1 PCB DESIGN - A QUICK WALK THROUGH SREEKANTH N NAMPOOTHIRI.

-

Upload

charlie-titterington -

Category

Documents

-

view

217 -

download

3

Transcript of 1 PCB DESIGN - A QUICK WALK THROUGH SREEKANTH N NAMPOOTHIRI.

1

PCB DESIGN - A QUICK WALK THROUGH

SREEKANTH N NAMPOOTHIRI

2

Agenda

• Introduction

• PCB Over View

• E-CAD Tool Sets

• PCB Design Life Cycle

• PCB Manufacturing

• Common Design Tips

• Latest technologies in PCB

• PCB Dictionary

3

Introduction

• ‘PCB’ stands for Printed Circuit Board Design

• PCB, is used to mechanically support and electrically inter connect components using conductive pathways called as traces, etched from copper sheets laminated onto a non-conductive substrate

• PCBs were designed and laid out by hand using adhesive tapes & pads on clear drafting film

• ECAD system is developed historically to engineer the electronic circuit boards more efficiently

• The PCB design never much affected circuit performance in the past where the speed of operations were too slow. But Industry demands real engineering expertise on PCB nowadays where the rise time of silicon fell into Pico second ranges.

• Modern day examples of the high speed signals include DDR - DDR2 Bus, USB, SATA, PCI Express, PCI, Gigabit Ethernet etc. High speed design techniques must be applied to the printed circuit boards containing these and other high speed signals to ensure proper and reliable operation

• Engineers are assigned the task of design mixed analog and fast rise-time digital boards, and have all signals arrive at their destination cleanly

4

PCB OverView

• PCB is a stack of Different layers-Cu foils, Cores, Prepregs,Solder Mask& Silk screen

• Laminate Cores (with both side copper sheets) & Copper foils are used to construct Electrical Layers ) (Eg :- FR-4)

• Pre-preg material is used as isolation layer between two electrical layers.

• General standard on PCB is IPC-2221A

• Cross sectional View of a Multi Layer PCB

5

E-CAD Tool Sets There are many EDA vendors in the industry who have developed Electronics-CAD tool chains.

The major players are Cadence, Mentor Graphics,Zuken,Altium & the tools are :

• Allegro from Cadence

• Board Station,Expedition,PADS etc from Mentor Graphics

• Visula,Cr5000,CadStar etc from Zuken

• Pcad/Altium Designer from Altium

6

PCB Design Life Cycle

• ECAD Library Development

• Schematic Entry

• Net-list porting

• Critical net analysis & Rule settings

• Component Placement & BGA fanout

• Routing

• Design Rules, DFM,DFA verification

• Post processing

• Gerber , Drill files & Supportive files Generation

7

PCB Design Life Cycle• ECAD Library Development

ECAD Library contains of electronic parts which has a schematic Symbol,a PCB footprint and an association of both. It shall be developed as per IPC standards & recommendations. Many companies nowadays maintain a standardised master library management system.

• Schematic Entry

Schematic Entry is the process of converting the logical electronic design to a pictorial representation using symbols, nets etc.

• Net-list porting

It is the process of creating a net list file and port the same to a PCB design environment where all the logical symbols are mapped to PCB footprints.

• Critical net analysis & Rule settings

High speed interfaces/nets are identified and different placement/routing rules are set up.

• Component Placement & BGA fanout

Floor planning & component placements plays very critical role in PCB engineering. Logical grouping of components are done.DFA/DFT principles are applied in component placement.BGAs are fanned out prior to the routing face.

8

PCB Design Life Cycle• Routing

Routing is the process of establishing the physical path for conducting electricity in a printed circuit board. Different electrical rules need to be applied while routing high speed tracks, differential pair routing, GND-POWER splitting etc.The main routing topologies are Single ended, Differential pair, Daisy Chain,Star,T etc

• DRC

Design Rule Check is the process of verifying all the rules such as min track width,space constraints.

• Post processing

After verifying the 100% routing completion & electrical DRC clearance, the design data needs to be prepared with silk screen alignment, solder masking,Fab notes updation etc etc.

• Gerber & drill files Generation

RS274-EX format is the accepted Gerberfile format and all the layer’s gerber files are generated seaparately.The drill files are generated in excellon format

All the files will be provided to the PCB vendor for starting the manufacturing process.

A set of files like Drill & Assmebly drawings,Centroid data,Solder paste data etc also generated from the design file

9

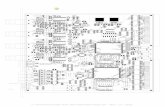

PCB ManufacturingWhat Happens to Gerber files ?What Happens to Gerber files ?

• Load the Gerber & drill files in CAM station

• Perform CAM analysis & final layer stack up

• Generate uniform Solder Mask Data

• Perform Panalization

• Add common fiducials & create test coupons, if required.

• Core Laminate is selected in required thickness & panel Size

• Photo Resist material is applied to both side of the core laminate

• Develop the –ve image of the inner layers in core laminate by exposing with UV light

• Wash off the unhardened photo resist material

• Etch off the unwanted copper

• Remove the photo resist materials on the track & pads

10

PCB Manufacturing Continues…• Automatic Quality Inspection (AQI) is done

• All the inner layer etching is completed same way

• Outer layer copper foil is added to the inner core stacks with pre-preg isolation

• All Electrical layers are stacked & pressed in pressing machine

• Panel is gone for CNC drilling,PTH plating etc

• Outer Layers are developed & Solder Mask is applied.

• The panel is taken for Surface finish process such as HASL,ENIG etc

• Bare Board Test (BBT) is performed on the panel with a Flying probe tester

• De-panellize & ship the boards after final QA

.

.

11

Latest Technologies in PCB Design

• Use of uBGAs,SOCs

• Mixed Signal technologies- Analog,Digital,RF

• Controlled Impedence PCBs

• Use of micro,blind/Buried Vias

• Back drilling

• Embedded passives

• Flexible PCBs

• Optical PCB tracks

12

Common Design Tips Tips for Improving Signal Integrity

• For all high speed signals use controlled impedance traces

• Place series termination resistor as close to the driver IC as possible.

• Match the timing relation between clock and data signals using length and time-delay calculations. Account for the fact that signals travel faster in microstrip than in stripline

• Keep the routing of the differential signals symmetrical. Keep the number and placement of the vias symmetrical.

• If multiple powers share a power plane, and if the power plane is used as a reference plane for return signal of high speed traces use stitching capacitors to “stitch” the boundaries of the power plane islands.

Tips for Avoiding Cross Talk

• Give preference to stripline over microstrip when routing critical signals sensitive to cross talk

• Reduce the separation between the signal and ground layers as far as possible while still achieving the required impedance

• Space out the critical high speed traces as much as possible. A minimum spacing of twice the signal width is a good number.

.

13

Common Design Tips Continues…• If guard trace is used, use vias to connect the guard trace to ground

• Make sure traces in adjacent layers run perpendicular to each other

Tips for Power Supply Noise Reduction

• Make sure traces in adjacent layers run perpendicular to each other

• Keep the separation between power and ground plane as small as possible

• Use wider traces & large vias to connect decoupling capacitors to power and ground planes

• Place decoupling capacitors as close to the IC power pins as possible

• Use large number of decoupling capacitor to reduce total effective series inductance

Tips for EMI Reduction

• Keep the power and ground signal layers as close as possible

• Keep all traces that carry high frequency and fast edge rate signals in stripline in place of microstrip & well inside the edge of the board

• Make provision for a ferrite bead at the entry path of power supply to reduce the conducted emission

.

14

PCB Dictionary• PCB – Printed Circuit Board Design

• PTH-A hole in a circuit board that has been plated with metal (usually copper) on its walls to provide electrical connections between conductive patterns

• Via – A PTH that electrically connects the signal between two/more layers

• Annular Ring – The conductive material surrounding a hole

• Etch -Chemical removal of metal (copper) to achieve a desired circuit pattern

• Ground Plane-A conductor layer, or portion of a conductor layer, used as a common reference point for circuit returns, shielding, or heat sinking

• Mil - One-thousandth of an inch (0.001").

• DFM-Design for Manufacturability

• DFT-Design for Testability

• DFA-Design for Assembly

15

Thank you

Tecnopark Karyavattom Trivandrum 695 581India

Tel +91-471-6661000Fax +91-471-2527215

www.tataelxsi.com

End slide