1 introduction to guide right componenets with single implant reduced size

Transcript of 1 introduction to guide right componenets with single implant reduced size

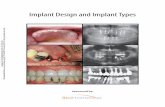

Guide Right™ Surgical Guide System

INTRODUCTION

use of Guide Right™ COMPONENTS

use with a SINGLE IMPLANT CASE

verification with PA X-ray

includes: mesio-distal correction only (not bucco-lingual)

2.3013

Challenges with Current 3D Surgical Guides

Most require off-site fabrication

Costly and time delay, several days to two weeks

May result in difficulty fitting the patient when placed at the

time of surgery

May require a 2nd cone beam X-ray of cast

Best Practices for Implant Success

Implants should be placed within the envelope of available bone to

increase clinical success.

Pre-surgical radiographs facilitate evaluation of the proposed angle of

the long axis of the guide sleeve and proposed implant placement.

3D Radiographs allow us to determine if planned implant placement

conflicts with the adjacent roots, the maxillary sinuses, nerves,

and if it is within the envelope of available bone.

In-office or lab fabrication

Evaluate with 2D & 3D imaging

Allows linear and angular correction

Enables precision implant placement

Cost effective

A System of Components

for the fabrication and correction of diagnostic & surgical guides

in one or two dimensions

Basic Fabrication & Correction

of

DIAGNOSTIC and SURGICAL Guides

Featuring

GUIDE RIGHT COMPONENTS

standard & magnetic guide posts cylindrical & open guide sleeves

GENERATION ll BENDING TOOL

angular correction linear correction

PERIAPICAL X-RAYS

FABRICATION OF

DIAGNOSTIC guideSURGICAL guide

Guide Right™ COMPONENTS

used in

Fabrication of DIAGNOSTIC & SURGICAL Guides

Guide Posts: standard · magnetic offset

Guide Sleeves: cylindrical · open

Drills

Pin-vice

Generation ll Bending Tool

Standard Guide Posts

Short Guide Post18 mm x 9 mm x 3/32 in.

Straight Guide Post 30 mm x 2.9 mm x 3/32 in.

Magnetic Guide Posts

Straight

3.0 mm od

Offset

3.0 od X 0.5 mm os

3.0 od X 1.0 mm os

3.0 od X 1.5 mm os

3.0 od X 2.0 mm os

3.0od X 2.5 mm os

3.0 od X 3.0 mm os

Cylindrical Guide Sleeves

Anterior

Straight Cut 3.0 mm x 10 mm

Posterior

Angle Cut 3.0 mm x 10 mm

Large Diameter

4.5 mm id x 5.0 mm

Large Diameter

5.3 mm id x 5.0 mm

Magnetic Guide Post & Open Guide Sleeve Set

4.0 mm Open Guide Sleeve (short)

4.0 mm Open Guide Sleeve (short)

4.0 mm x 10 Magnetic Guide Posts

4.0 mm x 1 mm Offset Magnetic Guide Post

2.0 mm x 5.0 mm Pilot Drill

2.0 mm x 10.0 mm Pilot Drill

Drillsused with straight hand piece

3/32”

5/64” drill

Pin vice may be used for more accurate placement

Magnetic Offset Guide Post

3.0 X 0.5 offset

Magnetic Offset Guide Post

3.0 X 1.0 offset

Magnetic Offset Guide Post

3.0 X 1.5 offset

3.0 X 2.0 offset

Magnetic Offset Guide Post

3.0 X 2.5 offset

Magnetic Offset Guide Post

3.0 X 3.0 offset

Magnetic Offset Guide Post

Single Bendcorrections in one plane

Guide Right™

Generation ll Bending Tool

Guide Right™

Single Implant Case

ALB 2.2013

single bend

use of protractor

use of bending tool

Fabrication of DIAGNOSTIC Guide

A pencil line can be drawn on the cast to guide a proposed osteotomy axis. (Not shown)

A hole is drilled through the prostheticly planned long axis of the implant into the cast with a 3/32” drill.

The drill is removed from 3/32” hole, the cast is lubricated with

petroleum jelly for easy removal and, if necessary, undercuts

are blocked out.

A 3 mm guide post is placed in the hole

A 3 mm guide sleeve is placed on the post and Triad® Gel is added to

capture the cleats on the sleeve and to lingual & incisal surfaces of

several of the adjacent teeth. After curing the DIAGNOSTIC guide &

securely seating it in the patient an X-ray is taken.

The radiograph taken with the initial DIAGNOSTIC guide indicates a

correction is needed to avoid hitting the root of the adjacent tooth with

the osteotomy / implant.

The Guide Right™ protractor is placed over the pre-op

DIAGNOSTIC X-ray to indicate the proposed correction of 9 . NOTE the relationship between the proposed guide sleeve with the adjacent root.

Guide Right™

Generation ll Bending Tool

• A straight 3 mm magnetic guide post is placed in the block of the bending tool.

• The 3 mm stylus is placed over the post.

• Pressure is applied to point of stylus moving it to the 9 correction indicated

according to the protractor reading.

Step 2 Locate 3/32” hole in the center of the v-cut and place the bottom half of the

guide post into the hole. Tighten the set screw.

Step 1 Place bending tool plate on a secure flat surface with the degree increments

at the top & the stainless steel bar with the v-cut at the bottom.

Step 3 Locate the hole in the bottom of the stylus that you will use that will fit over

the top half of the guide post (3.0 mm, 4.0 mm or 5.0 mm).

Step 5 Using the stylus as a lever, bend the guide post to the degree of angle of

correction. You may need to ease the point of the stylus beyond the

point of the desired degree.

Step 6 Loosen screw and remove guide post and the stylus to find the guide post

bent to the desired angle.

Step 4 Fit the stylus over the guide post securely with the point directed at

zero degrees and the bottom of the stylus in contact with the V block.

Guide Right™

GENERATION II BENDING TOOL

SINGLE BEND review

The magnetic guide post is placed in the initially planned

prosthetic axis prior to correction.

The planned prosthetic axis is changed by bending

a straight magnetic guide post 9 .

Fabrication of SURGICAL Guide

To fabricate the final SURGICAL guide, a 3.3 mm open guide

sleeve is placed over the corrected guide post which was bent 9 .

Triad® Gel is added to capture the cleats

to form the final SURGICAL guide.

An X-ray of the altered guide sleeve angle noting the implant

position farther away from the root of the adjacent tooth.

Pre-op DIAGNOSTIC guide Corrected SURGICAL guide

Prior to surgery the final SURGICAL guide with the

3.3 mm open guide sleeve securely seated in the patient.

Clinical view of the 2 mm pilot drill with 3.0 mm stop

shaft in the 3.3 mm open guide sleeve

After the 2 mm drill is used the alignment is checked with a 2 mm Direction

Indicator placed in the 2 mm osteotomy and post-op X-ray is taken.

Note the X-ray of the 2 mm Direction Indicator in place to check the

alignment of the 2 mm osteotomy indicates a satisfactory placement.

Now the use of successive larger drills can proceed.

A 2.5 mm drill is centered in the 3.3 mm open guide sleeve.

The next larger (2.7 mm) drill is used.

A 3.2 mm drill is centered in 3.3 mm open guide sleeve.

Finally, the implant is placed with the carrier using the guide sleeve.

A final X-ray is taken to view accuracy of implant placement.

(1) 3/32” drill

(1) 2 mm pilot drill with / 8.5 long / 3 mm stop

(1) 3 mm Straight Stainless Guide Post

(1) 3 mm Cylindrical Guide Sleeve

(1) 3.3 mm Open Guide Sleeve

(1) 3 mm Magnetic Guide Post

(1) Generation ll Bending Tool & 3 mm Stylus

(1) Direction Indicator

Guide Right™ Protractor

Triad® Gel

Products used in this presentation

1.800.314.0065 • www.deplaque.com

Step 2 Locate 3/32” hole in the center of the v-cut and place the bottom half of the

guide post into the hole. Tighten the set screw.

Step 1 Place bending tool plate on a secure flat surface with the degree increments

at the top & the stainless steel bar with the v-cut at the bottom.

Step 3 Locate the hole in the bottom of the stylus that you will use that will fit over

the top half of the guide post (3.0 mm, 4.0 mm or 5.0 mm).

Step 5 Using the stylus as a lever, bend the guide post to the degree of angle of

correction. You may need to ease the point of the stylus beyond the

point of the desired degree.

Step 6 Loosen screw and remove guide post and the stylus to find the guide post

bent to the desired angle.

Step 4 Fit the stylus over the guide post securely with the point directed at

zero degrees and the bottom of the stylus in contact with the V block.

Guide Right™

GENERATION II BENDING TOOL

SINGLE BEND review

COMPOUND BEND overview

Step 1 Position a straight or offset guide post in the bending plate, tightening the set

screw against one of the flat surfaces on the lower half of the guide post.

Step 4 The 2nd bend in the second plane is made after rotating the guide post up away

from the surface of the bending plate to register the stylus point back at 0 degrees.

Step 5 Slide the stylus support bar down under the stylus until it supports the stylus.

Tighten the side screws before making the second bend.

Step 7 Remove the stylus and place the guide post back in the cast with the

appropriate side indicated by a mark facing the buccal or lingual surface.

Be sure the post is in the correct position.

If the post needs to be corrected by a linear movement an offset guide post can be used.

Off sets available in the 3 mm guide post: 0.5,1,1.5, 2.0 ,or 3.0 mm.

Step 3 The set screw is loosened and the guide post is rotated 90 ° next flat surface.

Step 2 The 1st bend can be made to the right or left direction.

Step 6 The second bend can be made in either direction according to the x-ray.

Guide Right™

GENERATION II BENDING TOOL

Guide Right™ Surgical Guide System

Start With Precision. Place With Confidence.

1.800.314.0065 • www.deplaque.com