29/09/2004Steinbeis Transfercentre Biomedical Engineering 1 OZONE-SAFE Innovative system for...

-

Upload

herbert-richardson -

Category

Documents

-

view

219 -

download

1

Transcript of 29/09/2004Steinbeis Transfercentre Biomedical Engineering 1 OZONE-SAFE Innovative system for...

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

1

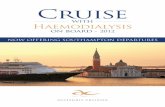

OZONE-SAFE

Innovative system for Haemodialysis Equipment

Disinfection

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

2

OZONE-SAFE

Innovative system for haemodialysis equipment disinfection:

Compact, integrated, totally pre-assembled instrument

Easy to be integrated in haemodialysis equipment

Quick installation in little space

Compact container, mounted on table, wall or ground

Electrical / mechanical section easily accessible

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

3

OZONE-SAFE operational requirements

6 Fresenius haemodialysis machines

2 distribution ringpipes: RO water / ozonated water

Ozonated water circulating

Consumption of ozonated water: 6 x 0.6 L/min = 0.216 m3/h

Dose: 3 mg/L ozone in water

Ozone production: 0.65 g/h => 2 g/h designed

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

4

HDM

buffertank

RO-plant

OzoneSafe

HDM

HDM

HDM

HDM

HDM

waste water

tap water

HDM…haemodialysis machine

OZONE-SAFE System Concept

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

5

OZONE-SAFE components

Dry air

Waste water

Heat

Water+ ozone

Feed gas+ ozone

RO water

Ozonegenerator

Contact system

Ozonedestruct.

Haemodialysisequipment

Off-gas

Electric power

Measurement& Control unit

Prototype

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

6

Dielectric barrier discharge

High Voltage Electrode

Discharge Gap Dielectric Barrier

Ground Electrode

High

Voltage

AC

Generator

Micro discharges: Duration 10 ns, Diameter 100 m

~

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

7

OZONE-SAFE ozone generator

High-voltagetransformer

Electricpower

Feed gas+ ozone

Dry air /oxygen

Discharge cell

Coolingsystem

Frequencyconverter

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

8

OZONE-SAFE PrototypeFlow diagram

diaphragmpump

air dryer

air

gas flowmeter filter

0.3, 5

dischargetubes (ozone)

ozoneconc.meter

air + ozone

ozonedestruction backpressure

valve air

membranecontactsystem

pressuresensor

inlet valve

gearpump

waterflow

ringfeed

ring reflux

ROwater

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

10

OZONE-SAFE tests:ozone production

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

0 0,5 1 1,5

air flow SL/min

O3 % wt 1 bar

prod rate g/h 1 bar

O3 % wt 1,7 bar

prod rate g/h 1,7 bar

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

11

OZONE-SAFE tests:test setup

RO water inlet (6 bar gauge)

OZONE SAFE

prototype

V3

V1

V2

Ring pipe

Stub 1

Stub 2

RO water0.5 – 1.5 bar g

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

12

OZONE-SAFE tests:ozone concentration in water, stubs closed

0

2

4

6

8

10

12

0 10 20 30 40 50 60

Cgas [g/Nm³]

Cli

qu

id [

mg

/L]

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

13

OZONE-SAFE tests:typical photometer readout

-0,01

0,09

0,19

0,29

0,39

0,49

0,59

190 210 230 250 270 290 310 330 350

wavelength [nm]

exti

nct

ion

A

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

14

OZONE-SAFE tests:draining via stubs

0

1

2

3

4

5

6

7

0 1 2 3 4 5 6 7

drain flow [L/min]

Cli

qu

id [

mg

/L]

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

15

-0,05

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,00 100,00 200,00 300,00 400,00 500,00 600,00 700,00

time [s]

exti

nct

ion

OZONE-SAFE tests:ozone conc. in water, step response

29/09/2004 Steinbeis Transfercentre Biomedical Engineering

16

OZONE-SAFEadvantages

• Complete electric and hydraulic system contained in small cabinet

• Gas cylinders for feed gas not required

• Cooling water for ozone generator not required

• Lightweight membrane contactor produces bubblefree ozonated water

• Supply of up to 6 haemodialysis machines with Cliquid > 3 mg/L