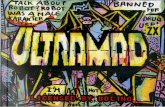

Zx self prime

description

Transcript of Zx self prime

ZX

Summarize

ZX

Application scope

100 30%

The meaning of type

100

Denote self-priming pump

3(m /h)Denote the rated capacity of pump

ZX

(mm)Denote the diameter of pump's inlet

100 20

Denote rated head

1

www.eastpump.com E-mail:[email protected]

Our ZX series of self-priming pumps are saving energy products which are according to the relevant tech-

nical documents in national and international. It is self-priming centrifugal pump, it has many excellencies,

such as compact structure, convenient operation, balanced running, easy maintenance, high efficiency,

long life, strong self-priming ability and so on. It don't require to install bottom valve, it only need assure there

is stated liquid before work. So it predigests the pipeline, and improves the work condition.

It is applicable for environment protecting of city, building, fire fighting, chemical industry, pharmacy,

dyestuff, printing and dyeing, brewing, electric power, plating, paper making, industrial and mining

flushing, equipment cooling and so on;

Impact drive sprinkler can spray like raindrop, it is a good tool for farm, nursery, garden and tea garden;

It is applicable for clean water, sea water, chemical industrial medium liquid with acid and alkali and

general mushy serosity (the viscosity of medium is 100 centipoise, containing solid quantity may reach

to lower than 30%);

It can match with all types and specifications of filter press, it is the best pump which can transfer serosity

to filter.

Brief introduction of type ZX

Operation principle and structure description

70

www.eastpump.com E-mail:[email protected]

This pump adopts the structure of axial hydraulic pulser. Pump casing is constituted by suction chamber,

fluid reservoir, volute chamber, hydraulic pulser hole, gas-liquid separate chamber and so on, after pump

starting normally, impeller will suck the liquid of suction chamber and the air in suction line, and they will

mix in the impeller, through the centrifugal effect, liquid with gas will flow to the exterior of volute chamber,

forming certain thickness of white foam and high-speed revolving liquid ring in the exterior of impeller. The

mixture of gas-liquid enters into gas-liquid separate chamber through diffusible pipe. At this time, because

flow speed is reduced suddenly, so the light gas will separate from the mixture of gas-liquid, gas will rise to

discharge continually through the vent of pump casing. The liquid without gas will back return to fluid rese-

rvoir, and enter into impeller again through hydraulic pulser hole, and mix with the suction gas in suction

line of impeller, and through the high-speed revolving effect of impeller, flow to the exterior of impeller

again. While it goes round and round, the air in suction line reduced continually until there is no air, it will

finish the self-priming process and pump will work normally.

There is cooling chamber in some bearing foot of pump. While bearing overheats to bring the temperature

of bearing body is more than 70 , we can infuse cooling liquid to cool it circularly by anyone joint of the

cooling liquid pipe which is outside the cooling chamber. The sealing mechanism of tandem seal rings can

avoid liquid leak from high-pressure area to low-pressure area, the fore seal ring installs on the pump body,

the back seal ring installs on the bearing body, it should be replaced by new one while the seal ring is wea-

ring and influences the efficiency and self-priming of pump.

2

Brief introduction of type ZXZX

Materials table

Structure drawing

ZX

1 2 4 5 6 7 8 9 10 11 12 13 143

12 11 10

2 3 4 5 6

14

12 11 10 9

7

1

813

www.eastpump.com E-mail:[email protected]

Coup-ling

Pumpshaft Bearing Mechani

calseal

Bearingpart

Pumpshell

Outletplate

Inlet plate

Front sealring

ImpellerBack cover

Waterfender

AddingLingnid hole

Backliquidhole

3

Structure drawing of type ZX

ZX

Collection of chara cteristic curve8

5

80

75

70

65

60

55

50

45

40

35

30

25

20

17

.5 15

12

.5 10

7.5 5

H(m

)

32ZX

3.2

-50

32ZX

3.2

-32

40ZX

6.3

-20

50

ZX

18

-20

40

50

ZX

10

-40

50ZX

15-1

2

50ZX

15-6

0

50

ZX

12

.5-5

0

65

ZX

25

-32

80ZX

40-2

2

65

ZX

30

-15

80ZX

35-1

3

80

ZX

50

-32

10

0ZX

10

0-2

0

100ZX

80-1

60

100ZX

100-4

0

80

ZX6

5-5

580ZX60-7

0

15

0ZX

16

0-5

5

100Z

X100-

65

100ZX

70-8

0

150ZX

150-8

0

20

0ZX

28

0-6

5

2 4

6

8

1

0 1

2 1

6 2

0 2

5 3

0 3

5 4

0 4

5 5

0 5

5 6

0 6

5 7

0 9

0 1

20

1

50

17

5 2

00

2

50

3

00

35

03

Q(m

/h)

www.eastpump.com E-mail:[email protected]

4

Collection of chara cteristic curve of type ZX

ZX

ZX Performance parameter sheet

r/min kW

32ZX3.2-32

32ZX3.2-50

40ZX10-40

40ZX6.3-20

50ZX15-12

50ZX18-20

50ZX20-30

50ZX10-40

50ZX12.5-50

50ZX15-60

65ZX30-15

65ZX25-32

80ZX35-13

80ZX40-22

80ZX50-32

80ZX60-55

80ZX60-70

100ZX100-20

100ZX100-40

100ZX100-65

100ZX70-80

150ZX160-55

150ZX150-80

200ZX280-65

3.2

3.2

10

6.3

15

18

20

10

12.5

15

30

25

35

40

50

60

60

100

100

100

70

160

150

280

32

50

40

20

12

20

30

40

50

60

15

32

13

22

32

55

70

20

40

65

80

55

80

65

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

2900

1450

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

4

4

4

4

4

4

4

4

4

4

5

5

2

2

2

2

2

2.5

2.5

1.5

1.5

1.5

2

2

3.5

2

2.5

2

1.5

2.5

2

2

2

2

2

1.5

1.1

1.1

4

1.1

1.5

2.2

4

4

5.5

7.5

3

5.5

2.2

5.5

7.5

15

22

11

22

30

30

45

55

90

www.eastpump.com E-mail:[email protected]

(m) (m) (min/5m)

Type

3(m /h)

Capacity Head Rotate speed NPSH Self-suction performance

Motor power

5

Performance parameter sheet of type ZX

ZX Dimension drawing for installation and table

ZX

ZX Dimension sheet for installation

A BD 1 P1 d-z D1 P1 d-z H H1 H2 L L1

120

120

130

130

140

140

140

140

140

160

160

160

185

185

185

195

195

205

205

215

215

260

260

315

90

90

100

100

110

110

110

110

110

125

130

130

150

150

150

160

160

170

170

180

180

225

225

280

14-4

14-4

14-4

14-4

14-4

14-4

14-4

14-4

14-4

18-4

18-4

18-4

18-4

18-4

18-4

18-4

18-4

18-4

18-4

18-8

18-8

18-8

18-8

18-8

120

120

120

130

140

140

140

140

140

160

140

140

160

160

160

185

185

185

185

195

195

215

215

260

90

90

90

100

110

110

110

110

110

125

110

110

130

130

130

145

145

150

150

160

160

180

180

225

14-4

14-4

14-4

14-4

14-4

14-4

14-4

14-4

14-4

18-4

14-4

14-4

14-4

14-4

14-4

18-4

18-4

18-4

18-4

18-8

18-8

18-8

18-8

18-8

360 340

360 340

400 330

400 330

400 280

400 280

400 330

460 360

460 380

500 360

480 360

460 380

480 360

460 380

460 380

700 450

700 450

600 415

700 460

780 520

780 520

800 550

900 600

1000 750

16 4

16 4

18 4

18 4

16 4

16 4

18 4

18 4

18 4

18 4

16 4

18 4

16 4

18 4

18 4

18 4

18 4

18 4

18 4

18 4

18 4

18 4

18 4

18 4

145

145

170

150

145

145

150

150

150

170

130

160

145

160

175

185

190

170

190

190

195

220

170

220

310

310

340

340

315

305

340

370

365

410

330

370

340

375

400

460

480

420

470

520

525

550

665

780

465

465

480

480

450

436

480

460

510

580

420

510

420

530

550

640

670

590

660

710

720

765

820

970

720

720

820

820

750

730

820

840

920

1000

810

930

735

950

950

1270

1300

1150

1350

1445

1150

1165

1174

1220

135

135

140

140

130

132

140

135

140

165

140

145

145

150

150

185

185

180

195

195

200

300

300

400

32ZX3.2-32

32ZX3.2-50

40ZX10-40

40ZX6.3-20

50ZX15-12

50ZX18-20

50ZX20-30

50ZX10-40

50ZX12.5-50

50ZX15-60

65ZX30-15

65ZX25-32

80ZX35-13

80ZX40-22

80ZX50-32

80ZX60-55

80ZX60-70

100ZX100-20

100ZX100-40

100ZX100-65

100ZX70-80

150ZX160-55

150ZX150-80

200ZX280-65

www.eastpump.com E-mail:[email protected]

L

H

d-zD1

P1

d-z

L1

H2

H1

B

A

D1

P1

TypeDimension of inlet flange Dimension of outlet flange Hole distance of

baseplate Holediameter H-olenumber

Dimension of exteri or cemter

6

Inlet

Dimension drawing for instabllation and table of type ZX

ZX

The instruction of installation

;

;

;

A. 3.5

B.

C. 2~3

D.

;

;

0.1

3~4

70

12 M12 1.25

www.eastpump.com E-mail:[email protected]

We should pay attention to the deferent concentricity of pump shaft and motor; it is important for the

operation and life of pump whether the installation is right or not, we must install and proofread it carefully;

The coupling of pump must be tightened by nut, and in order to prevent loosing of nut, it should be locked,

or else impeller is easy to move, and will bring mechanical failure;

In order to keep certain liquid storage in pump body, get better self-priming ability and prevent dry friction

of mechanical seal, the inlet of pump must be higher than the central line of pump shaft;

When install the suction line, we should pay attention to the followings:

A.The height of the suction should not be higher than 3.5 meter, if it is possible, the height of the suction

should be lower than the lowest level of water tank, and to do the best to shorten the length of suction line,

install less elbow, which is propitious to shorten the self-priming time and improve the self-priming function.

B.In the suction line, the valve, flange and so on should prevent leakage of gas and liquid, namely, leakage

of gas isn't allowable in the suction line.

C.It should install filter in the suction line to prevent solid enter into the pump body.The effective overflow pr-

oportion of the filter should be 2-3 times of the section in suction pipe,filter should be checked periodically.

D.It should have own supports in the suction pipe and discharge pipe, pump body isn't allowable to bear

the load of pipeline.

7

Instruction of installation and using of type ZX

The using of pump

Preparative and check before start

When we install the pump, the electrostatic grounding resistance of pump and pipeline should achieve

the stated requirement;

When we install the pump, we should check the pipeline and the pump carefully to confirm if there is stone,

sand and so on or not.

Proofread the installation clearance and concentricity of the coupling of pump and motor, the allowable

deviation of disalignment is 0.1mm. The altitudinal difference of shaft between the pump and the motor

may be adjusted by the sheet copper and sheet iron which is set under the foot.

If there isn't blight when units keep operation for 3-4 hours actually, we will think the installation is done, we

should check the temperature of shaft during commissioning, and the temperature of bearing body shou-

ldn't more than 70 ;

If it has set the plastic pipe which inside hole diameter is 12 for the cooling water joint of cooling chamber

in the pump bearing body, the dimension of screw thread should be M12*1.25;

If it has installed check valves in the discharge pipe of pump, and that it couldn't discharge gas successfully

during self-priming process, we should add small discharge pipe and valve in the vent of pump.

www.eastpump.com E-mail:[email protected]

According to the running condition of pump, this series of self-priming pumps adopt calcium base grease

of high quality and 10# machine oil to lubricate separately, the pump which adopts calcium base grease

to lubricate should fill the bearing tank with calcium base grease periodically, if the oil level of the pump

which adopts machine oil to lubricate isn't enough, we should fill it.

Check whether the liquid storage in the pump shell is higher than the margin of impeller or not, if it isn't en-

ough, we may fill the pump body with liquid storage from the liquid filler on the pump shell directly. If the

liquid storage isn't enough, it shouldn't operate, or else the pump couldn't work normally, and it is easy to

destroy mechanical seal.

Check whether the revolving parts of pump is blocked or not.

Check whether the foot of pump body and the nut is loose or not.

Check the concentricity and parallelism for the shaft of pump and the main shaft of motor.

Check whether the intake pipe leaks gas or not, if there is leakage, we must solve it.

Open the valve of suction pipe, open the control valve little(don't open fully).

8

ZXInstruction of installation and using of type ZX

9

www.eastpump.com E-mail:[email protected]

Start and operation:

Inching self-priming pump, pay attention to whether the revolving direction of pump shaft is right or not.

Pay attention to whether there is abnormal noise and shock or not during revolving period.

Pay attention to the reading of pressure and vacuum gauge, after certain time of undulation, if the read-

ing of pressure and vacuum gauge is steady after start, it means that there is enough liquid in the pump, it

will transfer liquid normally.

Before pump starts to transfer liquid normally, namely in the process of self-priming, we should pay attent-

ion to the rising of water temperature in pump specially, if the process is too long and the water temperat-

ure in pump is too high, we should stop pump to check the reason.

If the liquid temperature in pump is too high to self-priming, we may stop unit provisionally, and make use

of the liquid in discharge pipe to flow backwards to the pump or fill the pump with liquid from the liquid

filler on the pump body directly, to reduce the liquid temperature, then start the pump.

It may be the reason of cavitation when pump occurs strong shock and noise during the operation period,

the reason of cavitation has two kinds: First, the flow speed in intake pipe is too large; Second, the suction

lift is too high. We may adjust control valve of vent and heighten the reading of pressure gauge when the

flow speed is too large, it should be removed quickly when there is block in the intake pipe; We may reduce

the installation height of pump when the suction lift is too high.

If the malfunction causes pump to stop during working period, and it need start again, the control valve of

vent should open little(don't close fully), it is good for discharging gas from vent during the process of self-

priming, and it can guarantee that pump start in less load condition.

Pay attention to check whether there is leakage in pipeline or not.

Stop pump:

We should shut off the gate valve in discharge pipe firstly.

Make sure that the running of pump has stopped.

In the cold season, we should discharge all of liquid storage in the pump body and

water in the cooling chamber of bearing body, to avoid the parts are frozen.

ZXInstruction of installation and using of type ZX

ZX

www.eastpump.com E-mail:[email protected]

The maintenance and disassembly

This pump has the characteristics of simple structure and long life. It doesn't require to disassemble in normal

condition. We only need remove the malfunction momentarily.

We should pay attention to several main parts when maintain it:

Rolling bearing: We should replace bearing when pump keeps running for long time and bearing has wore out.

Fore seal ring, back seal ring: We should replace it when seal ring has wore out.

Mechanical seal: If there isn't leakage in mechanical seal, it shouldn't be disassembled to check. If there is

large leakage under the leaky hole of bearing, mechanical seal should be disassembled to check. When

disassemble the mechanical seal, we should put and take it lightly, pay attention to clean the fitting surf-

ace, protect the mirror surface of static ring and dynamic ring, and prohibit to hit it. The main reason of le-

akage in mechanical seal is the friction of mirror surface. We may polish the mirror surface to renew it. Ano-

ther reason is that the O type rubber sealing ring (or absorber) isn't installed well or has distortion and

ageing. At this time, we should adjust or replace the O ring to assemble it again.

The order of disassembly:

Disassemble the motor or take off the coupling.

Disassemble the bearing body assembly, to check the radial clearance of impeller and fore seal ring, and

whether the nut of impeller is loose or not.

Disassemble the nut of impeller, take off the impeller, to check the radial clearance of impeller and back seal ring.

Take off the set screw of mechanical seal, pull off the dynamic ring part of mechanical seal, check the joint

state for the surface of dynamic ring and static ring, check the seal state for O -type seal ring(or absorber).

Take off the set screw of coupling, pull off the coupling.

Disassemble the cover of bearing, disassemble the pump shaft and bearing.

Assemble according to contrary order.

10

Maintenance and disassembly of type ZX

ZX

www.eastpump.com E-mail:[email protected]

a.

b.

c.

d.

e.

f.

a.

b.

c.

a.

b.

c.

a.

b.

c.

d.

e.

f.

a.

b.

c.

d.

e.

f.

a.

b.

c.

d.

e.

f.

a.

b.

c.

d.

a.

b.

c.

d.

11

Malfunction reason and remove method type ZX

www.eastpump.com E-mail:[email protected]

Malfunction reason and remove method

Malfunction Reason Remove method

Water pump couldn't discharge water

Noise and shake are large

The discharge isn't enough

The power of shaft is too large

a. There isn't liquid storage in pump

shell or the liquid storage isn't en-

ough;

b. Suction pipe leaks gas;

c. The revolving speed is too low;

d. The suction lift is too high or the

suction pipeline is too long;

e. The leakage of mechanical seal is

too large;

f. The gas in suction pipeline couldn't

discharge from vent.

a.Add enough liquid storage;

b.Check and remove the leakage;

c.Adjust the speed of rotation;

d.Reduce the suction lift or shorten the

suction pipeline;

e.Repair or replace;

f.Discharge it.

a.The foot isn't stable;

b.The pump shaft is curving;

c.There is NPSH;

d.The bearing is wore out;

e.There is sundries;

f.The main shafts of pump and

motor aren't concentric.

a.The flow passage of impeller and

the suction pipe are blocked;

b.The impeller and the seal of

impeller are wore out;

c.The power isn't enough or the

revolving speed is too low.

a.The flow capacity is too large;

b.The revolving speed is too large;

c.The shaft of pump is curving or

impeller is blocked;

d.The flow passage in pump

is blocked.

a.Increase the pressure of vent;

b.Reduce it befittingly;

c.Replace or adjust it;

d.Remove block.

a.Remove block;

b.Replace the ring;

c.Reinforce power, adjust to the rated

revolving speed.

a.Reinforce it;

b.Replace or adjust it;

c.Adjust the work condition;

d.Replace it;

e.Clean the sundries;

f.Adjust the concentricity.

12

ZXMalfunction reason and remove method type ZX