18

-

Upload

ezhilan-sundaram -

Category

Documents

-

view

212 -

download

0

description

Transcript of 18

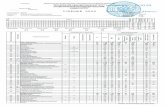

Akesowan and Choonhahirun J. Anim. Plant Sci. 23(1):2013114EFFECT OF ENZYME TREATMENT ON GUAVA JUICE PRODUCTION USINGRESPONSE SURFACE METHODOLOGYA. Akesowan and A. ChoonhahirunDepartment of Food Science and Technology, School of Science and Technology, University of the Thai Chamber ofCommerce, Bangkok 10400, Thailand.Corresponding author e-mail: [email protected] (RSM) wasused toinvestigatethe effects of enzymeconcentration(500-900ppm)andincubation time (30-90 min) on viscosity of guava puree and pH, titratable acidity, clarity, yield, total soluble solid (TSS)andascorbicacid ofguavajuice. Inaddition,thenumericaloptimizationwasconductedtofindthebestenzymecondition. The result indicated that the enzyme treatment reduced guava puree viscosity, promoted juice clarification andincreased valuesfor titratableacidity, yield, TSS andascorbicacid ofguavajuice thanthatwithout enzyme. Onlyregression models of guava puree viscosity, yield, TSS and ascorbic acid with coefficient of determination (R2) of 0.9706,0.9785,0.9678and0.9687,respectivelyweresignificant, reliable andsuitabletodescribetheexperimentaldata.Increasing of enzyme concentration and incubation time decreased puree viscosity and increased yield, TSS and ascorbicacid. Enzymeconcentrationwasthemostsignificantvariable affecting theseproperties.The optimalenzymetreatmentrecommended to add 869.36 ppm pectinase in guava mash and incubated for 71.27 min before filtration process. Underthiscondition, predictedpureeviscosity,yield,TSSand ascorbicacidwere160.07cps,85.10%,5.60 Brixand54.27mg/100 ml, respectively. In conclusion, the development of guava juice quality can be achieved by pectinase application.The RSM successfully revealed that increasing of enzyme concentration and incubation time related to decreased guavapuree viscosity and increased yield, TSS and ascorbic acidof guava juice. The usage of proper pectinase concentrationand incubation time would be an approach to enhance guava juice characteristics.Key words: Guava juice processing, enzyme treatment, pectinase, response surface methodology.INTRODUCTIONGuava(Psidiumguajava L.)isa tropicalfruitwhich usuallyconsumedasfresh.Itisrichinlycopeneandascorbicacid, especially it contains ascorbicacid(100-200 mg/100 g) higher than a fresh orange juice (60-80 mg/100 ml) (Sidhu, 2006; Chopda and Barrett, 2001).In addition, it is a good source of vitamin A, omega-3 and-6polyunsaturatedfattyacids, dietaryfiber, potassium,magnesium and antioxidantpigments such as carotenoidsandpolyphenols (Mahattanatawee etal., 2001). Astheripenedguavaishighlyperishablewhenkeptatambienttemperature, itisprocessedinvarious commercialguavaproductsincluding puree,paste,cannedslicesinsyrupandjuice.Among theseproducts, the guavajuice hasbecomeeconomicallyimportantinthemarket. Theconsumptionoftropicalfruitjuicelikeguavajuicehasbeenincreasingcurrentlybecauseitisnatural,highinnutritionalvalues and used asanalternativetootherbeverages such as soft drinks, tea and coffee.The conventionalguavajuiceprocessingcanbemade by mechanicalpressingofguava mash.Theobtained juice is cloudy and low in ascorbic acid due to ahigh contentofascorbicacidsremains inthepomace(Kuar etal.,2009). Theuseofenzymeinamashtreatmentisnowessentialinjuiceindustryanditshowsincreasesinyieldand ascorbicacid and alsopromotesjuice clarification inashortprocessing (Sarioglu etal.,2001:Demir etal.,2004). The enzymes includingpectinase,cellulaseand/orarabinase assistinthehydrolysisof pecticsubstances, pectins, celluloses orhemicelluloses.Consequently,it isadvantageoustofacilitate thesubsequentfiltrationprocessandincreasejuice yield (Kuar et al., 2009). The time to add enzyme isdependenton thetypeoffruitsusedinjuiceprocessing.Generally,thepectinaseisappliedduringthemacerationpretreatment forreducingtheviscosityoffruitmashandthe juice produces high yield and nutritive values (Sun etal., 2006).Theachievementofenzymetreatmentinfruitjuiceprocessing isinfluencedbyseveral processvariablessuch as enzyme concentration,incubationtime,incubation temperature or these interactive effects (Rai etal.,2004;Lee etal.,2006). Moststudies reported ontheoptimalenzyme conditionswhereoneprocessvariablewas varied in different levels whilekeeping the others ataconstantlevel. Thereisnoresultofinteractioneffectsamongthe variablesanditdoesnotdepicttheneteffectofvariousparametersonthe reactionrate (Rai etal.,2004). Responsesurfacemethodology(RSM)is aneffectivetool whichuses quantitativedatainanexperimentaldesigntooptimizeaprocess (Vieira et al.,The Journal of Animal & Plant Sciences, 23(1): 2013, Page: 114-120ISSN: 1018-7081Akesowan and Choonhahirun J. Anim. Plant Sci. 23(1):20131152012). Acentralcompositerotatabledesign(CCRD)isanexperimentaldesign to defineempirical models orequations for describing theeffectoftest variables andtheirinteractionson theresponses (Sun etal.,2006).RSM has been used for optimizing processes infruit andvegetablejuiceproduction (Rai etal.,2004;Sin etal.,2006;Sun etal.,2006). Kaur etal.(2009) revealedthatthevariationof guava juice yield wasafunctionofenzymehydrolysis pretreatmentconditionswhere theindependentvariables includingenzymeconcentration,temperatureandincubationtimewereestablishedusingRSM. However,otherqualityparameterssuchasclarity,TSS and ascorbic acid have not been investigated.The objective of this study was to investigate theeffectof enzymeconcentrationandincubationtimeonviscosityofguavapureeandphysicochemicalpropertiesof guava juice such as pH, titratable acidity, clarity, yield,TSSandascorbicacidusingRSM. Theoptimizingenzymaticcondition for guavajuice production wasalsodetermined.MATERIALS AND METHODSFruit: Ripened guavas (Psidiumguajava L.) with 80-90% maturity and free from visual blemishes and bruiseswere purchasedfromalocalmarket. The firmnessofguavaswasmeasuredand guavas with peakforcevaluesbetween 16.5 and 18.5 N were used in this study.Enzyme source: PectinexUltraSP-L(Novozymes,Denmark), produced from Aspergillus aculeatus, containsdifferentpectinolyticandcellulolyticenzyme(endo-polygalacturonase(EC3.2.1.15;C.A.S.No.9032-75-1),endo-pectinlyase(EC4.2.2.10;C.A.S.No.9033-35-6)and pectin esterase (EC 3.1.1.11; C.A.S. No. 9025-98-3),andotheractivities,suchas |-galactosidase,chitinaseandtransgalactosidase. The enzymehas its activity of26,000PGper ml (polygalacturonaseactivityper ml),optimum pH at 3.5-6.0and optimumtemperature below90 C (Abdullah et al., 2007).Guavajuicepreparation: Ripened guavas were washedwithtapwater, trimmed to remove blemishs (if any), cutinhalvesanddeseeded. Theguavahalveswereslicedintoabout2cmthicknessandblended withappropriateamountofaddedwater usinga Waringblender (700G,Waring Laboratory, Torrington, CT, USA) for 3 min. Theguava puree was filtered through a cheese cloth to obtainthe juice.Enzymetreatment: Foreachexperiment, 200 g guavapureewassubjectedtodifferent enzymetreatmentconditions, asgiven in Table 1. The reactionwas carriedoutinawaterbathshaker (30 2 C)withaconstantstirringrateof100rpm,andthen heatedat 90 Cfor5min inordertoinactivate enzymeactivity. Theguavapureewasfilteredthroughacheeseclothtoobtainthejuice.Physicochemical propertiesPureeviscosity: TheviscositywasmeasuredbyaBrookfieldviscometer(ModelRVDV-II,BrookfieldEngineering Laboratory, Stoughton, MA, USA) equippedwith a spindle no.02 at 100 rpm. Each 200 ml sample waspreparedina250 ml-beakerandthemeasurementwasmade at room temperature (28 2 C).pH: ThepH-meter(Model320,Mettler-ToledoLtd.,Essex,UK)wasusedtomeasurepHofeachsampleaccording to AOAC (2005) procedure.Titratableacidity: A10 ml juicesamplewasdilutedwith40 ml water,andthentitratedwith0.1NsodiumhydroxideuntilreachingtheendpointatpH=8.2,asdescribed by Barrett etal. (2007). Thetotalaciditywasexpressed as citric acid.Clarity: Claritywasdeterminedbymeasuringtheabsorbanceat660nmusingaspectrophotometer(Spectronic21,Bausch&Lomb,USA)accordingtothemethod of Sin et al. (2006). Distilled water was used as areference.Yield: Thejuiceyieldwasestimatedasa percentageofweight of thejuiceobtainedtotheinitialpuree.Theformula is:Yield=% 100guava of Weightwater added of Weight juice of WeightTotalsolublesolid (TSS): The guavajuicewasmeasured forTSSby an Abberefractometer(ShanghaiPrecision&ScientificInstrumentCo.,Shanghai,China)at room temperature (28 2 C).Ascorbic acid: Juice sample was determined for ascorbicacid by titrationwitha2,6-dichlorophenolindophenolsodium salt solution as reported in AOAC (2005).Firmness: Firmness wasdetermined by atextureanalyzer(ModelLRX,LloydInstruments,Hampshire,UK).The maximumforce(N)requiredtopenetrateeachsample up to 4 mm from the outer surface using a flat testcell (10 mm diameter) was recorded.Experimentaldesign: Twoindependentvariables;enzymeconcentration(500-900ppm)andincubationtime (30-90 min) were investigated for their influences onviscosityofguavapureeand physicochemicalpropertiesofguavajuice.Acentralcompositerotatabledesign(CCRD)foratwo-variable,fivecombinationscoded -1.41, -1,0,1, 1.41 wasemployedtostudythecombinedeffectoftheseindependentvariables.Experimentaldesign and actualvaluesfor guava production are showninTable 1.Thisdesignrequiredthirteen setsofrandomizedexperiments,whichincludedfourfactorialAkesowan and Choonhahirun J. Anim. Plant Sci. 23(1):2013116points,five centralpointsandfourextraaxialpoints,asevidence in Table 2. The model proposed for the responseisY = b0+ b1X1+ b2X2+ b1121X+ b2222X+ b12X1X2(1)Where Y is the response calculated by the model;X1andX2arethecodedenzymeconcentrationandincubation time, respectively, and b1and b2are linear, b11andb12arequadratic,andb12isinteractioncoefficient,respectively (Anderson and Whitcomb, 2005).Statisticalanalysis: Theproductionofguavajuice wascarriedoutinduplicate and allanalyseswerecarriedoutintriplicate. The data wassubjectedtoanalyzeforanalysisofvariance(ANOVA)andmultipleregressionusingtheDesign-ExpertTrial version8.0.2 software(State-EaseInc.,Minneapolis,Minnesota,USA)(Anderson and Whitcomb, 2005).RESULTS AND DISCUSSIONEnzymetreatmentonguava pureeandjuice: Table2shows guavapureeviscosityand physicochemicalpropertiesof guavajuicewithandwithoutenzymetreatment. The addition of pectinase caused a decrease inpuree viscosity, thus resulting in an ease of juice filtrationprocess. The obtained guavajuice was also highintitratable acidity, yield, TSS and ascorbic acid, but low inpH andabsorbancevalues. This canbeexplainedthatpectinase, whichinclude pectinmethylesteraseandpolygalacturonase, assistinpectinhydrolysis. Theirreactions cause a release of carboxylicacids andgalacturonicacids.Thisleads toadecreasein pureeviscosityand pH ofjuice, but asignificantincreaseintitratableacidity and juiceyield (Tadakittisarn etal.,2007). Besides these enzymes, arabinaseandcellulasecan convertarabanandcellulosetosolublesugars,resultinginanincreaseof TSS inguavajuice. Inaddition,theenzymesreactontheguavapeel whichisrich in ascorbic acids (Chopda and Barrett, 2001), thus anincrement of ascorbicacid would bedueto thepectinbreakdownfromthe peel. The pectinase-treated guavajuice also demonstratedalower absorbancevalue inrelationtothatwithout enzymetreatment,indicating thatthe juicewasmore clear. Thiswaspossiblyduetotheagglomerationofdegradedproductsfrom pectinasehydrolysis ofpectin,followedwiththeprecipitationoffineparticles asthetime increased (Sin etal.,2006;Tadakittisarn etal.,2007). Thisfinding was alsoconfirmed by theworkof Abdullah etal., (2007) whostudiedontheenzymaticclarification ofcarambolafruitjuice.Statisticalanalysisonmodelfitting: Theexperimentalresponses as a function of enzyme concentration (X1) andincubationtime (X2) on guavajuice production aresummarizedinTable2.Thevaluesof pureeviscosity(cps), pH, titratableacidity (%), clarity (Abs),yield (%),TSS (Brix) andascorbicacid (mg/100 ml) werewithinthe ranges of 160.07-197.67, 3.70-3.73, 0.60-0.67, 1.716-1.779,75.23-85.14,4.75-5.65and45.95-55.36,respectively. RegressionanalysisandANOVA results inTable3shows thatthecalculatedF-valuesof fourresponsessuchas puree viscosity,yield,TSSandascorbicacid weresignificantatp0.05).Thesevaluesindicated thatthemodelswere fittedandreliable. However, theadequacy ofthe modelneededtobe further checkedbythecoefficientofdetermination(R2). The closer the value of R2to 1, the better correlationbetween theexperimentalandpredicted values. FromTable3, R2values forguavapureeviscosity,yield,TSSandascorbicacidwere0.9706,0.9672,0.9678and0.9687, respectively. ThesemodelsshowingR2greaterthan 0.8 implied that each model indicated a good fit (Sinetal.,2006). Nevertheless, someresearcherssuggestedthat alargevalueofR2doesnotalwaysimplythattheregressionmodelisagoodone. IncreasingR2canbeobtainedbyaddingavariabletothemodel. Thus,itispreferred to use an adjR2to evaluate the model adequacyand it should be over 0.8 (Koocheki et al., 2010). As seeninTable3,adjR2valuesof pureeviscosity, yield,TSSandascorbicacid werealsohightoadvocateforahighsignificanceofthemodel. Moreover,otherparameters,namely predR2whichshouldbecloserto1and adeqprecision which should be greater than 4, of these modelsinTable3aresupportiveofthesignificanceofthemodels. FromTable3,thecoefficient ofvariation (CV)of yield wasthelowest,indicating that thisresponse hadbetterprecisionandreliabilityofexperimentsascomparedwith otherresponses. Inconclusion,thesemodelsadequatelyrepresentedtherealrelationshipbetween the variables chosen.Effectonguavapureeviscosity: Guavapureeviscosityhasbeenconsideredasanimportantqualityparameterrelated to the juice filtration or pressing, namely a relativelowviscosityleadstoabetterfiltration. The regressionmodelofpureeviscosityasafunctionof enzymeconcentrationandincubationtime canbedescribedbythefollowingequation afterremovingnon-significantterms:Guavapureeviscosity = 23.68 +0.54 X1***+0.26 X2***4.1121X ***(2)where X1= enzyme concentration (ppm) and X2=incubation time (min).***Significant at 0.001 level.From equation2,the model indicated that thevariationin pureeviscositywas significantly affectedbypositivelinear(p