150mm Wafer Transfer

description

Transcript of 150mm Wafer Transfer

MIT Lincoln Laboratory

150mm Wafer Transfer

Keith Warner, Andy Loomis

April 7, 2000

MIT Lincoln Laboratory

Transfer Process Goals

Adhesive-based wafer-to-wafer bonding

2 – 5 µm bondline thickness, thermal limits on post-transfer processing, +/- 2 µm alignment accuracy with existing tools

Complete transfer of NU processes, also useful for other device types

Oxide fusion bonding (Adopt existing process from CCD work)

< 1 µm bond layer, post-transfer processing ~400°C (Tungsten CVD plugs, “hot” Al), +/- 1 µm alignment with tool to be purchased

Determine technology limits on this program

Sub-micron via placement with oxide bonding

Build/specify tools using stepper technology techniques

MIT Lincoln Laboratory

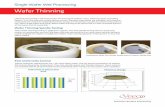

Wafer Bonding - Voids

Voids are formed after the SOI handle wafer is removed

• Particulate - Cleaning, clean area, inspection, filtration

• Pinholes and oxide quality - Starting material

• Adhesion – Cleaning

• Bubbles – Vacuum outgassing of epoxy

MIT Lincoln Laboratory

Wafer Bonding - Voids

12/16/99 3/2/00

(After wafer thinning decorative etch)

Void – free wafer transfer achieved

MIT Lincoln Laboratory

Wafer Bonding - Alignment

• Alignment method – depends on type of tool

– Early work used Research Devices flip-chip bonder

– Limitations of optical system restricted accuracy to +/- 5 µm

MIT Lincoln Laboratory

Wafer Bonding - Alignment

– Karl Süss mask aligner with infrared optics

– Better than +/- 2 µm accuracy, repeatable

MIT Lincoln Laboratory

Wafer Bonding - Alignment

Accurate alignment achieved

(Same wafer without voids)

MIT Lincoln Laboratory

Wafer Bonding – Bondline Uniformity

• Wafer flatness – Double side polished ultra-flat wafers

• Adhesive curing cycle – Experiments started (Research Devices tool is not designed for wafer-to-wafer bonding; available pressure is inadequate)

• Spacers – Latex microspheres

• Particulate – Cleaning, inspection, filtration

(2-5 µm required across wafer)

Still working on optimization

MIT Lincoln Laboratory

Wafer Bonding Apparatus and Operation

MIT Lincoln Laboratory

Status

• Void-free transfer successful

• Alignment accuracy adequate for devices currently available (“North2”)

• Method identified to meet bondline requirements – experiments are underway

• Full-time effort has started