266NR_2010-03

-

Upload

ricardo-argentton-ficanha -

Category

Documents

-

view

214 -

download

1

Transcript of 266NR_2010-03

Survey of Materials and Equipment at Works for the Classification of

Ships and Offshore Units

March 2010

Rule Note NR 266 DT R02 E

Marine Division 92571 Neuilly sur Seine Cedex – France

Tel: + 33 (0)1 55 24 70 00 – Fax: + 33 (0)1 55 24 70 25 Marine website: http://www.veristar.com Email: [email protected]

���� 2010 Bureau Veritas - All rights reserved

ARTICLE 1

1.1. - BUREAU VERITAS is a Society the purpose of whose Marine Division (the "Society") is the classi-fication (" Classification ") of any ship or vessel or structure of any type or part of it or system therein col-lectively hereinafter referred to as a "Unit" whether linked to shore, river bed or sea bed or not, whetheroperated or located at sea or in inland waters or partly on land, including submarines, hovercrafts, drillingrigs, offshore installations of any type and of any purpose, their related and ancillary equipment, subseaor not, such as well head and pipelines, mooring legs and mooring points or otherwise as decided by theSociety.

The Society:• prepares and publishes Rules for classification, Guidance Notes and other documents (“Rules”);• issues Certificates, Attestations and Reports following its interventions (“Certificates”);• publishes Registers.

1.2. - The Society also participates in the application of National and International Regulations or Stand-ards, in particular by delegation from different Governments. Those activities are hereafter collectively re-ferred to as " Certification ".1.3. - The Society can also provide services related to Classification and Certification such as ship andcompany safety management certification; ship and port security certification, training activities; all activi-ties and duties incidental thereto such as documentation on any supporting means, software, instrumen-tation, measurements, tests and trials on board.

1.4. - The interventions mentioned in 1.1., 1.2. and 1.3. are referred to as " Services ". The party and/or itsrepresentative requesting the services is hereinafter referred to as the " Client ". The Services are pre-pared and carried out on the assumption that the Clients are aware of the International Maritimeand/or Offshore Industry (the "Industry") practices.1.5. - The Society is neither and may not be considered as an Underwriter, Broker in ship's sale or char-tering, Expert in Unit's valuation, Consulting Engineer, Controller, Naval Architect, Manufacturer, Ship-builder, Repair yard, Charterer or Shipowner who are not relieved of any of their expressed or impliedobligations by the interventions of the Society.

ARTICLE 22.1. - Classification is the appraisement given by the Society for its Client, at a certain date, following sur-veys by its Surveyors along the lines specified in Articles 3 and 4 hereafter on the level of compliance ofa Unit to its Rules or part of them. This appraisement is represented by a class entered on the Certificatesand periodically transcribed in the Society's Register.

2.2. - Certification is carried out by the Society along the same lines as set out in Articles 3 and 4 hereafterand with reference to the applicable National and International Regulations or Standards.

2.3. - It is incumbent upon the Client to maintain the condition of the Unit after surveys, to presentthe Unit for surveys and to inform the Society without delay of circumstances which may affect thegiven appraisement or cause to modify its scope.2.4. - The Client is to give to the Society all access and information necessary for the safe and efficientperformance of the requested Services. The Client is the sole responsible for the conditions of presenta-tion of the Unit for tests, trials and surveys and the conditions under which tests and trials are carried out.

ARTICLE 33.1. - The Rules, procedures and instructions of the Society take into account at the date of theirpreparation the state of currently available and proven technical knowledge of the Industry. Theyare not a standard or a code of construction neither a guide for maintenance, a safety handbookor a guide of professional practices, all of which are assumed to be known in detail and carefullyfollowed at all times by the Client.Committees consisting of personalities from the Industry contribute to the development of those docu-ments.3.2. - The Society only is qualified to apply its Rules and to interpret them. Any reference to themhas no effect unless it involves the Society's intervention.3.3. - The Services of the Society are carried out by professional Surveyors according to the applicableRules and to the Code of Ethics of the Society. Surveyors have authority to decide locally on matters re-lated to classification and certification of the Units, unless the Rules provide otherwise.

3.4. - The operations of the Society in providing its Services are exclusively conducted by way ofrandom inspections and do not in any circumstances involve monitoring or exhaustive verifica-tion.

ARTICLE 4

4.1. - The Society, acting by reference to its Rules:• reviews the construction arrangements of the Units as shown on the documents presented by the Cli-

ent;• conducts surveys at the place of their construction;• classes Units and enters their class in its Register;• surveys periodically the Units in service to note that the requirements for the maintenance of class are

met.

The Client is to inform the Society without delay of circumstances which may cause the date or theextent of the surveys to be changed.

ARTICLE 55.1. - The Society acts as a provider of services. This cannot be construed as an obligation bearingon the Society to obtain a result or as a warranty.5.2. - The certificates issued by the Society pursuant to 5.1. here above are a statement on the levelof compliance of the Unit to its Rules or to the documents of reference for the Services providedfor.In particular, the Society does not engage in any work relating to the design, building, productionor repair checks, neither in the operation of the Units or in their trade, neither in any advisory serv-ices, and cannot be held liable on those accounts. Its certificates cannot be construed as an im-plied or express warranty of safety, fitness for the purpose, seaworthiness of the Unit or of its valuefor sale, insurance or chartering.5.3. - The Society does not declare the acceptance or commissioning of a Unit, nor of its construc-tion in conformity with its design, that being the exclusive responsibility of its owner or builder,respectively.

5.4. - The Services of the Society cannot create any obligation bearing on the Society or constitute anywarranty of proper operation, beyond any representation set forth in the Rules, of any Unit, equipment ormachinery, computer software of any sort or other comparable concepts that has been subject to any sur-vey by the Society.

ARTICLE 66.1. - The Society accepts no responsibility for the use of information related to its Services which was notprovided for the purpose by the Society or with its assistance.

6.2. - If the Services of the Society cause to the Client a damage which is proved to be the directand reasonably foreseeable consequence of an error or omission of the Society, its liability to-wards the Client is limited to ten times the amount of fee paid for the Service having caused thedamage, provided however that this limit shall be subject to a minimum of eight thousand (8,000)Euro, and to a maximum which is the greater of eight hundred thousand (800,000) Euro and oneand a half times the above mentioned fee.The Society bears no liability for indirect or consequential loss such as e.g. loss of revenue, lossof profit, loss of production, loss relative to other contracts and indemnities for termination of oth-er agreements.6.3. - All claims are to be presented to the Society in writing within three months of the date when the Serv-ices were supplied or (if later) the date when the events which are relied on of were first known to the Client,and any claim which is not so presented shall be deemed waived and absolutely barred. Time is to be in-terrupted thereafter with the same periodicity.

ARTICLE 77.1. - Requests for Services are to be in writing.

7.2. - Either the Client or the Society can terminate as of right the requested Services after givingthe other party thirty days' written notice, for convenience, and without prejudice to the provisionsin Article 8 hereunder. 7.3. - The class granted to the concerned Units and the previously issued certificates remain valid until thedate of effect of the notice issued according to 7.2. here above subject to compliance with 2.3. here aboveand Article 8 hereunder.

7.4. - The contract for classification and/or certification of a Unit cannot be transferred neither assigned.

ARTICLE 88.1. - The Services of the Society, whether completed or not, involve, for the part carried out, the paymentof fee upon receipt of the invoice and the reimbursement of the expenses incurred.

8.2. Overdue amounts are increased as of right by interest in accordance with the applicable leg-islation.8.3. - The class of a Unit may be suspended in the event of non-payment of fee after a first unfruitfulnotification to pay.

ARTICLE 9

9.1. - The documents and data provided to or prepared by the Society for its Services, and the informationavailable to the Society, are treated as confidential. However:• clients have access to the data they have provided to the Society and, during the period of classifica-

tion of the Unit for them, to the classification file consisting of survey reports and certificates whichhave been prepared at any time by the Society for the classification of the Unit;

• copy of the documents made available for the classification of the Unit and of available survey reportscan be handed over to another Classification Society, where appropriate, in case of the Unit's transferof class;

• the data relative to the evolution of the Register, to the class suspension and to the survey status of theUnits, as well as general technical information related to hull and equipment damages, are passed onto IACS (International Association of Classification Societies) according to the association workingrules;

• the certificates, documents and information relative to the Units classed with the Society may bereviewed during certificating bodies audits and are disclosed upon order of the concerned governmen-tal or inter-governmental authorities or of a Court having jurisdiction.

The documents and data are subject to a file management plan.

ARTICLE 1010.1. - Any delay or shortcoming in the performance of its Services by the Society arising from an eventnot reasonably foreseeable by or beyond the control of the Society shall be deemed not to be a breach ofcontract.

ARTICLE 1111.1. - In case of diverging opinions during surveys between the Client and the Society's surveyor, the So-ciety may designate another of its surveyors at the request of the Client.

11.2. - Disagreements of a technical nature between the Client and the Society can be submitted by theSociety to the advice of its Marine Advisory Committee.

ARTICLE 1212.1. - Disputes over the Services carried out by delegation of Governments are assessed within theframework of the applicable agreements with the States, international Conventions and national rules.

12.2. - Disputes arising out of the payment of the Society's invoices by the Client are submitted to the Courtof Nanterre, France.

12.3. - Other disputes over the present General Conditions or over the Services of the Society areexclusively submitted to arbitration, by three arbitrators, in London according to the ArbitrationAct 1996 or any statutory modification or re-enactment thereof. The contract between the Societyand the Client shall be governed by English law.

ARTICLE 1313.1. - These General Conditions constitute the sole contractual obligations binding together theSociety and the Client, to the exclusion of all other representation, statements, terms, conditionswhether express or implied. They may be varied in writing by mutual agreement.13.2. - The invalidity of one or more stipulations of the present General Conditions does not affect the va-lidity of the remaining provisions.

13.3. - The definitions herein take precedence over any definitions serving the same purpose which mayappear in other documents issued by the Society.

BV Mod. Ad. ME 545 k - 17 December 2008

MARINE DIVISION

GENERAL CONDITIONS

March 2010

RULE NOTE NR 266

NR 266Survey of Materials and Equipment at

Works for the Classification ofShips and Offshore Units

SECTION 1 GENERAL

SECTION 2 SURVEY OF MATERIALS AND EQUIPMENT AT WORKS

SECTION 3 GENERAL INDEX

2 Bureau Veritas March 2010

Section 1 General

1 Scope of application 5

1.1 Purpose

2 Application 5

2.1 General2.2 Explanatory notes, symbols and abbreviations2.3 Notice regarding column 5 (survey during fabrication)2.4 Notice regarding electrical equipment

Section 2 Survey of Materials and Equipment at Works

1 Summary (tables) 8

1.1 Foreword

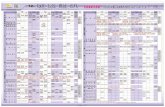

Table 1 Raw Materials and Components for Hull - item A 9Table 2 Hull Outfittings - item B 11Table 3 Fire Protetion, Detection and Extinction Systems - item C 15Table 4 Cargo Environmental Control, IG (Inert Gas) Systems - item D 18Table 5 Main Diesel Engines and their Auxiliaries - item E 20Table 6 Main Turbines, Main Boilers, and their Auxiliaries - item F 24Table 7 Auxiliary Machinery - item G 29Table 8 Cargo Handling and Containment Systems of Liquefied Gas 43

Carriers - item HTable 9 Cargo Handling and Containment Systems of Oil/FLS Tankers or 47

Chemical Tankers - item ITable 10 Fire Fighting Ships - item J 51Table 11 Electrical Equipment - item K 52Table 12 Specific Equipment for Offshore Units - item L 60Table 13 Refrigerating Installation covered by Additional Class Notation 64

REFER (REF-CARGO, REF-CONT, REF-STORE) - item MTable 14 Automation Systems covered by Additional Class Notation 67

AUT (AUT-UMS, AUT-CCS, AUT-PORT, AUT-IMS) - item NTable 15 Lifting Appliances covered (or not covered) by Additional Class 68

Notations ALP, ALM, ALS - item OTable 16 Container Lashing Equipment, covered by Additional Class 71

Notation LASHING - item PTable 17 Installations covered by Additional Class Notation SPM 72

(Single Point Mooring) - item QTable 18 Installations covered by Additional Class Notation DYNAPOS 73

(Dynamic Positioning) - item RTable 19 Pollution Prevention Installation covered by Additional Class 74

Notation Cleanship (CLEANSHIP, CLEANSHIP AWT,CLEANSHIP SUPER, CLEANSHIP SUPER AWT) - item S

Table 20 Availability of Machinery covered by Additional Class Notation AVM 75(AVM-APS, AVM-DPS, AVP-IPS) - item T

March 2010 Bureau Veritas 3

Section 3 General Index

1 Key-words and labels (from A to Z) 76

1.1 Table 1 Key-words and labels (from A to Z)

4 Bureau Veritas March 2010

NR 266, Sec 1

March 2010 Bureau Veritas 5

SECTION 1 GENERAL

1 Scope of application

1.1 Purpose

1.1.1 Rule Note NR266 summarizes the certificationrequirements for materials and equipment (generallyreferred to as « products ») which are covered by the classand used or fitted on board the following units:

• Ships surveyed by the Society during construction inaccordance with the Rules for the Classification of SteelShips (NR467)

• Offshore units surveyed by the Society during construc-tion in accordance with the Rules for the Classificationof Offshore Units (NR445).

2 Application

2.1 General

2.1.1 The requirements for materials and equipment cov-ered by the class and used or fitted on board are given inthe relevant parts of the Rules for the Classification of SteelShips (NR467) or Offshore Units (NR445), as applicable.

2.1.2 In case of inconsistency, the requirements of theapplicable Classification Rules for the concerned unit pre-vail over the provisions of the present NR266.

2.1.3 In the case of a discrepancy between the provisionsof the applicable International and National Regulationsand those of the Society’s Rules, the former takes normallyprecedence. A valid certification to MED96/98/EC asamended for its Annex A1 items is to be recognised for clas-sification purpose.

2.1.4 The Society reserves the right to modify the require-ments given in the present NR266 to formulate new ones orto change their application in order to take into account theparticulars of a given construction, as well as local circum-stances.

2.1.5 The particular conditions and requirements expressedby National Flag Authorities, owners, shipyards or manufac-turers can lead to additional surveys or other services to bespecified and agreed in each case by the concerned parties.

2.1.6 Shipboard tests or tests on board (both at the moor-ings and during sea trials) are not covered by this NR266and are additional to the workshop tests. Refer to relevantprovisions of NR467 and NR445 regarding shipboard tests,i.e. see NR467, Pt C, Ch 1, Sec 15 for Machinery systems(typical).

2.2 Explanatory notes, symbols andabbreviations

2.2.1 Symbols used in the tables implemented in Section 2have the following meaning:

“C” indicates that a product certificate of the Society isrequired with invitation of the Surveyor to attend the testsunless otherwise agreed, in addition to the manufacturer’sdocument stating the results of the tests performed and/orcompliance with the approved type as applicable.

Note 1: An alternative survey scheme (mode I) may be agreed bythe Society with the manufacturer whereby the attendance of theSurveyor will not be required as indicated above. Accordingly, theproduct is covered by a Certificate for Alternative survey (“CA“)delivered by the Society. The appropriate required documents andinformation are detailed in the procedures stated in the agreementfor admission to the alternative survey scheme.

“W” indicates that a manufacturer’s certificate is required,stating the results of the tests performed and/or compliancewith the approved type as applicable.

“D” indicates that manufacturer’s evidence of compliancewith the approved type is required.

“X” indicates that examinations and tests are required.

Where fitted, each additional index h/c/s indicates a spe-cific type of test:

h : Hydraulic pressure test (or equivalent)

c : The test (or a part of it) may be carried out at theyard or on board

s : Non destructive tests as per Rules.

2.2.2 Column 1 (item code)

Column 1 contains an alpha-numeric code for ease of refer-ence equipment or component.

2.2.3 Column 2 (name)

Column 2 contains the name of the equipment or compo-nent with, eventually, its sub-systems.

2.2.4 Column 3 (material certification)

Column 3 indicates the nature of the document that is to besubmitted by the manufacturer or supplier of the concernedmaterial. Consistently with the Rules or agreed specifica-tions, this document includes data such as material tests(chemical composition and mechanical properties), non-destructive tests and surface hardness (if hardened).

NR 266, Sec 1

6 Bureau Veritas March 2010

2.2.5 Column 4 (design assessment index)Column 4 contains the design assessment index. The mean-ing of the letters TA and DA is the following:

TA : Type Approval is requiredDA : Design Appraisal of the product is required; this

one may be carried out at choice:- either for a specific unit, or- using the Type Approval procedure.

Note 1: Where nothing is mentioned in column 4, a design assess-ment of the specific unit is not required.

2.2.6 Columns 5 to 7 (examination and tests)Column 5, column 6 and column 7 summarize the type ofexamination and tests required, and to be carried out by themanufacturer.

a) During fabrication: for welded construction or, as a gen-eral rule, depending on the type of equipment con-cerned, this may include: mechanical tests, NDT,dimensional checks, balancing, etc.

b) After completion: consistently with the relevant activi-ties mentioned in step a) above, this includes the finaltests such as hydraulic test, function test, heat rise tests,dielectric tests, etc.

c) Running tests: this includes function tests at works or onboard, where applicable.

2.2.7 Column 8 (product certification)Column 8 indicates the nature of the document to be sup-plied by the manufacturer of the concerned product.Note 1: The document type is agreed according to the applica-ble certification frame and/or production survey scheme imple-mented. Document type ‘C’ corresponds to products subject toindividual or batch certification by the Society. In case of mass-pro-duced items manufactured in series according to a defined type,document type ‘W’ or ‘D’ may be required as stated at the typeapproval stage.

2.2.8 Column 9 (remarks)Column 9 indicates the remarks (if any) associated to theconcerned equipment or component.

2.3 Notice regarding column 5 (survey dur-ing fabrication)

2.3.1 As a general rule, even if a cross “X” is not fitted in acell under column 5, examination and tests during fabrica-tion may be required with invitation/attendance of the Soci-ety’s Surveyor.

2.4 Notice regarding electrical equipment

2.4.1 Due to the great variety of electrical equipment (itemK), it has not been possible to give herewith the details ofthe surveys to which these electrical equipment are to besubmitted. For certain given types of equipment, specialtype tests leading to their approval are required; the pro-grammes for such type tests are set up for each category ofequipment, together with the requirements for their carryingout, and the conditions of validity of the Type approval cer-tificate are given in the relevant Sections of the Rules for theClassification of Steel Ships (NR467) and Offshore Units(NR445).

As defined in NR467, Pt C, Ch 2, Sec 1, the auxiliaries con-sidered as essential are typically as follows:

1- Equipment for primary ‘essential services’ (serviceswhich need to be maintained in continuous operation):

• steering gear

• actuating systems of controllable pitch propellers

• scavenging air blowers, fuel oil supply pumps, fuelvalve cooling pumps, lubricating oil pumps and coolingwater pumps for main and auxiliary engines and tur-bines necessary for the propulsion

• forced draught fans, feed water pumps, water circulatingpumps, condensate pumps, oil burning installations, forsteam plants or steam turbines ship, and also for auxil-iary boilers on ship where steam is used for equipmentsupplying primary essential services

• azimuth thrusters which are the sole means for propul-sion/steering with lubricating oil pumps, cooling waterpumps

• electrical equipment for electric propulsion plant withlubricating oil pumps and cooling water pumps

• electric generators and associated power sources sup-plying the above equipment

• hydraulic pumps supplying the above equipment

• viscosity control equipment for heavy fuel oil

• control, monitoring and safety devices/systems forequipment for primary essential services

• speed regulators dependent on electrical energy formain or auxiliary engines necessary for propulsion

• starting equipment of diesel engines and gas turbines.

The main lighting system for those parts of the ship nor-mally accessible to and used by personnel and passengersis also considered (included as) a primary essential service.

2.a- Equipment for secondary ‘essential services’ (serviceswhich need not necessarily be in continuous operation):• windlasses

• thrusters

• fuel oil transfer pumps and fuel oil treatment equipment

• lubrication oil transfer pumps and lubrication oil treat-ment equipment

• preheaters for heavy fuel oil

• sea water pumps• starting air and control air compressors

• bilge, ballast and heeling pumps

• fire pumps and other fire-extinguishing medium pumps

• ventilation fans for engine and boiler rooms

• services considered necessary to maintain dangerouscargo in a safe condition

• navigation lights, aids and signals• internal safety communication equipment

• fire detection and alarm systems

• electrical equipment for watertight closing appliances

• electric generators and associated power supplying theabove equipment

• hydraulic pumps supplying the above mentioned equip-ment

NR 266, Sec 1

March 2010 Bureau Veritas 7

• control, monitoring and safety for cargo containmentsystems

• control, monitoring and safety devices/systems forequipment for secondary essential services

• cooling system of environmentally controlled spaces.

2.b- Equipment for secondary ‘essential services’ (servicesfor maintaining conditions of habitability for people onboard):

• cooking

• heating

• domestic refrigeration

• mechanical ventilation

• sanitary and fresh water• electric generators and associated power sources sup-

plying the above equipment.

In the case of installations to be granted an additional classnotation, all the electrical equipment used for these installa-tions is to be considered as assuming an ‘essential service’;such is to be the case, for example, of driving motors forcompressors of refrigerating plants constructed and sur-veyed by the Society, lifting appliances for ships classedwith ALP, ALM, ALS notations, etc.

The Society reserves the right to add other auxiliaries to thislist, whenever deemed necessary and more especially forinstallations of peculiar types.

NR 266, Sec 2

8 Bureau Veritas March 2010

SECTION 2 SURVEY OF MATERIALS AND EQUIPMENT AT

WORKS

1 Summary (tables)

1.1 Foreword

1.1.1 The materials and equipment are organized in differ-ent families labelled “Items” followed by a letter (A to T),and a number for its sub-items where applicable; this con-stitutes an alpha-numeric code for ease of reference equip-ment or component as specified in Sec 1 of this NR266.

For each “Item” (and its sub-items where applicable), thecertification requirements are summarized in a correspond-ing table. These tables are not to be considered as an alter-native to or a substitute to the applicable Classification Rulerequirements. Materials or equipment which are not consid-ered in these tables are to be dealt with as per relevant pro-visions of applicable Classification Rules and/or as percriteria set up in agreement with the Society.

Item Title

Item A

Item B

Item C

Item D

Item E

Item F

Item G

Item H

Item I

Item J

Item K

Item L

Item M

Item N

Item O

Item P

Item Q

Item R

Item S

Item T

Raw Materials and Components for Hull

Hull Outfittings

Fire Protetion, Detection and Extinction Systems

Cargo Environmental Control, IG (Inert Gas) Systems

Main Diesel Engines and their Auxiliaries

Main Turbines, Main Boilers, and their Auxiliaries

Auxiliary Machinery

Cargo Handling and Containment Systems of Liquefied Gas Carriers

Cargo Handling and Containment Systems of Oil/FLS Tankers or Chemical Tankers

Fire Fighting Ships

Electrical Equipment

Specific Equipment for Offshore Units

Refrigerating Installation covered by Additional Class Notation REFER (REF-CARGO, REF-CONT, REF-STORE)

Automation Systems covered by Additional Class Notation AUT (AUT-UMS, AUT-CCS, AUT-PORT, AUT-IMS)

Lifting Appliances covered (or not covered) by Additional Class Notations ALP, ALM, ALS

Container Lashing Equipment, covered by Additional Class Notation LASHING

Installations covered by Additional Class Notation SPM (Single Point Mooring)

Installations covered by Additional Class Notation DYNAPOS (Dynamic Positioning)

Pollution Prevention Installation covered by Additional Class Notation CLEANSHIP (CLEANSHIP, CLEANSHIP AWT,CLEANSHIP SUPER, CLEANSHIP SUPER AWT)

Availability of Machinery covered by Additional Class Notation AVM (AVM-APS, AVM-DPS, AVP-IPS)

March 2010 Bureau Veritas 9

Table 1: Raw Materials and Components for Hull - item A

RAW MATERIALS AND COMPONENTS FOR HULL - ITEM A

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

A1Steel plates, profiles, bars and pipes for main structure C (1) (2) (1) Approval as per NR216 and NR480

(2) See material certification

A2Aluminium alloy plates, profiles, bars and pipes for mainstructure

C (1) (2) (1) Approval as per NR216 and NR480(2) See material certification

A3Filler products for welding (welding consumables) TA (1) W (1) Type approval as per NR216

A4Aluminium alloy rivets for main structure and fixation of alu-minium alloy superstructures on steel hull

C (1) (2) (1) Approval as per NR216(2) See material certification

A5 Transition joints steel / aluminium alloy for fixation of super-structures on steel hull

C TA (1) C (1) Approval as per NR216 and NR480

A6 Stem, stern post, rudder horn skegs and solid rudder pieces inforged or cast steel

C DA X s C

A7Cast steel shaft-brackets C DA X s C

A8

Composite materials DA (1) X (2) X (2) C / D (3)

(1) DA for structural assembly; see provisions of NR546, Sec 8

(2) A representative sample of the structural assembly is to be tested and qualified as per agreed program; relevant tests to be carried out by a testing laboratory accepted by the Society

(3) Document type C or D according to the agreed survey scheme

(4) Type approval or case-by-case approval by the Society; see provisions of NR546, Sec 8

• Adhesives intended for marine structural applications DA (1) W

• Reinforcement fibers TA (4) W

• Resin systems TA (4) W

• Core materials for sandwiches TA (4) W

A9Aluminium alloy castings C (1) (2) (1) Approval as per NR216

(2) See material certification

A10Steel castings C (1) (1) See material certification

March 2010 Bureau Veritas 10

A11Steel forgings C (1) (1) See material certification

A12Pod housing for azipod steering system C DA X s C

A13Thruster tunnel for transverse tunnel thruster system C DA X s C

RAW MATERIALS AND COMPONENTS FOR HULL - ITEM A

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 11

Table 2: Hull Outfittings - item B

HULL OUTFITTINGS - ITEM B

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

B1

Steering gears DA X X (2) C (1) For hydraulic pump casings(2) Under load on board(3) Pumps belonging to class I piping system. See item G31(4) Proof loading of steering chains and rods(5) To comply with class I piping system. See item G26

1- Pumps C (1) DA (3) X h C

2- Cylindrical shell of hydraulic cylinders, rotor housing forrotary vane steering gear

C X h s C

3- Rams, piston rods C X C

4- Tiller, rotor for rotary vane steering gear, quadrant, steeringchains and rods

C X s (4) C

5- Piping system and components (5)

B2

Rudder DA (1) For welded construction(2) For streamlined rudder blade of watertight construction1- Rudder stock, rudder shaft, pintles, coupling bolts C X (1) X C

2- Rudder blade C X X h c (2) C

B3Bower anchors C DA (1) or

TA (2)X s C (1) DA for ordinary anchors

(2) TA for HHP and VHHP anchors

B4Anchor chain cable C (2) (1) X s C (1) Approval as per NR216 and NR480

(2) Additionally the approval of manufacturing process is required for round bars in grades Q2 or Q3

B5 Anchor chain cable accessories (shackles, kenter shacklesand swivels)

C (1) X s C (1) Approval as per NR216 and NR480

B6

Motorized windlasses DA (1) X X (4) X (4) C (1) Or assessment by the mean of type tests according tospecial conditions

(2) See item G26 for piping(3) For electrical motors, refer to item K; for other systems,

refer to relevant provisions of this NR266 and of NR467(4) No load tests at works, and anchoring tests on board as

per agreed program(5) If of welded construction

1- Main shaft C X s C

2- Casing or body, drum / gipsy-wheel, and main load-bearingstructures

C X s (5) X s C

3- Hydraulic systems (2) (3) X h C

March 2010 Bureau Veritas 12

B7

Fibre ropes (1) (2) X s C (1) Include the fibre ropes intended for towing and mooringlines, emergency towing arrangement, cargo handlinggear or similar applications. Exclude the fibre ropes spe-cific for offshore units which are covered in items L15and L16

(2) Requirements as per NR216, Ch 4, Sec 1, [5]

B8 Sea inlets and outlets distance pieces or pad C C (1) (1) For valves more than 100 mm in diameter

B9 Transducer compartment C DA X h C

B10Hawse pipes (1) C X C (1) Cast piece

B11Side scuttles and windows C DA X (1) C (1) Hose test on board

B12Shell doors C DA X s (1) X c C (1) Hose test on board

B13 Hatch covers C DA X s (1) C (1) Hose test on board, for watertight covers

B14Watertight doors C DA X h s (1) C (1) a- at works: hydraulic test for passenger ships

b- on board: hose test

B15 External ramp C DA X s (1) X c C (1) Watertightness as applicable: see item B14

B16 Movable deck and inner ramp C DA X s X c C

B17

Hydraulic power station for handling items B11 to B15 DA X C (1) For electrical motors, refer to item K5; for other systems,refer to relevant provisions of this NR266 and of NR467.For piping, valves and fittings, see items G26 and G27

(2) Material certificate C for class 1 pressure vessels; Material certificate W for class 2 or 3 pressure vessels; See item G30

(3) For pump housing, material certificates (C / W) accord-ing to the piping class. See item G31

(4) See item G28

1- Pumps C / W (3)

X h C

2- Electrical motors (1) (1) X C / W

3- Flexible hose assembly (4) TA X h C

4- Hydraulic Jacks-accumulators C / W (2)

DA X h s X C

HULL OUTFITTINGS - ITEM B

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 13

B18 Mast and king posts for cargo derricks, derricks posts, cranecolumns welded to the ship structure (1)

C DA X s X C (1) See items O1 and O2

B19 Shrouds for item B18 DA X (1) C (1) Breaking test on specimen

B20

Loading instrument or calculator (1) DA or TA (2)

X (3) X (4) C (1) Concerns only ships for which the Rules require a load-ing calculator

(2) a- approval of hardware, unless the system is duplicated(two computers available on board for loading calcula-tions only)b- approval of basic softwarec- approval of application software consisting in dataverification which results in the 'endorsed test condition'

(3) As per provisions of NR467, Pt B, Ch 11, Sec 2, [4](4) Following installation on board with reference to the

approved manual; on board tests as per Rules

B21

Articulations and hydraulic cylinders of split hopper dredgerand split hopper units

DA X X h X (1) For welded construction(2) See item B17

1- Cylinder housing C X (1) X s C

2- Covers C X s C

3- Piston rods, pins of hinges and eyes C X s C

4- Main bolting C X s C

5- Hinge eyes and pins (dock houses and main hinges) C X X s C

6- Hydraulic power station for handling hydraulic cylinders (2) (2) (2) (2) C

B22

Emergency towing arrangement (ETA) C TA X X X C (1) Buoy and line-throwing appliance may be type ap-proved

(2) Certificate W (works’): for the rope only(3) May be type approved

1- Towing pennant / hook W C

2- Chafing gear: chain and associated accessories C C

3- Fairleads W C

4- Strongpoint (inboard end fastening of the towing gear);main framing, stopping device

C C

5- Pick-up gear: rope, buoy, line-throwing appliance (1) W (2)

6- Pedestal roller fairlead W (3)

HULL OUTFITTINGS - ITEM B

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 14

B23

Corrosion protective coating (epoxy or equivalent), in dedi-cated seawater ballast tanks of ships of not less than 500 grosstonnage and double-side skin spaces arranged in bulk carriersof length ≥ 150 m

W (1) TA (2) (1) (1) (1) It is the responsibility of the shipbuilder and the Ownerto choose the coating and have it applied in accor-dance with the manufacturer's requirements

(2) Only for ships assigned with the additional service fea-ture or the additional class notation CPS (WBT): coat-ing system approval as per NR530 CoatingPerformance Standard

B24

Towing equipment - within the scope of service notationTUG (1)

DA (2) X X (5) X (5) C (1) Including towing hook, towing winch, hook quick-re-lease device, winch quick-release device, winch slipdevice - within the scope of service notation TUG(NR467, Pt D, Ch 14)

(2) Or assessment by the mean of type tests according tospecial conditions

(3) See item G26 for piping(4) For electrical motors, refer to item K; for other systems,

refer to relevant provisions of this NR266 and of NR467(5) Function tests / static tests at works, and test trials under

load on board; as per agreed program(6) If of welded construction

1- Hook W X s C

2- Main shaft C X s C

3- Casing or body, drum / gipsy-wheel if any, and main load-bearing structures

C X s (6) X s C

4- Hydraulic systems (3) (4) X h C

HULL OUTFITTINGS - ITEM B

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 15

Table 3: Fire Protection, Detection and Extinction Systems - item C

FIRE PROTECTION, DETECTION AND EXTINCTION SYSTEMS - ITEM C

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

C1

Fire-resisting and fire-retarding divisions and associated doors:Class A, B, H ...

(1) In the case of a discrepancy between the provisions ofthe applicable international and national regulationsand those of the BV Classification Rules, normally theformer take precedence. A valid certification to MED96/98/EC as amended for its Annex A1 items is to berecognised for classification purpose

(2) Document type C or D according to the applicable certifica-tion frame and/or production survey scheme implemented

- fire-resisting and fire-retarding divisions(bulkheads or decks)

TA (1) X C / D (2)

- associated doors W TA (1) X C / D (2)

C2Upholstered furniture, excluding the frame TA (1) X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C3Materials for pipes penetrating A or B class divisions(where they are not of steel or other equivalent material)

TA (1) X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C4Materials other than steel for pipes conveying oil or fuel oil:pipes and fittings, valves, flexible pipe assemblies

W TA (1) X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C5Materials for electrical cables penetrations through A or Bclass divisions

TA (1) X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C6Materials with low flame spread characteristic includingpaints, varnishes and similar, when they are required to havesuch characteristic

TA (1) X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C7Non-combustible materials TA (1) X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C8Vertically supported textiles TA (1) X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C9Primary deck coverings TA (1) X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C10Fixed foam fire-extinguishing systems and associated foam-forming liquids

TA (1) X h s X c C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C11Fixed powder fire-extinguishing systems, including powder TA (1) X h s X c C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

March 2010 Bureau Veritas 16

C12 Flexible pipes and expansion bellows of non-conventionalmaterial for any type of fluid

TA (1) X h s C (1) (1) See item G28

C13Sprinkler heads for automatic sprinkler systems TA (1) X X c C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C14Nozzles for fixed pressure water-spraying fire-extinguishingsystems for machinery spaces, boiler rooms and spaces in-tended for the carriage of vehicles

TA (1) X X c C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C15Sensing heads for automatic fire alarm and fire detection sys-tems

TA (1) X X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C16Fixed fire detection and fire alarm systems (3) TA (1) X X c C / D

(2)(1) See itemC1, remark (1)(2) See item C1, remark (2)(3) See item N4

C17Explosive mixture detecting systems (3) TA (1) X X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)(3) See item N4

C18Portable explosive mixture detecting apparatus TA (1) X X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C19Fixed instruments for measuring the oxygen content for inertgas systems serving cargo tanks

TA (1) X X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C20Portable instruments for measuring the oxygen content for in-ert gas systems serving cargo tanks

TA (1) X X C / D (2)

(1) See item C1, remark (1)(2) See item C1, remark (2)

C21Fire dampers TA (1) X s C (1) See item C1, remark (1)

C22Bedding components TA (1) X C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C23Equivalent water-mist fire-extinguishing systems TA (1) X h s X c C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C24Equivalent fixed gas fire-extinguishing systems TA (1) X h s X c C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

FIRE PROTECTION, DETECTION AND EXTINCTION SYSTEMS - ITEM C

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 17

C25Fixed local application fire-extinguishing systems TA (1) X h s X c C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C26Equivalent water-mist automatic sprinkler systems TA (1) X h s X c C / D

(2)(1) See item C1, remark (1)(2) See item C1, remark (2)

C27 Fire extinguishers TA X C / D (1)

(1) See item C1, remark (2)

C28Surface linings (of bulkheads and ceilings) (1) TA X C / D (1) See item C6

C29Floor coverings (1) TA X C / D (1) See item C6

C30Fire windows TA (1) X C (1) See item C1, remark (1)

C31 Prefabricated fire resisting elements (sanitary blocks for exam-ple)

TA (1) X C (1) See item C1, remark (1)

C32

Fire pumps and their prime movers DA X c (2) C (1) For electrical motors, refer to item K; for other systems, refer to relevant provisions of this NR266 and of NR467Diesel engines as per item E1

(2) Performance test for bilge and fire pumps according to NR467, Pt C, Ch 1, Sec 10, [20.5.1]. See item G31

1- Fire pumps C X s X h C

2- Prime movers (1) (1) X (1) X (1) X (1) C

C33 Fire hydrants, pipes, shore connections, valves and accesso-ries

(1) (1) (1) (1) (1) Requirements according to relevant class of piping; seeitems G26 and G27

C34Fire hoses TA (1) D (1) See item C1, remark (1)

C35Dual-purpose nozzles TA (1) D (1) See item C1, remark (1)

C36

High pressure CO2 fire smothering systems DA X c C (1) Vessels: see item G30(2) Piping: as per relevant provisions of items G26 and

G271- Gas bottles (1) C DA X h s C

2- Distribution systems (2) C / W DA X h s C

C37Low pressure CO2 fire smothering storage systems C DA X h s X c C

FIRE PROTECTION, DETECTION AND EXTINCTION SYSTEMS - ITEM C

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 18

Table 4: Cargo Environmental Control, IG (Inert Gas) Systems - item D

CARGO ENVIRONMENTAL CONTROL, IG (INERT GAS) SYSTEMS - ITEM D

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

D1 Inert gas generator system: boiler flue gas or oil fired inert gasgenerators (1)

C DA X X h s X C (1) See item G15

D2Burning units for item D1 (1) X DA X X C (1) See item G16 (and item F16)

D3Uptake valves of main boilers (1) X DA X h X c C (1) Considered as class 1 piping accessory: see item G27

D4Expansion bellows (1) C TA X C (1) See item G28

D5Inert gas scrubber C (1) DA X X (2) X c C (1) The materials should be adapted to the corrosion resis-

tance with the treated gas(2) See item G30 for pressure vessels

D6Blowers DA X X c C

D7Deck water seal DA X h X c C

D8Non return devices supplementing the deck water seal DA X c C

D9 Discharge pipe from scrubber to overboard C (1) X h c C (1) The materials should be adapted to the corrosion resis-tance with the transported fluid

D10Isolating valves from IG system and cargo tanks (1) C DA X s X h X c C (1) See item H15 or I10 according to the case

D11 Regulating valves (1) DA X h X c C (1) See item G27 for accessories of pipes (valves and fit-tings)

D12

Control and monitoring systems and components(gauge, sensors, oxygen analyser, etc…) (1)

TA X X C / D (2)

(1) See item N5(2) Document type C or D according to the applicable cer-

tification frame and/or production survey scheme im-plemented (in case of mass-produced itemsmanufactured in series according to a defined type:document type as stated at the type approval stage)

March 2010 Bureau Veritas 19

D13Breathing valves or devices TA X (1) X c C (1) Setting verification

D14Inert gas coolers (1) DA X h X C (1) See item G30 for pressure vessels

D15

Other IG Systems / Nitrogen generator system or N2 gas gen-erator system where inert gas is produced by separation of theair into its component gases: i.e. compressed air processedthrough a bundle of hollow fibres, semi-permeable mem-branes or adsorber materials (1)

C DA X h s X C (1) The requirements for inert gas systems given in itemD1, applicable to vessels, piping arrangements, alarmsand instrumentation downstream of the generator, etc.,are to be complied with, as far as applicable

D16

Feed air compressors for item D15 and their prime movers DA X c (1) (1) On board; general examination(2) For electrical motors, refer to item K; for other systems,

refer to relevant provisions of this NR266 and of NR467(3) Together with dryers if any

1- Feed air compressors W X h (3) C

2- Prime movers (2) (2) (2) X (2) X (2) C

D17Air receivers and process tanks for item D15 (1) C DA X h s (2) C (1) See item G30 for pressure vessels

(2) Including calibration of safety devices

D18Synthesis gas modules for item D15 (1) DA X W (1) For special types of process, the Society reserves the

right to add requirements or modify those given in itemD18

D19Feed air treatment system for item D15 (1) W DA X h s C (1) See item G30 for pressure vessels

CARGO ENVIRONMENTAL CONTROL, IG (INERT GAS) SYSTEMS - ITEM D

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 20

Table 5: Main Diesel Engines and their Auxiliaries - item E

MAIN DIESEL ENGINES AND THEIR AUXILIARIES - ITEM E

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

E1

Main and auxiliary diesel engines with D > 300 mm (1)D: Cylinder bore, in mmFor mass-produced engines with D ≤ 300 mm, see item E11

(2) TA X s (3) (4)

X X (5) (6) C (1) Main propulsion engines; engines driving electric gen-erators, including emergency generators; engines driv-ing other auxiliaries essential for safety and navigationand cargo pumps in tankers, when they develop a pow-er P ≥ 110 kW

(2) In addition, material tests may also be required, at theSociety's discretion, for piping and valves for startingair lines and any other pressure piping fitted on the en-gines.

(3) The magnetic particle test of tie rods/stay bolts is to becarried out at each end, for a portion which is at leasttwice the length of the thread

(4) For important structural parts of engines, in addition tothe non-destructive tests specified in this NR266, ex-amination of welded seams by approved methods of in-spection may be required

(5) Type test: stages A, B and C as per NR467, in the pres-ence of a Surveyor of the Society

(6) In addition to the type test, diesel engines are to be sub-jected to works trials, as per NR467, normally witnessedby the Surveyor except where an Alternative InspectionScheme (BV Mode I) has been granted or where other-wise decided by the Society on a case-by-case basis

(7) For items 4, 9 and 10, material tests are also requiredfor parts made of materials other than steel, e.g. alu-minium and its alloys, ductile and spheroidal or nodu-lar graphite cast iron

(8) Material tests for bedplates, frames, crankcases andentablatures are required even if these parts are notwelded and for any material except grey cast iron

(9) If bore > 400 mm(10) Bore > 300 mm

1- Crankshaft C DA X s (11) X C

2- Crankshaft coupling flange (non-integral) for main powertransmissions

C (9) X W

3- Coupling bolts for crankshaft C (9) DA X W

4- Steel piston crowns (7) C (9) X s (12) X W

5- Piston rods C (9) X s (13) X W

6- Connecting rods, together with connecting rod bearingcaps

C X s (14) X W

7- Crossheads C (9) X W

8- Cylinder liners C / CA (10)(21)

X W

9- Steel cylinder covers (7) C / CA (10)(21)

X (12) X W

10- Bedplates of welded construction; plates and transversebearing girders made of forged or cast steel (7) (8)

C X s (11) X W

11- Frames and crankcases of welded construction (8) C X W

12- Entablatures of welded construction (8) C X W

13- Tie rods C / CA (21)

X s (15) X W

14- Shafts and rotors, including blades, for turbochargers C (16) (20) X W

15- Bolts and studs for cylinder covers, crossheads, mainbearings and connecting rod bearings; nuts for tie rods

C / CA (10)(21)

X s (15) X W

16- Steel gear wheels for camshaft drives C (9) X s (15) X W

�17- Cylinder cover, cooling space X h (17) C / W

(22)

March 2010 Bureau Veritas 21

�18- Cylinder liner, over the whole length of cooling space X h C / W

(22)(11) Non-destructive tests: magnetic particle or liquid pene-

trant (all), and ultrasonic (all)(12) Non-destructive tests: magnetic particle or liquid pene-

trant (if bore > 400 mm), and ultrasonic (all)(13) Non-destructive tests: magnetic particle or liquid pene-

trant (if bore > 400 mm) and ultrasonic (if bore > 400 mm)(14) Non-destructive tests: magnetic particle or liquid pene-

trant (all), and ultrasonic (if bore > 400 mm)(15) Non-destructive tests: magnetic particle or liquid pene-

trant (if bore > 400 mm)(16) See NR467, Pt C, Ch 1, Sec 14(17) For forged steel cylinder covers and forged steel piston

crowns, test methods other than hydrostatic testing maybe accepted, e.g. suitable non-destructive tests anddocumented dimensional tests

(18) Where the cooling space is sealed by the piston rod, orby the piston rod and the shell, the pressure test is to becarried out after assembly

(19) Turbocharger air coolers are tested on the water sideonly

(20) Turbochargers: see item E12(21) Material certificate C (or CA) depending on the agreed

survey scheme(22) Component certificate C / W depending on the agreed

survey scheme

E1

19- Cylinder jacket, cooling space X h C / W (22)

20- Exhaust valve, cooling space X h C / W (22)

21- Piston crown, cooling space X h (17) (18)

C / W (22)

22- Fuel injection system (injection pump body pressure side,injection valve, injection pipes)

X h C / W (22)

23- Hydraulic system (piping, pumps, actuators etc. for hy-draulic drive of valves)

X h C / W (22)

24- Scavenge pump cylinder X h C / W (22)

25- Turbocharger, cooling space (20) X h C / W (22)

26- Exhaust pipe, cooling space X h C / W (22)

27- Engine driven air compressor if any (cylinders, covers, in-tercoolers and aftercoolers); air side, water side

X h C / W (22)

28- Coolers, each side X h (19) C / W (22)

29- Engine driven pumps (oil, water, fuel, bilge) X h C / W (22)

E2

Cooling pumps, lubricating oil pumps, independent of itemE1, and their prime movers

(1) Pump housing: material certificate (C / W) according tothe piping class. See item G31

(2) Non electrical (i.e. hydraulic); for electrical motors, re-fer to item K

1- Cooling pumps, lubricating oil pumps, independent of E1 C / W (1)

X h C

2- Prime movers (2) X h C

E3Heat exchangers (lubricating oil or fresh water coolers, fuelheaters)

C DA or TA

X h s X C

MAIN DIESEL ENGINES AND THEIR AUXILIARIES - ITEM E

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 22

E4Exhaust gas-boilers (1) C DA X h s X c C (1) See item G15

E5Starting air receivers of item E1 (1) C DA or

TAX h s (2) X (3) C (1) See item G30 for pressure vessels

(2) Including setting of safety devices, if any(3) During sea trials of the ship (capacity check)

E6

Air compressors for filling of item E5, and their prime movers DA (1) Including coolers, if any(2) Under load, on board (capacity)(3) Non electrical (i.e. hydraulic); for electrical motors, re-

fer to item K

1- Air compressors for filling of item E5 X h (1) X (2) C

2- Prime movers (3) X h C

E7Turning gears of item E1 X X (1) C (1) On board

E8Scavenging and supercharging compressors or blowers C (1) TA X X h X (2) C (1) Shaft and rotor where D > 300 mm

(2) Tests to be carried out during bench trials of the engineon which these equipment are mounted

E9Regulation and safety devices DA X (1) X c (1) C (1) During running load tests

E10Pressure pipes (water, lubricating oil, fuel oil, and compressedair pipes), valves and other fittings

C X h C (1) See items G26 and G27

E11

�

Mass-produced diesel engines with cylinder bore D ≤ 300 mm(1)

W (2) TA X s (2) X (2) X (3) (4) CA (5)

(1) Mass-produced engines (as defined by IACS UR.M5,M14 & M.23) admitted to an alternative inspectionscheme (BV mode I survey scheme)

(2) The provisions of item E1 regarding survey of enginecomponents and evaluation of test results are to becomplied with, as far as applicable. Work’s certificates(W) are required for components and tests of engineparts, and for the works' trials

(3) Type test in the presence of a Surveyor, as per NR467and a program accepted by the Society; the selection ofthe engine to be tested from the production line is to beagreed upon with the Surveyor

(4) In addition to the type tests, diesel engines are to besubjected to works trials as per NR467 within theagreed Alternative Inspection Scheme (BV Mode I)

MAIN DIESEL ENGINES AND THEIR AUXILIARIES - ITEM E

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 23

�E11

(5) Society's product certificate for alternative survey (CA)to be issued for the diesel engine; the appropriate doc-uments and information required are detailed in proce-dures stated in the agreement for admission to thealternative survey scheme

E12

Turbochargers (1) (1) For special types of turbochargers, the Society reservesthe right to add/modify the requirements given in itemE12

(2) Material tests (mechanical properties and chemicalcomposition) are required for shafts and rotors, includ-ing blades. Works’ certificate W may be accepted forturbochargers fitted on diesel engines with cylinderbore D ≤ 300 mm

(3) Type approval for turbochargers admitted to an alterna-tive survey scheme (BV Mode 1); type tests as peragreed program

(4) Overspeed test and dynamic balancing, as per Rules(5) The cooling spaces of turbochargers are to be hydrostat-

ically tested at a test pressure of 0,4 MPa or 1,5 times themaximum working pressure, whichever is the greater

(6) Mechanical running test at the bench for 20 minutes atmaximum rotational speed at room temperature; forManufacturers who have facilities in their works for test-ing turbochargers on an engine for which they are in-tended, the bench test may be replaced by a test run of20 minutes at overload (110% of the maximum continu-ous output) on such engine; where turbochargers are ad-mitted to an alternative inspection scheme, the Societymay accept a bench test carried out on a sample basis

(7) Turbochargers not included in 1- are to be designed and constructed according to sound marine practice and de-livered with the works’ certificate (W) relevant to the bench running test and the hydrostatic test as per Rules

1- Turbochargers fitted on main propulsion engines; enginesdriving electric generators, including emergency generators;engines driving other auxiliaries essential for safety and navi-gation and cargo pumps in tankers, having a power of1000 kW and above

C (2) DA or TA (3)

X h s (4)(5) X (6) C

2- Turbochargers not included in 1- (7) X h s X (7) W

MAIN DIESEL ENGINES AND THEIR AUXILIARIES - ITEM E

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 24

Table 6: Main Turbines, Main Boilers, and their Auxiliaries - item F

MAIN TURBINES, MAIN BOILERS, AND THEIR AUXILIARIES - ITEM F

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

F1

Steam turbines (1)(all steam turbines, including propulsion steam turbines,steam turbines intended for auxiliary services essential forsafety and navigation, or for driving cargo pumps in tankers)

DA X X X (2) C (1) For mass-produced turbines which are requested to betype approved by the Society, the tests and trials on aprototype are to be carried out in the presence of theSurveyor. The minimum required attendance of theSurveyor at the production tests and trials will beagreed between the manufacturer and the Society on acase by case basis.

(2) Shop trials as per Rules(3) Thermal stability test of rotors (solid forged and welded

rotors of propulsion turbines are to be subjected to athermal stability test where the service temperature ex-ceeds 400°C; this test is to be carried out after heattreatment and rough machining or at a later stage offabrication, in accordance with a procedure agreed bythe Society)

(4) Balancing and overspeed test of rotors(5) Material tests (all) and NDT: magnetic particle or liquid

penetrant (all) and Ultrasonic or X Ray examination(sample)

(6) Material tests (all) and NDT: magnetic particle or liquidpenetrant (spot as agreed between the Manufacturerand the Surveyor)

(7) Material tests (sample) and NDT: magnetic particle orliquid penetrant (sample) and Ultrasonic or X Ray ex-amination (sample)

(8) See items G26 and G27(9) Material tests and NDT: as required in the appropriate

Sections of the Rules(10) Including overspeed tripping device test(11) See item G1(12) Such as pressure gauges, thermometers, speed indica-

tors, vibration detectors(13) Accuracy (calibration) to be checked(14) See item G30 for pressure vessels

1- Rotating parts (turbine rotors, shafts, stiff and flexible cou-plings, bolts for couplings and other dynamically stressedparts, integral pinions and gears)

C (5) X s X s (3) (4) C

2- Stationary parts (castings and plates for casings) W (6) X s X h s C

3- Blades C (7) X s X C

4- Piping, valves and associated fittings (8) W (9) X s X h X C

5- Regulation and safety devices X X (10) C

6- Flexible coupling (11) C / W DA X C / D

7- Measuring instruments (12) TA X c (13) X c C

8- Turbine and nozzle casings W (6) X s X h s C

9- Intermediate coolers and heat exchangers (14) C DA X s X h C

March 2010 Bureau Veritas 25

F2Manoeuvring and distribution valves of item F1 C (1) DA X X X c C (1) For casing only

F3

Main condensers DA X h X (1) C (1) During sea trials(2) Including chemical analysis(3) Hydraulic test, or examination by an agreed procedure

1- Tubes C (1) X h (3)

2- Tubes plates C X

3- Water boxes and shells X

F4Turning gears of item F1 X (1) (1) On board

F5

Circulating pumps and their prime movers X C (1) Pump housing: material certificates (C / W) accordingto the piping class. See item G31

(2) Non electrical (i.e. hydraulic); for electrical motors, re-fer to item K

1- Circulating pumps C / W (1)

X h C

2- Prime movers (2) X h C

F6

Lubricating oil pumps and their prime movers (2) X C (1) Pump housing: material certificates (C / W) accordingto the piping class. See item G31

(2) See item E2(3) Non electrical (i.e. hydraulic); for electrical motors, re-

fer to item K

1- Lubricating oil pumps C / W (1)

X h C

2- Prime movers (3) X h C

F7

Extraction pumps and their prime movers (2) X C (1) Pump housing: material certificates (C / W) accordingto the piping class. See item G31

(2) See item F5(3) Non electrical (i.e. hydraulic); for electrical motors, re-

fer to item K

1- Extraction pumps C / W (1)

X h C

2- Prime movers (3) X h C

F8Air ejectors (1) X h X (2) C (1) Or vacuum pumps and their non electrical prime movers

(2) On board, general examination

F9Lubricating oil coolers (1) C (2) DA X X h X C (1) See item E3

(2) For tubes and plates: chemical analysis supplied by themanufacturer

F10Drain coolers (1) C (2) DA X X h X C (1) And steam traps - see item G30 for pressure vessels

(2) Casing only (material certificate W, if vessel class 2 or 3)

MAIN TURBINES, MAIN BOILERS, AND THEIR AUXILIARIES - ITEM F

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 26

F11

Main boilers (1) and their accessories DA X X h X (2) C (1) See item G30 for pressure vessels(2) On board under load(3) If forming or welding(4) For cylindrical boilers only (internal test)(5) For tubes and headers of steam heaters only(6) And accessories, see item G27(7) See item G27(8) Capacity test on prototype(9) Setting and accumulation tests(10) See items G26 and G27(11) For pressure pipes(12) On board during sea trials(13) Accuracy to be checked

1- Drums and headers C X s X s h C

2- Tubes C X h (3) C

3- Furnaces (e.g. cylindrical and vertical boilers) C X X s h (4) C

4- Longitudinal stays and screwstays C X C

5- Superheaters (heaters, tubes) C X X s h (3) C

6- Economizers C X s h C

7- Air heaters (5) C X s h C

8- Valves (6) C X h C

9- Safety valves (7) C DA X h (8) X c (9) C

10- Miscellaneous pipes and flanges connecting various parts(headers, superheaters, etc.)

C (10) X h (11) X C

11- Automatic burning system X h X (12) C

12- Level indicator pillars TA X h c X c C

13- Remote level indicators TA X h c X c (12) C

14- Pressure gauges and thermometers X h c (13) X c C

F12

Feed pumps of item F11 and their prime movers DA X C (1) Casing and assembling bolts (centrifugal pumps)(2) Main parts before assembling(3) See item G31(4) Rotor balancing (centrifugal pumps)(5) Non electrical (i.e. hydraulic); for electrical motors, re-

fer to item K

1- Feed pumps (3) C (1) X (2) X h X (4) C

2- Prime movers (5) X h C

F13Feed water heaters (1) C (2) DA X X h X (3) C (1) And steam traps - see item G30 for pressure vessels

(2) Casing only (material certificate W, if vessel class 2 or 3)(3) On board, during sea trials

F14

Forced circulation pumps of item F11 and their prime movers DA X (2) C (1) Casing and assembling bolts(2) On board during boiler tests(3) Non electrical (i.e. hydraulic); for electrical motors, re-

fer to item K(4) See item G31

1- Forced circulation pumps (4) C (1) X X h C

2- Prime movers (3) X h C

MAIN TURBINES, MAIN BOILERS, AND THEIR AUXILIARIES - ITEM F

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 27

F15Forced draught fans X (1) (1) On board during boiler tests

(2) Non electrical (i.e. hydraulic); for electrical motors, re-fer to item K

and their Prime movers (2) X h C

F16

Burning units of item F11 DA (5) X (1) C (1) On board during boiler tests(2) See items G26 and G27(3) Non electrical (i.e. hydraulic); for electrical motors, re-

fer to item K(4) Calibration to be checked(5) DA not required when the burning unit is already de-

sign approved as part of F11 / G15

1- Pumps X h W

2- Heaters DA X h W

3- Filters X h c W

4- Valves and pipes, safety devices (2) C X h X c W

5- Prime movers of 1- (3) X h W

6- Pressure gauges X h c X c (4) W

F17

Gas turbines including propulsion gas turbines, gas turbinesintended for auxiliary services essential for safety and naviga-tionItem F17 does not apply to mass-produced gas turbines (1)

TA X X (2) X (2) C (1) ‘Mass-produced’ gas turbines admitted to an alternativeinspection scheme (BV mode I survey scheme) are tobe tested in accordance with agreed programme. Theselection of the turbine to be tested from the productionline is to be agreed upon with the Society’s Surveyor

(2) Type tests: stages A, B and C as per Rules. In additionto the type tests of gas turbines, shop trials are to be per-formed as per Rules

(3) Thermal stability test of rotors (solid forged and weldedrotors of propulsion turbines are to be subjected to athermal stability test where the service temperature ex-ceeds 400°C. This test is to be carried out after heattreatment and rough machining or at a later stage offabrication, in accordance with a procedure agreed bythe Society)

(4) Balancing and overspeed test of rotors(5) Material tests (all) and NDT: magnetic particle or liquid

penetrant (all) and Ultrasonic or X Ray examination(sample)

(6) Material tests (all) and NDT: magnetic particle or liquid penetrant (spot as agreed between the Manufacturer and the Surveyor)

1- Rotating parts (compressors and turbine rotors, shafts, stiffand flexible couplings, bolts for couplings and other dynam-ically stressed parts, integral pinions and gears)

C (5) X s X s (3) (4) C

2- Stationary parts (castings for casings intended for a temper-ature exceeding 230°C and plates for casings intended for atemperature exceeding 370°C or pressure exceeding 4 Mpa)

W (6) X s X h s C

3- Blades C (7) X s X C

4- Piping, valves and associated fittings (8) W (9) X s X h X C

5- Regulation and safety devices X X (10) C

6- Flexible coupling (11) C / W DA X C / D

7- Measuring instruments (12) TA X c (13) X c C

8- Turbine and nozzle casings W (6) X s X h s C

�9- Intermediate coolers and heat exchangers (14) C DA X s X h C

MAIN TURBINES, MAIN BOILERS, AND THEIR AUXILIARIES - ITEM F

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 28

�(7) Material tests (sample) and NDT: magnetic particle or

liquid penetrant (sample) and Ultrasonic or X Ray ex-amination (sample)

F17

(8) See items G26 and G27(9) Material tests and NDT: as required in the appropriate

Sections of the Rules(10) Including overspeed tripping device test(11) See item G1(12) Such as pressure gauges, thermometers, speed indica-

tors, vibration detectors(13) Accuracy (calibration) to be checked(14) See item G30 for pressure vessels

MAIN TURBINES, MAIN BOILERS, AND THEIR AUXILIARIES - ITEM F

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

March 2010 Bureau Veritas 29

Table 7 : Auxiliary Machinery - item G

AUXILIARY MACHINERY - ITEM G

N° Item

Mat

eria

lce

rtifi

catio

n

Product certification

Remarks

Des

ign

asse

ssm

ent

inde

x

Examinations and tests

Cer

tific

atio

n

During fabrica-

tion

Aftercomple-

tion

Running tests

G1

Clutches and flexible couplings (1)(for propulsive and auxiliary plants)

DA (4) (1) See item G5 regarding main propulsion shafting com-ponents

(2) For metallic parts, i.e. shafts, flanges, power transmit-ting parts: material certificate 'C' or 'W' depending onthe agreed survey scheme. Welds if any to be docu-mented according to agreed specification

(3) For hydraulic or pneumatic equipment(4) As a general: when index DA is required, this may be done

for a specific unit or using the type approval procedure.Flexible couplings of non-standard type are to be con-sidered on case-by-case basis with the Society

(5) Document type C or D according to the applicable pro-duction survey scheme implemented. In case of mass-produced items manufactured in series according to a de-fined type, document type ‘W’ or ‘D’ may be required asstated at the type approval stage

1- when torque ≥ 1 kNm C / W (2)

X h (3) X (3) C

2- when torque < 1 kNm X h (3) X (3) C / D (5)

G2

Reduction gears, reverse reduction gears, and multipliers (1) DA X X (5) (1) Material tests and non-destructive examination (pin-ions and wheel bodies, rims, plates and other elementsintended for propulsion, gear casings of welded con-struction) as per NR216

(2) Static balancing test of rotating components (in partic-ular gear wheel and pinion shaft assemblies with thecoupling part attached. Where n2⋅d ≥ 1,5⋅109, gearwheel and pinion shaft assemblies are also to undergoa dynamic balancing test

(3) Verification of cutting accuracy, meshing test, hydro-static tests (hydraulic or pneumatic clutches, pressurepiping, pumps casings, valves and other fittings)

(4) Under load on board: during the sea trials, the perfor-mance of reverse and/or reduction gearing is to be ver-ified. Shipboard tests to be carried out as per NR467, PtC, Ch 1, Sec 15 for Machinery systems

(5) Survey of shafts and their connections (flange couplings,hubs, bolts pins) as per relevant provisions of item G5

1- Reduction and/or reverse gears intended for propulsionplants:

• with a transmitted power P ≥ 220 kW C X s (2) X h s (3) X (4) C

• with a transmitted power P < 220 kW W X (4) W

2- Other reduction and step-up gears:

• with a transmitted power P ≥ 110 kW C X s (2) X h s (3) X (4) C

• with a transmitted power P < 110 kW W X (4) W

March 2010 Bureau Veritas 30

G3

Main thrust blocks (5) C (1) DA X (2) X s (3) X (4) C (1) For frame only(2) If of welded construction(3) Examination after running test(4) Under load on board(5) See item G5 regarding main propulsion shafting com-

ponents

G4

Thrust shafts, intermediate shafts, shaft couplings and rigidshaft couplings (dismountable type) (3)

C DA X (1) X s (2) C (1) If welded construction or shrunk elements(2) a- on board: contact on bearing to be examined

b- checking of fitting(3) See item G5 regarding main propulsion shafting com-

ponents

Cardan shafts (flanges, crosses, shafts, yokes) (3) C DA X s C

G5

Main propulsion shafting (1)(shafts, couplings, clutches and other shafting componentstransmitting power for main propulsion)

DA X s X h s (4) X (5) C (1) For shafting components in diesel engines, turbines,gears and thrusters, refer to relevant items of this NR266

(2) Material tests (all) and NDT: magnetic particle or liquidpenetrant (all, if diameter > 250 mm) and ultrasonic ex-amination (all, if diameter > 250 mm)

(3) Material tests (all); NDT not required(4) Parts of hydraulic couplings, clutches of hydraulic re-

verse gears and control units, hubs and hydraulic cyl-inders of controllable pitch propellers, including pipingsystems and associated fittings, are to be hydrostaticallytested to 1,5 times the maximum working pressure.Works’ certificates (W) required

(5) Alignment to be checked on board(6) Sterntubes, when machine-finished, and propeller shaft

liners, when machine-finished on the inside and withan overthickness not exceeding 3 mm on the outside,are to be hydrostatically tested to 0,2 N/mm2. Works’certificates (W) required