Worm Gear Calculation

-

Upload

prashasscribd -

Category

Documents

-

view

1.424 -

download

42

description

Transcript of Worm Gear Calculation

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Module 2 - GEARS

Lecture 15 WORM GEARS

Contents

15.1 Worm gears an introduction

15.2 Worm gears - geometry and nomenclature

15.3 Worm gears- tooth force analysis

15.4 Worm gears-bending stress analysis

15.5 Worm gears-permissible bending stress

15.6 Worm gears- contact stress analysis

15.7 Worm gears- permissible contact stress

15.8 Worm gears -Thermal analysis

15.1 INTRODUCTION

Worm gears are used for transmitting power between two non-parallel, non-intersecting

shafts. High gear ratios of 200:1 can be got.

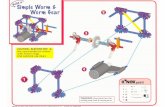

(a)

(b) Fig.15.1 (a) Single enveloping worm gear, (b) Double enveloping worm gear.

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Fig.15.2 The cut section of a worm gearbox with fins and fan for cooling

15.2 GEOMETRY AND NOMENCLATURE

Fig. 15.3 Nomenclature of a single enveloping worm gear

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

a. The geometry of a worm is similar to that of a power screw. Rotation of the worm

simulates a linearly advancing involute rack, Fig.15.3

b. The geometry of a worm gear is similar to that of a helical gear, except that the

teeth are curved to envelop the worm.

c. Enveloping the gear gives a greater area of contact but requires extremely

precise mounting.

1. As with a spur or helical gear, the pitch diameter of a worm gear is related to its

circular pitch and number of teeth Z by the formula

(15.1) 22Z pd

2. When the angle is 90 between the nonintersecting shafts, the worm lead angle is equal to the gear helix angle. Angles and have the same hand.

3. The pitch diameter of a worm is not a function of its number of threads, Z1.

4. This means that the velocity ratio of a worm gear set is determined by the ratio of

gear teeth to worm threads; it is not equal to the ratio of gear and worm

diameters.

(15.2) 12 1

Z= Z2

5. Worm gears usually have at least 24 teeth, and the number of gear teeth plus

worm threads should be more than 40:

Z1 + Z2 > 40 (15.3)

6. A worm of any pitch diameter can be made with any number of threads and any

axial pitch.

7. For maximum power transmitting capacity, the pitch diameter of the worm should normally be related to the shaft center distance by the following equation

(15.4) 1

0.875 0.875C Cd3.0 1.7

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

8. Integral worms cut directly on the shaft can, of course, have a smaller diameter

than that of shell worms, which are made separately.

9. Shell worms are bored to slip over the shaft and are driven by splines, key, or

pin.

10. Strength considerations seldom permit a shell worm to have a pitch diameter less

than

d1 = 2.4p + 1.1 (15.5)

11. The face width of the gear should not exceed half the worm outside diameter.

b 0.5 da1 (15.6) 12. Lead angle , Lead L, and worm pitch diameter d1 have the following relation-

ship in connection with the screw threads.

1

Ltan = (d 15.7)

13. To avoid interference, pressure angles are commonly related to the worm lead

angle as indicated in Table 15.1.

Table 15.1 Maximum worm lead angle and worm gear Lewis form factor for various pressure angles

Pressure Angle

n

(Degrees)

Maximum Lead

Angle (degrees) Lewis form factor

y

Modified Lewis

form factor Y

14.5 15 0.100 0.314

20 25 0.125 0.393

25 35 0.150 0.473

30 45 0.175 0.550

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Table 15.2 Frequently used standard values of module and axial pitch of worm or circular pitch of gear p in mm:

Module m mm 2.0 2.5 3.15 4.0 5.0 6.3

Axial pitch p mm 6.283 7.854 9.896 12.566 15.708 19.792

Module m mm 8 10 12.5 16 20

Axial pitch p mm 25.133 31.416 39.270 50.625 62.832

b) Values of addendum and tooth depth often conform generally to helical gear

angle of

er.

d) The axial pitch for different standard modules are given Table 15.2

15.3 FORCE ANALYSIS

practice but they may be strongly influenced by manufacturing considerations.

c) The load capacity and durability of worm gears can be significantly increased by

modifying the design to give predominantly recess action i.e. the

approach would be made small or zero and the angle of recess larg

Fig. 15.4 Worm gear force analysis

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

a) The tangential, axial, and radial force components acting on a worm and gear are

illustrated in the Fig. 15.4

b) For the usual 90 shaft angle, the worm tangential force is equal to the gear axial force and vice versa.

F1t = F2a (15.8)

F2t = F1a (15.9)

c) The worm and gear radial or separating forces are also equal,

F1r = F2r (15.10)

If the power and speed of either the input or output are known, the tangential force

acting on this member can be found from equation

(15.11) 1t

1000 WF =V

1. In the Fig. 15.4, the driving member is a clockwise-rotating right hand worm.

2. The force directions shown can readily be visualized by thinking of the worm as a

right hand screw being turned so as to pull the nut (worm gear tooth) towards

the screw head.

3. Force directions for other combinations of worm hand and direction of rotation

can be similarly visualized.

15.3.1 Thrust Force Analysis.

The thrust force direction for various worm and worm wheel drive conditions are shown

in Fig. 15.6

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

(a)

(b)

Fig.15.6 (a) and (b) Worm gears thrust force analysis

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

The thread angle of a screw thread corresponds to the pressure angle n of the worm. We can apply the force, efficiency, and self-locking equations of power screw directly to

a worm and gear set. These equations are derived below with reference to the worm

and gear geometry. Figs.15.7 to 15.9 show in detail the forces acting on the gear.

Components of the normal tooth force are shown solid. Components of the friction force

are shown with the dashed lines.

Fig. 15.7 Forces on the worm gear tooth

Fig. 15.8 Worm driving

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Fig. 15.9 illustrates the same directions of rotation but with the torque direction reversed

(i.e., gear driving). Then contact shifts to the other side of the gear tooth, and the normal

load reverses.

Fig.15.9 Gear driving (Same direction of rotation)

The friction force is always directed to oppose the sliding motion. The driving worm is

rotating clockwise:

(15.12)

(15.13)

(15.14)

2t 1a n n n

1t 2a n n

2r 1r n n

F =F =F cos cos -f F sin

F =F cos sin+f F cos

F =F sin

nF =

F =

Combining eqns. (15.12) with (15.13), we have:

n

n

F cos cos - f sin2t = F cos sin + f cos1t

(15.15)

Combining eqns. (15.12) with (15.14) and (15.13) with (15.14), we have:

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

(15.16) n n

2r 1r 2t 1tn nsin sinF =F =F =F

cos cos - f sin cos sin + f cos

15.4 KINEMATICS

The relationship between worm tangential velocity, gear tangential velocity, and sliding

velocity is,

(15.17) 21

V = tan V

15.5 EFFICIENCY

Efficiency is the ratio of work out to work in. For the usual case of the worm serving as input member,

(15.18)

The overall efficiency of a worm gear is a little lower because of friction losses in the

bearings and shaft seals, and because of churning of the lubricating oil.

15.6 FRICTION ANALYSIS

The coefficient of friction, f, varies widely depending on variables such as the gear

materials, lubricant, temperature, surface finishes, accuracy of mounting, and sliding

velocity. The typical coefficient of friction of well lubricated worm gears is given in Fig.

15.10.

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Fig. 15.10 Friction of well lubricated worm gears, A for cast iron worm and gear and B for case hardened steel worm and phosphor bronze worm gear

The sliding velocity Vs is related to the worm and gear pitch line velocities and to the

worm lead angle by

1 2s

V VV = =cos sin (15.19)

Fig.15.11 Velocity components in worm gearing

1 t n n nF F c o s s in - f F c o s (1 5 .2 0 )

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

a) Eqn. 15.20 shows that with a sufficiently high coefficient of friction, the gear

tangential force becomes zero, and the gear set self-locks or does not over-

haul.

b) With this condition, no amount of worm torque can produce motion.

c) Self-locking occurs, if at all, with the gear driving.

d) This is desirable in many cases and helps in holding the load from reversing,

similar to a self-locking power screw.

The worm gear set self-locks if this force goes to zero, which happens if

(15.21) nf cos tan

A worm gear set can be always overhauling or never overhauling, depending on the

selected value coefficient of friction (i.e., and to a lesser extent on n).

15.7 BENDING AND SURFACE FATIGUE STRENGTHS

Worm gear capacity is often limited not by fatigue strength but by cooling capacity. The

total gear tooth load Fd is the product of nominal load Ft and factors accounting for

impact from tooth inaccuracies and deflections, misalignment, etc.). Fd must be less

than the strength the bending fatigue and surface fatigue strengths Fb and Fw The total

tooth load is called the dynamic load Fd, the bending fatigue limiting load is called

strength capacity Fb, and the surface fatigue limiting load is called the wear capacity Fw.

For satisfactory performance,

Fb Fd (15. 21) and Fw Fd (15.22)

The dynamic load is estimated by multiplying the nominal value of gear tangential

force by velocity factor Kv given in the following Fig.15.

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

(15.23) 2d v2t 2t6.1+VF = F K = F

6.1

Adapting the Lewis equation to the gear teeth, we have

(15.24) b b bF =[ ] bpy = [ ] bmY Where, [b] is the permissible bending stress in bending fatigue, in MPa, Table 15.3

Table 15.3 Permissible stress in bending fatigue, in MPa0.5

Material of the gear [b] MPa

Centrifugally cast Cu-Sn bronze 23.5

Aluminum alloys Al-Si alloy 11.3

Zn alloy 7.5

Cast iron 11.8

b is the face width in mm 0.5 da1 p is the axial pitch in mm, Table 15.2

m is module in mm, Table 15.2

y is the Lewis form factor, Table 15.1

Y is modified Lewis form factor, Table 15.1

By assuming the presence of an adequate supply of appropriate lubricant, the following

equation suggested by Buckingham may be used for wear strength calculations

(15.25) w 2F =d bKw

Fw Maximum allowable value of dynamic load under surface fatigue condition.

dg - Pitch diameter of the gear.

b - Face width of the gear.

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Kw - A material and geometry factor with values empirically determined from the Table

15.4.

Table 15.4 Worm Gear Wear Factors Kw

Material Kw (MPa)

Worm Gear

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Surface area of A for conventional housing designs may be roughly estimated from the

Eqn 15.27,

(15.27) 1.7A =14.75 C

Where A is in m2 and C (the distance between the shafts) is in m.

Housing surface area can be made far greater than the above equation value by

incorporating cooling fins. Rough estimates of C can be taken from the following

Fig.15.12.

Fig.15.12 Influence of worm speed on heat transfer

15.9 DESIGN GUIDELINES

The design guidelines for choosing the lead angle, pressure angle, addendum

dedendum, helix angle and the minimum number of teeth on the worm gear are given in

Tables 15.5 to 15.8.

-

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Table 15.5 Recommended pressure angles and tooth depths for worm gearing

Lead angle in degrees

Pressure angle n in degrees

Addendum ha in mm

Dedendum hf in mm

0-15 14.5 0.3683 p 0.3683 p

15-30 20 0.3683 p 0.3683

30-35 25 0.2865 p 0.331 p

35-40 25 0.2546 p 0.2947 p

40-45 30 0.2228 p 0.2578 p

Table 15.6 Efficiency of worm GEAR set for f = 0.05

Helix angle in O

Efficiency in %

Helix angle in O

Efficiency in %

Helix angle in O

Efficiency in %

1.0 25.2 7.5 71.2 20.0 86.0

2.5 46.8 10.0 76.8 25.0 88.0

5.0 62.6 15.0 82.7 30.0 89.2

Table 15.7 Minimum number of teeth in the worm gear

Pressure angle n 14.5o 17.5o 20o 22.5o 25o 27.5o 30o

Z2 minimum 40 27 21 17 14 12 10

Table 15.8 Maximum lead angle for normal pressure angle

Normal Pressure angle n 14.5o 20o 25o 30o

Maximum lead angle max 16 o 25 o 35 o 45 o

------------------------