoint for the towing bridle when used as a tether to pre-vent the lasher from being accidentally dropped whiletransferring around a pole or other obstruction. Strand tensioning mechanism The strand tensioning mechanism works through a systemof levers. When engaged and locked under the strand, itprovides uniform traction through a wide range of pullingline and strand angles.Automatic brake The anti-backroll brake is a ratchet device which operatesautomatically when the lasher stops and tension is removedfrom the towing line, and is released when towing isresumed. It is not necessary to maintain tension in the tow-ing line when the lasher is not in motion. The automaticbrake will be released when the towing eye assembly ispressed toward the rear of the lasher. To move the lasherbackwards, first clamp the lashing wire to the strand. If thelasher is within reach, release the brake by pushing backagainst the towing assembly. If it is not within reach andthe towing line is attached to the towing eye assembly,release the brake by pulling back on the towing line. Whenthe towing line is attached to one of the pulling eyes on thefront of the gear housing a separate line attached to thetowing eye assembly may be used to release the brake.

As we stated in the beginning of this book, you shouldNEVER operate a lasher unless you’ve been properlytrained in advance, or are being directed by a properlytrained linesperson who is responsible for your work.However, you should find this section of the book helpfulin remembering the right sequence of steps to take inusing your lasher.

Using yourG Lasher

Preparing a lashing wire coil1. Remove the lasher from its case. Remember! It weighs

71 lbs. (32 kgs).2. Cut and remove the coil binding holding the looped end

of the wire at the coil eye or center (inside end) of coil.3. Cut and remove two opposite bindings. Do not cut the

other two bindings.4. Pull out the looped end of the wire until the first turn

is tight against the binding, and cut off the loop. Pullout about 12 in. (30 cm) of wire from the inside of thecoil. The loose end should come out of the face side of the coil.

5. Cut off the loop on the outside end of the lashing wireto prevent snarling.

6. If the coils are installed aloft, see that the strand ten-sion roller is engaged under the strand, the rear cablelifter is closed, the front cable lifter is open and therotating drum locked.

7. Loosen the wing nut on the cover latch and open thelatch. The cover will open automatically.

8. Place the coil in the magazine. The top side of the coil should be toward the open side of the magazine.Position the coil with the two coil bindings in therecesses. Feed the free (inside) end of the wire fromthe center of the coil through the throat in the coverand over the grooved pulley in the hinged cover of the magazine.

9. Close the cover, latch, and tighten the wing nut untilthe cover contacts the coil lightly.

10. Cut the two remaining bindings and remove them.11. Tighten the wing nut as far as it will go by hand.

Do not use pliers.12. Thread the lashing wire around the snubbing pulleys

in the direction indicated by the arrows and thenthrough the wire guide roller.

13. The front lifter of the lasher should be left open andthe drum in the locked position as the machine wasremoved from the lasher case.

GMP G Lasher

Lashing wire magazines & capacities The lasher has two magazines for loading of lashing wire;each can hold a coil of .065 in. x 450 ft. (1.65 mm x 137 m)wire. Note: .045 in. x 1200 ft. (1.1mm x 365 m) coils maybe used as an alternate. Each magazine has two rollers forguiding and tensioning wire during lashing. The wire coilsare held stationary in the magazines, with the wire feedingfrom the center of the coil eye through a throated hole andover a guiding roller; it is then threaded around the rollersand wound onto the cable/strand bundle.Your lasher can use a single wire or two wires simultane-ously (often called “double-lashing”) wherever extrastrength is desired. Unlike other machines, the balance ofa GMP lasher is not adversely affected by the amount ofwire loaded in either magazine. There are two rubber strand drive wheels mounted in theforward part of the machine in the drive housing andgeared directly to the rotatable drum. A smaller trailerwheel located in the rear of the carriage supports the rearend of the lasher on the strand. Maximum traction is pro-vided by forcing the strand into the groove of the two rub-ber drive wheels by means of a tensioning device actuatedthrough a system of levers. This feature provides uniformtraction regardless of the angle between the pulling lineand the strand. Adjustable rear gates & cable lifter The rear cable lifter rollers are adjustable vertically toaccommodate cables of various diameters and are held inthe open position by a spring catch on each side. To openthe rear cable lifter loosen the bottom knurled knob suffi-ciently to swing free. Swing both gates open until thespring catches are engaged. DO NOT force the gates openpast the point of engagement of the spring catches toavoid deforming the springs.To adjust the rear cable lifter, open the rear cable lifter,and loosen the bottom knurled knob sufficiently to swingfree. Raise or lower the cable lifter rollers on each side byturning the knurled knobs at the top of each verticaladjusting screw until the desired height is obtained.Observe that the rollers are in proper alignment and swingthe bottom knurled knob up into the closed position andtighten securely.

10

Placing the lasher on the strand 1. Open the rear cable lifter, adjust it to its lowest

position and close it.2. The strand tensioning roller assembly should be in the

open position, placed against the side of the aluminumhousing. This is done by depressing the lever projectingup through top of cover of gear unit and turning itclockwise to the open position.

3. Attach a handline to the strand and to the lasher handle and raise the lasher to the strand by means of the handline.

4. With the machine at the required height, open the rearcable lifter past the spring lock and place the lasher onthe strand. Also, attach one of the snap hooks on thelasher tow bridle (rope) to a pulling eye and the otherhook to the strand as a tether.

5. Engage the strand tension roller assembly by pressingthe lever all the way down and turning it counterclock-wise, allowing it to rise. When the strand tension rollerassembly is in the engaged position, the end of its sup-porting casting is engaged in the grooved guide on theinside of the gear housing.

6. Raise the cable to the strand (by hand), close rear cable lifter and let the cable rest on the rollers.Estimate the amount the rollers should be raised to elevate the cable to within 1⁄4 in. (6 mm) of thestrand. Lift the cable slightly (by hand), open thecable lifter, lower the cable clear of the opening andturn the adjusting knobs on top of the threaded postsuntil the lifter is raised the desired amount. Raise thecable (by hand) and close the lifter.

7

GMP G Lasher

6

Cable LifterAdjusting Knob

Cable LifterAdjusting Knob

Vertical Cable Rollers

HandleStrand Tensioning RollerLever in closed position

Spring Lock Rear Cable Lifter and Release Knob Spring Lock

7. Pull out sufficient lashing wire for termination andclamp the lashing wire to the strand at least 12 in.(30 cm) behind the lasher.

8. Close the front gate assembly. Remove the tow linesnap hook from the strand and attach the snap hookto the other tow eye of the lasher.

9. The lasher is now prepared to lash cable.Transferring the lasher around a pole or other obstruction

1. Before transferring around a pole, temporarily termi-nate the lashing wire near the pole with a lashing wiregrip, pull out sufficient wire for the final terminationand the cut.

2. Open the front gate all the way.3. Move the lasher forward or backward along the strand

until the drum locks.4. Attach one of the lasher bridle snap hooks to a lasher

towing eye on the front of the machine. Now pass thebridle under the strand, past the obstruction and attachthe other snap hook to another lasher pulling eye.

5. Press down the strand tension roller lever and turn itclockwise to disengage it from the strand.

6. Raise the lasher from the strand and transfer themachine to the strand in the next span following theinstructions beginning in step 5 of the preceding section.

Instructions for over-lashingWhen lashing a cable or cables to an existing cable thesame procedure is followed with one exception. The strandtension roller assembly should be removed so as not tointerfere with existing lasher cable. This is a simple proce-dure which should only be attempted while on the groundand working on a suitably stable work surface.

11

GMP G Lasher

About yourG Lasher

12

Note: Do not set the lasher vertically on the rear gate toavoid damage to the spring catches.1. Remove the four screws holding the gear housing

cover and remove the cover.2. Position the lasher with the gear housing facing to the

right and the rear gate to the left.3. Remove the three #10-25 filister head screws which

will allow the complete strand tension roller assemblyto drop out through the bottom of the gear housing.

4. Reinstall the gear housing cover and your G lasheris now capable of over-lashing cable(s) up to thecapacity of the machine.

Note: Be sure to save the parts. To reinstall simply reversethe above procedure.When placing the lasher into its case, have the front cablelifter assembly open and put the rotor assembly in thelocked position. Keep the lasher in the carrying case at alltimes when not in use. Lubrication advice The gears of the G Lasher are lubricated at the factory witha specially formulated graphite-based lubricant. This lubri-cation will last indefinitely provided that the gear housingis left unopened and uncontaminated by solvent or debris. If, during the course of your G Lasher’s service life, it isever returned to the factory for repair and reconditioning,it will receive a thorough cleaning during disassembly andwill be freshly relubricated as it was when new. Do notattempt to lubricate the gears as improper lubrication cancause eventual slippage due to lubricant flowing to othersurface areas during operation. The only parts whichshould require occasional lubrication with S.A.E. 10 or 20motor oil, are the threads of the rear cable lifter and hingesto keep them operating freely. Wipe off any excess oil.Repairs & maintenance From time to time it may be necessary to make minor fieldrepairs; the following list of parts will prove helpful inordering what you need. However, nobody can give yourlasher as thorough a check-up as the people who builtit...GMP. Our experienced technicians will check everydetail, thoroughly clean and re-lubricate your machine andput your lasher back in like-new shape within 10 workingdays, guaranteed. Just call the factory for full details onour lasher maintenance program.

Look at your G Lasher for a moment. You will see it consists of a rotating drum supported on a carriage; thestrand and cable pass through this carriage during the lashing operation.As you look at the carriage, you will see it also has a forward direct gear drive mechanism, cable and strandrollers, front and rear gates, various pulling eyes and ananti-backroll brake. The major components are made of heat-treated, high-strength aluminum alloy, bronze, stainless or zinc-platedsteel. Sealed aircraft-type, dust-proof ball bearings are onall shafts and the drum, with other moving parts mountedon Oilite bushings. At about 71 lbs. (32 kgs) without wire, your machine’sweight and features give it an optimal strength-to-weightratio for the heavy-duty work of lashing large telephonecable(s) or electrical distribution cables.Cable capacities The G Cable Lasher can be used for securing aerial cablefrom about 21⁄2 in. up to 5 in. (65 - 125 mm) diameter tosuspension strands from 3⁄8 in. to 3⁄4 in. (9 -19 mm) diame-ter with a spiral lashing of .065 in. (1.65 mm) stainlesssteel lashing wire. (A modification for .045 in. / 1.1 mmstainless steel wire is also available.) The G Lasher has the capability of lashing any number of cables to a singlesuspension strand provided that the entire diameter of thecable bundle not exceed 5 in. (125 mm).

5

Underside of Lasher

Towing Bridle

StrandTensioning

Roller (closed)

Strand DriveWheels

Front Gate and Latch

Rear StrandRoller

Rear CableLifter inclosed position

GMP G Lasher

4

Importantprecautions

The proposed cable run should be pre-surveyed to deter-mine the terrain and field conditions that will be encoun-tered in the lashing operation. Among those factors to beconsidered (not by limitation) are:(a) vehicle & pedestrian safety (b) condition of poles, anchors, guys and strand (c) proper bonding and grounding of strand

and attachments (d) obstructions such as trees, limbs and

drop wires (e) clearances and separations on poles shared by

other utilities (f) clearances over roads, driveways, walkways

and crossings Protect your work site with advance warning devices atstrategic points to warn traffic and pedestrians of theobstruction in the area. Check your machine first! Prior to using the machine, check that it is in good repair,that all of the parts and mechanical assemblies are intactand in good working order. If the machine has not beenproperly maintained it may well be unsafe to use and poseunnecessary risk to the user. GMP Lashers can be profes-sionally repaired and/or overhauled at the factory withquick turnaround and minimal downtime. Use the proper safety equipment! Before working aloft, inspect all your climbing and safetyequipment to make certain it is in good repair. And whileyou are aloft, ALWAYS wear a body belt with a safetystrap securely attached to help prevent you from falling. Also, you should always raise and lower your lasher onlywith a proper aerial handline (such as our 68590 or08192) or a truck lift. Use the bridle assembly at pole transfers! When transferring the lasher around a pole or otherobstruction, use the bridle assembly as a tether to preventdamage to the machine in case it is dropped. This alsoallows you to concentrate on your own safety first ratherthan the safety of the machine.

13

G1 Gear Housing 05475G2 Gear Housing Cover 05525G3 Towing Bridle Assembly 07357G4 Towing Bridle Stop Bolt 09007

Towing Bridle Stop Nut 03569G5 Strand Drive Wheel 05486G6 Strand Drive Wheel Nut 03039G7 Pulling Eye 13398G8 Top Roller Assembly Screw 03305

Top Roller Assembly Washer 16005G9 Top Roller Assembly 15192G10 Pulling Eye Screw 16041

Pulling Eye Nut 02854G11 Clamping Washer 05485G12 Rear Strand Drive Shaft 07363

(shaft, gears & bearing)G13 Front Strand Drive Shaft 07364

(shaft, gear & bearing)G14 Ratchet Pawl Spring 03037G15 Rubber Sleeve 03041G16 Steel Guide 05502G17 Shoulder Screw 05527

Shoulder Nut 03272G18 Ratchet Brake Pawl 07346G19 Idler Gear 05496G20 Oilite Bearing 03056G21 Idler Gear Shaft 03038G22 Clamping Nut 03030G24 Ratchet Brake Collar 05531G25 Ratchet Brake Copper Latch 05532G26 Tru-Arc Ring #50 03277G27 Drive Shaft 05510G28 Collar 05535G29 Timing Gear 25224G30 Drive Shaft Gear Assy. 07362G31 Spring Screw 03040G32 Towing Bridle Pivot 05501G33 Spacer 05534G34 Stop Pin 09463G35 Retaining Ring Screw 03291

Retaining Ring Lockwasher 03260G36 88013 Bearing 03054G37 Bearing Retainer Rings

3 ea. required 030242 ea. required 030251 ea. required 24825

G38 Tru-Arc Ring #125 09447G39 Towing Bridle Spring 05530G40 Pivot Retaining Ring 15220G41 5-40 x 3⁄4 Filister Screw 17677G42 5-40 x 5⁄8 Flathead Screw 09442G43 Strand Lifter Assembly 07302G44 10-24 x 5⁄8 Filister Screw 03298G45 Wire Coil Door Assembly 07305G46 Door Pulley 14413G47 Door Pulley Bearing 09435G48 Door Release Spring 24991G50 Handle 05506G51 1⁄4 x 20 Flathead Screw 03271G52 .065 in. Wire Pulley 28147 G53 Front Plate Assembly 15163G54 Left Lock 03121G55 Right Lock 03120G56 10-24 x 1⁄2 Filister Screw 03298G57 Locking Bolt 07580G58 Locking Bolt Spring 03089G59 Locking Bolt Retainer 03090G60 Locking Bolt Retainer Nut 03087G61 Rotor Body 05474G62 Ring Gear 05491G63 1⁄4-20 x 1 Allen Screw 17542G64 Spacer 05481G65 Strand Roller w/Bearings 26076G66 Strand Roller Shaft 05495G67 1⁄4-20 x 1 Flathead Screw 03271G68 Rear Plate Assembly 07307G69 Swing Bolt Spring 03078G70 Swing Bolt Assembly 07547G71 Front Bearing Ring 05478G72 Rear Bearing Ring 05479G73 6-32 x 3⁄8 Filister Screw 03293G74 Ball Bearing 88038 26051G75 Eccentric Screw 03091G76 Wire Guide Assembly 07312G77 10-24 x 7⁄8 Filister Screw 03300G78 Front Cable Lifter Assembly 07319G79 Hex Head Screw 03375G80 10-24 x 1-1⁄8 Filister Screw 09440G81 10-24 x 3⁄4 Filister Screw 03299G82 Side Roller Assembly 15191G83 10-24 x 3⁄4 Filister Screw 03299G84 Rear Lifter Assembly 07310

GMP G Lasher

3

Read me first!

This manual covers the care, operation and maintenanceof your GMP model G Cable Lasher, which you can use tolash cables from about 21⁄2 in. up to 5 in. (125 mm) dia. tosuspension strand, or smaller cable sizes to an existinglashed cable and strand (a process called “over-lashing”). This machine is intended for use ONLY by properly trainedjourney linespeople or other craftspeople under the DIRECTsupervision and responsibility of those individuals.As such, this manual’s scope is specifically limited to the machine’s functions, and no attempt is made todescribe the proper procedure for placing and lashing aerial cable plant.We cannot be held liable for any direct or indirect con-sequences arising from use of the product by any indi-viduals not already properly trained in its use. If you would like information about professional trainingprograms, call us for details.

14

G2

G1

G5G5

G6

G8

G7 G9

G11

G12

G10

G13G15

G14

G22G27

G27

G28

G29

G32

G32

G38

G38

G31G41

G42

G40

G39

G43

G44

G33

G35

G26

G34

G37

G25 G24 G23

G36

G20

G21

G19 G18

G17G16

G3

G4

G30

GMP G Lasher

15

G61

G62 G69

G63 G70

G65

G66

G67

G64

G60

G59

G58

G57

G56

G54

G55

G53G68

G75G74

G72

G73

G71

G45

G48

G52

G51 G50

G47G46

G46

G49

G45

G84G78

G81

G80G79 G76

G77

G83

G82

Table ofcontents

Read me first! . . . . . . . . . . . . . . . . . . . 3Important precautions . . . . . . . . . . . . 4Check your machine first . . . . . . . . . . . . . . . . . . . . . . . . 4Use the proper safety equipment . . . . . . . . . . . . . . . . . . 4Use the bridle assembly at pole transfers. . . . . . . . . . . . 4

About your G Lasher . . . . . . . . . . . . . 5Cable capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Lashing wire magazines and capacities . . . . . . . . . . . . . 7Adjustable rear gates and cable lifter . . . . . . . . . . . . . . . 7Front gate and pulling eye . . . . . . . . . . . . . . . . . . . . . . . 8Strand tensioning mechanism . . . . . . . . . . . . . . . . . . . . 8Automatic brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using your G Lasher. . . . . . . . . . . . . . 8Preparing a lashing wire coil. . . . . . . . . . . . . . . . . . . . . . 9Placing the lasher on the strand . . . . . . . . . . . . . . . . . . 10Transferring the lasher around a pole or other obstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Instructions for over-lashing . . . . . . . . . . . . . . . . . . . . 11Lubrication advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Repairs and maintenance . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix: Parts summary . . . . . . . . 13

2

GeneGeneral Machine Productsral Machine Products (KT), LLC 3113111 1 Old Lincoln Hwy TrevTrevose, PA 190ose, PA 19053 USATELTEL:: 215-357-5500FAFAX: 21X: 215-5-357357--66216216 E-E-MAMAIILL: in: inffoo@[email protected] WEB: htWEB: http:tp://w//wwwww.GM.GMPPttoolools.s.comcom

GMP reserves the right, without notice, to make changesto equipment design or components as progress inengineering or manufacturing methods may warrant.