Workpiece Material: D2 · 2010. 11. 9. · H01 - H40 B5L SB2 H05 - H15 B7H PBC-1 H05 - H25 B0L...

Transcript of Workpiece Material: D2 · 2010. 11. 9. · H01 - H40 B5L SB2 H05 - H15 B7H PBC-1 H05 - H25 B0L...

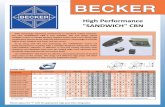

Workpiece Material: D2

Workpiece Hardness: 62 + 2 HRc

Workpiece Tolerance: + .0008"

Surface Finish Tolerance: Ra 16 µin

2

Technical Info. - Index

Using our Ultrahard Cutting Materials - Selection Criteria ..................................................................................................................................... page 3

Check List for Determining the Cutting Materials Grades (i.e. Hard- Cutting) ............................................................................................... page 3

Workpiece Material Groups (DIN ISO 513) ................................................................................................................................................................. page 4

Groups of Cutting Materials ............................................................................................................................................................................................. page 5

Range of Application (DIN ISO 513) For Material Groups, P, M,K, N, S, H .......................................................................................................... page 6

Designation of Tipped Inserts, ISO, BECKER Comparison ....................................................................................................................................... page 7

Variations of Tipped Corners for all Ultrahard Cutting Materials ................................................................................................................... page 8 & 9

Wear Resistance and Toughness , Comparison of all our Ultrahard Cutting Materials ............................................................................... page 10

Positive Top Rake Geometries ...................................................................................................................................................................................... page 11

ISO Insert Nomenclature ...................................................................................................................................................................................... page 12 & 13

Flank Wear Characteristics of our Ultrahard Cutting Materials ........................................................................................................................... page 14

Cutting Edge Geometry & Surface Finish Surface Roughness Rt & Feed Rates ........................................................................................... page 15

Ultrahard Cutting Materials Grades - Materials - Performance ................................................................................................................. page 16 & 17

Cutting Data for Turning - P: Sintered Steel, Powdered Alloys .......................................................................................................................... page 18

Cutting Data for Turning - K: Cast Iron, Grey & Nodular Cast Iron ...................................................................................................................... page 19

Cutting Data for Turning - N: Nonferrous Metals & Nonmetallics ........................................................................................................... page 20 & 21

Cutting Data for Turning - S: Super-Alloys & Titanium ........................................................................................................................................... page 22

Cutting Data for Turning - H: Hard Materials ................................................................................................................................................... page 23 & 24

Cutting Data for Milling - K: Cast Iron, Grey & Nodular Cast Iron ...................................................................................................................... page 25

Cutting Data for Milling - N: Nonferrous Metals & Nonmetallics ............................................................................................................ page 26 & 27

Cutting Data for Milling - H: Hard Materials .............................................................................................................................................................. page 28

Trouble Shooting for PCD Applications ..................................................................................................................................................................... page 29

Trouble Shooting for CBN Applications ..................................................................................................................................................................... page 30

Welcome to the vast product offering from Becker Diamond of Germany. To achieve optimum applicationsuccess, closely follow the enclosed selection checklists. Maximum machining performance with Beckerproducts is achieved through a calculated selection of required cutting materials, and proper macro-cuttingedge geometries. Please be advised that machining with Becker tools will be significantly different from whatyou have become accustomed to with normal carbide tooling. Due to the physical properties of the Beckercutting materials, and the range of micro-cutting edge geometries, it is important that you completely rethinkyour machining approach when determining selection criteria.

When selecting the Becker grades from our comprehensive range, a complex performance profile of themachining result is required. Due to the different variations of tipped corner styles, macro and micro cuttingedge geometries, careful pre-planning is required to ensure that the best tool is selected for the givenapplication.

The overall machining system should also be reconsidered in order to achieve full performance from theBecker product. Use the most rigid and accurate tooling systems available. Machinery and equipment shouldbe compatible with the machining tasks. Particular attention must be paid to the general rigidity, theslideways, spindles and work-holding systems. When all working parameters are optimized, you can achievesurface finishes in a nanometer range as a standard using Monocrystalline Diamond for non ferrous metals andwith PCBN for hard cutting of hardened steel.

3

Using our UltrahardCutting Materials - Selection Criteria

Example: Turning case-hardened steel HRc 62 ap=0.01", continuous cut in stable circumstances, a surface qualityof Ra=24µ" must be achieved (At Ra=24µ" the overall machining environment must be checked for suitability)

2nd StepRange of application H-20

1st StepMaterial group H

3rd StepCutting material: SB40 (T) at Vc=358-520 SFM ap=.01"

1.) Determine the material group as per DIN ISO 513 .......................................................................................................... page 4

2.) Determine the range of application for your material group as per DIN ISO 513 ................................................ page 6

3.) Then determine the cutting data for your area of application based on the surfacequality required, and machining application ............................................................................................................ page 18-28

4.) Check your selection of cutting material based on the grade description ................................................... page 16-17

5.) Determine the correct insert type including tipped corner style .......................................................................... page 8-9

6.) Based on nose radius and finish requirements, determine feed rate ...................................................................... page 15

Check List for Determining the Cutting Materials Grades (i.e. Hard- Cutting)

4th StepNose radius required

* Please note that these recommendations are guidelines based onrigid part set-up, good machine rigidity, and general machining practices.

Choose material spec. and hardness on page 4

With application range and finish in mind, choose grade andspecs. range on page 23

With corner radius in mind, choose feed rate required onpage 15

Based on depth of cut, choose your range of application onpage 6

laciteroehTssenhguoRecafruS

suidaRrenroC

)ver/hcni=f(etaRdeeF

niµaR niµtR 800.=r 610.=r 130.=r 740.=r 360.=r

42 001 200. 300. 400. 500. 600.

36 052 300. 400. 600. 700. 900.

521 005 500. 700. 900. 110. 410.

052 0001 600. 900. 210. 510. 810.

4

Workpiece Material Groups(DIN ISO 513)

noitacifitnedIruoloc&rettel

slairetaMniaMfoegnaR

snoitacilppaOSI edarGREKCEB

P leetSsyolladeredwopderetniS

01P-10P HB 71-CBP

51P-50P HB 51-CBP

52P-51P HB 01BS

04P-02P HB 1CBS

M leetSsselniatS **

sihtrofelbatiustonDCProNBC.egnarnoitacilppa

refer,cRH84evobasleetssselniatsroFHegnarnoitacilppaot

K

norItsaCnorItsaCyerG

53GG-01GGnorItsaCraludoN

05GGG-3.04GGG-04GGG07GGG-06GGG

52K-10K HB 01-CBP

52K-10K HB 51-CBP

02K-50K HB 71-CBP

02K-50K LB 52-CBP

04K-50K HB 01BS

53K-01K LB 52BS

04K-51K HB 1CBS

N

slateMsuorrefnoNscillatemnoN

,syollamunimulAmunimulAnociliS-hgiH+woL

,s'CMM,syolla,syollamuisengaM

,syollareppoC-reppoC,slatemsuoicerP,eznorB,ssarB

etihparGdnanobraC,PRC,PRG,scitsalP,stisopmoc

evisarba-hgihrehtodnascimareCscillatemnoN

53N-10N MD CDM

53N-50N PD L-CDP

04N-50N PD CDP

04N-01N PD S-CDP

S:muinatiTdnasyolla-repuS

syollalaicepstnatsisertaeH,tlaboCrolekciNnodesab

syollamuinatiTdnamuinatiT

51S-10S HB 01-CBP

51S-10S HB 51-CBP

02S-10S MD CDM

03S-10S HB 01BS

52S-50S LB 52-CBP

04S-51S HB 1CBS

H

:slairetaMdraHyllufrodezirubraC

cRH56ot84morfsleetsdenedrah,leetsloot,SSH

sselniatsseires004&003,leetskrowtohdnadloc

,leetsgnirps,leetsgniraeb-llab

,noritsacdellihc,sllornoritsacdellihc

,syollanoritsacdellihcsyollagnicafdrah

edibracderetnis

02H-10H LB 04-CBP

52H-10H LB 52-CBP

53H-10H LB 04BS

04H-10H LB 52BS

51H-50H HB 71-CBP

52H-50H LB 03-CBP

03H-50H LB 02-CBP

04H-02H HB 1CBS

5

Groups of Cutting Materials

As per DIN ISO 513 (2001) there are nowadditional identification letters forcarbide (also cermet) and ceramic.

Furthermore new identification lettersfor the ultrahard cutting materialsPolycrystalline Cubic Boron Nitride,Monocrystalline and PolycrystallineDiamond have been introduced.

Groups of cutting materials (DIN ISO 513)=WH edibracdetaocnU

=FH edibracdeniargeniF

=TH NiTro,CiT,temreC

=CH detaoctub,evobasA

=AC lAtnetnocniam,cimareC2O

3

=MC lAtnetnocniam,cimarecdexiM2O

3sedixonahtrehtostnenopmocsulp,

=NC iStnetnocniam,cimarecedirtinnociliS3N

4

=RC lAtnetnocniam,cimareC2O

3decrofnier,

=CC detaoctub,evobasascimareC

=MD dnomaiDenillatsyrconoM

=PD dnomaiDenillatsyrcyloP

=LB NBCtnetnocwolhtiwedirtiNnoroBcibuCenillatsyrcyloP

=HB NBCfotnetnochgihhtiwedirtiNnoroBcibuCenillatsyrcyloP

=CB detaoctub,evobasaedirtiNnoroBcibuCenillatsyrcyloP

6

Range of Application (DIN ISO 513)for Material Groups P, K, N, S, H

7

Designation of tipped insertsISO - BECKER Comparison

OSIREKCEB

noitangiseDngiseD

srenrocdeppitfotnuomA

2 3 4

A

WEWMCMCDP

,renrocdeppit1decrofnieredibrac

S-ASWES-CMCDM

,renrocdeppit1sedargdilos

C ***

,renrocdeppit2decrofnieredibrac

DS-CPM-CP

,egdedeppit1sedargdilos

F MV

ecaflluF

E ***

dediselbuoDecaflluf

SCBS

BS

diloS

8

Variations of Tipped Cornersfor all Ultrahard Cutting Materials

OSIREKCEB

noitangiseDngiseD noitpircsedpiT edarG OSI

AWEWM

,sedarg-NBCPdecrofnieredibraCNBCPfossenkciht

"930.-420.=reyal

,51-CBP,01-CBP71-CBP

52-CBP,02-CBP04-CBP,03-CBP

HBHBLBLB

2-A CM,sedarg-NBCPdecrofnieredibraC

NBCPfossenkciht"930.-420.=reyal

,51-CBP,01-CBP71-CBP

52-CBP,02-CBP04-CBP,03-CBP

HBHBLBLB

3-A CM,sedarg-NBCPdecrofnieredibraC

NBCPfossenkciht"930.-420.=reyal

,51-CBP,01-CBP71-CBP

52-CBP,02-CBP04-CBP,03-CBP

HBHBLBLB

AL-CDP

CDPS-CDP

sedarg-DCPdecrofnieredibraCCDP,L-CDP

S-CDPPDPD

3-A CM sedarg-DCPdecrofnieredibraCCDP,L-CDP

S-CDPPDPD

S-A SWEsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

2S-A S-CMsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

S-A CDMedarg-dnomaiDenillatsyrconoMdiloS

tnemecrofniertuohtiwCDM MD

D S-CPsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

9

Variations of Tipped Cornersfor all Ultrahard Cutting Materials

OSIREKCEB

noitangiseDngiseD noitpircsedpiT edarG OSI

2-D M-CPsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

3-D M-CPsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

4-D M-CPsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

F MV,sedarg-NBCPdecrofnieredibraC

ecaflluF

,51-CBP,01-CBP71-CBP

52-CBP,02-CBP04-CBP,03-CBP

HBHBLBLB

F MVsedarg-CDPdecrofnieredibraC

ecaflluFS-CDP,CDP PD

SCBS

BSsedarg-NBCPdiloS

tnemecrofniertuohtiw01BS,1CBS04BS,52BS

HBLB

**SG-CBS

SG-BS

sedarg-NBCPdiloSegdegnittucelohw

tnemecrofniertuohtiw

01BS,1CBS04BS,52BS

HBLB

** SG-CBPsedarg-NBCPdecrofnieredibraC

egdegnittucelohw

,51-CBP,01-CBP71-CBP

52-CBP,02-CBP04-CBP,03-CBP

HBHBLBLB

**SG-CDPSG-S-CDP

sedarg-CDPdecrofnieredibraCegdegnittucelohw

S-CDP,CDP PD

10

Wear Resistance and Toughness,Comparison of all our UltrahardCutting Materials

11

Positive Top Rake Geometries

ekaRpoT segatnavdA egatnavdasiD

tresnievitagen)1)L/R(elgnaekarevitisop)2

egdegnittucprahs)3

:slairetaMgnittuCCDM

deepsgnittuchgihyrev)1tucfohtpedegral)2erusserpgnittucon)3eerf-rrubyletulosba)4

stimilecnarelotllamsyrev)5efilloothgihyrev)6

ecafrusfonoitcuderelttil)1evitisopybdesuachsinif

elgnaekar

tresnievitisop)1)L/R(elgnaekarevitisop)2

egdegnittucprahs)3

:slairetaMgnittuCS-CDPdnaCDP

htpedegralylemertxe)1tucfo

erusserpgnittucwol)2eerf-rrub)3

stimilecnarelotllams)4

ecafrusfonoitcuderelttil)1evitisopybdesuachsinif

elgnaekar

tresnievitisop)1)N(elgnaekarevitisop)2

egdegnittucprahs)3

:slairetaMgnittuCgnirobrofCDPdnaCBP

erusserpgnittucwol)1eerf-rrub)2

stimilecnarelotllams)3gnahrevohgih)4

deepsgnittuchgih)5

ecafrusfonoitcuderelttil)1evitisopybdesuachsinif

elgnaekar

tresnievitisop)1)N(elgnaekarevitisop)2

egdegnittucprahs)3

:slairetaMgnittuCCBPdna,S-CDP,CDP

erusserpgnittucwol)1eerf-rrub)2

stimilecnarelotllams)3deepsgnittuchgih)4

ecafrusfonoitcuderelttil)1evitisopybdesuachsinif

elgnaekar

tresnievitagen)1)N(elgnaekarevitisop)2

egdegnittucprahs)3

:slairetaMgnittuCBS,CBS

tucfohtpedtaerg)1erusserpgnittucwol)2stimilecnarelotllams)3

deepsgnittuchgih)4

ecafrusfonoitcuderelttil)1evitisopybdesuachsinif

elgnaekar

12

ISO InsertNomenclature

13

ISO InsertNomenclature

14

Flank Wear Characteristicsof our Ultrahard Cutting Materials

1) MDC - Monocrystalline Diamond (DM)Monocrystalline diamond is the hardest known mineral. It’s outstanding abrasive hardness and highest

homogeneity enable the manufacture of ultra sharp and notch free micro-cutting edge qualities, (as it is groundfrom a single crystal) - not achievable using other cutting materials. The sharpness of the cutting edge produces aslight cutting pressure without any heat generated during machining. The unsurpassable wear resistance retainsthe perfect micro-cutting edge quality over an extremely long tool life. MDC cannot be used on aluminium withfillers.

2) PCD - Polycrystalline Diamond (DP)The core structure (ultra-fine to coarse grain) of the Polycrystalline Diamond provides a higher toughness, yet

lower wear resistance and reduced micro-cutting edge quality than with Monocrystalline Diamond. The reactionbehaviour is identical, yet the higher toughness extends the application range considerably. Materials with a lowto very high content (from 2% to 70%) of abrasives fillers can be machined with excellent tool life.

3) CBN - Polycrystalline Cubic Boron Nitride (BH and BL)Polycrystalline Cubic Boron Nitride is the second hardest cutting material next to Diamond, however, it has far

less in common with Diamond. Reaction resistance reaches 1,250°C which makes this cutting material have avery high wear resistance, toughness, compression strength and thermal hardness ideal for self-induced hotcutting mode of hardened steels.

Flank Wear of Ultrahard Cutting Materials

Flank wear has a significant influence on the life of all cutting tools. Due to the excellent flank wear resistanceof all Becker cutting materials, they are clearly superior to conventional cutting materials in many fields. Typically,the Becker product will exhibit negligible flank wear - if any at all, thereby resulting in extremely long tool life.

The following drawing shows the difference of tool life under the same machining conditions for inserts with aclearance angle of 7° respectively 11°. Tool life of the insert with 11° angle will be 1.6 times longer than that of 7°before they reach the same width of flank wear. The following aspects should be taken into account in order tochoose the adequate cutting edge geometry.

Under normal working conditions, abrasion will usually cause a certain degree of flank wear. Mono- andpolycrystalline diamonds, however, are susceptible to abrasion caused by oxidation at a heat exceeding 650°C.The cause of flank wear is due to the extremely high thermal conductivity of diamonds. It is thereforerecommended to select the smallest possible clearance angle for all diamond tools (if formation of burrs is of noimportance). This selection will increase passive cutting pressure, leading to a better surface finish.

In contrast, CBN’s low thermal conductivity flank wear is usually not only caused by abrasion, but alsooxidation, diffusion, or adhesion, when applied for high speed cutting (HSC) and also self-induced hot cuttingmode of hardened steel. With this point in mind, the correct clearance angle for external and internal turning ispivotal with regards to the friction between flank and the work piece. The passive cutting pressure and thetemperature it is reaching can be controlled not only by the clearance angle, but also by the micro cutting edgegeometry. In order to obtain maximum tool life, interaction of those facts must be considered.

15

Cutting EdgeGeometry & Surface Finish

Surface Roughness Rt & Feed Rates

The practical application proves that the theoretically calculated value can hardly be achieved, since theenvironmental conditions tend to be imperfect. Unstable machining conditions, incorrect workholding, chucking,faulty or wrong tool system, wrong cutting speed and depth of cut etc. will impair the results. Conversely, workingtowards near perfect working conditions can result in an improved surface finish due to improved and optimizedcutting edge geometries. In particular, the general reduction of the minor cutting edge angle, as well as themicro-geometries, with PCBN (for more cutting pressure) should be mentioned. In order to obtain the variousstages of excellent surface finishes while hard-cutting, the T-land styles are of great influence. For a mirror-finishsurface of nonferrous metals and nonmetallics, Becker is able to supply even MDC-inserts with a T-Land, ifnecessary.

With regards to high-performance cutting of all types, Becker has developed a variety of inserts with WIPERgeometry for internal, external and milling processes. The WIPER edge replaces the above-mentioned minorcutting edge, reducing its angle to a minimum, thereby reducing the theoretically computed surface roughnessby 2 to 4 times.

In practice this is the alternative for high-performance and high-tech cutting:

1) 2-4x higher feed rate = same surface finish 2) same feed rate = 2-4x improved surface finish

Wiper inserts are available for:• FormCut• MonoCut• MiniCut• ISO-HardCut

In addition to the improvements gained in productivity bydecreased flank wear, Becker products will result in significant gainsin product quality.

One can simply calculate the theoretical surface roughness Rt- also known as R max and Rz. (In practice itusually runs up to four times the Ra value). The theoretical value, however, is again based on a perfect cuttingedge geometry with a wide minor cutting edge angle. Using Becker MDC and PCD when machining nonferrousmetals and non-metallics or CBN for grey cast iron results in hardly any flank wear or deformation of the cuttingedge - due to the excellent flank wear resistance of our tools. It is therefore possible to complete the precisedata for the required surface roughness, provided the cutting environment in itself will not hamper themachining as such.

In practice, the values of roughness will typically be less than the theoretical calculation when hard-cuttingwith CBN. This is due to a simple reason: the cutting process itself is influenced by self induced hot-cutting modewhich can cause an extremely high passive cutting pressure.

laciteroehTssenhguoRecafruS

suidaRrenroC

)ver/hcni=f(etaRdeeF

niµaR niµtR 800.=r 610.=r 130.=r 740.=r 360.=r

42 001 200. 300. 400. 500. 600.

36 052 300. 400. 600. 700. 900.

521 005 500. 700. 900. 110. 410.

052 0001 600. 900. 210. 510. 810.

16

Ultrahard Cutting MaterialsGrades - Materials - Performance

sedarG OSI ecnamrofreP-noitisopmoC noitacilppA

CDM&DCP-dnomaiDenillatsyrcyloPdna-onoM

CDM MD

gnittuC.erutcurtsonhtiwdnomaidenillatsyrconomdiloS,segamadorcimtuohtiwdnaprahsylemertxesiegde

stlusereerf-rrubgniwolla,erusserpgnittucongnitarenegtnatsiserraewknalfylemertxE.orezotesolcsecnarelothtiw

.ssenhguotwol,ytivitcudnoclamrehtmumixamdna

erupllafognihsinifrepuS-nondnaslatemsuorrefnon

evisarbaonhtiwscillatem.nocilisrotnemecrofnier

)hceThgiH-CSH(

L-CDP PD

tirgenifartlufodnomaiddecrofnieredibrac,enillatsyrcyloPerusserpgnittuclaminim,ssenprahsegdegnittuchgih,ezis

dnaecnatsiserraewknalfdooG.secnarelotesolcgniwolla.ssenhguot

suorrefnonerupllafognihsiniFhtiwscillatemnondnaslairetam

evisarbafotnetnocwolyrev.nocilisrotnemecrofnier

CDP PD

,ezistirgeniffodnomaiddecrofnieredibrac,enillatsyrcyloPerusserpgnittucwoldnassenprahsegdegnittucdoog

dnaecnatsiserraewknalfdesaercnI.secnarelotesolcgniwolla.ssenhguot

foesopruplarenegdnagnihsiniFdnaslatemsuorrefnonlla

fotnetnocwolhtiwscillatemnon.nocilisrotnemecrofnierevisarba

S-CDP PD

,ezistirgesraocfodnomaiddecrofnieredibracenillatsyrcyloPgniwollaerusserpgnittucwoldnassenprahsegdedoog

knalfhgiH.gnillimrofsecnamrofreptseB.secnarelotesolc.ssenhguotdnaecnatsiserraew

dnaesopruplareneg,gnihsiniFhtiwscillatemnonllafognillim

fotnetnochgihotmuidem.nocilisrotnemecrofnierevisarba

NBCtnetnoChgiH-edirtiNnoroBcibuCenillatsyrcyloP

1CBS HB

hgihhtiwedargedirtiNnoroBcibuCenillatsyrcylopdiloShtiwdengiseD.ezistirgmuidemdnaNBCfotnetnoc

,ytilibatslamreht,ecnatsiserraewknalflanoitpecxednagnihguorrofssenhguotdnahtgnertsnoisserpmoc

.CPHdnaCSH.noritsacyergfognihsinif

noritsacyerGnoritsacdellihC

drah-iNsyollarepuS

syolladeredwopderetniS

01BS HB

hgihhtiwedargedirtiNnoroBcibuCenillatsyrcylopdiloSdnaCPH,CSH.ezistirgenifdnaNBCfotnetnoc

tnellecxegnisuac)52GG(noritsacyergfognihsinifrepus.ssenhguotdnaecnatsiserraewknalf

noritsacyerG52GG

syollarepuSsyolladeredwopderetniS

01-CBP HB

edargedirtiNnoroBcibuCdecrofnieredibracenillatsyrcyloPknalftcefrep,ezistirgenifdnaNBCfotnetnochgihhtiw

fognihsinifrepusdnaCSH.ssenhguotdnaecnatsiserraew.syollarepusfognihsinifdna)52GG(noritsacyerg

noritsacyerG52GG

syollarepuSsyolladeredwopderetniS

51-CBP HB

edargedirtiNnoroBcibuCdecrofnieredibracenillatsyrcyloPelbaruovafehT.ezistirgenifdnaNBCfotnetnochgihhtiw

raewknalfdoogyrev,syolladeredwopderetnisrofedarg.ssenhguotdnaecnatsiser

noritsacyerGsyollarepuS

syolladeredwopderetniS

71-CBP HB

edargedirtiNnoroBcibuCdecrofnieredibracenillatsyrcyloPslecxeedargsihT.ezistirgenifdnaNBCfotnetnochgihhtiw

dnaesopruplareneg:noitacilppafosdleifniamowtnidenedrahfognittuc-drahdna,noritsacraludonfognihsinif

.tnaloocdoolfgnisu)45-84cRH(leets

noritsacraludoN)07GGG-04GGG(

gnittuc-draH)45-84cRH(

syolladeredwopderetniS

17

Ultrahard Cutting MaterialsGrades - Materials - Performance

sedarG OSI ecnamrofreP-noitisopmoC noitacilppA

NBCtnetnoCwoL-edirtiNnoroBcibuCenillatsyrcyloP

02-CBP LB

edargedirtiNnoroBcibuCdecrofnieredibracenillatsyrcyloProfdereenignE.ezistirgenifdnaNBCfotnetnocwolhtiwtsehgihnehw)56-65cRH(leetsdenedrahfognittuc-drah

niecnamrofrepdooG.niµ23-niµ8aR(laicurcsihsinifecafrus.gnittucsuounitnocsallewsasnoitpurretniyvaeh

sleetsdenedraH)56-65cRH(

gnittucyrdniµ23-niµ8aRrof

"020.-"600.=pa

52BS LB

fotnetnocwolhtiwedirtiNnoroBcibuCenillatsyrcyloPdiloS,htgnertsnoisserpmoctsehgiH.ezistirgenifdnaNBC

cRH(gnittuc-drahnehwecnatsiserraewknalfdnassenhguotlamrehT.)"970.-"210.=pa(.tucfohtpedhgihhtiw)56-65rofelbatiuS.deniattatuctfosadnadecudersiytivitcudnoc

oslA.gnittucdetpurretniyvaehsallewsasuounitnoc.deepsgnittucwolyrevatanoritsacyergfognihsinif

sleetsdenedraH)56-65cRH(

gnittucyrdniµ521-niµ23aRrof

"970.-"210.=panoritsacyerG

)mfs0411-008cV(

52-CBP LB

htiwedirtiNnoroBcibuCdecrofnieredibracenillatsyrcyloPraewtnellecxE.ezistirgenifdnaNBCfotnetnocwol

-drahrofssenhguotdnahtgnertsnoisserpmoc,ecnatsiserdnasuounitnocrofesopruplareneG)26-45cRH(.gnittuc

-niµ23aRhsinifecafrustagnittucdetpurretniylthgilsgnittucwolyrevatanoritsacyergfognihsinif,oslA.niµ521

.deeps

sleetsdenedraH)56-65cRH(

gnittucyrdniµ521-niµ23aRrof

"610.-"300.=panoritsacyerG

)mfs0031-579cV(

03-CBP LB

htiwedirtiNnoroBcibuCdecrofnieredibracenillatsyrcyloPraewtnellecxE.ezistirgenifdnaNBCfotnetnocwol

-drahrofssenhguotdnahtgnertsnoisserpmoc,ecnatsiserrofelbatiuS)tnaloocdoolfgniylppa56-65cRH(.gnittuc

hsinifecafrustagnittucdetpurretniylivaehdnasuounitnoc.niµ36-niµ23aR

sleetsdenedraH)56-65cRH(

roftnaloocdoolfhtiwniµ36-niµ23aR"610.-"300.=pa

04BS LB

fotnetnocwolhtiwedirtiNnoroBcibuCenillatsyrcyloPdiloS,ecnatsiserraewemertxE.ezistirgenifartludnaNBC

gnittuc-drahyrdrofssenhguotdnahtgnertsnoisserpmoc.tucfohtpedrewolhtiwsetardeefrehgihta)56-65cRH(

.gnittucdetpurretniylthgilsdnasuounitnoctatuctfosyreV

sleetsdenedraH)56-65cRH(

gnittucyrdniµ23-niµ8aRrof

"060.-"210.=pa

04-CBP LB

fotnetnocwolhtiwedirtiNnoroBcibuCenillatsyrcyloPdiloSyrdrofecnatsiserraewtcefreP.ezistirgenifartludnaNBC

.tucfohtpedwolhtiwsetardeefrehgihtagnittuc-drah.gnittucdetpurretniylthgilsdnasuounitnoC

sleetsdenedraH)26-65cRH(

gnittucyrdniµ36-niµ23aRrof

"210.-"200.=pa

18

Cutting Data for TurningP: Sintered Steel, Powdered alloys

slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

P-

10

Pn

oitacilp

paf

oe

gna

Rc

V

PleetS

deretnis

dered

wo

psyolla

gni

nruT

51

P-

10

P6

ega

pees

52

P-

01

P6

ega

pees

)C

PH(

04

P-

02

P6

ega

pees

MFS:cV

MFS:cV

MFS:cV

57

22-

00

31

00

31-

31

85

79-

88

45

72

2-0

03

10

03

1-3

18

57

9-8

84

57

22-

00

31

00

31-

31

85

79-

88

4

elbats

nu

)ht

ped

deirav(

)T(

51-C

BP)

T(51-

CBP

)T(

51-C

BP)

T(51-

CBP

)T(

01-C

BS)

T(1

CBS

)T(

01BS

)T(

1C

BS

su

ou

nitn

oc)F(

51-C

BP)F(

51-C

BP)

T(51-

CBP

)T(

1C

BS)

T(51-

CBP

)T(

71-C

BP)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)F(71-

CBP

)T(

71-C

BP)F(

01-C

BP)

T(51-

CBP

)T(

71-C

BP)

T(01

BS

ylth

gils+

ylivaeh

detp

urretni

)T(

51-C

BP)

T(51-

CBP

)T(

51-C

BP)

T(1-

CBS

)T(

1C

BS)

T(71-

CBP

)T(

1C

BS)

T(1

CBS

)T(

1C

BS

)T(

01-C

BP)

T(01-

CBP

)T(

71-C

BP)

T(01

BS)

T(01

BS

ecio

hC

etanretl

A:2

noitis

oP

|eci

oh

Cyra

mirP:

1n

oitiso

P,sedar

GN

BC

Pyl

no

gni

nrut

su

ou

nitn

oc)

prahS(

=F,gni

nrut

su

ou

nitn

ocd

nadet

purret

nir

of)

dnaL-T(

=T

Turn

ing

19

Cutting Data for TurningK: Cast Iron, Grey & Nodular Cast Iron

Turn

ing slaireta

Mf

os

noiti

dn

oC

lavo

merpi

hc0

4K

-1

0K

noitacil

ppa

fo

eg

naR

cV

Ks

nori

tsaC

tsacyer

g()

nori

01G

G51

GG

02G

G

gni

nruT

51

K-

10

K6

ega

pees

52

K-

01

K6

ega

pees

)C

PH

+CS

H(0

4K

-0

2K

6e

gap

ees

MFS:cV

MFS:cV

MFS:cV

00

56-

52

92

52

92-

52

61

52

61-

83

11

00

56-

52

92

52

92-

52

61

52

61-

83

11

00

56-

52

92

52

92-

52

61

52

61-

83

11

elbats

nu

)ht

ped

deirav(

)T(

51-C

BP)

T(51-

CBP

)T(

52-C

BP)

T(51-

CBP

)T(

51-C

BP)

T(52-

CBP

)T(

1C

BS)

T(01

BS)

T(52

BS

)F(01-

CBP

)F(01-

CBP

)F(01-

CBP

)T(

01BS

)T(

1C

BS

su

ou

nitn

oc)F(

51-C

BP)

T(51-

CBP

)F(52-

CBP

)T(

01-C

BP)F(

01-C

BP)F(

52-C

BP)

T(1

CBS

)T(

01BS

)T(

52BS

)F(01-

CBP

)F(01-

CBP

)T(

01BS

)T(

01BS

)T(

1C

BS

ylth

gils+

ylivaeh

detp

urretni

)T(

51-C

BP)

T(51-

CBP

)T(

52-C

BP)

T(01-

CBP

)T(

01-C

BP)

T(52-

CBP

)T(

1C

BS)

T(1

CBS

)T(

52BS

)T(

01-C

BP)

T(01-

CBP

)T(

01BS

)T(

01BS

)T(

01BS

Ks

nori

tsaC

tsacyer

g()

nori

52G

G03

GG

53G

G

elbats

nu

)ht

ped

deirav(

)T(

51-C

BP)

T(51-

CBP

)T(

52-C

BP)

T(51-

CBP

)T(

51-C

BP)

T(52-

CBP

)T(

01BS

)T(

01BS

)T(

52BS

)F(01-

CBP

)F(01-

CBP

)T(

01-C

BP)

T(1

CBS

)T(

1C

BS

su

ou

nitn

oc)F(

01-C

BP)F(

01-C

BP)F(

52-C

BP)

T(01-

CBP

)T(

51-C

BP)F(

52-C

BP)

T(01

BS)

T(1

CBS

)T(

52BS

)F(01-

CBP

)F(01-

CBP

)T(

52-C

BP)

T(1

CBS

)T(

01BS

ylth

gils+

ylivaeh

detp

urretni

)T(

01-C

BP)

T(01-

CBP

)T(

52-C

BP)

T(01-

CBP

)T(

01-C

BP)

T(52-

CBP

)T(

1C

BS)

T(1

CBS

)T(

52BS

)T(

01BS

)T(

01BS

)T(

01BS

Ks

nori

tsaC

tsacral

ud

on(

)n

ori04

GG

G05

GG

G06

GG

G07

GG

G

elbats

nu

)ht

ped

deirav(

)T(

71-C

BP)

T(71-

CBP

)T(

1C

BS)

T(71-

CBP

)T(

1C

BS

su

ou

nitn

oc)

T(1

CBS

)F(71-

CBP

)T(

1C

BS)F(

71-C

BP)

T(1

CBS

)T(

71-C

BP

)T(

71-C

BP)

T(71-

CBP

)T(

1C

BS

ylth

gils+

ylivaeh

detp

urretni

)T(

1C

BS)

T(71-

CBP

)T(

1C

BS)

T(71-

CBP

)T(

1C

BS)

T(71-

CBP

)T(

51-C

BP)

T(51-

CBP

)T(

1C

BS

ecio

hC

etanretl

A:2

noitis

oP

|eci

oh

Cyra

mirP:

1n

oitiso

P,sedar

GN

BC

Pyl

no

gni

nrut

su

ou

nitn

oc)

prahS(

=F,gni

nrut

su

ou

nitn

ocd

nadet

purret

nir

of)

dnaL-T(

=T

20

Cutting Data for TurningN: Nonferrous Metals & NonmetallicsTu

rnin

g slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

N-

10

Nn

oitacilp

paf

oe

gna

Rc

V+

tR

Ns

uorref

no

Nslate

mm

uni

mul

At

uo

htiw

syollan

ocilis

gni

nruT

)dee

ps-h

gih(

)CS

H(0

2N

-1

0N

6e

gap

ees)

CSH(

03

N-

02

N6

ega

pees

)C

PH

+CS

H(0

4N

-5

2N

6e

gap

ees

µ)z

R(t

Rµ

)zR(

tR

µ)z

R(t

R

-ni

µ2.3ni

µ001-

niµ001

niµ002

-ni

µ002ni

µ004-

niµ2.3

niµ001

-ni

µ001ni

µ002-

niµ002

niµ004

-ni

µ2.3ni

µ001-

niµ001

niµ002

-ni

µ002ni

µ004

elbats

nu

)ht

ped

deirav(

CD

MC

DPC

DPC

DM

CDP

CDP

CD

MC

DPC

DP

0579-52925218-0031

5218-00315218-0591

0056-00310056-0031

0056-52610025-0031

0025-0031

su

ou

nitn

ocC

DM

L-C

DPC

DPC

DM

L-C

DPC

DPC

DM

L-C

DPC

DP

00031-52925218-0031

5218-00310579-0591

0056-00310056-0031

5218-52610025-0031

0025-0031

ylth

gils+

ylivaeh

detp

urretni

CD

MC

DPC

DPC

DM

CDP

CDP

CD

MC

DPC

DP

0579-52925218-0031

5218-00315218-0591

0056-00310056-0031

0056-52610056-0031

0025-0031

Ns

uorref

no

Nslate

mm

uni

mul

Ahti

wsyolla

%21na

htssel

nocilis

elbats

nu

)ht

ped

deirav(

S-C

DPS-

CDP

S-C

DPS-

CDP

S-C

DPS-

CDP

0056-05910517-0591

0585-05910056-0591

5784-05910585-0591

su

ou

nitn

ocC

DM

CDP

S-C

DPC

DPS-

CDP

CDP

S-C

DP

5784-00930056-0031

0517-00310585-0031

0056-05915784-0031

0585-0031

ylth

gils+

ylivaeh

detp

urretni

S-C

DPS-

CDP

S-C

DPS-

CDP

S-C

DP

0056-05910517-0591

0585-05910056-0591

5784-0591

Ns

uorref

no

Nslate

mm

uni

mul

Ahti

wsyolla

naht

ero

mn

ocilis%21

elbats

nu

)ht

ped

deirav(

S-C

DPS-

CDP

S-C

DP

0585-05915784-0591

0093-0591

su

ou

nitn

ocS-

CDP

S-C

DPS-

CDP

S-C

DPS-

CDP

S-C

DP

0093-00620585-0031

0523-57225784-0031

5292-05910093-0031

ylth

gils+

ylivaeh

detp

urretni

S-C

DPS-

CDP

0585-05915784-0591

decu

dersi

taht

yln

oefil

lo

otsi

ti,)slatem(

tnal

ooc

do

olfr

o)scitsal

p(ri

A:tnal

oo

C.

detceffat

on

si,revew

oh,

hsinif

ecafrus

eht,

gnil

ooc

tu

ohti

wg

nittuc

neh

w

21

Cutting Data for TurningN: Nonferrous Metals & Nonmetallics

Turn

ing slaireta

Mf

os

noiti

dn

oC

lavo

merpi

hc0

4N

-1

0N

noitacil

ppa

fo

eg

naR

cV

+t

R

Ns

uorref

no

Nslate

md

nare

pp

oC

syollare

pp

oc,ez

nor

b,ssarb

su

oicerp

slatem

gni

nruT

)dee

ps-h

gih(

)CS

H(0

2N

-1

0N

6e

gap

ees)

CSH(

03

N-

02

N6

ega

pees

)C

PH

+CS

H(0

4N

-5

2N

6e

gap

ees

µ)z

R(t

Rµ

)zR(

tR

µ)z

R(t

R

-ni

µ2.3ni

µ001-

niµ001

niµ002

-ni

µ002ni

µ004-

niµ2.3

niµ001

-ni

µ001ni

µ002-

niµ002

niµ004

-ni

µ2.3ni

µ001-

niµ001

niµ002

-ni

µ002ni

µ004

elbats

nu

)ht

ped

deirav(

CD

ML-

CDP

CDP

CD

MC

DPS-

CDP

CD

MC

DPS-

CDP

5218-05910585-0031

5784-5790056-0591

0025-00315784-579

0585-52615784-0031

0554-579

su

ou

nitn

ocC

DM

L-C

DPC

DPC

DM

L-C

DPS-

CDP

CD

MC

DPS-

CDP

0579-05910517-0031

0585-5795218-0591

0585-00315255-579

0056-52610025-0031

5224-579

ylth

gils+

ylivaeh

detp

urretni

CD

MC

DPC

DPC

DM

CDP

S-C

DPC

DM

CDP

S-C

DP

0579-05910585-0031

0025-5790056-0591

0025-00310025-579

0585-52610554-0031

5784-0031

N-

no

Nscillate

mscitcal

per

up

-ert

uo

htiw

tne

mecrof

ni

elbats

nu

)ht

ped

deirav(

CD

ML-

CDP

CDP

CD

ML-

CDP

CDP

CD

ML-

CDP

CDP

0579-05910585-5261

0093-00310585-0591

0093-00310523-579

0585-05915292-579

0523-056

su

ou

nitn

ocC

DM

L-C

DPC

DPC

DM

L-C

DPC

DPC

DM

L-C

DPC

DP

57311-00310585-579

0093-5790585-0031

0523-5790523-056

0585-00310062-056

5292-056

ylth

gils+

ylivaeh

detp

urretni

CD

ML-

CDP

CDP

CD

ML-

CDP

CDP

CD

ML-

CDP

CDP

0579-05910585-5261

0093-00310585-0591

0093-00310523-579

0585-05915292-579

0523-056

N-

no

Nscillate

mscitsal

p-er

htiw

tne

mecrof

ni)PR

C,PRG

/ei(

elbats

nu

)ht

ped

deirav(

CD

MS-

CDP

CD

MS-

CDP

S-C

DPS-

CDP

S-C

DP

0093-00620523-5261

5292-57225292-0031

5292-5790062-579

0093-056

su

ou

nitn

ocC

DM

S-C

DPC

DM

S-C

DPS-

CDP

S-C

DPS-

CDP

0554-00315292-0031

0523-05910062-579

5292-0560062-056

0554-056

ylth

gils+

ylivaeh

detp

urretni

CD

MS-

CDP

CD

MS-

CDP

S-C

DPS-

CDP

0093-52920523-5261

5292-57220062-0031

0523-5790062-579

decu

dersi

taht

yln

oefil

lo

otsi

ti,)slatem(

tnal

ooc

do

olfr

o)scitsal

p(ri

A:tnal

oo

C.

detceffat

on

si,revew

oh,

hsinif

ecafrus

eht,

gnil

ooc

tu

ohti

wg

nittuc

neh

w

22

Cutting Data for TurningS: Super-Alloys & TitaniumTu

rnin

g slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04S

-1

0Sn

oitacilp

paf

oe

gna

Rc

V

Ssy

olla-rep

uSt

natsisertae

hsy

ollaesa

blekcin

syolla

,817len

ocnI

,cin

omi

N,y

olletsaH

yola

psaW

gni

nruT

51S

-1

0S6

ega

pees

52S

-5

1S6

ega

pees

04S

-5

2S6

ega

pees

MFS:cV

MFS:cV

MFS:cV

52

92-

52

61

52

61-

57

98

31

1-0

56

52

92-

52

61

52

61-

57

98

31

1-0

56

52

92-

52

61

52

61-

57

98

31

1-0

56

elbats

nu

)ht

ped

deirav(

)T(

51-C

BP)

T(52-

CBP

)T(

51-C

BP)

T(52-

CBP

)T(

01BS

)T(

52BS

su

ou

nitn

oc)F(

51-C

BP)F(

01-C

BP)F(

02-C

BP)F(

01-C

BP)

T(51-

CBP

)T(

01BS

)T(

01BS

)F(51-

CBP

)F(52-

CBP

)T(

51-C

BP)

T(01-

CBP

)T(

52BS

ylth

gils+

ylivaeh

detp

urretni

)T(

51-C

BP)

T(01-

CBP

)T(

01-C

BP)

T(1

CBS

)T(

01-C

BP)

T(01-

CBP

)T(

1C

BS)

T(1

CBS

)T(

01BS

)T(

51-C

BP)

T(51-

CBP

)T(

1C

BS

Ssy

olla-rep

uSm

uinatit

mui

natitsy

olla

elbats

nu

)ht

ped

deirav(

su

ou

nitn

ocC

DM

CD

MS-

CDP

CD

MC

DM

S-C

DP)

T(52

BS

)T(

52-C

BP)

T(52-

CBP

ylth

gils+

ylivaeh

detp

urretni

S-C

DP)

T(1

CBS

S-C

DP)

T(1

CBS

)T(

52C

BS

)T(

52-C

BP)

T(52

BS

ecio

hC

etanretl

A:2

noitis

oP

|eci

oh

Cyra

mirP:

1n

oitiso

P,sedar

GN

BC

Pyl

no

gni

nrut

su

ou

nitn

oc)

prahS(

=F,gni

nrut

su

ou

nitn

ocd

nadet

purret

nir

of)

dnaL-T(

=T

23

Cutting Data for TurningH: Hard Materials

Turn

ing slaireta

Mf

os

noiti

dn

oC

lavo

merpi

hc0

4H

-1

0H

noitacil

ppa

fo

eg

naR

cV

+a

R

Hdra

Hslaireta

mde

nedra

hleets

45-84cR

Hg

ninr

utdra

h

gni

nruT

51

H-

10

H6

ega

pees

02

H-

50

H6

ega

pees

)C

PH(

04

H-

02

H6

ega

pees

niµ

aR

niµ

aR

niµ

aR

23-

83

6-2

35

21-

36

23-

83

6-2

35

21-

36

23-

83

6-2

35

21-

36

elbats

nu

)ht

ped

deirav(

)F(52-

CBP

)F(52-

CBP

)F(52

BS

517-025816-884

585-554

su

ou

nitn

oc)

T(04

BS)

T(71-

CBP

)F(52-

CBP

)T(

04BS

)T(

71-C

BP)F(

52-C

BP)

T(02-

CBP

)T(

04BS

)T(

52BS

025-093585-324

517-025025-853

355-324816-884

554-523025-093

355-324

ylth

gils+

ylivaeh

detp

urretni

)T(

02-C

BP)

T(71-

CBP

)T(

52-C

BP)

T(02-

CBP

)T(

71-C

BP)

T(52-

CBP

)T(

02-C

BP)

T(04

BS)

T(52

BS

025-093816-884

585-324884-853

585-554585-853

884-093355-324

025-093

Hdra

Hslaireta

mde

nedra

hleets

06-45cR

Hg

ninr

utdra

h

elbats

nu

)ht

ped

deirav(

)T(

03-C

BP)F(

52-C

BP)

T(03-

CBP

)F(52-

CBP

)T(

52BS

)F(52

BS

585-554548-585

585-324087-355

585-093585-554

su

ou

nitn

oc)

T(04

BS)

T(04-

CBP

)F(04-

CBP

)T(

04BS

)T(

52BS

)F(04-

CBP

)T(

04BS

)T(

52BS

)T(

52BS

585-324056-884

087-355585-324

585-324087-025

025-093585-093

585-093

ylth

gils+

ylivaeh

detp

urretni

)T(

02-C

BP)

T(04

BS)

T(52-

CBP

)T(

02-C

BP)

T(52

BS)

T(52-

CBP

)T(

02-C

BP)

T(52

BS)

T(52

BS

355-324056-554

056-884884-093

585-554585-093

884-853816-324

025-093

Hdra

Hslaireta

mde

nedra

hleets

56-85cR

Hg

ninr

utdra

h

elbats

nu

)ht

ped

deirav(

)T(

04-C

BP)

T(52-

CBP

)T(

03-C

BP)

T(52-

CBP

)T(

04BS

)T(

52BS

087-025585-554

355-324355-554

025-093025-093

su

ou

nitn

oc)

T(04

BS)

T(04-

CBP

)T(

52-C

BP)

T(04

BS)

T(03-

CBP

)T(

52-C

BP)

T(04

BS)

T(04

BS)

T(52

BS

025-554087-025

585-554585-093

355-093355-554

025-853025-093

025-093

ylth

gils+

ylivaeh

detp

urretni

)T(

02-C

BP)

T(03-

CBP

)T(

52-C

BP)

T(02-

CBP

)T(

03-C

BP)

T(52-

CBP

)T(

02-C

BP)

T(52

BS)

T(52

BS

884-093585-554

056-884884-853

585-554816-884

554-523585-554

585-554

yln

og

ninr

uts

uo

unit

noc

)pra

hS(=F,g

ninr

uts

uo

unit

noc

dna

detp

urretni

rof

)d

naL-T(=T

24

Cutting Data for TurningH: Hard MaterialsTu

rnin

g slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

H-

10

Hn

oitacilp

paf

oe

gna

Rc

V

Hdra

Hslaireta

mtsac

dellih

Cs

nori

tsacdelli

hcsll

orn

oritsac

dellihc

syollan

oridra

H-iN

gni

nruT

51

H-

10

H6

ega

pees

02

H-

50

H6

ega

pees

)C

PH(

04

H-

52

H6

ega

pees

MFS:cV

MFS:cV

MFS:cV

57

9-8

84

05

6-5

23

88

4-3

61

57

9-8

84

05

6-5

23

88

4-3

61

57

9-8

84

05

6-5

23

88

4-3

61

elbats

nu

)ht

ped

deirav(

su

ou

nitn

oc)

T(01

BS)

T(01

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

01BS

)T(

01BS

ylth

gils+

ylivaeh

detp

urretni

)T(

1C

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

01BS

)T(

01BS

Hdra

Hslaireta

mg

nicafdra

hsyolla

elbats

nu

)ht

ped

deirav(

su

ou

nitn

oc

ylth

gils+

ylivaeh

detp

urretni

)T(

1C

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

1C

BS)

T(1

CBS

)T(

01-C

BP)

T(01

BS)

T(01-

CBP

)T(

01BS

)T(

01BS

)T(

01BS

Hdra

Hslaireta

mderet

nisdi

brace

elbats

nu

)ht

ped

deirav(

su

ou

nitn

oc)

T(52

BSS-

CDP

)T(

1C

BS

)T(

1C

BS)

T(1

CBS

ylth

gils+

ylivaeh

detp

urretni

ecio

hC

etanretl

A:2

noitis

oP

|eci

oh

Cyra

mirP:

1n

oitiso

P,sedar

GN

BC

Pyl

no

gni

nrut

su

ou

nitn

oc)

prahS(

=F,gni

nrut

su

ou

nitn

ocd

nadet

purret

nir

of)

dnaL-T(

=T

25

Cutting Data for MillingK: Cast Iron, Grey & Nodular Cast Iron

Hig

h-S

pee

d M

illin

g

slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

K-

10

Kn

oitacilp

paf

oe

gna

Rc

V

Ks

nori

tsaC

tsacyer

g()

nori

01G

G51

GG

02G

G

deeps-

hgi

Hg

nillim

)CS

H(5

1K

-1

0K

6e

gap

ees)

CSH(

52

K-

01

K6

ega

pees

)C

PH

+CS

H(0

4K

-0

2K

6e

gap

ees

MFS:cV

MFS:cV

MFS:cV

52

18-

00

93

52

92-

52

61

52

61-

83

11

52

18-

00

93

52

92-

52

61

52

61-

83

11

52

18-

00

93

52

92-

52

61

52

61-

83

11

elbats

nu

)ht

ped

deirav(

)T(

1C

BS)

T(1

CBS

)T(

1C

BS

su

ou

nitn

oc)

T(01-

CBP

)T(

71-C

BP)

T(52-

CBP

)T(

01-C

BP)

T(71-

CBP

)T(

52-C

BP)

T(1

CBS

)T(

52-C

BP

)T(

51-C

BP)

T(1

CBS

)T(

01-C

BP

ylth

gils+

ylivaeh

detp

urretni

)T(

01-C

BP)

T(71-

CBP

)T(

52-C

BP)

T(1

CBS

)T(

71-C

BP)

T(52-

CBP

)T(

1C

BS)

T(52-

CBP

)T(

51-C

BP)

T(01-

CBP

)T(

01-C

BP

Ks

nori

tsaC

tsacyer

g()

nori

52G

G03

GG

53G

G

elbats

nu

)ht

ped

deirav(

)T(

51-C

BP)

T(51-

CBP

)T(

1C

BS

su

ou

nitn

oc)

T(01-

CBP

)T(

71-C

BP)

T(52-

CBP

)T(

01-C

BP)

T(52-

CBP

)T(

1C

BS)

T(52-

CBP

)T(

51-C

BP)

T(1

CBS

)T(

01-C

BP

ylth

gils+

ylivaeh

detp

urretni

)T(

01-C

BP)

T(71-

CBP

)T(

52-C

BP)

T(1

CBS

)T(

52-C

BP)

T(1

CBS

)T(

52-C

BP

)T(

51-C

BP)

T(01-

CBP

)T(

01-C

BP

Ks

nori

tsaC

tsacral

ud

on(

)n

ori04

GG

G05

GG

G06

GG

G07

GG

G

elbats

nu

)ht

ped

deirav(

su

ou

nitn

oc)

T(71-

CBP

)T(

52-C

BP)

T(1

CBS

)T(

71-C

BP)

T(1

CBS

)T(

71-C

BP

ylth

gils+

ylivaeh

detp

urretni

)T(

71-C

BP)

T(1

CBS

)T(

71-C

BP)

T(1

CBS

)T(

71-C

BP

ecio

hC

etanretl

A:2

noitis

oP

|eci

oh

Cyra

mirP:

1n

oitiso

P,sedar

GN

BC

Pyl

no

noisrev

dnal-T,t

nalo

oct

uo

htiw:

gnilli

M

26

Cutting Data for MillingN: Nonferrous Metals & NonmetallicsH

igh

-Sp

eed

Mill

ing

slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

N-

10

Nn

oitacilp

paf

oe

gna

Rc

V+

tR

Ns

uorref

no

Nslate

mm

uni

mul

At

uo

htiw

syollan

ocilis

deeps-

hgi

Hg

nillim

)CS

H(0

2N

-1

0N

6e

gap

ees)

CSH(

03

N-

02

N6

ega

pees

)C

PH

+CS

H(0

4N

-5

2N

6e

gap

ees

µ)z

R(t

Rµ

)zR(

tR

µ)z

R(t

R

-ni

µ2.3ni

µ001-

niµ001

niµ002

-ni

µ002ni

µ004-

niµ2.3

niµ001

-ni

µ001ni

µ002-

niµ002

niµ004

-ni

µ2.3ni

µ001-

niµ001

niµ002

-ni

µ002ni

µ004

elbats

nu

)ht

ped

deirav(

CD

MS-

CDP

S-C

DPC

DM

S-C

DPS-

CDP

CD

MS-

CDP

S-C

DP

00591-578452641-0062

00031-006205261-5784

00031-00620579-0062

57311-57845218-0062

0056-0062

su

ou

nitn

ocC

DM

S-C

DPS-

CDP

CD

MS-

CDP

S-C

DPC

DM

S-C

DPS-

CDP

00591-578452641-0062

00031-006205261-5784

00031-00620579-0062

57311-57845218-0062

0056-0062

ylth

gils+

ylivaeh

detp

urretni

CD

MS-

CDP

S-C

DPC

DM

S-C

DPS-

CDP

CD

MS-

CDP

S-C

DP

00591-578452641-0062

00031-006205261-5784

00031-00620579-0062

57311-57845218-0062

0056-0062

Ns

uorref

no

Nslate

mm

uni

mul

Ahti

wsyolla

%21na

htssel

nocilis

elbats

nu

)ht

ped

deirav(

S-C

DPS-

CDP

S-C

DPS-

CDP

S-C

DPS-

CDP

00031-006257311-0062

57311-00620579-0062

5778-00620585-0591

su

ou

nitn

ocS-

CDP

S-C

DPS-

CDP

S-C

DPS-

CDP

S-C

DP

00031-006257311-0062

57311-00620579-0062

5778-00620585-0591

ylth

gils+

ylivaeh

detp

urretni

S-C

DPS-

CDP

S-C

DPS-

CDP

S-C

DPS-

CDP

00031-006257311-0062

57311-00620579-0062

5778-00620585-0591

Ns

uorref

no

Nslate

mm

uni

mul

Ahti

wsyolla

naht

ero

mn

ocilis%21

elbats

nu

)ht

ped

deirav(

S-C

DPS-

CDP

S-C

DP

0579-00625218-5722

5784-0591

su

ou

nitn

ocS-

CDP

S-C

DPS-

CDP

0579-00625218-5722

5784-0591

ylth

gils+

ylivaeh

detp

urretni

S-C

DPS-

CDP

S-C

DP

0579-00625218-5722

5784-0591

decu

dersi

taht

yln

oefil

lo

otsi

ti,)slatem(

tnal

ooc

do

olfr

o)scitsal

p(ri

A:tnal

oo

C.

detceffat

on

si,revew

oh,

hsinif

ecafrus

eht,

gnil

ooc

tu

ohti

wg

nittuc

neh

w

27

Cutting Data for MillingN: Nonferrous Metals & Nonmetallics

Hig

h-S

pee

d M

illin

g

slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

N-

10

Nn

oitacilp

paf

oe

gna

Rc

V+

tR

Ns

uorref

no

Nslate

md

nare

pp

oC

syollare

pp

oc,ez

nor

b,ssarb

su

oicerp

slatem

deeps-

hgi

Hg

nillim

)CS

H(0

2N

-1

0N

6e

gap

ees)

CSH(

03

N-

02

N6

ega

pees

)C

PH

+CS

H(0

4N

-5

2N

6e

gap

ees

µ)z

R(t

Rµ

)zR(

tR

µ)z

R(t

R

-ni

µ2.3ni

µ08-

niµ001

niµ002

-ni

µ002ni

µ004-

niµ2.3

niµ08

-ni

µ001ni

µ002-

niµ002

niµ004

-ni

µ2.3ni

µ08-

niµ001

niµ002

-ni

µ002ni

µ004

elbats

nu

)ht

ped

deirav(

CD

MS-

CDP

CD

MS-

CDP

CD

MS-

CDP

05261-57840579-0062

57311-57845218-0062

0579-00930517-5722

su

ou

nitn

ocC

DM

S-C

DPC

DM

S-C

DPC

DM

S-C

DP

05261-57840579-0062

57311-57845218-0062

0579-00930517-5722

ylth

gils+

ylivaeh

detp

urretni

CD

MS-

CDP

CD

MS-

CDP

CD

MS-

CDP

05261-57840579-0062

57311-57845218-0062

0579-00930517-5722

N-

no

Ner

up

scillatem

scitsalp

-ert

uo

htiw

tne

mecrof

ni.e.i(

)ssalgixel

p

elbats

nu

)ht

ped

deirav(

CD

MS-

CDP

CD

MS-

CDP

CD

MS-

CDP

00031-57840579-0062

5218-52920517-0591

0517-57220025-5261

su

ou

nitn

ocC

DM

S-C

DPC

DM

S-C

DPC

DM

S-C

DP

00031-57840579-0062

5218-52920517-0591

0517-57220025-5261

ylth

gils+

ylivaeh

detp

urretni

CD

MS-

CDP

CD

MS-

CDP

CD

MS-

CDP

00031-57840579-0062

5218-52920517-0591

0517-57220025-5261

N-

no

Nscillate

mscitsal

p-er

htiw

tne

mecrof

ni)PR

C,PRG.e.i(

elbats

nu

)ht

ped

deirav(

S-C

DPS-

CDP

S-C

DP

0517-05910025-0591

0093-0031

su

ou

nitn

ocS-

CDP

S-C

DPS-

CDP

0517-05910025-0591

0093-0031

ylth

gils+

ylivaeh

detp

urretni

S-C

DPS-

CDP

S-C

DP

0517-05910025-0591

0093-0031

decu

dersi

taht

yln

oefil

lo

otsi

ti,)slatem(

tnal

ooc

do

olfr

o)scitsal

p(ri

A:tnal

oo

C.

detceffat

on

si,revew

oh,

hsinif

ecafrus

eht,

gnil

ooc

tu

ohti

wg

nittuc

neh

w

28

Cutting Data for MillingH: Hard MaterialsH

igh

-Sp

eed

Mill

ing

slairetaM

fo

sn

oitid

no

Clav

omer

pihc

04

H-

10

Hn

oitacilp

paf

oe

gna

Rc

V+

aR

Hdra

Hslaireta

mde

nedra

hleets

06-45cR

Hg

nillim

drah

deeps-

hgi

Hg

nillim

51

H-

10

H6

ega

pees

02

H-

50

H6

ega

pees

)C

PH(

04

H-

02

H6

ega

pees

niµ

aR

niµ

aR

niµ

aR

23-

83

6-2

35

21-

36

23-

83

6-2

35

21-

36

23-

83

6-2

35

21-

36

elbats

nu

)ht

ped

deirav(

su

ou

nitn

oc)

T(04

BS)

T(71-

CBP

)T(

52-C

BP)

T(04

BS)

T(71-

CBP

)T(

52-C

BP)

T(52

BS)

T(52

BS

5292-52610062-3641

5292-52615292-3641

0062-00315292-3641

0062-83115722-579

ylth

gils+

ylivaeh

detp

urretni

)T(

02-C

BP)

T(03-

CBP

)T(

52-C

BP)

T(02-

CBP

)T(

03-C

BP)

T(52

BS)

T(52

BS)

T(52

BS

5722-00315292-3641

0093-88713112-8311

5292-00315292-3641

0062-00315722-8311

Hdra

Hslaireta

mde

nedra

hleets

56-85cR

Hg

nillim

drah

elbats

nu

)ht

ped

deirav(

su

ou

nitn

oc)

T(04

BS)

T(71-

CBP

)T(

52-C

BP)

T(04

BS)

T(71-

CBP

)T(

52BS

)T(

52BS

)T(

52BS

8803-52615292-5261

5292-05915292-3641

5292-36415292-8871

0062-00315722-8311

ylth

gils+

ylivaeh

detp

urretni

)T(

02-C

BP)

T(03-

CBP

)T(

52-C

BP)

T(02-

CBP

)T(

03-C

BP)

T(52

BS)

T(52

BS)

T(52

BS

0062-36415292-5261

0093-31120062-0031

5292-36415292-5261

0062-36415722-0031

ecio

hC

etanretl

A:2

noitis

oP

|eci

oh

Cyra

mirP:

1n

oitiso

P,sedar

GN

BC

Pyl

no

gni

nrut

su

ou

nitn

oc)

prahS(

=F,gni

nrut

su

ou

nitn

ocd

nadet

purret

nir

of)

dnaL-T(

=T

29

Trouble Shooting forPCD Applications

snoitacilppADCP-gnitoohSelbuorT

melborP esuaC noitcAdetsegguS

ytilauqecafrusrooP

noitarbiV .1 pu-tes&lootfoytidigirkcehC

etardeefhgihooT .2 repiwotegnahcrosuidaresonesaercni,etardeefrewoL

edarggnorW .3 ezisniargrenifesoohC

raewerutamerPdeepsgnorW .1 )selbatatadgnittuckcehC(deepsesaerceD

edarggnorW .2 ezisniargresraocesoohC

gnippihcegdE

noitarbiV .1 pu-tes&lootfoytidigirkcehC

atadgnittucgnorW .2 noitacilppauoyrofatadgnittucnisdeef&sdeepskcehC

edarggnorW .3 ezisniargresraocesoohC

gnigdolsidpiT

gnittucevissecxEerutarepmet

.1 pitottnaloocesaercnI

.2 deepsesaerceD

.3 tucfohtpedecudeR

.4 ezispitesaercnI

:snoitacilppaDCPotylppaselurlareneggniwollofeht,eugolatacsihtnisnoitadnemmocerehtotnoitiddanI

spu-tesdnasenihcamdigiR-sgnahrevolootmuminiM-

elbissopelgnaegdegnittucevitisoptsomesoohC-scilatemroftnaloocesU-scilatem-nonrofriaesU-

30

Trouble Shooting forCBN Applications

snoitacilppANBC-gnitoohSelbuorT

melborP esuaC noitcAdetsegguS

ytilauqecafrusrooP

noitarbiV .1 pu-tes&lootfoytidigirkcehC

deefhgihooT .2 repiwotegnahcrosuidaresonesaercni,etardeefrewoL

tresniprahsooT .3 elgnarefmahcesaercnI

edarggnorW .4 ezisniargrenifesoohC

raewerutamerP

deepsgnorW .1 )selbatatadgnittuckcehC(deepsesaercnI

tresniprahsooT .2 elgnarefmahcesaercnI

edarggnorW .3 ezisniargrenifesoohC

gnippihcegdE

noitarbiV .1 pu-tes&lootfoytidigirkcehC

noitpurretnI .2 enohdnaelgnarefmahcesaercnI

edarggnorW .3 ezisniargresraocesoohC

noitarbiV

pu-tesrooP .1 pu-tes&lootfoytidigirkcehC

deefthgilooT .2 .C.O.Dro/deefesaercnI

erusserphcumooT .3 elgnaegdegnittuc/yrtemoegtresnievitisoperomesoohC

perpegdereporpmI .4 elgnarefmahcecudeR

erusserphcumooT .5 suidaresonecudeR

:snoitacilppaNBCotylppaselurlareneggniwollofeht,eugolatacsihtnisnoitadnemmocerehtotnoitiddanI

spu-tesdnasenihcamdigiR-sgnahrevolootmuminiM-

elbissopelgnaegdegnittuctsegralesoohC-elbissopreverehwstresnievitageN-

MiniCut - Index

BECKER has developed the MiniCut Tool System especially for boring from adiameter of .157” to .984” in PCD, CBN and MDC optimizing the advantages ofeach material type.

All boring bars are designed in solid tungsten carbide with integrated throughcoolant and enable boring depths of up to 7xD. Our MiniCut tools are

used on machining centers and turning machines.Contrary to most conventional tool

systems we use the positive indexableinserts type EPHW and EPHT. Theadvantages of the 75° insert styleenables higher cutting performanceand precision. The tipped boring barshave the identical shape for the fulldiameter range.

The Wiper-Indexable Inserts withneutral or positive rake angle andtipped Wiper- Boring Bars with neutralrake angle are used for high-techmachining with high productivity, alsoincreasing the flexibility of the MiniCut-System considerably.

Tipped Carbide Boring Bars, PCD ........................................... page 33

Tipped Carbide Boring Bars, CBN ................................. page 34 & 35

Adapter Sleeve for Boring Bars ............................................... page 35

Boring Bar, Solid Carbide, C...SWUC, Inch ............................. page 36

Boring Bar, Solid Carbide, E...SEUP, Inch & Metric ............... page 36

EPHT Fullface, fullface wiper edge, PCD .............................. page 37

EPHW Fullface, fullface wiper edge, PCD ............................ page 37

EPHT wiper edge, MDC .............................................................. page 38

EPHW wiper edge, MDC ............................................................ page 38

EPHT, PCD ....................................................................................... page 38

EPHT wiper edge, PCD ............................................................... page 39

EPHW, PCD ..................................................................................... page 39

WCGW Fullface, PCD .................................................................. page 39

EPHT Fullface, fullface wiper edge, CBN .............................. page 40

EPHW Fullface, CBN .................................................................... page 40

EPHW Fullface wiper edge, CBN ............................................ page 41

EPHT EW, EW wiper edge, CBN ................................................ page 41

EPHW EW, EW wiper dge, CBN ............................................... page 42

EPHW EWS wiper edge, CBN ................................................... page 42

WCGW Fullface, CBN .................................................................. page 43

33

Tools - PCD / MDC

PCD Tipped Carbide Boring BarsCylindrical solid carbide boring bar with oneclamping surface, tipped cutting edge andinternal coolant feed

For Adapter Sleeves, see page 35

PCD / MDC Tipped Carbide Boring Bars, wiper edgeCylindrical solid carbide boring bar with oneclamping surface, tipped cutting edge andinternal coolant feed

For Adapter Sleeves, see page 35

EG-X dnahtfelrothgiR nwohsrabdnahthgiR

dnahthgiRnoitangiseD dnahtfeLnoitangiseDsnoisnemiD

nimd l d 7g f l2 r PD MD

10RPUEG-F5.3X 10LPUEG-F5.3X751. 51.3 831. 970. 74.

400. !

20RPUEG-F5.3X 20LPUEG-F5.3X 800. !

10RPUEG-F40X 10LPUEG-F40X

791. 51.3 751. 890. 55.

400. !

20RPUEG-F40X 20LPUEG-F40X 800. !

40RPUEG-F40X 40LPUEG-F40X 610. !

10RPUEG-H50X 10LPUEG-H50X

632. 49.3 791. 811. 17.

400. !

20RPUEG-H50X 20LPUEG-H50X 800. !

40RPUEG-H50X 40LPUEG-H50X 610. !

10RPUEG-H60X 10LPUEG-H60X

572. 49.3 632. 831. 97.

400. !

20RPUEG-H60X 20LPUEG-H60X 800. !

40RPUEG-H60X 40LPUEG-H60X 610. !

EG-X egderepiwdnahtfelrothgiR nwohsrabdnahthgiR

dnahthgiRnoitangiseD dnahtfeLnoitangiseDsnoisnemiD

nimd l d 7g f l2 r PD MD

10WRPUEG-F5.3X 10WLPUEG-F5.3X751. 51.3 831. 970. 74.

400. ! !

20WRPUEG-F5.3X 20WLPUEG-F5.3X 800. ! !

10WRPUEG-F40X 10WLPUEG-F40X

791. 51.3 751. 890. 55.

400. ! !

20WRPUEG-F40X 20WLPUEG-F40X 800. ! !

40WRPUEG-F40X 40WLPUEG-F40X 610. ! !

10WRPUEG-H50X 10WLPUEG-H50X

632. 49.3 791. 811. 17.

400. ! !

20WRPUEG-H50X 20WLPUEG-H50X 800. ! !

40WRPUEG-H50X 40WLPUEG-H50X 610. ! !

10WRPUEG-H60X 10WLPUEG-H60X

572. 49.3 632. 831. 97.

400. ! !

20WRPUEG-H60X 20WLPUEG-H60X 800. ! !

40WRPUEG-H60X 40WLPUEG-H60X 610. ! !

PDC

-S

PDC

MD

C

PDC

-L

PDC

-S

PDC

MD

C

PDC

-L

34

Tools - CBN

CBN Tipped Carbide Boring Bars

Cylindrical solid carbide boring bar with oneclamping surface, tipped cutting edge andinternal coolant feed.

For Adapter Sleeves, see page 35

Note: X3.5T-GEUPLT01: F= sharp cutting edge, T= T-Land

EG-X dnahtfelrothgiR nwohsrabdnahthgiR

dnahthgiRnoitangiseD dnahtfeLnoitangiseDsnoisnemiD

nimd l d 7g f l2 r HB LB

10TRPUEG-F5.3X 10TLPUEG-F5.3X

751. 51.3 831. 970. 74.

400. ! ! ! !

20FRPUEG-F5.3X 20FLPUEG-F5.3X 800. ! ! !

20TRPUEG-F5.3X 20TLPUEG-F5.3X 800. ! ! ! !

10TRPUEG-F40X 10TLPUEG-F40X

791. 51.3 751. 890. 55.

400. ! ! ! !

20FRPUEG-F40X 20FLPUEG-F40X 800. ! ! !

20TRPUEG-F40X 20TLPUEG-F40X 800. ! ! ! !

40FRPUEG-F40X 40FLPUEG-F40X 610. ! ! !

40TRPUEG-F40X 40TLPUEG-F40X 610. ! ! ! !

10TRPUEG-H50X 10TLPUEG-H50X

632. 49.3 791. 811. 17.

400. ! ! !

20FRPUEG-H50X 20FLPUEG-H50X 800. ! ! !

20TRPUEG-H50X 20TLPUEG-H50X 800. ! ! ! !

40FRPUEG-H50X 40FLPUEG-H50X 610. ! ! !

40TRPUEG-H50X 40TLPUEG-H50X 610. ! ! ! !

10TRPUEG-H60X 10TLPUEG-H60X

572. 49.3 632. 831. 97.

400. ! ! !

20FRPUEG-H60X 20FLPUEG-H60X 800. ! ! !

20TRPUEG-H60X 20TLPUEG-H60X 800. ! ! ! !

40FRPUEG-H60X 40FLPUEG-H60X 610. ! ! !

40TRPUEG-H60X 40TLPUEG-H60X 610. ! ! ! !

SB10

SB25

SB40

SBC

1

35

Tools - CBN

CBN Tipped Carbide Boring Bars, wiper edgeCylindrical solid carbide boring bar with oneclamping surface, tipped cutting edge andinternal coolant feed.

For Adapter Sleeves, see below

Note: X3.5T-GEUPLT01: F= sharp cutting edge, T= T-Land

Adapter Sleeve for Boring Bars form X...GEUPAdapter Sleeves enable versatile use of the boring bars in all areas

Coolant feed is provided through the adapter.Only for BECKER - Form X...GE

EG-X egderepiwdnahtfelrothgiR nwohsrabdnahthgiR

dnahthgiRnoitangiseD dnahtfeLnoitangiseDsnoisnemiD

nimd l1 d 7g f l2 r HB LB

10WTRPUEG-F5.3X 10WTLPUEG-F5.3X

751. 51.3 831. 970. 74.

400. ! ! ! !

20WFRPUEG-F5.3X 20WFLPUEG-F5.3X 800. ! ! !

20WTRPUEG-F5.3X 20WTLPUEG-F5.3X 800. ! ! ! !

20WFRPUEG-F40X 20WFLPUEG-F40X

791. 51.3 751. 890. 55.

800. ! ! !

20WTRPUEG-F40X 20WTLPUEG-F40X 800. ! ! ! !

30WTRPUEG-F40X 30WTLPUEG-F40X 210. ! ! !

20WFRPUEG-H50X 20WFLPUEG-H50X

632. 49.3 791. 811. 17.

800. ! ! !

20WTRPUEG-H50X 20WTLPUEG-H50X 800. ! ! ! !

40WTRPUEG-H50X 40WTLPUEG-H50X 610. ! ! !

20WFRPUEG-H60X 20WFLPUEG-H60X

572. 49.3 632. 831. 97.

800. ! ! !

20WTRPUEG-H60X 20WTLPUEG-H60X 800. ! ! ! !

40WFRPUEG-H60X 40WFLPUEG-H60X 610. ! ! !

40WTRPUEG-H60X 40WTLPUEG-H60X 610. ! ! !

hcnInoitangiseD D d d 7H d 7H mm H l raBgniroB

53-526.0-PADA 526. 751. 831. 5.3 155. 49.3 L/RPUEG-F5.3X

04-526.0-PADA 526. 791. 751. 4 155. 49.3 L/RPUEG-F40X

05-526.0-PADA 526. 632. 791. 5 155. 49.3 L/RPUEG-H50X

06-526.0-PADA 526. 513. 632. 6 155. 49.3 L/RPUEG-H60X

cirteMnoitangiseD D d d 7H H l raBgniroB

5361-PADA 61 4 5.3 41 001 L/RPUEG-F5.3X

0461-PADA 61 5 4 41 001 L/RPUEG-F40X

0561-PADA 61 6 5 41 001 L/RPUEG-H50X

0661-PADA 61 6 6 41 001 L/RPUEG-H60X

SB10

SB25

SB40

SBC

1

36

Tools for PCD / CBN