2012 sesame producer_guide_13_feb

-

Upload

alemu-temesgen -

Category

Food

-

view

755 -

download

1

Transcript of 2012 sesame producer_guide_13_feb

P a g e | 1

FOREWORD Every year since 1982, a Sesame Production Guide has been published to share and update producers with experiences

of the SESACO Production and Research teams. The teams work together expanding the boundaries and knowledge of

sesame production. As the sesame industry evolves, more information and experience is shared with a widening diverse

group of producers and researchers.

TABLE OF CONTENTS 1 ADVANTAGES 10 PLANTING

2 INTRODUCTION 11 Seed Metering Equipment

2 CROP DESCRIPTION 11 Planting Rates

3 U.S. Growing Area 12 MOISTURE AND NUTRIENTS

3 Temperature 12 Moisture Management

3 Growth 12 Dryland

4 Development 13 Irrigation

6 FIELD SELECTION 15 Nutrient Management

6 Soils 15 PEST

6 Herbicide Carryover 15 Weeds and Herbicides

6 Sesame in Rotation 17 Diseases

8 PREPLANT CONSIDERATIONS 18 Insects

8 No-till 19 Wildlife

8 Conventional Tillage 19 HARVEST

9 Preformed Raised Beds 19 Moisture matters

9 Row Spacing 20 Header

9 Dry and Buster Planting 20 Threshing

9 PLANTING DATES 21 PLANTING EQUIPMENT SETTINGS

10 Traditional Areas 23 DEVELOPMENT OF SESAME

10 Expansion Areas

ADVANTAGES OF GROWING SESAME One of the most efficient crops for volumes of 6 to16

inches of plant available water.

A versatile crop grown in arid/semi-arid regions with

unique attributes to fit almost any cropping system.

Offers more potential return for less cost (less risk)

than other crops.

Can be more profitable with limited resources than

other crops using the same level of resources.

Excellent drought and heat tolerance. Performing

where other crops fail.

Common equipment used for other crops can be

used to produce sesame.

Has shown excellent disease and insect tolerance

and has shown to grow well in cotton root rot infested

soils.

Relatively negligible economic damage from wild

hogs, deer, and/or birds.

Deep tap root may reach and utilize nutrients and

moisture below the root zone of other crops.

As a non-host for root-knot nematodes, rotation with

sesame has shown to reduce nematode levels.

Adds beneficial residue not only on the surface but

within the soil profile, resulting in improved tilth and

topsoil protection.

Is a standard nation-wide program crop. No follow up

crop is required to receive program payments.

Multi Peril Crop Insurance Pilot Program established

in specific counties of Texas and Oklahoma in 2011.

Stretch limited water supplies by dividing acres with

higher moisture demanding crops.

Has worked well as a catch crop option following

failed wheat, canola or cotton.

Has not shown iron or zinc deficiencies on high pH

soils.

Grows well in no-till and results in mellow soil with

residue that allows uniform planting.

During the drying phase (last 30-40 days), soils may

collect and store rainfall for the following crop.

P a g e | 2

INTRODUCTION

SESACO is the premier genetic developer, processor, and

marketer of U.S. grown sesame. SESACO has used

traditional breeding to develop the only non-dehiscent

(ND) sesame varieties in the world (U.S. patent number

6,100,452). ND sesame changes the way sesame has

been cultivated and harvested for 7,500 years.

Even today, 99% of the sesame grown in the world is still

harvested manually because traditional sesame capsules

shatter during the drying stage before harvest. SESACO

ND varieties mature and dry standing in the field and then

are harvested direct from standing plants. Traditional

sesame with known traits such as drought, heat, insect,

and disease tolerance is now completely mechanized by

the ND genes. In 2008, SESACO released the first

Improved Non-Dehiscent (IND) varieties (U.S. patent

number 8,080,707).

CROP DESCRIPTION

Sesame (Sesamum indicum) is a broadleaf summer crop

with similar growth habits to cotton and soybeans.

Generally, it is 3-5 feet tall; and, with good moisture and

fertility, sesame can reach 5-6 feet. Varieties can be single

stemmed or have branches.

Flowering starts about 35-45 days after planting, typically

setting two new flowers per day. Sesame is indeterminate

but generally flowering stops after 75-85 days.

The fruiting form is called a capsule. The first capsule is

about 1-2 ft above the ground. Capsules are divided by

carpels like a cotton boll. There are 4 rows of seeds in each

capsule with about 70 seeds produced in each capsule.

The plant is very leafy and succulent prior to physiological

maturity (PM) which normally occurs 95-110 days after

planting. PM is when 75% of the capsules on the main

stem have mature seed. Normally, sesame will self-

defoliate by full maturity and drydown 120-150 days after

planting. Frost may accelerate drydown and prepare the

crop for an earlier harvest. A killing freeze will terminate the

crop and typically dry down the plants in 7 to 10 days.

Usually a freeze after PM does not damage the crop.

Photo 1. A mature capsule cut open to present seed arrangement. Photo by J. Simon.

Photo 2. Sesame in mid bloom with full size capsules 6 node pairs below open flower.

Cover Photo. Irrigated sesame on the High Plains in rotation

with corn and cotton.

P a g e | 3

Fig. 1. SESACO’s traditional production areas have been mainly in TX, OK,KS, and some in AL, as shown in green. Sesame

can be grown in many areas of the southern United States.

U.S. Growing Area

SESACO has ambitious goals to grow more sesame each and every year. As shown in purple in Figure 1, SESACO is

expanding into areas outside of the traditional TX, OK, and KS production area. These areas have previously grown

sesame either as commercial production or game bird food plots. In the expansion areas, sesame is being planted as

both a primary crop and a double crop behind wheat. Sesame offers producers an alternative rotational crop that can be

integrated into many cropping systems like potatoes, watermelons, etc.

Temperature

Sesame is very heat tolerant. Cool temperatures are

more limiting to production than hot or even very hot

temperatures. Sesame has produced excellent yields

while enduring very hot temperatures (120ºF) in the

deserts of Arizona and around the world.

The threshold temperature for growing degree days of

sesame is 60.6ºF. When night temperatures go below

this threshold, it takes longer for the crop to mature.

Typically, sesame requires 115 days from emergence to

the first frost date. Sesame needs to reach physiological

maturity prior to frost to make optimum yield.

Growth

As shown in Figure 2, sesame is characterized by a slow

growth rate in the first 30-35 days to reach only 12” while

the root is growing faster than the leaves and stems. This

is followed by a rapid increase in height of roughly 12”

every 7-10 days to reach 4 feet by 60 days from planting.

At the end of flowering, the plants no longer grow.

With limiting moisture conditions, the final plant heights

are lower, but the pattern of slow growth followed by fast

growth during the reproductive phase exists under all

conditions.

Fig. 2. Normal growth curve for sesame.

P a g e | 4

Development

There are four phases in the development of sesame

as shown in Table 1. Each of these (excluding the

ripening phase) are divided into stages based upon

events which can be identified. With this information,

producers should make timely applications of inputs

and schedule future activities as the crop develops.

Vegetative Phase

Germination stage

For the germination stage, soil temperatures need to

maintain a minimum of 70ºF at planting depth. Final

stand should be judged at 7 days after planting.

During the germination stage, a rain can create a crust

in the soil over the sesame. If the seed is located

inside the crust, there is almost no hope for emergence,

and the sesame should be replanted. If the seeds are

germinating below the crust, there is a possibility that

the crust will crack and allow for emergence. The stage

ends when the seedlings emerge.

Seedling stage

The seedling stage is a tough time for producers

because of the slow pace of growth. This stage is still

too small to cultivate. The stage ends when the 3rd

pair

of true leaves are as long as the 2nd

pair.

Juvenile stage

In the juvenile stage there is a dramatic surge in growth.

At this stage, it is important to consider cultivating and

sidedressing. The stage ends when the first green buds

are visible.

Pre-reproductive stage

The pre-reproductive stage is the most important stage to

optimize production. This is the last chance to sidedress,

let alone get a tractor into the field. From this stage until

late bloom, it is important to minimize stress to the crop.

This is the optimum stage to apply more fertilizer if

needed. This stage ends when 50% of the plants have

open flowers.

Reproductive Phase

Sesame is an indeterminate species, meaning there is an

overlap between the stages at different periods of the

growing season. The seed in the first capsule may be

mature while the upper portion of the plant is flowering.

Early bloom stage

In the early bloom stage, flowers may not make capsules.

In sesame it is normal for the white flower petals (corolla)

to drop off the buds in the evening. The part of the flower

that makes the capsule will remain on the plant. This

stage ends when there are 5 pairs of capsule nodes on

the main stem.

Photo 3. Natural bloom shed from healthy floral ovaries/

capsules, not caused by stress, insects, or disease.

Table 1. The phases and stages of sesame development.

Phase/Stage End point of stage Days after

Planting

Vegetative

Germination Emergence 0-5

Seedling Third pair true leaf length

equals second 6-25

Juvenile First buds 26-35

Pre-

reproductive 50% open flowers 36-40

Reproductive

Early bloom 5 node pairs of capsules 41-48

Mid bloom Branches and minor plants

stop flowering 49-74

Late bloom 90% of plants with no open

flowers 75-80

Ripening Physiological maturity(PM) 81-102

Drying

Full maturity All seed mature 103-112

Initial drydown First dry capsule 113-123

Late drydown Full drydown 124-134

These numbers are based on S32 planted in mid May 2005-2008, in Uvalde, TX, under irrigation.

P a g e | 5

Mid bloom stage

The mid bloom stage is the most productive stage

because the main stem and branches are putting on

capsules. Even though the plants flower 5-6 weeks, 70-

75% of the flowers are put on the 2nd

and 3rd

week of

flowering. Plants are pulling deep moisture at this time

with roots that may match or exceed plant height. At this

stage, the lower leaves that are shaded will drop. This

stage ends when the branches and minor plants stop

flowering.

Photo 4. Nectaries or rudimentary flowers may make

capsules in high sunlight conditions.

Late bloom stage

The late bloom stage defines the last irrigation. Irrigating after this stage may not be beneficial or may even be harmful by causing regrowth and/or preventing timely drydown. This is also the time to compare fields to make harvesting plans. The field that ends the late bloom stage first will most likely be the first to harvest, even if it wasn’t planted first. Differences in fertility and seasonal moisture influence the end of this stage. This stage ends when 90% of the plants have no open white flowers.

Ripening Phase

This phase is not divided into stages. Technically, it starts during the reproductive phase when the first capsule is formed. During this phase, most of the leaves fall off the plants. Leaves will turn yellowish green before dropping.

This stage ends at physiological maturity (PM). PM is when 75% of the capsules on the main stem have seed that have changed color from milky white to a cream/tan color. Mature seed will have a dark seed tip and a line on one side. PM is important because after that point, the crop is less susceptible to yield loss due to frost.

Drying Phase

Full maturity stage

The plants continue yellowing, lose the final leaves, and lose moisture. The full maturity stage ends when 90% of all plants have seeds mature to the top of the plant.

Photo 5. When seed are mature, the seed change color from a milky white as in the capsule below to a cream color in the capsule on top.

Initial drydown stage

During the initial drydown stage, new producers begin to worry about capsules opening. Capsule tips open just enough to let moisture escape the capsule and seed to dry. There may be some light seed loss from the tips of the capsules; however, the bulk of sesame’s weight is further down in the capsule. This stage ends when 10% of the plants have a dry capsule.

Late drydown stage

The late drydown stage is the final stage. The stage ends when the seed has 6% moisture and can be harvested. An indication that sesame has reached 6% moisture is when the plants are brittle and capsules easily snap off.

Key Factors

The key factors affecting the length of the various stages are as follows:

Good soil moisture will shorten germination and seedling stages but will lengthen the rest of the stages.

Higher fertility will shorten seedling stage but will lengthen the rest of the stages. The effect on germination stage is unknown.

P a g e | 6

Higher than normal temperatures will shorten the vegetative and reproductive phases.

Cool night temperatures will lengthen the ripening phase and full maturity stage.

Low humidity, wind, and/or heat will shorten all of the stages in the drying phase.

Frost may, and a hard freeze will, terminate the plants at any stage. In a freeze, even though plants will be brown in 3-5 days, they will not be dry enough to harvest for 7-10 days.

FIELD SELECTION

Soils

Sesame grows best on medium to light well-drained soils

that do not stand water. Sesame has been successfully

produced on most soil types. Water logged soils inhibit

oxygen to the roots and suffocate plants. If the plants do

not die, they will become more susceptible to root rots.

Sesame prefers slightly acid to alkaline soils (pH 5-8) with

moderate fertility. Although yield potential may be

reduced, sesame has shown to grow well in as low as 4.0

pH.

Sesame is more sensitive to saline soils than cotton or

alfalfa. Beware of years where the water table is low and

irrigation well water becomes more concentrated with

salts.

Sesame has a deep tap root that grows best in deep non-

compacted soils. Maximum yields are achieved when

there is no compaction. However, producers have

recognized one benefit of sesame’s root is the ability to

reduce compaction problems. This generally will require

time and energy that may come at a cost to yield.

Herbicide Carryover

Sesame is a broadleaf, like sunflowers, cotton, and

soybeans; and is NOT a grass. Sesame is not commonly

listed on labels, so follow the plant back restrictions for

cotton when making decisions for sesame.

Herbicide breakdown in the soil varies with light,

moisture, temperatures, and/or pH. A residual herbicide

that did not harm sesame in previous years could harm

sesame.

Monitor rainfall and irrigation since the previous crop

herbicide application. Herbicides can be dispersed,

diluted, or moved from the sesame root zone. If in doubt,

conduct a field trial by hand planting sesame in various

locations of the herbicide treated land to test emergence

and survival.

No Risk of Carryover Problems

In university studies, preemergence herbicides (PRE)

alachlor (Intrro®), diuron (Direx®), linuron (Linex®),

s-metolachlor (Dual Magnum®), and acetochlor

(Warrant®) used at normal rates showed no negative

effects on germination or stand.

Low Risk of Carryover Injury

Following hailed out cotton, sesame has been planted

after trifluralin (Treflan®) or pendimethalin (Prowl®) and

achieved normal stands. Normally, by the time adjusters

have released hailed out acres, these herbicides are not

as potent. “Yellow” herbicides applied just prior to planting

sesame may reduce or destroy stands.

Moderate Risk of Carryover Damage

There have been mixed results after prometryn

(Caparol®) or pyrithiobac (Staple®) applied preplant in

cotton. If these herbicides are located above or in the

seed line, sesame will not germinate. If these herbicides

are below the sesame, there may be an adequate stand.

In peanuts, sesame has followed imazapic (Cadre®) or

imazethapyr (Pursuit®), although in years of low rainfall,

the stands have been reduced substantially. When

applying dimethenamid (Outlook®) as a preplant in

peanuts, there have been results of no damage to

complete stand loss.

Very High Risk Rotations

Sulfuron wheat herbicides such as Amber®, Glean®,

Ally®, Finesse®, and Assert® have caused injury

ranging from complete stand destruction to little damage.

Often the sesame will germinate, but then will die within

10 days. Generally, corn and sorghum herbicide residues

from atrazine and sulfuron are detrimental.

Currently, studies are being conducted to determine the

rate and timing of application of 2,4D and other phenoxy

herbicides as a preplant burndown. 2,4D may destroy a

stand when applied too close to planting. 2,4D also

leaves a residue in the soil that can be picked up by the

sesame roots and in turn reduce yield.

P a g e | 7

Sesame in Rotation

SESACO strongly supports crop rotation. Rotating crops

with sesame will maximize the benefits of sesame to

those crops and return their benefit to sesame.

Producers have commented that after sesame, corn and

cotton will not show a stress as soon as fields following

other crops. None of the herbicides used in accordance

with a label in sesame have a rotation restriction to

interfere with another crop.

Primary crop

The highest yields have been achieved when sesame is

planted as the primary crop. Sesame is regularly planted

after the previous year’s cotton, corn, sorghum, peanuts,

alfalfa, or soybean crop without any problems. There

have been successful rotations with many vegetables as

well.

Double crop

Sesame is a viable double crop option for most

producers. With reduced water needs, sesame has the

ability to thrive in high temperature environments.

Sesame has shown profitable returns in these challenging

conditions.

Catch crop

Behind failed out cotton, sesame has been planted on

thousands of acres in Texas and Oklahoma. Producers

appreciate the relative tolerance of sesame to yellow

herbicides and not having to “bust below the yellows.”

This allows producers to use drills, planters, or both to

cover acres quickly after the adjuster has released the

field. Although the sesame growth cycle is about 30 days

shorter than cotton, each additional heat unit is

significantly valuable. Behind failed out corn or sorghum,

sesame typically does not work because of the

herbicides.

Reserved moisture

Overall, sesame is a low water use crop. Sesame is

unique in its ability to reserve late season moisture for the

following crop. Beginning in the late reproductive phase

and continuing through the ripening phase, sesame self-

defoliates and gets rid of most of its transpiring surfaces.

During drydown, or the last 30-40 days, water use is

minimal. Much of the rainfall that is received during this

period is not used by the sesame and reserved for the

following crop.

Residue

Sesame provides beneficial residue on the surface and

deep in the soil from its roots. The root matter of sesame

may result in noticeably more mellow soils. This

improves water infiltration and long term health of the soil.

Surface residue of sesame is generally 8-12 inches tall

and durable enough to catch snow and reduce blowing

sand. This residue is easily broken up and does not

interfere with tillage or planting equipment following

sesame.

Nematodes

Any crop that would benefit from having less root-knot

nematodes should benefit from a sesame rotation.

Research shows that sesame may be an effective

rotation crop to control peanut root-knot nematode

(Meloidogyne arenaria) and southern root-knot nematode

(M. incognita).However, sesame rotation is not effective

for the Javanese root-knot nematode (M. javanica).

Producers in Alabama have added sesame in rotation

with cotton, peanuts, and soybeans. Nematode levels are

reduced and yields increased significantly among those

crops in fields previously planted in sesame.

Break the disease cycles

Sesame is botanically in a different family than the crops

typically grown in the U.S. This means that most

diseases of common crops are most likely not going to

affect sesame, and the diseases that might affect sesame

are not hazardous to common crops.

Sesame after sesame and volunteer

Sesame after sesame can lead to an accumulation of root

rot spores. Eventually the root rots will reduce yields.

Growing a crop of wheat in between two summer sesame

crops does not provide enough of a buffer. An ideal

rotation is to have sesame every second or third year.

As with other crops, there is harvest loss that may

volunteer the next year. Some producers have wanted to

produce a crop from volunteer. The problem is

overpopulation and no way of controlling broadleaf

weeds. A few producers have successfully grown a

volunteer crop, but most have had to disk it in.

Volunteer sesame in any other crop has not caused

problems because commonly used herbicides easily kill

juvenile sesame. Producers have appreciated volunteer

sesame as a cover crop. As a cover crop, it does not use

much moisture, helps hold the soil from blowing, and is

easy to kill just before planting the intended crop.

P a g e | 8

Cotton after sesame

Cotton following sesame has benefited from reduced

nematode and disease pressure. Many producers have

incorporated sesame into their cotton rotation because it

increased yield; suppressed populations of root-knot

nematodes; and is not susceptible to cotton root rot

(Phymatotrichum omnivorum).

Wheat after sesame

Many producers have incorporated sesame into their

wheat rotation because it has shown to provide a

profitable double crop option. In southern areas,

producers prefer to grow sesame over higher water

demanding crops after wheat. The reserved moisture

allows the wheat to establish more early forage for cattle

gain. However, in northern areas sesame may push

wheat planting later, preventing forage production.

Timely sesame harvest should leave ample time and

opportunity for planting wheat for grain.

Peanuts after sesame

Many producers have incorporated sesame into their

peanut rotation because it has increased yield,

suppressed populations of root-knot nematodes, and

extended limited water.

PREPLANT CONSIDERATIONS Achieving an adequate stand is the most critical step to

becoming a highly successful sesame producer. Good

stand establishment depends on providing a firm

seedbed, protecting the seed from crusting during

emergence, and insuring the seed zone does not dry out.

Photo 6. Juvenile no-till sesame.

No-till

The basic principles of no-till are very beneficial to

planting sesame:

No-till residue protects moisture at the surface. This

may extend the planting window where more acres

can be planted before drying out.

The residue may “buffer” the surface from

environmental fluctuations. Although warm soil

temperatures may be delayed, fluctuations in

temperature are reduced.

Heavy rainfall droplets can be broken up by the

residue cover before impacting the ground, causing

surface crusting.

Reduces the threat of blowing sand in susceptible

fields.

Hair-pinning (pressing but not cutting through residue into

the seed trench) is often an issue. Hair-pinning reduces

seed-soil contact.

Photo7. No-till drilling sesame into standing wheat.

In the past, there has been concern about the amount of

residue that sesame may be planted into because of

shading. As long as the planting equipment is doing a

proper job of placing seed into the soil, the sesame is not

limited by the amounts of residue on the surface.

Conventional tillage

Clean tilling increases soil temperatures, insures an initial

weed free environment, and removes residue that may tie

up herbicides. Tillage can dramatically affect depth to

planting moisture. Understanding what and how different

tillage practices perform is critical.

P a g e | 9

It is important with sesame to plant into a firm seed bed.

There are several implements that will firm a seedbed.

Irrigation or a timely rain may firm a seed bed. Planting

through a crust is often best.

Sesame should not be planted in a trench. A large rain

during emergence may wash over the plants and

generally lead to replanting.

Preformed raised beds

Raised beds are used in sesame for two very opposite

reasons.

Dry conditions

A raised bed may provide a storage bank of moisture until

temperatures rise to sufficient levels to plant. With the

proper equipment, the top dry soil can be removed to

place seed in ideal planting moisture. Planter unit

attachments should be used to remove most of the dry

soil but not all. Exposing moist soil may cause baking of

the soil.

Wet conditions

Raised beds provide a way for excess moisture to be

drained from the seed zone. This allows better aeration

of the soil and reduces potential of seedling diseases.

Sesame is more sensitive to saturated soils than cotton.

Periods of saturated soils that turn cotton yellow in low

lying areas may kill sesame.

Row spacing

Producers will generally select their row spacing for

sesame to match their other crops to minimize equipment

changes. Lately, producers have shown a preference for

drilled or narrower rows. The advantages of narrower

rows are: the ability to canopy faster; more forgiveness in

stand establishment; and reduce evaporation losses from

the surface.

Evenly distributed plants have generally resulted in

healthier plants when there is less competition from one

another. Fewer plants per linear foot in a drill, compared

to many in wider rows are less affected by acute periods

of drought stress. After these periods of stress, the

healthier plants will react to rainfall and recover quickly.

When planting in a short season environment, drilling at

higher seeding rates is encouraged. The same yield per

acre can be achieved with more plants, with fewer

capsules per plant in less time.

Dry and buster planting

Dry planting is dangerous. If the sesame is planted

shallow in dry conditions and receives a rain, it may

become baked inside the crust at the surface. Sesame

dusted in that germinates on light showers may dry out

before reaching sustainable moisture.

Many times dry planting sesame does not establish a

stand sufficient to compete with weeds. Giving weeds

any head start in sesame can be a failure waiting to

happen. Depending on how much of an advantage the

weeds may have on the sesame, there is an economical

limit to what can be accomplished.

Buster planting is hazardous. Results have ranged from

poor to excellent in the right conditions. Water washing

over the seed trench may occur with just a small rain.

Blowing sand can cover emerged seedlings as well.

Buster planting should only be attempted in light sandy

soils that have high infiltration rates and/or with a high

probability of no rain or wind in the forecast for 10 days.

PLANTING DATES

Fig. 3. The map represents the traditional sesame areas, and the chart shows the times of planting, with the darker green being the optimum period in most years.

P a g e | 10

Traditional Areas

Figure 3 indicates the recommended planting dates for

traditional areas of SESACO production. The light green

shows the earliest and latest planting dates, and the dark

green shows the optimum time to plant.

The earliest date is based on when the soils should

maintain above 70°F at planting depth. There are warmer

years that allow earlier planting and cooler years that force

later planting. Sub-optimum temperatures during planting

and germination are a common issue when trying to plant

early.

The last planting dates are based on a combination of frost

dates in the northern areas and poor harvesting weather in

the southern areas. In southern areas, shorter days, less

heat, and high humidity prevent adequate drying.

The optimum dates are based on averages over many

years. Producers who plant earlier should have higher

yields because of greater day lengths and heat units. Yet,

producers that plant early going into an extended dry period

can have lower yields than the producers who plant later as

the rains return.

Early planted sesame generally gives the best yields and

the fewest pest problems. However, planting too early in

cool conditions for sesame can reduce yields because the

seedlings will grow slowly. Generally, sesame needs

about 10ºF more soil temperature than cotton for good

stand establishment. As shown in Figure 4, watch for

cold fronts or rain in the forecast which will lower

temperatures.

Fig 4. Example of soil temperature drop caused by a cold

front.

Volunteer sesame can be deceptive in that seeds can

germinate during a warm spell 30-45 days early.

Producers have then been lead to plant during cool

temperatures resulting in an inadequate stand. It is more

important to watch temperatures, moisture and the

forecast than the calendar date.

Expansion Areas

If you are not in the traditional area described above,

please contact SESACO for a recommended planting

date. There are many niche environments to consider

when selecting a planting date. Just as in the traditional

areas, crop rotations, annual moisture, and temperature

cycles must be considered to find a good planting date.

PLANTING

As with most any crop and no matter what equipment is

used, the overall goal is proper seed placement in

adequate moisture. Whether a conventional drill, no-till

drill, or planter, the philosophy is the same: minimize

seed depth to reduce the amount of time for emergence;

yet place the seed deep enough to ensure the seed will

not dry out before emergence. The keys to planting

sesame are securing sufficient moisture and temperature

to establish a strong advantage for sesame to compete

against weeds before preplant residual herbicides wear

off.

Photo 8. Check that the seed is in moisture often.

In most cases, the seed should be placed 1-1 ¾ inches

deep and into good moisture. Place the seed ½ inch to ¾

inch below the defined moisture line with a ¼ inch to 1

inch covering of dry soil above that line. Slowing tractor

speed down will increase uniformity in seeding depth.

While you are planting, the sun and wind can change the

depth to moisture. Check regularly during normal planting

conditions and more often on windy and hot days.

If a hot wind starts up, the seed will have to be planted

deeper to keep the moisture around the seed. Increased

planting rates are encouraged if planting deeper.

Sesame seed can imbibe moisture quickly. The initial

roots can grow down quickly, ahead of the drying line.

This may allow sesame to emerge on less moisture than

30

40

50

60

70

80

90

0 12 24 12 24 12 24 12

Time of day (24 hour clock)

Tem

pe

ratu

re (

F)

Soil temperature 1inch deepAir temperature

P a g e | 11

larger seeded crops. Be sure to press the seed into moist

soil and place dry loose soil above it to prevent drying

out. Seed firmers or rebounders are recommended. The

seed needs to have moisture around it for 3 days (warmer

late planting) to 5 days (cooler early planting). Air

pockets in a soil can be as large as or larger than a

sesame seed. Moisture does not move through air

pockets, it moves from soil particles to seed. Seed to soil

contact is critical.

Pressing seed into moist soil is important, but it is equally

important to not have compacted soil above emerging

sesame. Soil moisture cannot move from smaller pores to

larger pores. This being said, loose surface soil will

prevent moisture wicking from the seed zone and

generally will not bake into a hard crust. Planting in soil

that is too wet will often cause the closing wheels to

overly compact the row.

Seed Metering Equipment

Most metering mechanisms used to date have worked

successfully when maintained, set, and calibrated

properly. This includes plate planters, vacuum planters,

volumetric drill meters, and air drill meters.

Photo 9. Sesame seed is small. Proper calibration is critical.

Calibrating your planting equipment is critical. It is not

critical to the level of knowing the exact seeds per foot

like in current high valued crops, but it is easy with small

seed to be off by a pound or two. Take the time to

calibrate your planting equipment properly. Make repairs

where needed. A shot in the dark can be a shot in the

pocket book when you run out of seed or don’t put out

enough seed to make a stand.

Photo 10. Even distribution of seedlings in 7.5” drill.

Planting Rates

As shown in Table 2, most producers plant between 2.0

to 5.0 lbs/ac, depending on row spacing, equipment, and

planting conditions. The cheapest insurance for sesame

is to plant enough seed the first time.

Seeds are small and planted close together to help each

other to push up soil and emerge together. Planting

fewer seed/ft can end up with large skips.

Table 2. Planting rates for different row spacing.

Row Spacing (Inches) 40 36 30 15 7.5

Rate (lbs/ac) 2.2 2.5 3.0 4.0 5.0

Population (sd/ft) planted 27 28 28 19 12

Increase seeding rates when planting:

Deeper

In compacted soils

In cloddy soils

In cooler temperatures

In marginal moisture

When soils change within a field

In fields with possible harmful herbicides residues

Decrease seeding rates when planting:

In closer row spacing

In well prepared firm soils with good moisture

When soil temps are above 80 degrees

There have been no statistical differences in yield

between 3-8 plants per foot at harvest in studies on 30”,

36”, 38”, and 40” row spacing. One to two harvestable

plants per linear foot in a solid drill is a sufficient stand.

Recommended seeding rates have been developed from

years of experience in a wide range of conditions.

P a g e | 12

MOISTURE AND NUTRIENTS

Fig. 5. General water and nutrient use curve for all crops.

With sesame or any crop, resources such as water and

nutrients should be managed in a balanced fashion within

sufficient time to meet demand. Shown in figure 5, as

plants absorb water, they absorb nutrients that are

dissolved in the water. This results in the water and the

nutrient use curve being the same.

When plants are small with few leaves, little water is

transpired through the leaves, and nutrient absorption is

low. As the plant produces more leaves, more water is

transpired, more water containing nutrients is absorbed,

and both water and nutrient uptake increases. As the

plants mature, water uptake is reduced, which reduces

nutrient uptake.

If there is inadequate water, adding more nutrients will

not increase yield. Conversely, if there are inadequate

nutrients, rains and irrigations will not increase yield.

In order to have maximum yields, water and nutrients

need to be available just prior to bloom and through

bloom or approximately week 5 through 11 after planting.

Moisture Management

Water is to plants what blood is to animals: it carries

nutrients and chemicals into and throughout the plant. It

is used in the photosynthesis process to produce energy,

sugars, oils, and protein for growth and seed production.

Water is essential to cool the plant through transpiration

and prevent desiccation. Water is the first limiting factor

to production.

If water is available throughout the production cycle,

generally sesame will produce 80 to 120 pounds of seed

per inch of plant available water. Although sesame is a

drought tolerant plant, it still must have sufficient water.

Like any other plant, early canopy development is

important to produce adequate internode length and a

healthy fully leafed plant before bloom. At first bloom,

plants should be 10-12 inches tall and 8-10 inches wide.

Although sesame is able to endure longer periods

between droughts than other crops, the production

potential of the crop will be reduced if irrigation or rain is

not received at the optimum time. The ideal situation

would be to have a full profile of water, plant in moisture

and replace what is used without saturating at anytime.

Many producers try to plant at a time to match the peak

demand period of their crops with either a time of year

that historically sufficient rainfall or available irrigation

during flowering and seed fill.

To illustrate the comparative water use of sesame to

common crops, an independent crop consultant recorded

irrigation applied to sesame, sorghum, cotton and corn in

2009 in Uvalde, TX. In that year there was zero rain from

the beginning of the year through maturity. Table 3

shows that sesame used about half the water of corn to

achieve a comparatively good yield.

Table 3. Comparative water use to achieve good yields.

Crop Water Use

Sesame 12 to 16 inches

Sorghum 17.7 to 19 inches

Cotton 19 to 22 inches

Corn 22 to 24 inches

Table 4 shows the anticipated water use rates and

amounts that should be replaced by rainfall or irrigation

for optimum yields by development phase. The actual

water use rates will vary depending upon row spacing,

surface residue, humidity levels, sub-soil moisture, wind

and daily temperatures. Moisture sensors are important

to prevent either excess or under irrigation.

Table 4. Water use of sesame by development phase.

Phase Days after planting Water use

Vegetative 0 - ~40 2 – 4 inches

Reproductive ~41 - ~80 6 – 9 inches

Ripening ~81 – ~102 1 – 2 inches

Drying ~103 – harvest 1< inch

Dryland

In all production but especially in dryland production,

three types of moisture are important for successful

production;

Surface moisture surrounding the seed at planting is

critical to all crops. Moisture in sufficient supply is

needed to germinate the seed and establish the crop.

P a g e | 13

Sufficient stands are dependent upon adequate soil

temperatures and moisture for the seed to imbibe and

start the growing process. Deep moisture is of no benefit

if there is no surface moisture for early seedling

development. The lack of uniform moisture at planting is

the most common cause of poor stands. Because

sesame is such a drought tolerant crop, some producers

put it to the test at this stage thinking that drought

tolerance will overcome poor surface moisture.

Deep soil moisture is critical to keep the plant’s root

growing. Plant roots do not sense and grow to water –

but continue to grow through and into moist soil. If a

developing root tip encounters a dry layer, the root tip will

stop growing and often die. Since sesame has a tap root

system, the main root may not properly develop resulting

in a shallow more fibrous root. By knowing soil profile

status, better management decisions can be made, such

as application rates for fertilizer.

In season moisture that soaks into the profile will enable

the plant to continue to grow, set capsules and fill the

seed. The amount of water in the rain gauge does NOT

determine how much water is plant available. Many

heavy thunderstorms produce large amounts of water too

quickly to be absorbed by the soil and run off. Furrow

diking, residue, drill vs. row planting and other agronomic

practices can slow runoff and increase water absorption.

Irrigation

The key to irrigating sesame for maximum yields is to

monitor soil moisture and constantly evaluate internode

growth. Use either, soil moisture sensors, an auger or a

shovel to determine moisture levels. Like cotton, too

much water results in long main-stem internodes, tall

plants and delayed maturity. While inadequate water

produces short stressed plants with low leaf area,

reduced capsule formation, early termination of flowering,

and lower yields.

As previously described, starting with a full profile and

replacing what moisture is transpired or evaporated

throughout the season is ideal. Since normal is not

normally what happens, here are some tips.

Pivot Irrigation

As a starting point irrigate 1-1.25” every 6-8 days with a

total of 5-6 irrigations. This is a generalization for areas

that typically receive and/or store 6 to 8 inches of

moisture.

Photo 11. Irrigating in the late juvenile stage just

before visible buds.

Pre-irrigating to a full profile and planting into wet soil is

recommended. A pre-irrigation should join top moisture

to bottom moisture with no dry layer in between. In dry

years, enough water should be applied to wet the soil 1.5

to 2 feet deep. Adequate soil moisture is needed prior to

planting to:

prevent rapid surface drying at planting,

develop a deep root system and early robust canopy,

prevent early irrigations that cool the soil and

germinate weeds.

Dry surface conditions: If moisture is deep (within in 1

foot) and surface conditions are dry, applying 1-2 inches

prior to planting is preferred over relying on irrigation after

planting. It is preferred to not have to water up. On

occasion we are forced to add moisture just after planting

to wet the seed and drive moisture to meet below the

seed. It is to be important in sesame to be more

deliberate in actions than reactionary in these situations.

To be successful in this situation we recommend these

steps:

1. Day 1, Plant shallow (0.5-0.75 inches) to allow for

quick emergence and reduce time for the soil to crust

as it emerges.

2. IMMEDIATELY after planting apply glyphosate and

Dual.

3. IMMEDIATELY after applying herbicides, apply a light

irrigation (0.5 - 0.75 inches) to set and activate the

herbicide.

4. Day 3-5, as required lightly irrigate (0.3-0.5 inch) to

soften any crust and allow seedlings to emerge. The

amount and frequency will depend on soil types and

current evaporation rates. The objective is to keep the

moisture around the seed and root. This is a very

sensitive period when sesame is in the crook and

emerging. Broadcast sprays can damage tender plants

P a g e | 14

and/or cause shallow flooding over very small

seedlings that are in a crack or indentation. If at all

possible, try to avoid this application but sometimes it

is necessary.)

If conditions when starting are completely dry, some

additional precautions are warranted. Understand this

situation is acting against the historical nature of sesame.

Sesame’s history is to be grown in wet soils after a

monsoon season and then survive the rest of season

without much additional moisture. Sesame’s main asset is

to put down a deep root and access moisture and

nutrients there. At the same time sesame is sensitive to

saturated conditions that would be necessary to push

water deep.

In completely dry conditions, it is recommended to use

the techniques described above in getting a stand in dry

conditions above followed by:

1. Day 8-12, irrigate 0.75 – 1 inch to provide additional

moisture to the profile.

2. Install sensors to monitor soil moisture.

3. Wet the soil to 2 feet as soon as possible.

4. Maintain that moisture level throughout the crop.

Photo 12. The last irrigation is when the flowering is

ending.

Terminating Irrigation

Generally, irrigation is terminated when the sesame stops

flowering. Although it takes 25 days for a flower in the top

of the plant to mature seed, there is usually enough

moisture in the soil to terminate the crop. Adequate

moisture needs to be provided for capsule filling without

promoting regrowth. In cooler climates regrowth is less of

a factor but then seed maturation is limiting. Once the

night temperatures drop into the 40-50 range, sesame

development slows down. If nutrients are available, the

plants may continue to flower. It is important to force the

plant to stop flowering and concentrate on seed fill by

terminating irrigation. If the crop is still flowering after 85

days, do not irrigate any more.

Drip Irrigation

Drip irrigation of sesame is very similar to pivot irrigation,

with the biggest difference at planting. Because the

capillary action of water movement seldom reaches the

surface of the soil, the seeding zone is often dry, even

though the subsoil may be saturated with water. Rainfall

is almost a necessity to wet the surface soil for seeding.

It is advisable to have a bed of some kind to move dry soil

off at planting.

Row Irrigation

Sesame has some unique benefits for row watering. Its

low water demand allows it to be watered less when row

water is labor intensive. Fields that are difficult or less

efficient to water with short run lengths are candidates for

sesame.

Pre-irrigate then plant to moisture. The pre-irrigation will

generally be enough until the first buds form, about 30-35

days after planting. Watering up sesame with row

irrigation is risky. If water covers the top of the bed, the

resulting crust above and saturation around the seed will

usually prevent seedlings from emerging. As a starting

point¸ irrigate 2-4” every 10-16 days with a total of 3-4

irrigations. Reduce volumes only when effective rains

occur.

Sesame does not like saturated soils, and will turn yellow

and stop growing. If standing water occurs, the sesame

may die. Compared to other crops, in season

applications should be lighter applications and more

frequent, rather than complete bed soaking. Surge

techniques are recommended and watering alternate

rows helps prevent saturated soils. Depending on soil

type light irrigations may prevent problems if it rains

following irrigation. Just like cool temperatures are more

detrimental to sesame than hotter, over watering is more

detrimental than slightly under watering. Although it may

be called “flood” irrigating, please do not flood sesame.

Sesame prefers to keep the water in the rows and be

“row” watered versus “flooded”. If water is allowed to

collect at the field end against a border, that sesame may

be stunted or die.

P a g e | 15

Nutrient Management

Sesame is an efficient user of available nutrients. An

extensive root system allows sesame to capture mobile

nutrients deep in the soil. As with all crops, the highest

yields are with a balance of water and nutrients. A good

balance is 5 lbs of N, 2.5 lbs of P (P2O5) and 4 lb of K

(K2O) per inch of plant available water. As with water,

having the nutrients available relative to the demand is

important. Available means at the right time, place and

form that the plants can absorb them.

Historically, many fertility programs were developed off

the principle of a “yield goal” and the amount of nutrients

removed at harvest. In a 1,000 lb/ac crop, the seed taken

from the field contains 34.4 lbs of N, 16.6 lbs of P and 6.7

lbs of K. Plant material that will return to the soil would

contain about 30 lbs of N. From these estimates, Table 5

has been developed as a general recommendation for

sesame.

Table 5. Relation of water availability to amount of nutrients.

Water Availability Units

of N

Units

of P

Units

of K

Dryland (5-8”) 25-40 15 35

Dryland (8-10”) 40-50 20 40

Supplemental irrigation (6-8”) 40-60 25 50

Full irrigation (12-16”) 60-80 35 100

Nitrogen

A good average is that sesame will need 30 lbs of

nitrogen in a dryland situation. If wetter than usual at

planting, add more. If drier, use less. A blanket rate of

nitrogen may not be the best management practice

because soil type and depth vary. Depending on these

factors, the soil profile can provide 2-10 inches of

available moisture. Without any additional rainfall or

irrigation, 15-60 lbs of total nitrogen may be required to

balance that level of moisture.

As growing conditions develop during the season

additional nitrogen may be needed when conditions are

favorable. In this case, make additional applications prior

to flowering. Under irrigation or high rainfall, total

nitrogen demand can range from 60-80 lbs/ac.

Producers can split applications, putting on half before

planting and side dressing the other half just prior to

flowering. Producers that cannot do a split application,

use a slow release fertilizer to avoid excessive vegetative

growth.

Some proper nitrogen application methods include:

Placing fertilizer in the rows that are not receiving

seed in wider rowed drill applications.

Banding liquid fertilizer after or to the side of the

closing wheel.

In any configuration below the surface not in direct

seed contact.

Post emerge with dry fertilizer, or liquid fertilizer

applied through streamer nozzles

Fertigation through a center pivot.

Do not apply nitrogen in direct contact with the seed.

Do not broadcast liquid fertilizer over emerged

sesame.

Phosphorus and Potassium

Soil levels of P and K vary considerably in different parts

of the sesame growing area. Both elements are very

important to plant growth, and deficiencies can lead to

poor yields despite optimum water and N.

Phosphorus has low solubility and will move only small

distances in the soil. Most surface applied P stays at the

surface. Apply P as close as possible to the active root

system. P is the only nutrient that should be banded to

save money. N and K move in the soil.

Potassium is found primarily in the plant tissues with very

little in the seed. It is important for vegetative

components such as the stem. In most sesame growing

areas, K is not limiting.

PEST

Weeds and Herbicides

An important philosophy to producing sesame is to give

sesame an early clear advantage, and it will reward you

later by taking care of itself. Start with a clean field.

Final grades can be affected by weedy fields.

Johnsongrass, bindweed, mintweed, kochia,

lambsquarters, fall panicum, buffaloburr, tickseed, and

Russian thistle are difficult to clean out of sesame. Loads

delivered with seed from these weeds may lower your

grade.

P a g e | 16

Herbicides Labeled for Use on

Sesame

Presently in the US, there are only three herbicides

labeled for sesame:

Dual Magnum® (s-metolachlor) may be used as a

preemergence herbicide; applied after planting, but

before emergence to control pigweed and small seeded

grasses. The most common use is to apply a tank mix of

s-metolachlor with glyphosate within one day after

planting. The glyphosate controls existing weeds and the

s-metolachlor controls germinating weed seeds. As with

most herbicides, Dual Magnum® must be activated

(moved into the soil) by a rain or irrigation.

Photo 13. Do not spray Select Max® during flowering.

Select Max® (clethodim) is a grass herbicide and can be

sprayed in the first 30 days or after flowering. In 2009-

2011 timing studies, Select Max® prevented capsule

formation when sprayed during flowering as shown in

Photo 13. Some varieties are more susceptible than

others. Clethodim has shown to be effective against

Texas Panicum.

Roundup Max® (glyphosate) may be applied as a

burndown, with wiper applicators, and hooded sprayers in

row-middles. For burndown, glyphosate should be

applied before, during, or just after planting, but before

the seedlings emerge. Caution, sesame can emerge in as

little as 2.5 days. If it does emerge prior to application,

glyphosate cannot be used. If weeds are present, starting

over may be the only option.

Thick stands of weeds may need to be sprayed twice

before planting; first to kill larger weeds protecting smaller

weeds from being contacted by the herbicide and second

to reach the smaller weeds underneath.

Herbicide Research (not labeled)

The American Sesame Growers Association (ASGA)

is currently supporting herbicide research at Texas A&M,

Texas Tech, Oklahoma State, Kansas State, and Auburn

Universities. Initial work has shown diuron (Direx®),

linuron (Linex®), a premix of the two (LaybyPro®), and

acetochlor (Warrant®) are also good preemerge (PRE)

herbicides, and requests for labels will be filed with IR4.

Studies with “postemergence over the top” (POST OTT)

applications of herbicides for grasses has shown many

are effective. There are flushes of grass that can come

up later in the season and grow lower than the sesame.

Although the sesame has plenty of light, the fibrous roots

of grasses are very competitive for moisture. High

moisture grass content may delay harvest and should be

controlled. Timing of application studies using clethodim

(Select Max®) sprayed before and after flowering

controlled grasses, but can reduce yields substantially if

sprayed during flowering. Fluazifop-P (Fusilade®),

sethoxydim (Poast Plus®), and quizalofop p-ethyl

(Assure®) worked at all stages of growth with minimal

effect on the sesame.

Most herbicides that kill broadleaf weeds will also kill or

damage the sesame. In some areas of the world, a

second PRE herbicide (s-metolachlor or acetochlor) has

been applied over the top to extend residual weed

control. In 2008-2011 studies, diuron (Direx®) applied 4

weeks after planting produced yellowing on the sesame

leaves, but there was minimal yield loss. However,

application before 4 weeks and during flowering may

reduce yields.

Other studies have been made with postemerge directed

sprays from 2005-2010. Prometryn (Caparol®), diuron

(Direx®), linuron (Linex®), and a premix of the two

(LaybyPro®) have controlled emerged weeds and

provided residual control.

P a g e | 17

ASGA supported a study of worldwide research and use

of sesame herbicides. The following herbicides have

been used in sesame fields in Asia, Africa, Central

America, and South America:

PRE: alachlor (Intrro®), diuron (Direx®), fluometuron

(Cotoran) [Preliminary work in the US in 2008-2010

showed extensive potential damage from Cotoran],

linuron (Lorox®), pendimethalin (Prowl), and trifluralin

(Treflan®). Extensive work in the US on pendimethalin

and trifluralin have indicated that full rates recommended

for cotton may reduce stands on sesame unless they are

applied much in advance of planting, allowing the product

to break down to an acceptable level.

POST OTT: diuron (Direx®), fluazifop-P (Fusilade®),

haloxyfop (Verdict®), and sethoxydim (Poast Plus®).

POST DIR: diuron (Direx®).

Herbicide Drift

Sesame is extremely susceptible when it comes in

contact with some herbicides whether by drift or direct

contact. If the label has a cotton restriction, sesame will

most likely be similarly affected.

Glyphosate (Roundup®). Symptoms from glyphosate

drift vary. Very light drift may show no symptoms to

vegetative structures but reproductive structures may be

smaller or abort capsules for 1-3 weeks. Heavier contact

will cause sesame to turn yellow or die.

2,4D. Sesame is extremely susceptible. Residual 2,4D of

a preplant application may remain in the soil and can

destroy a stand of sesame. Damaged plants from drift

have twisting stems and will not make capsules for 1-3

weeks.

Glufosinate (Liberty®). Sesame will suffer from contact

with glufosinate.

Paraquat (Gramoxone®). Leaf damage or early loss of

leaves from paraquat reduces yields.

Cultivation

Cultivation can be an effective means of weed control in

sesame depending on the weed population and types of

weeds. However, cultivation cannot reliably control weeds

within the seed row that emerge while the sesame is

emerging.

As described earlier, sesame grows slowly in the

beginning, but accelerates its growth substantially about

30 days after planting. In the past, producers waited 3-4

weeks to cultivate, but with GPS equipment earlier

cultivation may now be possible.

Photo 14. Timely cultivation provides effective weed control.

Sesame roots follow moisture. With rain or irrigation in

the first few weeks after planting, the roots may grow

laterally and stay near the surface. Cultivating too close

to the plant will cut the roots and plants will wilt quickly.

On the other hand, during a dry season, roots may grow

more vertically allowing closer cultivation.

After the plants are about 12” tall, soil may be thrown up

on the base of the sesame plants, covering any small

weeds.

Sesame can be cultivated when slightly taller than axle or

toolbar height, but it should be done in the afternoon

when the plants are less turgid. Flower petals may fall,

but the young capsules are rarely knocked off by the

tractor. Breaking or creasing the main stem damages the

sesame.

Do not give up on what looks like a loss to weeds.

Sesame initially grows very slowly and after 30 days, will

grow up above many weeds. Cultivation may provide

considerable help.

Wicks or Wipers

The days prior to sesame’s rapid growth phase (20-30

days after planting) is a good time to have a height

differential between sesame and weeds to use a wick.

Diseases

Through plant breeding, present commercial varieties

have incorporated field tolerance to common diseases

encountered since 1978.

Cotton root rot (Phymatotrichum omnivorum). Sesame

is not susceptible to cotton root rot, and cotton is not

susceptible to sesame root rots. Producers in Arizona

and Texas have reported that cotton following sesame

has significantly less cotton root rot the following year.

P a g e | 18

Sesame root rot (combination of Fusarium oxysporum,

Phytophtora parasitica, and Macrophomina phaseolina).

These root rots have been encountered mostly on fields

where sesame is planted after sesame. The current

varieties are tolerant but not resistant to the root rots.

The best way to avoid sesame root rots is to rotate

different crops every summer.

An unidentified leaf disease (probably Pseudomonas) has

appeared in several years when there are cloudy damp

cool days, but the plants have grown out of the problem

when sunny days return. Normally, there has been little to

no economic damage encountered.

Rhizoctonia, Helmintosporium, Thielaviopsis, Verticillium,

Cercoseptoria, Cercospora, Pseudomonas, Cornespora,

and Leveillula have been reported in sesame in the US in

research nurseries but have not been seen in commercial

fields since 1978. A new type of Alternaria was seen in

2006 on the Caprock in both sesame and cotton but has

not repeated.

Insects

Through plant breeding, present varieties have

incorporated tolerance to all insects encountered since

1978. Since 1978, less than 5 fields have been destroyed

by insects and less than 10 have had significant

economic damage. All of these problems occurred prior to

1994 and were on fields planted late. Normally, beneficial

populations of insects control the few insects seen.

Silverleaf whitefly (Bemisia argentifolii). When the

silverleaf whitefly appeared in 1991, the varieties were

very susceptible. Since that time, whitefly tolerant

varieties have succeeded when planted on time. North of

Interstate 10 in Texas, the whitefly populations have

never built up to pose a significant economic threat to

sesame. In the Winter Garden area, late planted

sesame is susceptible to the whitefly in a hot dry year.

Sesame should be planted early to have the sesame

ripening before the whitefly reproductive cycle

dramatically increases. In the Lower Rio Grande Valley,

whitefly can be a severe problem necessitating two

growing seasons. Sesame should not be planted after

May 1, and can then be planted in July in light whitefly

years and mid-August in heavy whitefly years. Rains

appear to suppress the whitefly and newer varieties have

more tolerance to whiteflies.

Cotton aphid (Aphis gossypii). Sesame has not shown

susceptibility. In many years in fields with both crops

planted side-by side, the cotton 40” away from the

sesame is covered with honeydew while there were no

aphids on the sesame.

Beet army worm (Cupis unipuncta). In 1995, in the

Rolling Plains, the army worm did not attack the sesame

where cotton and alfalfa were devastated next to sesame

fields. In the fall of 2006, army worm devoured pigweeds

within the sesame field before moving to retire on the

sesame.

Cabbage loopers (Pieris rapae). In 1995, in the Rolling

Plains, the loopers did not move into the sesame,

although loopers have done some damage in the San

Angelo area in previous varieties.

Green peach aphid (Myzus persicae). Previous varieties

of late planted sesame were susceptible to the green

peach aphid – the major aphid in pecan groves. No

economic damage from aphids has been seen in sesame

since 1992.

Fire ants (Solenopsis invicta) can move down a seed line

and take every seed to their mound.

Cutworms (Various species) can mow down a seedling

stand and usually appear for a limited time that may or

may not coincide with the seedling stage.

Bollworms (Heliocoverpa zea) and garden webworms

(Achyra rantalis) have been seen in sesame but damage

has never reached an economic level.

Grasshoppers (Trichoplusia ni) can damage the edges

of the fields near pastures in dry years. Plagues during

the early stages can devour sesame while during later

stages damages are much less.

Yellow striped blister beetles (Epicauta vittata) which

can devastate other crops such as alfalfa and soybeans

have not affected sesame.

Miscellaneous caterpillars can damage sesame, but to

date, there has not been enough pressure to spray.

Most insecticides are not labeled for sesame. Bt

(Bacillus thuringiensis) and neem (Axadirachtin) are

cleared for use on sesame.

P a g e | 19

Photo 15. Hogs do negligible economic damage to sesame.

Wildlife

Wild Hogs

Wild hogs may bed-down in sesame but do not eat the

sesame. The only damage is in the bedding area and the

trails to water and food. There has been damage if the

sesame is left in the field after it could have been

harvested.

Deer

The only time deer damage sesame is when there is no

alternate food source. Deer set up trails in the sesame

on their way to cotton, corn and sorghum fields which can

be devastated. The deer may pick off capsules if the

sesame is left in the field for an extended time after it

should have been harvested.

Birds

Birds have done negligible damage to sesame. Hunters

have raised shattering sesame for dove hunting. The

new ND varieties release seed slowly all winter allowing

food sources for quail and pheasants. Flocks of doves

have stayed around sesame nurseries well into March.

Other animals

Cattle, sheep, horses, and goats do not like green

sesame. These animals have been turned into weedy

sesame fields, and they have done a good job cleaning

weeds from the sesame.

Game bird plots

By special written agreement SESACO permits seed to

be used by growers in overwintering game bird food plots.

ND sesame will degrade and release seed thru winter.

HARVEST

For more details see the SESACO Harvest Guide.

As sesame completes drydown, either by natural

maturation or result of a freeze, it will become ready for

harvest; exactly when to harvest is known by monitoring

the moisture of the sesame. Timeliness is the key to

maximize yield potential, so it is important for your

combine to be ready before your crop reaches target

moisture.

Photo 16. Sesame self-defoliates prior to harvest.

Moisture Matters

For optimum yields, sesame must be harvested as soon

as crop moisture falls below 6%. Fields that have green

weeds at harvest are especially vulnerable to moisture

problems. The green plant material will enter the combine

bin with the seed allowing the sesame to absorb the

excess moisture. Every effort should be made to

eliminate or reduce the green weeds in the field prior to

harvest. Harvesting below 6% will allow efficient seed

removal from the capsules with very little effort from the

combine.

Moisture is generally easy to check by seeing if capsules

“snap” when broken off the plant. If conditions are dry

enough to strip cotton, usually sesame is dry enough to

harvest.

Reaching 6% moisture is critical but NOT DIFFICULT.

Getting sesame below 6% moisture is no different than

getting corn below 14% moisture. Sesame cannot be

cost-effectively dried once it is combined. Rushing the

crop may result in price discount, and a few days of

patience might well be worth it. It is well worth the effort

of sampling a field for moisture at the elevator. Do not

wait to sample till you fill the combine bin.

P a g e | 20

Generally, sesame begins drying once humidity falls

below 50%. Drying can be rapid if proper sunshine and

humidity are present. Generally, after a rain, dry sesame

will be ready to harvest before cotton or sorghum.

Header

Draper headers are the most suitable header for sesame

harvest, as they are the least aggressive with the plant

and help the crop flow into the combine. The most

common header used is the conventional platform

header.

Photo 17. The most common header is a platform header.

Threshing

A conventional, rotary, red, green, yellow or gray combine

set properly can efficiently harvest sesame. There is no

one setting for a combine that will work in all conditions.

The initial settings are a starting point and not final

settings. Minimal breaking of seed can be obtained by

using a low/mid-range concave opening similar to corn

and cylinder speeds of 300-340 rpms. The air should be

set to 680-720 rpms and the chaffer/sieve is set to

roughly 6mm and 4mm, similar to flax.

To simulate the goal of threshing sesame, take a dry

sesame capsule, invert it, and twist it between your thumb

and forefinger while applying gentle pressure equal to

snapping a peanut shell. When the capsule snaps or

cracks, all of the sesame will be released without grinding

the capsules. First time producers are amazed to see

whole capsules exiting the combine without any seed in

them.

Seed grades received by the producer are largely

dependent on combine efficiency. Foreign Material (FM)

and moisture are the most common factors in lowering a

producer’s grade. Proper combine settings and timing

help to minimize this factor.

Photos 18-20. Any color combine will work in sesame.

Photo 22. Clean sesame filling the bin.

P a g e | 21

EQUIPMENT AND SETTINGS

If your equipment is not listed here, CALL SESACO, we

can help.

Broadcasting with a Brillion, Kinze brush meters and

double run grain drills do not work.

JD 1910 Commodity Air Carts

Use the fine seed meter (yellow). From the manual, start

with the flax setting and conduct a standard calibration

test to get within range of the proper setting. Then do an

in-field calibration of at least 2,000 ft to accurately set the

drill.

JD 1890 CCS Drill

Use the small rollers and calibrate using manufacturer

recommended flax setting as the starting point.

Box Drills

Calibrate using manufacturer recommended flax setting

as the starting point. Meters should be able to meter

without grinding seed. Check metering cups for proper

placement to have equal openings sizes.

John Deere MaxEmerge

Have not seen problems putting sesame through a

Central Commodity System.

Install JD Part No. AH129125 Knockout Wheel.

Lower the seed meter baffle in the small seed

position.

Disk Sorghum A43066 or Sugar Beet H136445

Follow Operator’s Manual “Adjusting Meter Hubs” for

seed leaking between the disk and seed meter

housing.

Use low range input sprocket.

Start with Driver 24 and Driven 26.

Driver changes about ½ lb/ac on 30” rows.

Driven changes about 1/10 lb/ac on 30” rows.

Driver Rate in lbs/ac

29 2.75-3.25

24 2.25-2.75

20 1.75-2.25

Vacuum should be set for 4 inches. Small changes in

the vacuum setting make huge differences in seeding

rates. At 4 inches, each cell is picking up 8-10 seed

per cell. On CCS systems you can see the plate

pickup seed through the window. With hopper boxes,

the hopper has to be separated from the meter to see

the seed picked up by the plate.

Check for other leaks where the seed box attaches to

the meter housing, and where the brush holder

attaches to the housing. Apply silicon and let dry.

Expect a small amount of leakage through the cell

even while running low air.

Always take time to double check and verify your

seeding rates. Start verifying your rate by using a

minimum known amount of seed, like one or two bags

before filling the planter. Continue to monitor

seeding rates to gain more and more confidence that

there are no problems.

If your planter is old or has planted a lot of treated

seed, do not expect to go directly to the field. It can

take some time to clear rust and seed treatment

buildup. Also, if force is applied to loosen the hub,

parts can be broken requiring replacement parts. If

the planter is new or recently overhauled, this setup

can take just a few minutes.

P a g e | 22

Monosem NG Plus Planter

Plate DC144-08 or DC 120-08

Light vacuum setting

When selecting a Monosem plate, check to get as many

cells on the plate as possible, even higher than 144 if

possible. Because a Monosem can actually singulate

sesame seed, the plate must turn at extremely fast speeds

when having a lower cell count to the plate. A 72 cell plate

restricts planter traveling speeds to below 2.5 mph. At high

plate speeds, seed are cut in half by the brass seed scraper

and sucked into the cell causing cell blockage by the

vacuum. There is no mechanism to remove the blockage

and soon all cells can be blocked.

CNH AMS 1200

CNH AMS 1200 vacuum planter has not been used to plant

sesame. SESACO is currently visiting with CNH about

plate recommendations. Call SESACO or talk to your

equipment dealer for ordering custom made plates at least

45 days ahead of your intended planting date. One

producer has modified his meter housing to contain the “JD

Knocker Assembly” #AH129125 for use with other small

seed crops.

Kinze EdgeVac

To date, the Kinze vacuum planter has not been used to

plant sesame. Contact your equipment dealer and

SESACO representative early to investigate a suggested

setup.

White

White planter has been successfully used. The producer

used a die cast grinder with a thin grinding wheel to make

notches in a blank seed plate. The plate contained 45

notches. Contact the manufacture for other possible

alternatives.

Horizontal Plate Planters

Two piece plastic plate sets for IHC and John Deere

planters can be ordered from: Lincoln Ag- Products

Company, Lincoln, Nebraska, at (402) 464- 6367,

lincolnagproducts.com. These compensate for false bottom

wear and provide good seed control.

John Deere: B-Sorg 00-30 Plate, BFR-1 Ring.

International: C-Sorg 00-30 Plate, CFR-1 Ring. A red

"Star Knocker" (CSK-1) helps these plates avoid seed

damage.

Cup or Bowl Meters

John Deere MaxEmerge bowl style meter: JD part #

A25081 Shim, A36323 Plate, and AA25319 bowl set.

John Deere 80: "Low rate sorghum attachment", JD

part # B31298 Feed Cup Spacer, B31205 32 Cell

Feed Cup, B31300 Thrust Washer.

P a g e | 23

FOR FUTHER INFORMATION CONTACT: (806) 892-3187

Visit our website: www.sesaco.com

Also visit the American Sesame Growers Association at: www.sesamegrowers.org

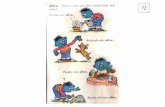

Germination Seedling Juvenile

Mid Bloom Early Bloom Pre-reproductive

Full Maturity Ripening Late Bloom

Initial Drydown Late Drydown Time to harvest

DEVELOPMENT OF SESAME