20373 En

-

Upload

mochamad-safarudin -

Category

Documents

-

view

3 -

download

0

description

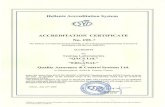

Transcript of 20373 En

-

Features and Advantages Blast and fire resisting walls are primarily designed to sepa-rate hazardous process areas on the topside facilities from living quarters and other non-hazardous areas. Design of new topsides as well as upgrading of existing platforms will involve the addition of blast resisting walls to improve overall safety of the facility. In both cases, the problem of cost effectiveness and topside weight is of great impor-tance.

Blast Resisting Walls Design and Strength Assessment

for Gas Explosions

Hazard Engineering

Methodology based on effective use of non-linear dynamic analysis methods has proven to achieve weight-optimum design of blast resisting walls which offer simple construc-tion and easy installation.

Time [sec]

0.20 0.10 0.00 0.30 0.40 0.50

0.00

0.40

0.80

1.20

Gas Explosion Pressure [barg]

-

2037-3-en

Further information: FORCE Technology Norway AS Subject to changes without notice

FORCE Technology Sweden AB Tallmtargatan 7

721 34 Vsters, Sweden Tel. +46 (0)21 490 3000 Fax +46 (0)21 490 3001 [email protected]

FORCE Technology, Headquarters Park All 345

2605 Brndby, Denmark Tel. +45 43 26 70 00 Fax +45 43 26 70 11

[email protected] forcetechnology.com

FORCE Technology Norway AS Claude Monets all 5

1338 Sandvika, Norway Tel. +47 64 00 35 00 Fax +47 64 00 35 01

FORCE Technology USA Inc. Tel. +1 713 975 8300

FORCE Technology Rusland LLC

Tel. +7(812) 326 80 92

Scope of work Typical scope of work for the design of blast resisting walls includes: Selection of architectural solution for the blast resisting

wall in conjunction with the wall supplier. Special con-sideration has to be made for the design of pipe pene-tration and the possible need to allow for relative verti-cal movements of decks (floors and roofs). Fire causes thermal expansion of walls which can impose addi-tional forces on primary columns and truss-work near walls.

Development of FE model for non-linear dynamic

analysis using LS-DYNA. Special attention is paid to proper representation of the wall supporting condi-tions. Supports shall allow for transfer of membrane forces to the primary structures and, where practical, the bending stiffness of decks shall be accounted for.

Definition of blast loading (time dependant blast pres-

sure), preferably based on data from Computational Fluid Dynamics (CFD) models.

Perform non-linear dynamic response analysis using LS-

DYNA. Effects of strain rate and if necessary, tempera-ture effects on material characteristics, are accounted for.

Deliverables Technical Report Description of FE model with assumptions regarding

support condition and load cases Definition of design gas explosion loads based on CFD

simulation Time dependent deflection, stress and strain response Colour fringes of stress and strains for maximum de-

flections Engineering solutions for required strengthening.

Options VIDEO showing the time depending deflection, stress

and strain response due to gas explosion loading HTML/PDF interactive report of the project results.

Time [s]

600

500

400

300

200

100

0 0 0.05 0.1 0.15 0.2

LS-Dyna3D, 0.7 bar

LS-Dyna3D, 1.0 bar

Deflection [mm] Wall deformation