Prepared by: Mohammed S. Al-Zamil Mohammed S. Al-Zamil Prepared For: Dr.M.Al-Ahmad.

Zamil PEB Brochure

-

Upload

albert-ericson-delfino -

Category

Documents

-

view

443 -

download

25

Transcript of Zamil PEB Brochure

Product Brochure

Zamil Steel Pre-Engineered Buildings

Product Brochure

Zamil Steel Pre-Engineered Buildings

Contents

About Zamil Steel .......................................................................... 3

Vision and Mission ........................................................................... 4

Zamil Industrial Investment Company .......................................... 5

Corporate Structure ......................................................................... 6

Manufacturing Facilities .................................................................. 7

Pre-Engineered Building System ..................................................... 8

Value. Strength. Flexibility. .............................................................. 10

Division Engineers ............................................................................ 11

Research and Development ............................................................ 12

Sales, Customer Service and Project Management .................... 13

Highest Quality Control Standards .................................................. 14

Products

Technical Data ................................................................................... 15

Basic Building Parameters ................................................................ 16

Primary Framing Systems ................................................................. 18

Structural Subsystems ...................................................................... 19

Building Accessories ......................................................................... 23

Crane Systems .................................................................................. 24

Mezzanine Systems .......................................................................... 25

Structural Components ................................................................... 26

Panels ................................................................................................ 27

Insulated Panels ................................................................................ 28

Standard Panel Colors ..................................................................... 29

Roof Drainage Components ............................................................ 30

Standard Trims .................................................................................. 31

Sundry Items ..................................................................................... 32

Major Projects .................................................................................. 33

Zamil Steel Network ......................................................................... 36

1

www.zamilsteel.com

Zamil Steel supplied more than 50,000 buildings to over 90 countries worldwide.

2 Zamil Pre-Engineered Steel Buildings

Welcome to Our Company...Zamil Steel Pre-Engineered Buildings Division

In Zamil Steel (ZS) Pre-Engineered Buildings (PEB) Division, we focus on meeting the needs of our worldwide customers for durable, affordable and versatile steel structures. After over thirty years in business, our customers remain our first priority. Every building that we design, manufacture, and deliver for erection is created with the satisfaction of the future occupants and owners in mind.

ZS – PEB is a Member of the Zamil Steel FamilyThe Pre-Engineered Buildings Division (PEB) of Zamil Steel is one of several business units operating under the Zamil Steel corporate umbrella. PEB is responsible for a major share of the company’s annual sales, and has reached the status of global leader in the marketplace. As a company, we attribute our success to the unmatched value of our products and the flexibility and agility of our employees in meeting the needs of our customers.

ZS has a solid history of steel design and fabricationZamil Steel Industries began operations in 1977, specializing in the design and manufacture of top quality pre-engineered steel buildings to be used as factories, shopping malls, warehouses, distribution centers, airplane hangars, and schools. This early enterprise represented the beginning of today’s Pre-Engineered Buildings Division.

In addition to Pre-Engineered Steel Building Division, Zamil Steel has another five divisions:

Canam Asia Ltd. Established in 2002, it is a joint venture between Zamil industrial investment company (ZIIC) and steel plus limited, an affiliate of the Canadian Canam Manac Group (CMG). The state-of- the art facilies in dammam - Saudi

Arabia and Ras Al-Khayma- UAE custom- design, fabricate and supply steel joists, most notably the open-web joists ideal for floors and roofs in both steel and concrete structures in addition to metal deck panels which are UL- certified.

Building Component Solutions. In 2008, Zamil Steel created a dedicated division for building components to support the retail market with quality building parts and provide a sustainable service of retrofitting and prolonged maintenance to Zamil Steel buildings. Structure Steel Division. In 1984, the company expanded, adding a dedicated structural steel plant. Zamil steel then became Saudi Arabia’s leading fabricator of structural steel to be used for power, desalination and petrochemical plants. Process Equipment Division. Established in 2003, Specializes in Steel and alloy process equipment including pressure vessels, heat-exchangers, storage tanks, reactor columns and others. Towers and Galvanizing Division. In 1986, Zamil Steel established a factory to manufacture galvanized steel lattice towers for telecommunication and electrical transmission towers in a brand new state-of the art plant. Zamil Steel towers are now exported internationally in far countries like New Zealand and Mexico.

Since its establishment in 1977, Zamil Steel has supplied more than 50,000 buildings to clients in over 90 countries. The Pre-Engineered Buildings Division is now a global leader in the export of pre-engineered steel buildings.

3

Our Vision

To be the world’s most reliable and innovative manufacturer, service and solution provider in the steel industry.

Our Mission

To supply high-quality steel products, providing related services and solutions to a worldwide client base while utilizing innovative technologies within an environment of motivated employees, focused on continuous improvement, highest business standards, work ethics and corporate citizenship, leading to added value for our customers and sustained return on investment to our shareholders.

www.zamilsteel.com

Zamil Steel is locally recognized and globally respected

4 Zamil Pre-Engineered Steel Buildings

Zamil Industrial Investment Company (ZIIC) is an international manufacturing and fabrication group. Its five sector businesses – Zamil Air Conditioners (ZAC), Zamil Steel (ZS), Zamil Glass Industries (ZGI), Insulation Sector and Concrete Sector. All ZIIC businesses are ISO 9001-2000 or ISO 9001 certified. ZIIC exports to most international markets and derives over a quarter of its revenues from outside Saudi Arabia.

ZIIC is headquartered in Dammam, Kingdom of Saudi Arabia. The company employs around10,000 people in 55 countries. It was founded in 1998 as a joint stock company. The Zamil Group, one of the most reputable and stable business groups in the Middle East, owns 60% of ZIIC shares. Investors from the GCC countries (Bahrain, Kuwait, Oman, Qatar, Saudi Arabia and United Arab Emirates) publicly own the remaining 40% of shares. Further information can be found at www.zamilindustrial.com.

Our network of Area Offices and Certified Builders provides local service and support to customers around the world. Our widespread reputation for quality and innovation has attracted global clients such as ABB, Procter & Gamble, General Electric, Coca Cola, Pepsi Cola, Nestle, Parsons, Toyota, BMW, Mitsubishi, Sanyo, Toshiba, Honda, Unilever, Isuzu, Daimler Chrysler, and Bechtel, to name a few.

Zamil Steel is a sector of Zamil Industrial Investment Company

5

www.zamilsteel.com

Our corporate structure allows each division to focus completely on the sales, design, and manufacture of its specialty products while utilizing a central support system to handle core functions smoothly and effectively.

Each division is managed separately and employs its own marketing, sales, and customer service personnel. Divisional engineering departments and manufacturing facilities are free to focus on the development and production of the finest quality products, providing each project with the individualized attention it deserves.

Zamil Steel A Closer Look at the Structure of ZS

Centralized support services has proven to be a convenient and efficient method of operation over the years – for both our employees and our customers

UAE

Administration

Finance

Purchasing&

Logistics

MarketingInformation Technology

Quality Assurance

Facilities Engineering

CentralizedSupport

Departments

Egypt

6 Zamil Pre-Engineered Steel Buildings

Zamil Steel Manufacturing Facilities

Zamil Steel- Dammam, Saudi ArabiaThe world’s largest PEB manufacturing facility, it has a production capacity of 400,000 square meters of pre-engineered steel buildings per month.

Zamil Steel- Ras Al-Khaimah, UAEMeeting the demand of the GCC countries for pre-engineered buildings. The state-of-the-art facility was innagurated in 2007.

Zamil Steel Buildings Co. - Cairo, EgyptThe leading supplier of pre-engineered buildings to the African continent, possessing more than 50% of the Egyptian market as well as exporting to more than 30 African nations.

Zamil Steel Buildings Vietnam Co. Ltd. - Hanoi & Ho Chi Minh City, VietnamServes the buoyant Vietnamese market and exports to the other ASEAN (Association of South East Asian Nations) countries. Zamil Steel Vietnam is accredited by the Singapore Structural Steel Society, and was honored in 2003 by the Vietnam Economic Times as winner of the ‘Golden Dragon’ prize for the best construction and construction material product.

Zamil Steel Buildings- Pune, India

The latest expansion of Zamil Steel Industries into the Indian peninsula joins the global set of manufacturing facilities for better serving the Indian market and neighboring countries.

The combined production capacity of these factories exceeds 8 million square meters per year, making ZSI the largest manufacturer and supplier of pre-engineered buildings in Asia, Africa and Europe.

Learn More about the Zamil Steel Advantage

At Zamil Steel Pre-Engineered Buildings, we are dedicated to increase awareness of our customers. We’ve specifically designed this brochure to provide an informative overview of our company and its products. To learn more, contact your local Zamil Steel representative nearest to you or visit our website at www.zamilsteel.com/peb to view our complete line of educational and marketing materials.

Saudi Arabia

UAE

Hanoi - Vietnam

India

HCMC - Vietnam

7

With Zamil Steel Pre-Engineered Building System, strength, value, and style — are custom-built into every project

www.zamilsteel.com

8 Zamil Pre-Engineered Steel Buildings

From planning to occupancy, nothing matches Zamil Steel’s Pre-Engineered Building System in terms of versatility, flexibility and total value-engineering.

9

Our customers choose pre-engineered steel buildings (PEB) over other types of construction for the following reasons: ValuePre-engineered steel structures require a lower initial investment, lower maintenance cost once completed, and are environmentally friendly as all materials can be recycled.

StrengthOur structures are designed and built to withstand severe weather conditions (wind, snow, rain) and even earthquakes.

FlexibilityLarge, clear spans allow our customers to house almost any type of business comfortably and efficiently, as well as to expand and change their setup whenever they desire.

Other distinct advantages include quick construction time and capacity for design flexibility – allowing our engineers to create a unique, and attractive appearance that fits the distinctive business image of each customer.

Zamil Steel buildings accommodate a wide variety of occupants, fromfactories and showrooms to shopping malls and hypermarkets. Be sure to browse our photo gallery of satisfied clients both in this brochure and at www.zamilsteel.com/peb

You’ll be amazed at the value, strength, and wide range of design possibilities available using the Zamil Steel Pre-Engineered Building system!

Here are just some of the ways Zamil Steel Pre-Engineered Buildings are currently being used:

° Shopping Malls ° Factories ° Commercial Showrooms ° Hypermarkets ° Office Buildings ° Warehouses ° Convention Centers ° Sports Arenas ° Workshops ° Labor Camps ° Distribution Centers ° Aircraft Hangars° Poultry Farmhouses

Zamil Steel Pre-Engineered Building SystemValue. Strength. Flexibility.

www.zamilsteel.com

10 Zamil Pre-Engineered Steel Buildings

ZS PEB Division Engineers:Project Excellence is Our Top Priority

Zamil Steel Pre-Engineered Buildings are simple and economical in design, yet fully functional and diverse in purpose. When it comes to innovations in engineering, Zamil Steel sets the standard for other PEB companies. The entire engineering/detailing process is 100% computerized.

Our engineers work diligently to provide accurate calculations that are completely explained and referenced. They strive for comprehensiveness and clarity, mindful that their work must be easily understood by consultants at locations around the world.

We meet and exceed international quality and design standardsUnless otherwise required, all ZSbuildings are designed and manufactured in accordance with the following US codes:

° Low Rise Building Systems Manual (MBMA – Metal Building Manufacturer’s Association Inc.)

° Manual of Steel Construction, Allowable Stress Design (AISC – American Institute of Steel Construction Inc.)

° Cold Formed Steel Design Manual (AISI – American Iron and Steel Institute)

° Structural Welding Code - Steel (AWS – American Welding Society)

The engineering groups of Zamil Steel collaborate from six different countries via electronic connections. They provide our clients with design calculations, approval drawings, erection drawings and other documents essential to the successful completion of every project.

Zamil Steel meet and exceed international quality and design standards

11

www.zamilsteel.com

The talented group of engineers and architects that makes up our R&D Department work within a culture that fosters idea generation and perfection to the fullest. The end result is a consistent flow of design, process and product innovations, bolstering the ZS position as a global industry leader.

When you choose Zamil Steel Pre-Engineered Buildings, you can be certain that your project will benefit from the dedicated efforts of our Product Research and Development Department.

We apply new ideas to every area of the companyThese are just a few of the core initiatives that occupy the resources and talents of the Zamil Steel R&D department:

° Refine details to constantly raise economical, safety and aesthetic standards° Develop software that improves customer service° Search for and test the viability of new products to complement and enhance our existing PEB systems.

We consistently focus on learning and training

Zamil Steel R&D professionals know that innovation needs to be shared throughout the company to achieve maximum success. That’s why learning is an ongoing activity throughout the Zamil Steel organization. The Products Research & Development Department engages in continuous training programs for all technical staff, in addition to providing extensive technical training to new sales executives and engineers.

The ZS PEB Research and Development Department: Constantly Engaged in Product Innovation

Zamil Steel promotes a culture rich in new ideas and innovation

12 Zamil Pre-Engineered Steel Buildings

Our Professionals Provide Unparalleled Sales, Customer Service and Project Management

Zamil Steel serves its customers through a growing global network of Local Area Offices. These centers accommodate the personnel needed to complete your project quickly and efficiently. Visit www.zamilsteel.com/peb for the location of the office nearest you.

Local Area Offices provide the following:

Instant InformationAn Area Sales Manager, Sales Support Engineer, and Erection Coordinator located nearby can address your needs immediately and thoroughly.

Quick Cost QuotesOver 80% of the inquiries we receive regarding price are answered within four working days by Area Sales Offices.

Complete QuotesEvery quote is supplied complete with proposal drawings for your verification, ensuring that your order is processed according to your exact specifications.

Fastest DeliveryDue to the efficient engineering systems, huge manufacturing capacity and sustained high stock levels of raw material, our buildings are designed, detailed, fabricated and shipped in record time. We’ll do everything possible to help meet your target date.

Expert Site CoordinationAn erection coordinator from our Local Office nearest to you will address your site needs once your materials arrive. The coordinator will inspect your building site and give advice according to Zamil Steel’s proven, stringent erection methods.

Certified BuildersVisit www.zamilsteel.com/peb to search for a certified builder in your area. These builders work closely with our Area Offices, who monitor their progress to ensure that Zamil Steel standards of quality are met throughout the project.

Project Management Department Project Management Department is responsible for certain projects with special needs and requirements that includes the Supply and/ or Erection in the scope of work by Zamil Steel.

Services include but not limited to:1. Prepare & submit the Site Quality Plan for the project including the erection method statement & rigging plans.2. Prepare detailed schedule showing the project priorities with delivery and erection sequences. 3. Monitor & control the site progress and milestones including change orders.4. Prepare comprehensive daily, weekly & monthly site reports.

13

www.zamilsteel.com

The Highest Quality MaterialsZamil Steel leads the industry in supplying upgraded materials for our building components. We offer unique features including:

° Plain Galvalume roof cladding° Coated cladding material° Hot-dip galvanized connection bolts° Hot-dip galvanized anchor bolts° Self drilling fasteners° Optional pre-galvanized material for secondary members.

Strict quality control procedures are maintained in order to insure the utmost consistency in the quality of Zamil Steel’s materials. The Quality Control department has the best engineers, tools and facilities to conduct the quality policy of Zamil Steel in accordance with international standards and best practices.

Zamil Steel provides you the highest quality materials

ZS PEB Sytems are Governed by the Highest Quality Control Standards

14 Zamil Pre-Engineered Steel Buildings

We Build Solid Structures – and Lasting PartnershipsAt Zamil Steel, our goal is not merely to win your current business, but to establish a lasting, beneficial partnership that meets all of your current building needs. We know that if every member of our staff works to earn your trust and confidence – we will win your future business.

The following pages provide important technical information about our products. For greater detail, refer to the Zamil Steel Technical Manual for Pre-engineered Buildings. Please feel free to contact a Zamil Steel representative if you have questions, and be sure to visit www.zamilsteel.com/peb for additional informational resources.

The PEB System:Technical Data

15

Pre-engineered buildings are defined by the following basic parameters: Building Width, Length, Height, Roof Slope, End Bay Length, Interior Bay Length and Design Loads.

Building LengthBuilding length is the distance between the outside flanges of endwall columns in opposite endwalls. It is a combination of several bay lengths.

Building HeightBuilding height is the eave height, which is usually the distance from the bottom of the main frame column base plate to the top outer point of the eave strut. When columns are recessed or elevated from the finished floor, eave height is the distance from the finished floor level to the top of the eave strut.

Building WidthNo matter what primary framing system is used, the building width is defined as the distance from outside of eave strut of one sidewall to outside of eave strut of the opposite sidewall.

Roof Slope (x/10)This is the angle of the roof with respect to the horizontal. The most common roof slopes should not be less than 0.5/10. Any practical roof slope is possible.

End Bay LengthThis is the distance from the outside of the outer flange of endwall columns to the center line of the first interior frame column.

Basic Building Parameters

3

16 Zamil Pre-Engineered Steel Buildings

Interior Bay LengthThis is the distance between the center lines of two adjacent interior main frame columns. The most common bay lengths are 6, 7.5, and 9 meters. Any bay length is possible up to 15 meters.

Design LoadsUnless otherwise specified, ZSI’s Pre-Engineered Buildings are designed for the following minimum loads:

Roof Live Load: 0.57 kN/m2

Design Wind Speed: 110 km/hDesign parameters of snow loads, earthquake loads, collateral loads, crane

loads or any other loading condition must be specified when requesting a quotation.

Loads are applied in accordance with American codes and standards applicable to pre-engineered buildings unless otherwise requested at the time of quotation. For more detailed information, please refer to the Zamil Steel Technical Manual for Pre-Engineered Buildings.

www.zamilsteel.com

PURLIN SPACING

17

Zamil Steel Pre-Engineered Buildings are constructed using a variety of framing systems. The diagrams on this page illustrate those most commonly employed. They are symmetrical at the ridge line.

Asymmetrical and non-equal Multi-span Framing Systems are also available. Please consult with your Zamil Steel representative nearest to you about your specific project requirements.

Primary Framing Systems

Clear Span (CS) Arched Clear-Span (AS)

Multi-Span “1” (MS-1) Arched Multi-Span (AMS-1)

Multi-Span “2” (MS-2) Single Slope (SS)

Multi-Span “3” (MS-3) Roof System (RS)

Lean-To (LT) Multi-Gable (MG)

18 Zamil Pre-Engineered Steel Buildings

Structural Subsystems

This section contains few subsystem examples of actual Zamil Steel Pre-Engineered Buildings, along with simple sketches of some of their structural configurations. For complete and detailed information, please refer to the Zamil Steel Technical Manual for Pre-Engineered Buildings.

Endwall Roof Extension

Sidewall Roof Extension

www.zamilsteel.com

Roof Platform

19

Structural Subsystems

Canopy

Curved Eave with Projection(without valley gutter)

Curved Eave without Projection(with valley gutter)

20 Zamil Pre-Engineered Steel Buildings

Structural Subsystems

www.zamilsteel.com

Transverse Partition

Parapet Fascia

Vertical Fascia with Back Up Panel and Valley Gutter

21

Top & Bottom Curved Fascia

Structural Subsystems

Bottom Curved Fascia

Center Curved Fascia

22 Zamil Pre-Engineered Steel Buildings

Building Accessories

Zamil Steel Pre-Engineered Buildings can be designed with your choice of a variety of attractive and architecturally sound accessory options. Windows, doors, natural lighting and ventilation accessories are available to fit almost any of your requirements.

Here are a few examples, as they appear in existing buildings. Please refer to the Zamil Steel Technical Manual for complete details and applications for your particular project.

Personnel Door

Roof Skylight

Roll-up Door

Ridge Ventilator

Fixed Louver

Insulation

Sliding Door

Power Ventilator

Window Adjustable Louver

Wall Light

Roof CurbShown supporting a Power Ventilator

www.zamilsteel.com

Turbine Ventilator

23

For buildings that require a crane system, Zamil Steel supplies the column or rafter brackets. The crane runway beams for top-running and underhunge crane systems will be supplied by Zamil Steel. For mono-rail crane systems the

runaway beam is supplied by the crane supplier. The customer needs to supply complete crane system details, data and supplier name, for the accurate design and estimation of all crane supporting buildings.

Crane Systems

Underhung Crane

Top Running Crane

Monorail Crane

24 Zamil Pre-Engineered Steel Buildings

Mezzanine Systems

The standard Zamil Steel mezzanine framing system consists of a steel deck supported by joists framed onto main mezzanine beams. The main beams may also be supported by intermediate columns if dictated by design loads. The top flange of the joists fits immediately below the top flange of the primary beams.

Applied floor loads, such as dead, live and collateral loads along with mezzanine column spacing, can affect the economy of a mezzanine system. Our Zamil Steel representative nearest to you can help you to determine the most economical mezzanine design and column spacing for

your project.

Unless otherwise specified, the primary mezzanine beams should run across the width of the building parallel to the main frame rafters. Joists should run parallel to the roof purlins along the length of the building.

Multi-level mezzanines, including features such as interior equipment platforms, catwalks, floor openings and staircases are also available. It is important to make the data for these requirements available to our Zamil Steel representative nearest to you at the time of quotation.

Mezzanine Beam Connection to Main Frame Column

Mezzanine Joist Connection to Mezzanine Beam

Joist Connection to Endwall Column

Mezzanine Plan

Mezzanine Floor View

www.zamilsteel.com 25

Structural Components

High grade steel plate conforming to ASTM A 572M Grade 345. Factory painted with a minimum of 35 microns (DFT) of corrosion protection primer.

Primary Built Up MembersMinimum Yield Strength is 34.5 kN/ cm2

Secondary MembersMinimum yield strength is 34.5 kN/ cm2

Bracing Systems

High grade steel conforming to ASTM A 607 Grade 50 or equivalent, available in 1.5 mm, 1.75 mm. 2.0 mm, 2.25 mm, 2.5 mm and 3.0 mm thickness. Factory painted with a minimum of 35 microns (DFT) of corrosion protection primer, or pre-galvanized finish.

The system shown is cable bracing, manufactured from ASTM A 475 extra high strength galvanized strands.

60

60

60

26 Zamil Pre-Engineered Steel Buildings

Panels

The panels used in the construction of Zamil Steel Pre-Engineered Buildings are composed of the following:

° Base metal of either Galvalume coated steel conforming to ASTM A 792M Grade 345B or aluminum conforming to ASTM B 209M Alloy 3003 Temper H26. Galvalume coating is 55% Aluminum and about 45% Zinc by weight.

° An exterior surface coating on painted panels of 25 microns of epoxy primer with a highly durable polyester finish.

° An interior surface coating on painted panels of 12 microns of epoxy primer and modified polyester or foam spec.

Single Skin PanelsMinimum Yield Strength is 34.5 kN/cm2

www.zamilsteel.com

Type “S” Profile

Type “ZW” Profile

Type “G” Profile

All dimensions are in millimeters.

27

Insulated Panels

The outer and inner metal skins of Insulated Panels conform to the same specifications as the single skin painted panels described above. In addition, Insulated Panels have a factory injected polyurethane core. Thermal transmission data can be found in the Zamil Steel

Technical Manual on Pre-Engineered Buildings.

Liner panels have one metal skin surface with polystyrene foam board adhered to it for better insulation.

Tempcon Roof & Wall Panel

Ex Liner Panel

All dimensions are in millimeters.

INNER SKIN PANEL OR ALUMINUM FOILT= 30, 40, 50, 75, 100 mm

49

INNER SKIN PANEL OR ALUMINUM FOILT= 30, 40, 50, 75, 100 mm

49

Dx Liner Panel

INNER SKIN PANEL OR ALUMINUM FOILT= 30, 40, 50, 75, 100 mm

49

Temparch Wall Panel

INNER SKIN PANEL OR ALUMINUM FOILT= 30, 40, 50, 75, 100 mm

49

Liner Panels

28 Zamil Pre-Engineered Steel Buildings

Standard Panel Colors

Panels are available in the below listed standard colors of Zamil Steel. Please refer to the Zamil Steel Panel Chart, as actual colors may vary from these printed samples.

Plain Galvalume Steel and Plain Aluminum panels are available in nominal thickness of 0.5mm and 0.7 mm, and in all standard colors of Zamil Steel.

Panels can be specially ordered to meet any base metal specification, coating, finish, color and thickness. Your Zamil Steel representative can provide complete information on price and delivery.

www.zamilsteel.com

- The shown colors closely approximate actual coating colors.

Frost White

Arabian Beige

Cactus Green

Leaf Green

Daisy Yellow

Royal Blue

Flame Red

29

12

12

12

12

12

Roof Drainage Components

Eave Gutters

Eave gutters and downspouts are made from the same material as standard Zamil Steel single skin panels and available in all standard panel colors.

Valley Gutters

Valley gutters are also available, and made from 1 mm thick plain galvanized coils. Zamil Steel does not supply internal downspouts for valley gutters.

High-Low Valley Gutter

Common Eave Valley GutterMaxseam Eave Gutter

Eave Gutter

Downspout Section

All dimensions are in millimeters.

412

30 Zamil Pre-Engineered Steel Buildings

Outside Corner Trim

Drip Trim

Expansion Join Trim

Eave Trim

Framed Opening Trim

Cap Fashing

Hood Trim

Gable Trim

www.zamilsteel.com

Standard Trims

Zamil Steel offers customers a variety of standard trims that provide a seamless finished look and style to the cladding of their pre-engineered buildings. Those most commonly used are illustrated below.

Trims are made from the same materials as standard Zamil Steel panels and available in all Zamil Steel standard panel colors.

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

25

10 HEM

60

128

38

12

210

20

16

10

185

20

16

20

16

All dimensions are in millimeters.

31

Sundry Items

Various hardware items required for the erection and finishing of your Zamil Steel Pre-Engineered Building are supplied for your convenience. Here are just a few items that are commonly used.

Fasteners

Nuts & Bolts

Sealants & Closures

Hillside Washers

Anchor Bolts

32 Zamil Pre-Engineered Steel Buildings

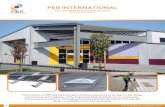

Value, strength and flexibility are evident in every Zamil Steel Pre-Engineered Building. But diversity of purpose is obvious as well. In countries around the world, pre-engineered steel buildings are being used as:

° Factories° Commercial Showrooms° Supermarkets° Office Buildings° Warehouses° Convention Halls° Workshops° Labor Camps° Distribution Centers° Aircraft Hangars° Restaurants° Schools° Almost any one, two, or three storey building

Look carefully at the following pages – the photos you’ll see represent a small selection of the 40,000 buildings designed and manufactured by Zamil Steel since its foundation in 1977. Note the diversity of purpose, size, design and style. We hope to add your building to our list of successful projects in the years to come.

www.zamilsteel.com

Diversity of Purpose

Rocell Bathware Ltd - Colombo, Sri Lanka

KAIKCO Showrooms - Ahmadi, Kuwait

Aircraft Shelter/Hangar - Riyadh, Saudi Arabia

Hanoi Golf Club - Vietnam

* For more international project please refer to “Major project” link: www.zamilsteel.com/peb/asp/mp.asp.

33

Nissan Showroom - Ahmadi, Kuwait

Doha Taxi / Qatar National Hotel - Qattar

Architecs & Const. Service J/S Co. - Acsc - Vietnam

Obayashi co. - Hardware Factory, Vietnam

NPK Fertilizer Factory - Malaysia

Ramis Trading Co. - Sharja, UAE

Mall of Arabia - Jeddah, Kingdom of Saudi Arabia

Atlas Corp. - Bucharest, Romania

34 Zamil Pre-Engineered Steel Buildings

Zamil Steel maintains a network of more than 65 area offices and 51 certified builders around the world

www.zamilsteel.com

Dn Hybrid Pte. Ltd. - Singapore

Manar Coil Painting Plant - Damascus, Syria

Urea Storage, Sohar Fertilizer Project - Sohar, Oman

Bristish-American Tobaco-Vinataba Jv Ltd - Vietnam

Vina Tawana Container Co., Ltd. - Vietnam

Villaggio/ Business Trading Co. - Doha, Qattar

Sari Mall - Jeddah, Kingdom of Saudi Arabia

* For more international project please refer to “Major project” link: www.zamilsteel.com/peb/asp/mp.asp.

35

Sales Offices, Builders and Agents

Zamil Steel Network

Bahrain : Manama Bangladesh : DhakaCambodia : Phnom PenhChina : Dailan : Qingdao : ShanghaiIndia : Pune : Mumbai : Chennai : Cochin : Hyderabad : Bangalore : RanchiIndonesia : Batam : Jakarta : MakassarIraq : BasraJapan : Tokyo : YokohamaJordan : AmmanKorea : SeoulKuwait : Kuwait City

: Safat : SalmiyaLaos : VientianeLebanon : TripoliMalaysia : Darul Iman : Johor : Kota Kinabalu : Kuala Lumpur : Penang : Sabah : SarawakMyanmar : Mandalay : Pyinmana : YangonOman : Muscat : Ruwi : Seeb AirportPakistan : Karachi : LahorePalau : KororPhilippines : Cebu : Davao : Manila

: Quezon CityQatar : DohaSaudi Arabia : Al Khobar : Dammam : Jeddah : Riyadh : TabukSingapore : SingaporeSri Lanka : ColomboSyria : DamascusTaiwan : TaipeiThailand : BangkokUAE : Abu Dhabi : Dubai : Ras Al Khaimah : SharjahVietnam : Da Nang : Haiphong : Hanoi : Ho Chi Minh : Nam dinhYemen : Mukalla : Sanaa

AustraliaAustralia : Sydney

North AmericaUSA : Houston

South AmericaUruguay : Montevideo

Algeria : AlgiersEgypt : CairoEthiopia : Addis Ababa

Ivory Coast : AbidjanLibya : TripoliSenegal : Dakar

Sudan : KhartoumTanzania : Dar-es-Salaam

Cyprus : NicosiaCzech Rep. : Prague : PrahaGreece : Athens : Neo Psychiko

Hungary : BudapestLuxembourg : LuxembourgPoland : WarsawPortugal : Porto City

Romania : Bucharest : IasiSpain : La Coruna : MadridUkraine : Kiev

Asia

Africa

Europe

36 Zamil Pre-Engineered Steel Buildings

www.zamilsteel.com

Statements, descriptions, specifications and dimensions contained herein are in effect as of the date of this issue. Zamil Steel reserves the right to make material subtitutions and changes in specifications and construcion methodology as and when deemed necessary.

Area Offices

Saudi Arabia : Dammam : Riyadh : Jeddah

Kuwait : Kuwait CityBahrain : ManamaQatar : DohaUAE : Dubai : Abu DhabiOman : MuscatYemen : Sanaa

Jordan : AmmanSyria : DamascusIraq : BaghdadBangladesh : DhakaPakistan : LahoreSri Lanka : ColomboIndia : Pune : Mumbai : New Delhi : Hydrabad : Chennai : Bangalore

Greece : AthensRomania : BucharestPoland : WarsawCzech Rep. : PragueSpain : MadridLuxembourg : Mersch

Egypt : CairoSudan : KhartoumNigeria : Port HarcourtAlgeria : AlgiersSenegal : DakarGhana : AccraTanzania : Dar-es-SalaamEthiopia : Addis AbabaLibya : Tripoli

Vietnam : Ho Chi Minh City : Hanoi : Haiphong : DanangThailand : BangkokMalaysia : Kuala Lumpur : Johor Baru : Kota KinabaluSingapore : SingaporeMyanmar : Pyinmana : YangonIndonesia : Jakarta : BatamPhilippines : ManilaLaos : VientianeCambodia : Phnom PenhJapan : Tokyo

Head Office

Address : P. O. Box 877 Dammam 31421 Saudi ArabiaTel : (966 3) 847 1840Fax : (966 3) 847 1291E-mail : [email protected] : www.zamilsteel.com

Issued May 2010