Xuan's Poster Board

Transcript of Xuan's Poster Board

Completed Projects

Cable Life Study

Relay does not provide enough protection for the

transformer and cause terminal cables to overload

Cable’s life drops to 2.7 years from 40 years because of

overloading

Safety tip: TRACK card and be aware of hazards

Solutions: Shift devices to other line

Keep temperature traced till find long-term solution

Learnings from work:

Situational safety awareness

Team collaborations reinforced

Interpersonal and communication skills

Real-world experience with transformer and

breaker testing

One-line Diagrams for power transmission

and substations

SKM Tools (Arc Flash)

AutoCAD

Thermodynamics (Energy)

On-going Project:

Develop visual risk ID of inspected substations

on Topographical map

CHP operation schedule and economic

analysis

Plant energy flow and cost model update

Identify and label overhead transmission lines

More research on cable overloading

Substation Score UPP Substation 8.43776

North Main Switchyard 8.41877

Smelter Substation 8.40989

Copperton Substation 8.36902

Magna/PacifiCorp 8.31334

Refinery Substation 8.07266

6190 Switchyard 6.87315

Arthur Switchrack 5.39835

No.2 Substation 4.94158

South Main Substation 6.67596

About Me

Master Student in Electrical Engineering at Case

Western Reserve University , Cleveland Ohio

Graduate in May 2016

Interested in Energy Optimization, Control

Systems and Automation

Utility Air

Ambient Air

Drain Water

Natural Gas (from Questar)

Pulsing Timer Pulsing Timer

Air FilterEvaprorative

Cooler

Gas Turbine & Generator Diverter Valve

Gas Compressor

Oil Cooler

ATM

Combustion Air Blower

Boiler

Steam

Feed Water

ATM

Condensate

Blowdown

Pow

er

Gas Compressor

Silencer

Ambient Air

Duct Burner

Feed Water

Xuan Wang—Electrical Engineer Intern

Energy System Optimization

Supervisor: David Van Hees

Optimization of Combined Heat

and Power (CHP) Operation

Substation Inspections

Inspected Arthur Switchrack, No.2 Substation, and South

Main Substation, scheduled for Arthur Substation

Visual inspections on transformers, breakers, and control

buildings

Safety Tip: TRACK every inspection

Watch for warnings and signage

Keep accompanied

Wear PPE

Step 1

Compare the operational cost of CHP

with old Boilers

When generating the same amount of steam,

the CHP costs half as much as running the old

boiler

Break-even point:

When natural gas price is $ 13.4/mmBTU, Boiler

and CHP will have same operation cost.

Step 3

Create an energy flow model that

determines the energy input and output

of the Combined Heat and Process

system

PI data:

Natural gas flow rate in SCFM and

temperature in °F

Water flow rate in GPM and temperature in °

F

Steam flow rate in LB/H, pressure in PSIG and

temperature in °F

Properties:

Heat values of natural gas

Water quality and properties

Power generation

Work out the economic value of

running CHP and determine its

operational schedule

Step 2

Find out the most cost efficient way to

operate the CHP

Under the condition of fixed electricity and nat-

ural gas price , we can operate CHP for our en-

tire steam or power demand

Red — 44KV Transmission Lines

Purple — RMP Transmission Lines

Yellow — Lower Voltage Transmission Lines

Assumptions

CHP and Boiler generation (power and

steam) meet plant demands

Steam is a saturated

Electricity import costs and natural gas price

are at $46/MWH and 2.18/mmBTU

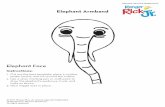

Combine Heat Power Process Flow Diagram

CHP Generation

CHP & Boiler Steam Generation

Team members:

Hana Baesmat, Blake Wilde,

Per Wenstad, Luke Kooyman,

Becca Novy