Woodsmith - 021

Transcript of Woodsmith - 021

-

7/24/2019 Woodsmith - 021

1/24

N O TE S FR O M TH E SH O P

2 50

O 2

-

7/24/2019 Woodsmith - 021

2/24

W OO'D SM lTI:

'WOODSMfTH (ISSN 0164-4114) ts published

bimonthly (January, March. May,

J~IY,

Sep

te m b e r, Novemberl b y W O O d s m U Il P u b lis h lJ1 g

Co.,

2200 Gfllnd Ave.,DesMoil)8s, lowa 50 312.

WOODSMrTH

Is

a reglslered

r od .m arl( o f

the

WoodsmilhPubllshlfl9

Co,

'Copyrlght 1982 byWoodsmllh Publishing Co,

A l l Rlghls Ras rVe~.

Subscriptions: One year (6 lssues) S10, lIvo

years (12 issuas) S18, Single copy price, 2.50

(Canada

and

Forelg~:addS2per yea,-)

Change O f

Address:

Please

be

sur.

to

Inc hide

00 111 our o ld

and

ne w address and a mailing

label from a recent issue

Pos tmas te r : S end change o f address nO lic

F o rm 3 5 7 9 , 1 0 W O O d s m ilh p u b nshi l lQ

Co ..

2 2 0 0

GrandAve.. DesM oine s ,

Iowa

50 312.

And the best hel p

know of

is

a ro ute

ta bl e. Ever since w e bllilf

the

ro uter ta bl

(shown in

\VoooSI lti ll 1N o ,

20),

m y ro ute

h as s pent a lo t

m o re tim e making dust . ,

ins tead o f

collecbing

it,

O kay, D on, why the big sales pitch o

th e r ou ter table?

As

mentioned above,

ave thi s thi n

about using too ls tha~ our reader. ar

likely

to hav e, A ltho ugh several br an d s

router ta bles are

on

~he m arket, I 'ea

prefer O\U' home-m ade version ,

I guess w hat I 'm getting at is this : L li

this router

table, 0

I used

it to bu ild

th

projects

in thi s issue .

UL

that

~rb

of

lm

p lie s th at y ou

have 10 bui ld . the rout er

tab

befo re

YOU

c an b uild an y

of

these

p. 'oje,c,

\V bic h is sort or true. So , 1 feel a litt

guiJt), b ec au se y ou m ay no t w ant to bui

it,

But

h in k it's .

pretty

good

tool,

S o

tend to

encourage

bu ild in g it.

Ana [ driv

myself

crazy

in th e p ro ce ss.

J.A'I 'H fJ 1'RO.nlCT ; ,

Tntllingf o a new su

ject, we 've received a lo t o f requests f

lathe pro jeets, A nd that presents a prob

lem , I don't have

much ex perience

wi

la th e w o rk , and to be honest ,

don' t g

that exc ite d abo ut it,

However,

S tev~ (our nellA ss is ta nt Ed

to r) is pret ty good on

a

lathe,

so

he 's th

one that go t us go ing o n th~ T urned l'Jo

Bowl in l hi s i ss ue , fae~,he ' s no w wor

in g

on

a series o f

articles

on tur ning ,

Why did

w e cho ose a bow l (facep lat

turning) to s tart this series ?

W ell, w e d id n't know w here to s tart,

w e sat d ow n and

talked

a bo ut.l t. S te ve s a

that

alm ost every bo ok

he's s e e n on C U

ingsuggests tl) at yo u

s h o u ld

s tart

OUt

wi

sp ind le turn ing '

(b etween

center$) to

lear

th e

basics,

1 said, Yeah, but

spindle

turning

us ually m eans tu rning legs , an d then

have to build

a

ta ble

to

go

with th e

legs

Steve

re sp on de d, W e ll, we could tum -

ample bowl,

but it

takes a

li tt le

mo

patience

to

learn

the

teehniqne s.

M y eyes

lit

up , 'Patience, th ere's m

favorite

word , L et's d o

it,

Th

next day,

Steve

em erged fro m th

s ho p w ith a p ro to ty pe o f the bow l he ha d

m ind , and handed it

to

m e, N ow , usuall

when

I see a w oo dw orking project , 1 stan

back,

CrOSSmy arms ,

and stroke

my

chi

w ith

serious look on m y face .

This tim e things were different.

As

held the bo wl, I could see the wood , but

cou ld al so feel it.

And

I co uld feel th

textu re and the

sh ape

of it,

That S

all it lo ok, N ow I'm excite d abou

bo wl tur ning, and I th in k w e'll be

doing

lo t m ore o f it ,

NEXT )LULING, July, 198 2

Ed itor

Donald B, Peschke

Des Ig n @ I ro clor

Ted Kralicek

A rt D ire ctor

Jon Snyd~r

Assistant Edito r

S te ve K ro hm er

Graphic D eslgner

Mo re fa S imm o n s

Sub scriptionManager

Sandy

J,

Baum

SubscHptfonAsslslanls

Chrlslel Bork

onna rins

Adm in is tra tiv e Ass ist an t

eheryl Scott

CC)fllrlbu tfn gEd iio r

AdolphE, Pescjike

.1 11 01;1'

1'1f I$

ISSU E.

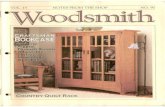

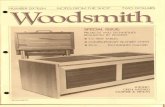

As soon as

w e

fi ni shed

the S cho olh ouse C lock fo r this issue, we

decided to hang it on the wall in OUI recep

tion

area.

Since

we

rent spac e in a large

bu ild ing, w e o ften get vis ito l' siookingill

to

see what the la te st pro ject is , The day we

put the

Schoo lhouse C lo ck on

th e w all,

we

ha d tw o requests

to buy

it on the spo t, , '

fo r $350,

N ow 1

w a s

faced w ith a to ugh decisioh.

Sho ul d

I

spend the weekend

building

arrother clock an d pick up an easy

~O?

0.,

should

r

do what I rea ll y want to

< 1 :

m ow

the-law n and

pull

w eed s in fhe garden?

'T OOLS.A

com m ent

1 heal ' fro m a

lo t o f

guys jus t stal'ting out in woodwonking

g oes s ome th in g lik e th is : I 'd lik e -to build a

pr oje ct like nha nS choo lh ous e C l o ck , , , i I

only had the to ols ,

\ e ll, we

built the clock, ~he

Curio

C ab in et, the

Lw-y

S us an a nd th e'l 1ive t (al l

show n in th is i$$ ue) w ith o nly

tWQ

mllio r

tools :

a

table saw

and a

router.

That s

ce rtainly no t m uch in the w ay o f to o ls .

Actually, I 'll have to

adrnit,

th at you do

lI eed one m ore too l. Pat ien ce, A ll o f these

pl,.jject~

involve mitered

joints,

Althoug h

o ne illite I' is no t

~ hat

d ifficult ~ cut,

whe n

} OU

hav e

to

cui-several m itersffor

an

octagona l

Irarne,

fo r insta,lI ce) , they all

have to mate per fectly . ~ 'h a t t end s t o take

a l it tl e t ime , A n d m ay be f ew t ri al cut s -o n

so m e

SCI aP

wood , (0m ' sho p is litered

with

SCIOPS

like

this.)

Question:

011

sai d yo u

used

router

fOl

all o f th ese pl'O jects , W hat kind o f

router

d id yo u us e?

W e h av e fOUlIouters in the sho p S e ars ,

R o c~ w e l l , S l.cInle y an d M a kit o .) . [tt.~not,

that we needed al l

of

th em .

It s ju st

that

we re

in the pro ce ss o f try ing them out,

B ut to answer the que stion we used a

lie ,

Sea TS O af tsmall J h p .

router fo r m ost

o f the work, Surprised ' w anted to use

th is router 1'01'

two

reasons , 'F if '.t, Llik e. to

us e

the

k in d o f equ ipment

that

mo s t o f.o \u '

readers are like y to

OWIl.

A nd s ec on d, I

w anted to use the new Seal's edge guide

an d

trammel-point.atjaehment

N o ,

251 19,

S15) , It's a pretty

nice liltle

gizmo.

N ow that we' re

Oll

the s ubject

of

routers, have a few other co m m e nts I 'd

lik e to make, I have the feeling th at,

toute rs are kind o f d re am ma c hin es f or

.woo dw orkers, W ith

all

L ho se bits and at

tachm ents , you ought to be able to cia

alm ost

811ything w ith

them ,

But the

process

of tu rn ing drea m s int o a

finished pro ject is no t always an easy one.

Consequently,

routers

sp end m o st o f their

tim e c o ll ectin g d us t,

ln fact, I 've com e to think of a router as

just a C ane y

motor

that needs som e he lp,

wdust

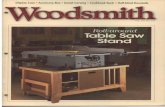

May, 1982

umber 21

Wcodsmith

-

7/24/2019 Woodsmith - 021

3/24

3

@ ODSMI'{ 'H

We In vlle y ou to s ha re y our woodworl

-

7/24/2019 Woodsmith - 021

4/24

I

c

II,. 3 ~~. 72

IUlllSj A

CUnlNG D'AGRAM

WOODSMIT

o /i .:t 31 x 21Jf. (23)

'I. )( 3Y 4 x 30/

(4V,)

1 : 1 / , . :t

30/. 8 h (9)

x 1 /... S ( 0)

I.

t

1/ , .. 3V,. (5)

2_8 ,0)

I~l 3..6~17..,,)

I~

x )/. .

cut to

6t

/1 x

7; .. 6

8

h

111 x I .. 17/,. (8h)

If . x It .. 21 ;

312 )

A C aa Si d

a C o .. . B ot to m s

C Cas. Top

o

Fromo Sid,.

E

Ffom.

8ottoms

F From o Top

G Dial frame

H Molding Stript

I

Doot To p

J

Door

Sid

K Doo, Bottoms

4

kindofexpense, you can also use a battery

operated quartz movement. The move

ment that

we

know

will

fit this clock istrom

the K l l X k il Company (Catalog: free). P.O.

Box

6: . 9,

Lake Geneva, \\1 5:H~7. The

quartz movement is Cat.

:\0.

12005.

$25.95.

This movement ha 't provisions f or b ou r

and minute hands (but not a calendar

hand), Bim-Bam chime. (that sound some

lhing like n electric door bell), an in-

MA T ER IA L S L IS T

Thi. Schoolhouse Clock is buill from just

tw o

oak

bo -d s

6-feetlong. That'S not what

I would

call

lot of lumber,

However ,

th ese boards mU8t be cut up in to

82

small

pieces (jUSllhc l'ight size and shape), and

c(u'el't.llyjoined togclhel:

I

hink that's the mos], intriguing thing

about clock-building, [t doesn't require

IOlof wood, , . but it does r eq uire lot or

woodwo rk in g s ki ll .

JOIN~RI: Joine.y is I>robably the most

important aspect or this clock. Almost

every joint is on di ipla)~ so it must be cut

aeeuratelj; However; that s not easy

be

cau se th e

pleees

are

s om ew h at s ma ll,

and

most of them are mitered at 22;< .

This miter angle is the result of the

ocw~'Onal(eight-sidcd) design theme. The

fram~ surrounding' the dial, the part ofth ...

ease extending below this frame. and the

n a m e for the Ria door all require miters

cu t at 22Yt .

Since each ofthese miters is joined wi.

the aid of n spllne. grooves mnsl be cut hi

all mitered pieces. Although thi$ can be

done 0.1II table Orradial-arm S i Iound

it,

was n whole lot easier on a router table. I

gut what I'm geltillJ: at here is that you

might want to build the router table

(shown in lVood.mith No. 20) before

launching into this Schoolhouse Clock.

Then:ne other consideration. The

woodworking

part

of [his project is both

fun and challenging. However. the result

is

lIot

8 clock. Rather. it's JUSt the casse for

the real tilL' of the clock: the works,

TH E C LO CK M OVE MEN T

\Vc dcsigned this schoolhouse dock to

accept two kinds of works: either the

traduional gear and 8111'ing movement,

or the modern replacement: a battery

operated lUU .tz movement,

1 01'he c1'Bull Hinge., ro , two pair . (D301

$.65 per pair)

Brass

1)001

Knob.

(0303l>.

$.55 each)

Bullet Catch. ',. diameter.

:Y.'

long

e I : ~ x l l . s s . r o

I

1 0

'Iurn-Button Latch. (1) 057, $.9[>per 10

Bm.ss Hanger. (l);lOO l, $1,5[>per 10)

4) Glass

(QI

Pendulum 0001:

W e

use

singlc~i.'(>ngthwindow gl'l-' for the pen

dulum door, and cut it to fit the door fram

oursclve. Jon (our Art Director) adde

the black lind (olclpainted borders .,-oun

lhe ~lIge of the g18$8,This is a nice Iiltl

touch, but not altogether: necessary -

requu-cs a llttte more artistic talent tha

I have.

OnCCihe harcJwllI-eand clock works ar

ordered (anll hopefully in hand), the woo

working can begin. l.tal1ed \\;th the case

TH E C ASE

The CMC (showl in Fig. 1) has six sides

\\;th the botLOmthree pieces forming

partial0

-

7/24/2019 Woodsmith - 021

5/24

o

,

,

I

,

. ,

~21 MltEI

l

.~. ~,...IAtan

ONflONt eec e

A

5

.S M'llJt

r

r

I

S I E V I EW

Dfl GIOOV(

AGUlll

rough length u:\ing il\ the sequence shown

in the CUlling Oingram to maintain

a

CO'l

tinous grain pattern. Next, both ends of

each piece a r e m it er ed ,

I started with the center beuom piece

(E ), miWrin~ both

end, at

22 -1 ,0 . Then I

glued it in Illace, Next, I cut the two other

bottom pieces lind glUl~1 th em in place.

Fig, ,I. Getting these pieces to fit tal, es a

little pillying around, Although they

should be mitered al cx~clly 2214 , in

reality they're cut to lit .0 the joint lines

to - e tight and match III) with the jOint lines

on the case,

FUI' the side picees (01 one end is mi

tered (at about 22 ) to mate with the

bottom

pieces. But

the other end (the top

end) is mitered at '15'. The final length of

both side piece. should be

8 1 ,

from long

point to long point.

Before gluing the side piece.

in

place, I

cut two notches in o ne piece for the do or

hinge, These notehe~are ~ . ide (or the

width of the hinj\'('s)and o/j. deep, On the

o ther .ide )Ji~ce

8

r , hole is drilled for a

bullet catch.

fimdly, the 2 wicl~frame top (F) is cut

to fit between the rabbets in the case, and

mitered Ill 4u ) to mate with the side

pieces, Fig, 5,

t . - OltOO V I

, 0[1 l

v. U NE

,. WIO(

~- ~ ~ - ~M~ ~. - -

\

/4-.~1.I.a

ON IAC~rOGf

G

GIIAlN

' 1 t C n O H

I

01

IA II

ON CI tOG

~..

JlGutl: ,

- . 1 , - 1 , . . . _ . ...j.:

. .

l .-

-~

~-

. . . . _ _

-

flouRI: I

WOODSMIr H

3~' final width,

Cl TTOI.E~ ;TlI,Five ohhese pieces the

two .ide. and three bottom pieces) can be

cut to final length now, (The top is cut

later), I .tarwd with the two side pieces

A , culting the tOP end square, The bot

tom end is cut at a 2 21 ,miter 50 the final

length (from the square end to the long

point of the mitered end) is 21. .

Next, the three bottom

pieces

(B) are

cut. I lteRc piece s arc mitered at 22~9on

both end.

so

the

finnl

length (from long

po in t, to 101l1( po int) j s 80/,.,

CltOQ\'(': I()lt ~1Il~~~

ow the gro ov es

for the sp line. eun be cut, As shown ill the

detail in ~'ig, :l, the gI'OOveIs positioned

Y,, 1 1 001

the long point of the miter to

allow room for the rabbets. Once the

grOO\'CS are Ctll. the splines are cut to fit.

ITh;

technique is

discussed

in

more

detail

on pug

8,)

R\Hllt:n;, Finally, rabbets must be rut

on both the fr'Ont( - < l i t ' and back edge of the

two .ide (AI and the three bottom pieces

(Bl- the top i. not rabbeted, The

o

x

V[

rabbet

on the front edge is for the door

frame, and the

1

x

1 1 ,

rabbet on the back

edge i orthe plywood back, Pig,

a .

Also,

y...

dcCI) rabbet on the top ends of the

two side picce (A) should be cut 1 , w ide

(to match the thickness of the lop piece).

se e

Fig,

2 ,

II~TO~m{.:,

Dry -assembfe

these five

pieces (llIinu~the lOp) to make

sure

every

thing fit. properly, Now final

measure-

ments 1 '0 1 ' the top C) ran be taken.

The top piece iNjoined to the two sides

with n rabbet and dado joint. see fig, 2,

Cut a I .dol'p dado tight along the

shoulder of the rabbet, Then CUta 1-abbet

on both .nd, of the tOPpiece

C).

lea\iIlg a

Wngue to fit in the gl'O()\'e,The key thing

here is that when the top is installed. the

two sides A) must be parallel. If this

forces the mitered joims on the three bo t

tom piece. slightl)' out o f alignment, it s

not too much of a problem because they'll

be covered with

a

moldillg

strip

later,

A> s~Mllt,.

AU

six pieces fo,' the case ca n

now be ghl('(1to(cthe,', I started with the

bottom pieces and worked my way around

to

the

tOI), I used tw o

band

(strap) clamps

around the perim et er o f the case to hold it

togethel' while the glue was drying,

THE DOOR FRAME

As the glue was drying on the case. ]

started work on the door frame - the six

pieces between the ease and the glass door,

Since oneorlhc~~~ixpieees is

2

wide. first

I ripped

a

:? widestrip. ~ ong,

Before cuttin~ the six pieces

LO

rough

length, Iesawl'(l (lipped on edge) this

strip to

a

Vi

thickness.

Then

r

cut off

a ]0

length for lhe to piece (Fl. and ripped the

remainder lV wide fOl'the two sides (D)

and thre e bottom p ieces (E ),

Now, each of

ih es e fiv e piece s

is cut to

-

7/24/2019 Woodsmith - 021

6/24

t

OtA l FRA ME

W00DSM1T

eWl

THE OCTAGONAL FRAME

A with all the other p ie ce s so fa r, th e

c cta go na l f rame ( su rr ou nd ing tbe dial) 1

cut from one

ship

of w ood

to get a eon

rinuous gt-ain

patrern.

Rip-a p ie ce o f stock 3 wide by

6 0

lo n

(seeCuttingDiag ,.am ) fo r the fra me p iece

(G). Then cut each piece to rough length

(7~ ),

Both

ends-ofeach

piece a re

mitere

at

22y

so th . fina l length is

6V..

from

long point

to

l ong po in t.

'rhis is not easy, In fact, the bes

approach is to make trial cuts OIl som

sc rap w oo d, T hen

fit

th e ( lig ht trial piece

together, If there'. more than an II gap

total)

on thi

s

assembly,

reset

the m ite

gauge

and

tr y a ga in, The p ie ce s

don't

hav

to

fit

p.,fectly (some corr ection

can

b

mad e d urin g assem bly ), bu t th ey sh ould

be c 1 0 8 ( l .

GROO~'E FORSPLINES, Now the grooves

ror the sp line s can be cu t. T hese g roo ves

m u st b e s te p pe d 51 > t hey don't sho w 01 1 th e

pe'~m0te

of th e

fram e, (This where the

router

table wonks like

ch arm . see

pag

8 fOl' details on L bis cut.) T hese sp line

g roove s s hould b e c ut clo se to th e WIck sid

of each p iec e to a llo w room for th e rabbet

on the fon t edge, see Fig. 6,

A fter (he spline grooves are cut.

l 1 .

deep by Vi wide rabbet is cu t O il th e froll

~face)side of e ach p ie ce , (Aga il t hi j; wa

do ne o n th e router

table.I

ASSE~18LY, Gluing'up this frame is do n

in f ~ First, I glue d pairs together t

f orm f o\u' sections. Then lued lwe se c

t ion s t ogether to I()I'm we h alv es , rr th

splines fit tightly in the grooves thi

gluing

can be

clone

without

clamps,

Jus

apply som e glue to th e m iters and the

s pl in es , a nd, push them together ,

To complete the fram e, I cleaned

IIp

th

m atjng ed ges o fth. tw o halv es w ith th e ji

show n on page 17, and glued them to

gether, Finally, [rounded over the ou ts ide

edge s with a V corner-round bit.

PJ.l'IVOOD INSERT, T he c lo ck movemen

is ;).ctu ally m ou nted to a p lyw Ood inser

that's cut to fit i ns id e t he octagonal fr ame

y o u r e u s in g -t h e

3341X

move men t from

JI11l.1l0)) SUllivan yo u

must -al so

cu t

4 Y -

-diameter hole

,in th e p lywood in se rt,

M OU NT ru e t'RAM E, Now the o cta go na

frame ca n be mounted to the case w ith I

fl at -head screws, l1 0 g ev a g oo d fitove r th

do or f rame, t also

screw ed

the o cta go na

Ir ame

to

th e d oo r fram e (goin) ' in fr om th

back), see Fig, 7,

MOLDING

STIlO 'S ,

O nce t~e

frame

is

i

p la ce . mo lding

st rips (H~ arc added to th

bottom hal f of the case, To make thes e

half-round st rips, l rounded both edges o

a piece of waste w ith a 0 / , , comer-ro un d

bit. Then 1

tipped

off 1t ' 'i -thick $ta ip t

get the.bali -ro und molding.

MOUNTINGTIJE OII.-'ND

IJEzeL.1 'hc~-e

a little han d-work involved in moun tin

l

C O R ,N E

lt0UN.o ON--

eO TH lOG ES

- ~ /. Pll 'WOOO

6

c u r H A U .tOUND

MOtb)N G

to

,m

A FT Y M OU NTING

O c r A j l < . . A M .

SCIIEW TO f \

FROM 8A CK

IO

,,

SE

ftGU RE

6' ,.-

ND VtEW

G

-

7/24/2019 Woodsmith - 021

7/24

their

ownmounting bracke t

that:sscI'e.wed

to

the

to p

of the case.

FINISHlN{:. I used

Wac JD anisll O il

to

fi n is h t his c lo ck c as e. The n ic e th in g 8bou~

this oil is thatit can

be

used to J j J I a l l Y gaps

between all of

those mi l;er~d

joints. Apply

a

liberal

amount of oil and sand with

220 -gJ'it

silicon carbide 1\.P~l'.This creates

a gO OI) that iU s t i legaps (and the po res ill

the oak W hen the gaps are filled, Wipeoff

the excess goop, let i t dry (2 4 ho ursk.end

add another coat oil.

7

1 2 _ . \ . ;

F IG UR E

Mllfl OUTSIDEEOGE-

STaA1GHr 81 l

MT~R

ENOS

R Sa

ROUND

O v E R

fOOE

'1GUlf

DET4I\ A

1

\ ,VQODSMITH

the bezel: LWOm ortis es m us t b e c ut.

O n e m ortise is t he siz e a nd d epth o f the

h ingeon lhe bra ss

frame

of the b ez el.

The

second mort ise- for

the

catch -

must

go

all the way ehrough the frame.

S'ee,Fig.

S. I

centered the bezel on th e Irame an d

marked the position of these mortises.

T hen I cut them out w ith

8

chisel.

T he last step is t o m ake a

little

wooden

latch t o ho ld t he beze l ca tch. F ig. 9 . This is

just

cu t

fr om

a piece

of scrap

and

m oun ted

with a

0 / 0

flat-head

screw .

TH PN ULUM OOR

The glass door

that

fits over the pendulum

is

probably

th e

mOSLdifficult

part of

this

PI Ojecl. The p ieces are smal l La begin \\~th

but

th en

tbere'sa

r ab be t c ut o n

eaeh.skleto

make them even smaller.

To

m ake

this door, l rippedseveral

small

strips V o x

10/,.',

see Detail ). in

Fig . 10.

One

e dg e of

each strip is rounded over.

and

then a

v

x W ' deep rabbet is cue below the

rounded-ever edge. (This rabbet will be

tbe

Inside

edge

o f lh e

door.)

Noll'

yo u

have to

CUl

pieces n'om these

s tr ip s to

fit. th e

d oo r tr ame . This

takes a

little

measu ri ng , and a

lot

o f lu ck. Here's

ho w

I went about it.

I knew

r

wanted tlie doorto over-lap the

f l . - a m e by V . . (The rabbet o n th e outside of

the

d 1

is v

wide, bu t

the overlap is

on ly

v. . because 1 w a nte d to le av e v ., / fo r clear.

ance.)

Goinl5

back 10 the

case,

l marked a

line

y . from the

inside

edge

of

the

door

frame,

Wherever

the marked

line crossed

a joint line. that was the length of each

piece

fo r the

door,

Once th e

pieces

have b ee n

cut to

le ngth,

grooves

~

outed fo r

the

splines ,

and

splines

are cui to fiL

the grooves, 1 01 '

assembly, t j~door is small enougb to

allow hand-pressure gluing at all joint

-

7/24/2019 Woodsmith - 021

8/24

WOODSMITH

SPLINE GROOVE. CONSIDERATIONS

Now that the miters are cut a ~'Oove

must be cut for the splines that join the

pieces together, These grooves can be cu

on either a table saw 01' radial arm saw

However, it's (iifficult to

CUL

a stopped

gr60ve- e$peci'ally in narrow pieces,

There is another way. Evel' since we

buill the renter table (shown in IVoPdsmilh

No,

20) ,

I've come to rely 011 it as all easy

,(1 accurate way to cut spline groove.~-

especially if the groove must be stopped.

After experimenting with thi .. cype o

operatic a lit~tc, I found three helpfu

additions to the router table,

SF-C ONDAIIYTO ',

The outer table's top

is designed wivh a lY,-diametel' opening

for the router bit, Lmade a secondary top

by dl.llillg a \4 hole in a piece of SCI'lI

J1 1so11 i e

This p is temporarily clamped

to the old top to provide a smooth surface

on all sides of the bit (which is neces

sal )t when working' with very small

workpieces).

eRRID

BITS, Since we usually work

with hardwoods, l dug deep in

Illy

pocke

and nought a l4 , carbide-tipped straight

router bit. Although this bit is expensive.

it's excellent for cutting spline grooves.

UXUAAlIY FENCE, Wilen cutting

spline groove in a cross miter, it's very

helpful to clamp a highel' fence to the ad

justable fence on the router table, I just

use a 4 stl'il) of;y, plywood, see ~'ig, 2,

1'101'n end miter, you'll need a fence

that's beveled at the same angle as the

miter, Here Lsimply bevel-rip the edge o

a 2x< ,see ~'ig, 4,

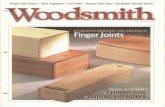

We used miter and spline pieces have been cut to rough

JOInery on every project in this length, Then the first cut fo

issue, That alone should indi - the miter is made. This

CU

cate it 's (Il lite ,I,,'ersatile joint, clears away most of the waste

Miters can solve a lot of prob- on only one end of each piece, I

lam s - especially on any type use the stop to make this cut so

of frame that requires special all pieces are cut to the same

cuts along the edge, length,

POI instance, you can make - 'Phe second cut is a tr imming

molding cuts or rabbets - operatlon. 1 move the stop

either on the inside 0 outside abont, 1 1 closer to the blade

edge - b o ro the pieces are - _ and trim off the very end o

mitered, This eliminates many ... each piece, Since only one side

of the headaches associated of

th e

blade is in contact with

with other Irame joil1t..~ (like

a

the wood, it has less tendency

mortise and tenon), to pull

0)'

push, an d the cut i

However, m iters do have ----------- --- ---------- clealler an d m o re

accurate

their bad side,

In

fact,

C I'OSS

miters (CUt the cut is being made,

01 '

push il awy, 'rhls Next,

r

mark the final length on the

across the face of a board) and end miters Cj'eelling ~hrows the cut out or line, To oll1el' end of each piece, and repeat lhe

(a bevel cut at the end of a board) are gel aroun8 this problem, use the follow-

tWO-ClIt

procedure This time, both cuts

probably the two worst joints in wood- it)g procedure.

t

be lined up by using the kerf in the

working, Pirst, J cut all the workpieces to rough fence as a guide,

The problem witb both of these joints is length - about l longer than needed fo)'

thaI ~'ou'l'ejoinillg end-grain to end-grain, the Iinal length. Then r set the miter g-auge

And no $:lue (no matter ho w strong it is) to the proper angle,

will hold this kind of joinL together FE:o ICEAND STep, When working Ob a

(for long), table saw, I attach. a plywood fence to th e

However, there is a simple solution: a miter gauge, 'rhe,fenceslIpports the work

spline, If a groove is cut in both mitered piece all the way to the blade, and also

pieces, a spline can be inserted to pushes the wasteout of the way,

strengthen the joint consideyably , The

spline not only adds mechanical strength,

but it also provides a good glue surface

liong grain to longgrain) between the sides

of the I\','ooe and the spline,

Yet, this solution creates another prob

lem: How do you cut the grooves fo,' the

splines , , ' accurately? In fact, howdo you

cui the mile, .. accurately?

SmlNG THE ANGLE

'l'he first step for euuing a miter is to set

the angle of the cut, The accuracy of yow'

setting, however, is limited

b y

the ac

curacy of the markings on your saw, Most

miter gauges and radial-arm saws leave

much to be desired.

To geL an accurate setting Luse an ad

ju:;table protraetor, ,(See Talking Shop in

W ood /md t1 1 No,

20,)

Tllis type of pro

tractor can easily be adjusted to Iracrions

ofa degree. and Lthe

saw blade, It's the nature of a saw b la de.to

either pull the workpiece imo the blade as

_JoinerY: iter S~line

A M ITER W ITH A SECRETPARTNER

To prevent the creeping mennoned

above, I fasten a .IOp block to che fence,

see Fig,

1.

The SLOpis helpful in three

3),5 ,

the saw blade tends ze push the

workpiece away, the stop

pt-eve.1U ;

ib.

ff

lhe blade tends to pull the workpiece, you

call counteract this action by pushing the

workpiece toward Ul'estop, Also, the stop

is very handy 1'0), cutting several pieces to

the same length,

MAKI:

-

7/24/2019 Woodsmith - 021

9/24

CrTl'IN(;

1 '

P.Sl'l.I:-1F.,To cut ,.olidwood

spline, the

Ii

rs

t cut

is

made by selling the

rip fence the

proper

distance fl'Omtbe

inside or the blade, Thllerly.

brush some glue

01 1

the mitered ends and in

the spline grooves. Theil aprlv a very thin

co at to

the spline, Now just p;.sh the joint

toge,hel' with hand 1 'CSSlU'e,

\ ait a

minute ... you

mean

OU

don';

damp the pteees tOl(cther?

Clamping mitered pieces is difficult at

best. and u su al ly e au ... more problems

than it solves. Besides, the strength of a

miter-and-splinajoim. i~t where

the t\VO

mitered ends meet. Rather, it's the spline,

~Iucd into the grooves on each mile. thnt

supplies all the strength.

The spline should tit in the groov es with

a good Irietion lit. Then. as glue is applied,

the spline

w i ll p ic k

up moisture and

swell,

milking the joim very tight .. In fact. aCLer

about

second$ it'. IIlmosLimpossible

L o

gellh. joint apart. evon ifyou wanled 10,

HOUl' 4

RGURE

;- G R A IN O U t E C T IO N

of the fence with the left edge llned up with

the start line, Then slowly push the

mitered

surface onto the bit, The bit ill

make

a

sliding CUI until the miter is resting

flat on the router table. but it'~ usually not

a problem if you're using a ~~.bit.

CUnlNG THESPLINES

Now all you have to do itiCut the splines 10

fit

the gl'OOVC$.'or gl'eate 1 strength, the

spline. should be cut so the grain is guing

across the joint line. Cutting this type of

spUne is

\ el )

similar to cutting

n rabbe t

on

the end of

a

board - except in this

ease.

the waste i~ the part you

WHIIL,

This i tt ll~U~lI precurious operation

because the lilly waste piece (which is the

spline you want to keep). usually gets

caught by the blade and I. hurled across

tbe room, never to be seen ajr,lin,

After fighting wich thi. aggra ation.

Ted (our Design Director) came up with a

procedure to solve this problem,

\VOODSMlTH

ROUTING A SPLINE GROOVE

Before cutting a spline groove. mark the

face side of

all

pieces with an

X .

If the

X

side isalways

placed

against the fence.

you'll be

UTe

the grooves on both pieces

line up properly,

1'IIROI:GH GROOVES.

Cut ting a Ih.'Ough

groove (from one odge to the other) is

relatively easy on both types of miters.

Simply place the

X

side of each

work -

piece against the

fence,

and make the cut.

The workpiece should always move from

right to left. \\1lh this direction of feed the

rotation of the route.' bit forces the work

piece against the fence .

sro r-r -en

GROO ~:S.

The

first step for

cutting a stopped groove is to mark where

you want the groove to stop 01 1 the mitered

end, Then measure the distance from this

mark to the pointed end of the miter.

This second measurement is used to

mark

start

and stop lines on the OULel'

table - one to the Icfl. and one to Ihe right

of the router bit.

se c

Pigs, 2 and

a ,

The actual cutting of a stopped groove

Pl1':;I ntSa problem, Since the X side

must always be ajr,linstthe fence, the ril(ht

and left ends of the workpiece are cut in

slightly different ways,

Yeah,

but which is the light

end

nnd

which is the left end?

Jr

you hold the mitered piece so the long

points are on top, the right end is the ri~ht

end. andtbe left end i~the left end, (This i.

the only way I eould figure out how

to

explain

what foUows,)

CIlOSS~)ITEII.To cut

a

stopped gl'OOVCn

a cross-mitered Illeeo,

I

make the firijl cut

01 1

the rigbtend of the workpiece, stopping

at th e stop' l ine, a s s ho wn in Fig . 2.

To make the cut on the left end. I posi

tion the pointed end of the miter directly

ever the start line. Then 1510\ 1) lu l lge

th~ workpiece onto the bit. and finish the

cut moving to Ihe loft.

se e

Fig, 3,

t:Nl>MITER, For

an

end miter, both cuts

ar e

l ade the

same

way

as the cross

miter.

except a beveled fence must be used, For

the right end, ju.,t feed the workpiece from

right to left, stopping at the stop line,

But for the other

end

(the left end). the

wo.'klliece must be plunged. Hold the

workpiece fi''JI.lyagnin'Llho beveleel edge

IGUlf 2

AUXtl.WV

nNe.

-

7/24/2019 Woodsmith - 021

10/24

WOODSMITH

0

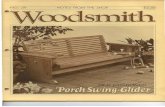

This little Lazy SU8;lnshould knock some

of the dust orf your router and put it to

good usc. I used

router for

two different

operations on this project: first, to cut the

exposed spline joints for the f''lime, and

then to CU t the fnune into a circle.

However, have to admit that the

router needs a little help in order to get

this project under way.

To cut the ~ oove. for the splincA (lhat

join the eight, pieces for the frame to

gether). 1 used the router table shown in

lI'oodsmilll No. 20. I also u . < O O the new

Scars eombinatien edge guide and tram

mel point attachment

(:-

-

7/24/2019 Woodsmith - 021

11/24

OODSM ITH

5

A djllsl tra mm el p oin t

10

r ou t i ns id e

circle, Star 1 i 8: id e o f frame altd

S/OIO/lllVork

0111 10

diameter Q Formica

iuser 1 1 8 ; 1 1 9 lIIetllod desel ibed il l text,

Adj 4t

IIoa ,, cl poi t

to ro ut

a

1

dia'lteler ci,'cle

011

olllside edge,

ouier

bit ill /li/ot holealld make SllCCCS

s tv e pas8681(nUIo l l t. ide was te

breaksfre.

. 6

II ~

lh O tfW

_r fo aonO _ A I

FEt O

lVltNlAIlf

l I fl aonOM

4 .,

7 DtAMflUl

CUT.Af t tc MA TCH

THICKNESS Of INSEllf

AGrkersStore

catalog,

2 1 8 1

Indushi.1 Blvd., Rogel'S,

MN 553 74 ,

-

7/24/2019 Woodsmith - 021

12/24

W O OD SM lTH

I~.

t sv, liS'

H

I

t), )I:

3 ,,.,,10 48

. .

I

Ii

I ~

,v. . . . . 1/. 12

I i

I

I~

..f

l

I

@

IK

I f , .

' , - ' 1 0

7~

U

F

I

F

~

8

B

I

H

Mt o

I

p

p IG

C

C

J J

A Inner Frvme Frtf8k (6) y'....

C 2V 9

8 Inner Frame s id OJ (6)

V i .

)t24 12

C Inner From. Pcnel

' 0 / 1 )C 8 4 15A1

o Corner Frt/Bk [4}

0 /1 .

2V 26

E Corner Sides (4)

'.1111 *_26

FApron. (2)

'0 /,.

l(Sy: . - lO 'A

G Filler StrIps (3)

cui to

fit

H Top/etm Framo (6) '0 /1 .

l

2%: 21

Y,

I Topl8tm Frame (6)

0 /1 .

lc

2~ - 141/~

J Top Ponel

V,. l( lOY._ 17/.

K 80S> F,,/8k (21

10 /1 . l 2:tA _ 21 7;;

L BCdeSides (2)

' : V t . l

2. - 14

M Door Frome Sliles (2)

' t . )(10/.. - 20''''

N Door Frome RoU. (2)

10/6 X

lA -16

o Side Ftame Stiles (4)

1 0 /,. x

1. - 20V,

P Side Frome Rail.l (4) 'o /i .

:It

to/.

9

Q

Drawor Frop'

1 0 / 1

40.16

R Drower SiC{o~ I,

)t

3 / t

2

S Drawer Back

lh :It 2 14

T Drawer

Bottom cut to

fi t

U Plywood Back

Ix 162Sh

CUTTING D IAGR AM

ATERIA LS LIST

1 2

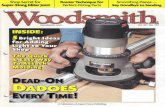

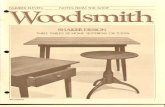

D es igning this Curio Cabinet calleil fo r

what seemed

to

be eonta-adietion. I,t

should have

8

light

and

aky

reeling

so it

doe sn 't o v erw he lm the co nte nts t al are

o n display. Yet, it should be

substantial

enough so th e contents seem protected,

\V ith that in m ind , 'fed designed th is

cabinet around a

whole

series

of

wooden

fl-am es -

some

w ith w oo den panels , and

som e w ith glass. (fbc net e1Tec~ 'is , I th ink,

u nice little display case.

O nce w e go t the d es ign wo rk o ut o J the

w ay, w e go t down to the fu n part: the

w o o dw o rking .

TH E IN SID E FRA MES

s ta rt ed w ith the th ree frames o n the

in s id e

of the

ca bine t.

and

wo rk ed

my

w ay

o ut. Each o fth e ;e fram es is b uilt the same

way: with miter and spl ine joints at each

corner, see l ig . 1.

JOIN1 )lG 'rH ~ FRA~IE f; .

First ,

I

r ipped

eno ugh w o o d 214 wide for the three

frames (six I(mg

and

s ix sho rt pieces ). an d

CUt

each p iece to . Ough length. Theil I

mitered both ends of each piece at 45 so

t he I ro n t/ ba ck pieces (A ) were 1 9 long,

alld the s id e. p ieces (B) were 1 2 long,

Ne)(L,

spl ine

grooves are

cut in the

m itered end s of each piec e. 'l'he easiest

\\lay to cut these grooves is on a touter'

fable. (Sec pate 8 fom o re o n

this

tech

nique) . A lle r th e g ro o v es

are.

cut, sp lines

are cut to fit th e g ro o ves .

TIlE BOTTO .\ 'lA M E.

The

bo tto m Iram e

rece iv es a pa ne l, s o

x ~ . . g ro o ves are

cut along the in s id e 'edges of each

franre

pieee. Fig. S.

Since

the pa nel (C )

I Q

this fram e can be

seen

through the glass d o o r, J d ecid ed to

build it o ut o f so li d w o o d . After I glu ed up

enough w oo d (or the panel, lrimmed it to

sise

so the

dimensions

w ere y r .

less

than

the grooveto groove measurements of the

f rame, s ee

Fig. 3.

(This v gap is neces

sary 1' 01 '

e~llansion/contl'action

of

solid.

w oo d panels.)

Next,

tonguesare cu t o n all

foul'

ed ges o f

the panel to.fiuin the greoves in the frame.

I cut thes e

V

x W ' to ngues o n the ro ur er

[a ble w itti a ,'aBOOt bit.

,V hen glu ing -uJ l this fram e, be sure th e

splines ar e p o si ti on ed so they d o n 't in te r

fer e

with the

pa nel , see 'F ig . 2. H o w ever ,

the pa nel is not glued in the gro o v es - it

m us t be ft.-eeto flo at.

Olrl'SlI)ET(lNCUES.The last step is to cut

a \4 x

1 1 .

to ngu e on bhe o uts id e perimeter

o r all three fr ames . O nce again , I used . the

ro uter table and a ra bbet b it to cut these

to ngues .

IN SIG HT, BUT ()UT OF HARM S REACH

Curio Cabinet

-

7/24/2019 Woodsmith - 021

13/24

:~P_OFR ,S

FLUSHWI END

OF CORNE Jt P IE CE

F IGU R E 6

13

OODSM{TH

FAO N T/S AC K

C O R NE R P IE C E

..J'

I ,,~

I

1 0

QURn;~

R I

e lf

~~. r-e-

J.. -/ '-,

i

I

A ; U r 5 ~ ~ : . : ~ ~

l

I

r-r-

Y .. I

r

GROO V E ;\ f C EN tE R

3

~.

I tENON . ;; TO

tt TH ICK .... .. CEN tER

-L,-

I

-

-;-I:::::==: ::I==== ~-

,

I. y. GjtOOVE . DEEP.) U

lLO\ Y 1 . fOR EX P NSION -:;:; '- ---1

fi G U R E 4

P NE l

..:;; , /.

GROOVE ON STOCK .....;;::::

~ ~~

I. . . . .. DEE~

1

1 81 11

//.

. -

FIGUAfl ~

1----2 ---~loo

.

~~

-

P N El

I

~

y

-

v /.i TONGUE~

- C

THE C B INE T FR ME

The, three inside frames are held together

with the next layer of frames - the eight

Corner pieces for the cabinet, The foul'

Ii'ontlback corner pieces

C D }

ar e-ripped to a

width of

2 ,

Thaiour side

corner

pieces

(E) are ripped to a width of l V . . All eight

pieces are

2 6

long,

SHOIJl.DERE) QU,\R'T>RROUND,

The foul'

fl'Ontiback pieces (D) are.joined to the side

pieces with a simple rabbet joint, But to

give

lIiis

jo in t a

little,mo.-e

cl ass,

1 made

a

shouldered

quarter-round cut

On the

Oll t

side comer of each piece,

Next, a rabbet is cut.on the inside corner

to accept the side corner piece (E), see Fig.

4. The rabbet should be cut so the side

piece (E) sticks out to form a shoulder

equal to the shoulder on the front piece.

see detail in l ig, 6,

$IDESANOAI'RON, The next step

I S

LOcut

tvO

aprons

(F) (,0 fit

between the side

c orn er p ie ce s

(E), These aprons a.'ajoined

to th e

sides with

a m ortise and

tenon joint,

TfY Qll re n ot p artiiculal. ly

fired

up

to

cu t a

mortise and

tenon you ould

achieve

the

same effect by cutting- -wide stopped

grooves on the inside edges of the side.

pieces and in the end of the apron, and join

fh~ two pieces with a spline,

OAD OES, FiI.ally, dadoes are cut in the

eigh~

corner

pieces and the two aprons to

mate with the tongues that

are a ll , ad y c ut

on .the inside frames,

The dadoes aCthe

tA l >

and bottom of each

corner piece arc cut so the face of the

f r ames

i~

u shw i th

tbe ,OJ)

and

bottom

ends

of each

corner

piece, When cutting

these dadoes,

uided Ihe pieces with the

miter gauge and used bhe rip fence as a

stop. Then when the grooves in the aprons

are cut,

1

used the same setting on the lip

fence so these grooves would be lined up,

The dado fOI' Lh ' middle frame (which

supports t he d r awe r ) is cut so it's centered

4 1 1 . . . down fl Om the center of the top dado, '

ASSEMBLY,

Before assembling all of

these

pieces, I

finish sanded than. - it's

8

whole lot easier to do it

now

than

nftel

assembly, Than

I

started assembly

by

gluing the aprons F) arid the sides

E

together,

Now these ~Wtlassemblies, plus the foul'

ti:ontlback

corner

pieees (0)

a re a ll glued

to

the

th ree

Inside , fr am e s, 1

apptied glue to

the dadoes and rabbets in each piece and

added them one by one, This whole assem

bly

is

held together'

with

band clamps. (Be

sure

to

che.ck

the

sq uar e

of

th ee

cabinet as

the band

clamps

are tightened.)

FILLflRS'TRrps.

At this point the cabinet

is;;tarting to lookpretty good - except for

the tongues sticking OUL on the fron.t and

back edges of the Inside frames, These

to ng ue s a re covered with 611el strips,

Th e f ill er strips (G ) that fi t on the tcp

and bottom frames should be the same

-

7/24/2019 Woodsmith - 021

14/24

WOODSMITH

.,... QUARrEl

ROUND W fT H

SHOU lDER

.. a.l ..

Fh S CREW

---I-:

';'1;ER1T~~JTO\PANEl

~ 1- .......

c ~ ~

o f l a e

r ?

.:tLl,~. 0 =

: r -

'M

lASE FRAME

r -

K IC KaO A R D BA SE

thickness as the frames, However. th

strip on the middle frame should be flll

with the tOPof the frame and extend 1

below

the

bottom of the frame, Fig,

7,

TOP AND BOnOM FRAMES

O nc e

agnin you have

to

make

two mo

fl-amo~joined with

a m ite r and

spline,

O

of these frames is for the top urthe cabine

while the other frame is part Ofth. base

the cabinet.

Since both frames

arc

the ..

am e

$i20

started by ripping four long pieces (H) an

four short pieces (1) to 2)',- wide, Th

length of each of these pieces is shown

FigUl' S, That is. these are the lengths

c\,e,'ythinR has gone perfectly up to now

In rcality. these pieces are cut to fit th

actual

dimension

of

the cabinet,

l he

bottom

frame ba s

the most critic

(it because of the way the shouldere

quarter-round (its around the perimeter

the cabinet. see Fig, 13, l got the measure

ments for this frame. and used it

standard

for the top frame,

)Ieasure the width

and

depth of th

cabinet

as

it stands. Add the width of bo

quarter-round cuts (this should be a tot

of

1-), lind

then

ad d

an extra 0 /, : , This exi

i~Ol' the space between the quarter

round cut and Ihe perimeter of the cabine

Now, all eillh pieces for both the

bouo

and top frames can be cut to thes

InC Iisu remen ts.

01'

f'1( )'

E, Aftel' the pieces for the to

n1lme are cut to length and the ends a

mitered, stopped spline grooves must b

cut on each mitered end, Then 1 4 . x

groo\'C$ are cut on the inside edges.

Next, a panel (J) is buill to (it inside th

frame, The panel is glued up of solid woo

ancl then cut to size 1 1 , ; smaller than th

Jl'I'Oovcto groove measurement, l~in

V I ~x 1 1 / tongues.arecut to iiI in the groove

in

th~

f,.. me. Fig, 9 ,

Bero,'.

attaching the

top

Irnme,

th

dl WCI' runners should be screwed in

place, Fig, 7. Then 3 IIi x Vi rabbet ., c

around the entire back side of the cabin

for the ,. plywood back.

1I(I1TOMPRA~IE.:\0 back to the botto

frame, The four pieces for the bouo

Ji me are already cut 10 length and m

tered,

so

all that's left is to cut the .toPile

spline I(I'oo\'es, Before assembling th

rnuno, rabbets are cut along one edge

uceept the base

(kickboard ).

TII~: AS;;,

At last there's somethin

ea~y, The base is just four boards (M an

N)joinl'd with a miter and spline. After it

assembled, the bottom frame isglued on

it, Then this assembly is screw,..

1

to th

bottom of the cabinet. Fig, 13,

GLASS DOOR AND SIDE PANELS

The glass door and the two side panels a

miter-and-spline f,'ames, (\Ve wouldn

want, to break the monoton), at lhi~ point

CORNER ...

RGU II: 13

1

@ ~ : : : : : .~ .

= , : : ; ~

< >

r , - .

TONGUE

,

1 4

RGUIE l l

,

l -

i---2()lr.-

TOPVtfWOFlASt

FtOV Rf It

r

1_ N]I _-I

2 'STO' GROOVE'It fROMEND

QUARTER 2 -;

ROUND I

WlfH Y.

SHOUlO,. ~~~.~o:n=O=M~f ==~~

I

GROOVE

ii

OlE'

L .M

It

.- ._ ttA88T FOa lASE

,lOUn 9 . .'. GROOVf

---2,-- -- 1 O

'AN(l

TOP....... , i-U 'ANn

fj.,

OUI\I tTER

ROUNOW'THIH-t11

SHOULOElt

C OIN ER D ET AIL

.i&~THROUGH GROOV~

-1- ',' roRSPUN'

(

NOli; eASESlOES

t~

2 ~- W IOE L

,

. . .

AGUaE,

If. JI I .. OROOV I

ro

M A TC H T ON G UE

-

7/24/2019 Woodsmith - 021

15/24

PL YW OOD

RE STS ON

10

GLASS fRA MES

IN MAGE

@

Wd oD N s t O . F OR G l A S S

RGURE19

Y ? i U A R T t R O U N O

WlfHsHOULDE.

~~ - ==O=A A =W= =~=F =~O =N=r ==~_ q ~~

i 5

to

CO~NEl

Et il

\ r: S f f O uL O at

2

r .6 1

/. QUARTk ROUND

Wi ll - SHOUlDP.

P )

FIGUR~

oooa fRAME

_I

8

,fIGURE l7

SIO~

GLA SS FRAME

I 1 1

~

D O O R F RA ME

~ y

QUARTER ROUNO

wrta

SHOULDER

ON 80tH EDGES

J

0

I

Tl~ :@

I ) SPLINE V THICIe

II

WIOf

fiGURE 14

1 .6 1

\ ' OO l)SM1TH

Although the basic construction of these

frames is exactly like all the rest of the

frames fhere are coupte

o f

little changes,

A ll 12 pieces for thew frames are ripped

to

a

width of 10/,, and

cut

to rough length.

Theil aU pieces are CUt to final length (mi

tered) to fit the openings in the cabinet.

(To get these pieces to fit, measure the

openings and add. total of

W -

this is

so

the frames overlap the openings

It ,

on

each side.)

SPLINE GROOVES.Here-are the change s.

On these frames the spline

grooves-are cut

all the way through (from edge to edge),

r u l 1

they're poSitioned off-center so they

don't interfere with the molding cuts on

the face of tbe frames.

li'irst, [ made the moldin ; cuts on th e

inside edges of all these pieces with a \I .

quarter- round bit. leaving a \ 1 0 shoulder.

Then cut a v . wide by % deep rabbet

below the

molding cut Fig 15

The spline grooves

can now be aligned

and cut ~ot.heydon't trim ofI an.)' part of

the quarter-round cut. Ne.xt, the splines

are cut and

the

frames

are assembled.

After th e glue is dl,,', the same type of

v . o

quarter round

cut is made around the

outside edges of each (J ,me.

RABBETS.

The rabbets on. the outside

edgeofthe door fra me and the side frames

are slightl;\' different, On the side frames

che.rabbets arecut.so the frames

fi t.

tightly

in.the openings. 's best to sneak up on the

cuts to get a snug fit. Then these n-ames

are glued into the openings.

The rabbets on the door

frame

al'e cut

K i

wide so there's enough clearance for the

hinges (Fig. 17). and so the door can be

opened

easily .

1' 11 CLASS.Once the [l-nmes l ir e bu il t,

they need some glass. 1 took the frames to

a local store to have the glas s cul to size.

While they were at it, had them cut a

glass shelf 1 0 . inside the cabinet.

The glass shelf is mounted with small

L-bracket shelf supports. The glass for the

doors and side panels is mounted with V i)(

v .t stops.

'I'll ~ ORA'WER. The last step on this

cabinet is to build the drawer. The.drawer

Iront is lipped, which means there are

rabbets on all Iour inside edges. Once the

drawer f ont has been rabbeted (see li'ig.

19).

th e

sides al1 joined to the fl:on~with a

half-blind rabbet

an d

dado joint. Then the

back is joined to the sides with a nOI11181

rabbet and dado.

Before assembllng the drawer, 1 cut one

more

shouldered

quartar-uound cut

around

the perlmeter of the drawer front.

FINISJlING. To finish this cabinet

r

applied two coatsof,\1iIWI(I< 'Valntlt stain.

When the stain was thoroughly dry,

brushed on three coats

of

Hope:s Tun g O i

Va 7t;sll This oil finish has just enough

varnish in it to add a gloss to the-finish. and

it's very easy to apply,

-

7/24/2019 Woodsmith - 021

16/24

WOODSMITH

for the mirror.

lIiRROH.

The easiest way to cut the mir

ror

is

to have someone else do it. [took the

Irame to a local

-

7/24/2019 Woodsmith - 021

17/24

17

OODSMITH

AUG RUSH

WlTHPlYWOOD

TRIM

OFf

DeBS

~ 'h .n y ou 're cu ttin g m ite,'> fo r

an octagonal (eighr-sided)

fl'lime

the chance for error in

creases dramatically. Each

J)icce I Ql the frame raquil e ij

L W Q cuts at 22Y - fill n i o t

of 16,iICI.d ens at this angle.

t

),OUI' set.ting is off just

~,deg,e .

the

combined gnp

would be abou; l t

thejoillts are oft'.yo u could

recut all the mite rs. and proba

bl

wind up even farther on

the other direction. Instead

some

minor

:uljustment~

can bt

made dur ing assembly. First. I

$ Itll~pieces to sre the r to fo rm

two halves of the octagon.

t

would

he

nice

if the four

open

ends of these two halves

fit

to

gether perfectly. But that

I'arely happens.

As lung as the gap between

these two halves is nut IIW I

lhan \ , , corrections can be

made fo r a p er fe ct

fit.

1 u s e the

jig shown in Fig. l

First 1 I;P a clean edge on a

pi

of plywood. Then I lay

the assembled halt-octagon

face rlown and tack the pl~r.

wood 10it. (This means the nail

h oles w ill b e o n th e b ack sid e o f

Illn.an d

you .hould ;nd up

with

a p er

fcd tit.

TACKHAlf.OctAGON

fOPlYWOOD _

FROM8O OM

iter i~_

JOINING AN OCTAGON

-

7/24/2019 Woodsmith - 021

18/24

WOODSM1TH

8

\Ve'ye received dozens of requests for

lathe projects and we've had lot ofdiscus

sions about what kind of project

to

do. We

finally decided to IUI'n a bowl (faceplate

turning) because it's the one project that

can

be accomplished

start-to-finish

on

a

lathe, anel stands alone when it's done.

Turning this fruit bowl requires several

basie lurninp; techniques. Yet. it doesn't

require years of experience or any really

special tools or equipment.

The bowl is designed

with a

shallow

slope on the

walls

so you can turn it with

out a lot of the problems associated

with

deep. sided bowls. AI ;o. the unusually

wide rim creates an appearance of very

thick walls ... eliminating the need ior

absolutely uniform wall thickness. (The

w nU s

can beany thickness you like without

affecting the final appearance of the bow ')

Anel finally, the base (also turned on the

faceplate) is fl>atoned to the bowl with a

round (turned) tenon. This is a practice

often used in turned projects that have

8

pedestal 01 base .

CUTTIN() S. $CI(;\J'ING. Before getting to

the details on this bowl, I'd like to mention

that most ofthe work is

done

with a cutting

(rather than scraping) action. Although

scraping the bowl would have

been

much

easier (there's really not much skiU re

quired in using'

t

scraper). it would have

taken much longer to turn, and the final

finish would have been poor at best.

The speed with which a bowl can be

turned

by

cutting, and the finish that can

be obtained are really enough reasons to

learn the techniques required to cut with

a

gouge. UL the real thrill is in seeing al l

those shavings on the top of the bench that

a re the result of cutting.

Now that

I ve reco mmended a

cutting

action, I should admil th at I used a com

bination of cutting and scraping on this

bowl. y usingijcrnpel'S for finishing work,

you can nClUlIlI~'improve the finish left by

the gouge. And there

a re

limes

(a s

in cut

ting the underside of the rim) that scraping

is either the only

way

possible

to

make

a

cut, or it may just be safer.

T H . : TOOLS . I used only 6ve tools to turn

the fruit bowl. (See page 22 for a detailed

explanation of the tools used.) A

1(,

shallow spindle gouge (that's been re

ground) does the ml\iority of

tbe

turning.

A domed semper is used after tbe gouge

for cleaning up end grain problems. A t

light scraper is used to form the underside

of the rim. A V a - skew is used to cut the

bead In the pedestal. And finally, parting

tool is used

t o

cut tho round tennon,

TRUING THEOWL L NK

I used a I .spindle gouge to turn the bow

blank true with the center. Any gouge

wil

work for truing the blank. but I f ind the

small

y .

gouj:tcworks well.

Position

the

short tool rest so that it's

the same height as the center point of tbe

bowl blank,

and

adjust it

so

that it's

par al

leI to tho edge of the block and about I . to

\4 . I I Y

from the widest point.

(It's

best

to rotate the lalhc by hand to be sure the

toolrest cle.,~ t,hebowl blank on

all

sides.)

Because of the large size of this bowl

and the fact that it hasn't been trued ith

the center yet. you'll want to set the speed

of the lathe

as

slow

as

possible. Until the

bowl blank's outside edge has been trued,

it's also a good idea to bring the tail stock

up to the blank to steady it. see Fig.

To true-up the blank. start the cut with

the handle of the gouge very low. and

slowly raise it until the cutting edge JUS

begins to CUt,see Fig.

Then slide the

gouge across the edge. with the U facing

straight up for the entire pass.

Until there i. surface for the gouge's

bevel to rest on, the culling action will

seem a little rough.

uta~

the bowl blank

rue UOWI. IlLANK. To turn this bowl

you11need a blank 12 quare by3~ thick.

The first step is to cut 7 pieces out of 4

(lY. -thick) lumber. Each piece is 3~

wide by 12 long. All

7

pieces are lamina ted

(face to fnl'e)to fo rm the 12 -squareblank.

(The bowl in the photo is glued a little

differently because was USing small

scra ps

fom around the

shop.)

After the blank is glued-Up, it's planed

smooth on Lheface that

will

be

attached

to

the faceplate. i hllllly, to make the initial

truing-up Mfer. I cut the bowl blank to a

1I~. diametercircle on a band saw

Once the block has been band-sawn,

attach a 6 diameter plywood disk (the

same

sizeas the faceplate) to the block and

let the assembly dry for 12 hours.

SHOP NOTE.

Because

1

used hard maple,

the bowl blank was extremely heavy. So [

glued the plywood disk directly to the bowl

blank without the usual paper insert.

r

felt

by doing this,

i

would achieve a stronger

bond without having to worry about the

paper separating while

1

was turning.

\Vbcn the glue is completely dry, the

faceplate is mounted to the plywood disk

with

14 w oodscrew s.

Then the faceplate

is attached

to

the head stock of the lathe.

-

7/24/2019 Woodsmith - 021

19/24

V O O D S M IT H

Using th .

\1,.

light scraper, fo rm tl,t

ntde l 8idc of the

lip

by making

l el 1l

lig/rt passes. U e a partial template to

clteck

1 /t 1 1

sh41)Cof Ih e

/.ip

~llAm.

2

Ro ta te t lt e J W l l d l e s u from M 6:

starlillg posiJion to th e J : OO posilioll.

f ol lo ,q j lf J t he a rc s h o w l I

Slightly

r ol l t lt e

gouge ov{J)'as It p roceeds tl rroug /r the Cllt,

PO S IT lOfo i

etten isn't the cast' . Several things may be

causing problems. The m o s t common prob

lem is that the gouge isn't sharp. There's

really no other way to PUt this,

it isn't

sharp

t

won't work.

Another nullo.' problem may be that the

bevel o(the gouge isn't rubbing against the

w o o d correctly. If the handle

~

aised too

high, and the bevel isn t rubbing. the

gouge

w i l l

digin and

sc a re

the, .. unnerve

)'OU to say the least.

Then there's another posSibiliLy. If the

gouge cuts for only part of a pass, then Lhe

solution may be to reposition the tool rest.

As the shape of the bowl develops, try

moving the to ol Tes t so It's somewhat

parallel

to

the side of the bowl. This should

make it easier for the gouge

to

follow the

profile of tho bowl and continue cutting.

Lfacontinuous cut seems impossible,

try

cutting for just one h al f the length of the

profile. Then make another, separate cut

to complete the pass. As long as the ridge

formed bel ween the two

C U W l

isn't too

large, it can be removed by the scraper

during the finish passes.

SHAPING THE COV ED liP

For now you only have to remove enough

material so the coved lip can be fonned

\\ith

a

scraper.

By

removing this waste

you can U SC the template to determine the

finished profile of the wall. (NOTE; The

y scraper sheuld be reground to an ex

treme fingemail shape. see page 22.)

Reposition the small tool rest so that it's

just below the center point of the blank.

Then, to form the coved lip. lake only light

cuts with the scraper. see Pig, 3. This

tend

to

take a few minutes to accomplish,

but ifheavy cu t s are made, the tear out will

be horrendous, C h e c k the profile of the lip

fI'equently with a partial template.

The scraper may need to be reshsrpened

several times before the final shape is

achieved. (V

\1

can teUwhen to resharpen

the scraper when it produces dust instead

of shavings.)

side of the bowl. Because much more

material needs to be removed from the

area around the base of the bowl than near

the lip, it's best to

begin

with short cuts

starting about I

from

the left edge, mov

ing the gouge from light

to

left.

Start each a u e c e s siv e p as s lightly to the

right (closer to the lip), B y doing this,

you'Dbe r e m o v i n g mote material from the

base

o( the bowl than from around the lip,

without having

to

take

an y

heavy cuts.

When using the gouge, start the cut by

addressing the wood with the

U

facing

ll'aight up, and the handle held low

enough to keep the cutting edge

away

(rom

the blank. Then slowly lilt the handle until

the gouge is cutting. As soon lUI the gouge

starts to CUL,slowly SlIing the handle in a

counter-elcckwtse arc. while genU)' rolling

the U of the gouge towards the left.

The cutting edge of the gouge should

move

in a shatlo,

are-s-whieh is

a

result

of

the handle mo ing ina much larger are. To

better describe lhe handle's movement,

think of Lhemovement of the handle's butt

in relationship to a clock C a c ( , t < C C Fig. 2,

The butt of the handle begiM the cut inthe

0 : 0 0 position. and willsomewhat followthe

perimeter of the clock face in a counter

clockwise rotation (towards your body)

until it's in the 3:00 posilion at the end

of the cut.

As the handle is raised through this arc.

it ma~' be necessary to let the tool slide

sideways (to the left) to make the fu ll cut.

The actual shape of the arc will vary to

SOmeextent 11the bowl profile changes,

but il w ill follow basically the same path.

As the gouge proceeds a c ross the peri,

meter of the bowl,

t

must also be rolled on

it,. side slightlyas the handle is lifted. If

the U ofthe gouge isn't rolled over to the

left 3S it's advanced, you could get a nasty

dig-in when the trailing edge or the gouge

comes in contact with the wood.

PROBl.E~IS. The results of this cutting

action should be thin shavin~ and a nice

finish

01 1

the bowl. Unfo,1unately, this

1

Set th~ tool ru t Yo aw a y from the

,-ides poi)lt, We ('ery ligM cuts ,dll,

tne

v gouge.

Then

procfed across th

e

-

7/24/2019 Woodsmith - 021

20/24

/

\V

1

RemOt 'e

tilt rc> ter

pinnacle using /Ire

8

Afte,' lite

Vi

gOl ' '' '.

Ihe V 8rrol'61' 1 0 clean up tile lip.

U T Y O _ G R O O V E

the safety of the rim. U S tbe long point of

a 1 : skew to cut a \ - sh a pe d groove in the

f a c e of the bowl at the

pencil

tine. se e Fig.

6. By cutting this groove first, the bevel of

the gouge

will

have a shoulder to rest

against at the

start

of the cut. This

wil l

prevent it from following its natural ten-

dency to shoot out toward the outside

edge, ruining the rim.

REMovlNCl TIn : INSU lt: WASn:.

To posi-

tion the 1 , . gouge to

start

the cut, lay the

gouge on its side,

with

lhe

U

pointing LO

a spo~ slightly above the center of the

bowl, and the bevel resting in th e g rc ov e,

The handlo s h o u l d be ju~i a little lower

than level a nd leaning slightly toward the

center of the bowl.

S(. (

Fig. 6.

\\'hen the gouge is presented

to

the

wood. it should be introduced firmly

to

start the cut. As:;oon as the gouge enters

the wood, begin to lower the handle and

slowly arc the cutting e d g e of the gouge

toward the center of the bowl As the

euuing edge reaches the highest part of

the arc. it's I(I1ldually roUed over so that

the open side of Ihe

U

is pointing

towards the center of the bowl.

The gouge should tl'avel in a .hallow arc

After the lip is fanned on the unde rside

of the rim. the finished profile on the out-

side ofthe bowl can be completed using the

~. gouge. The profile of the bowl

will

continue beyond the plywood faceplate.

but for now. just sbape the outside or the

bowl up to the plywood disk.

Check the profile often. using the coved

li p

as a

point

of reference for the template.

Whon iho finlll

pas s is

about to be made,

take

a m in u te

to

r e s h a r p e n

the gouge to

a

keen edge. 'rhe effort spent here

will

del1nitely show in the final finish,

tINI~1ICI. ) I ll. Anel tbe outside of the

bowl isshaped, the heavy domed scraper is

used

00

clean UI>the surface, see Fig. 4.

(Switch to the small scraper whenworking

near the eeved lip.) Be sure that the

scraper has a burr on its edge and that it's

always held :;0 that it's pointing down-

ward. To achieve

good

finish, make only

very light CUI.with the scraper.

TURNING THE INSI E OF THE OWL

To cut the inside of the bowl, set up the

large tool rest so it's slightly below the

center. and only

away from the face.

PItOTF.( I INC Til t: 1 11M .The first cut is for

-

7/24/2019 Woodsmith - 021

21/24

To be Sure that ilu:bowl isatlaclted I J

m e pedesl :JJ

80

I l lul

11'3

lfl e l. l< y a

piett oj plywood

Oil

to p oj Ih e b ow l, and

mcag r~ (ite

heigM 0/

all

} olll sides.

21

SCI. P lTWOOD-

?

~

the two to make it easier to remove later.

The first step is to true up the blank on

tho IMh. in the

arne

manner as the bowl

blank was trued. (The l~il stock can be

bl'ought up to the end of the block for

support if needed.) After the block is

trued, most of [he waste can be removed

from the area orthe bead and cove, redue

ing the diameter of this area to 2 v .

1 \VOL.

The next step is to layout the

I>osition. of the bead and cove on the blank.

Fil'lit I cut agroove with the parr ing sool \0

mark the depth of the cove at its deepest

point, see Fig. 10.

The next step is to slarl shaping the

profile of the basse using the gouge. Once

the basie shape of the b. ..;e is formed. the

cove can be tumedso that it blends in with

the bnse and also forms a centinuous curve

where it meets the bead. we Fig. 10. The

bend is then cut using either the small

scraper, or the skew chisel,

Tt'IISISr. TIlE TE N N O N . After the pedes

tal\ prul i1e iscompleted. use a parting tool

to cut a round umncn to fit the hole in the

bottom of the bowl. -v ri~. 11. \\'hen the

tennon is close

the

COITl-ct.

size, us e the

hole in the bowl to cheek for the filial fit.

Thi, way, there's little chance of the ten

non being cut too small, 1'hi.

i

bo a good

wny to be sure tha~ the tcnnon i.n't too

long. II the lennon is cut so that the (it is

tight, clamping the bowl to th~ pedestal

shouldn't be needed.)

finally. [ finish sanded the entire base

and then gave it a coal ofRfllis wax.

After it was buffed to a hilW sheen. I

removed the pedestal from the lathe and

.~pllrtcd the plywood disk

l\'l)1Il

the base.

ASSEMBLY

I used the method ShoWII in Fig. 12 to

assure that thebowl's rim i 1,,\,,'1when the

bowl I, I(lued to the 1 '

-

7/24/2019 Woodsmith - 021

22/24

H EA VY D OM ED SCRAPE R

turning to ols bein g ho ned 'o n a bench stone,

bu t for the li fe of me, Ica n'tdoit that wa:l '.~

SHO P N O 1 E :Because

honi ng' a go uge

will

hollow out the surface of any sh a)1)enin~

stone,

m ark one sid e of the stone w ith a

smallnotc h to des ig nate thai this side is fo,'

go~ges only. The side w ithou t- the-notch is

use d fo r only the flat , tools (skew s) .

To obtain a truely shar p ed ge, 1 use a

seri es ofthree slip stonestamed ium

i? d ;a

a fin e India and a soft A rk ansas.

HONING .

After the gouge is removed

c. om the grinder, the fi rst step is to re-

move the burr on the inside of the U .

Pla ce the slip insW e the U and hone

the en iire edge fro)n corn er to co rner by

sl idin g the cr owned edge

of th e

sl ip

back

and forth in vhe

U ,

Alwa:,:skee p the l Il '\ iO lity of the slip well

back in the P to prevent any chanceof it

teetering

and rounding

ov er

th e c utJ ;iog

edge. fthe U side of the ~ug e becom es

ro und ed over at the cu ttio 'g edge, it will

have to be reg rou nd un til it' s t1~t again,

After th e bu n' is remov ed from inside of

th e U , hone the bevel sid e of t he goug e.

Honing the inside of the U usually just

bends the burr over O t he . b evel edge.)

Hcning the bevel edge is a ls o done w ith a

slip - but th is time th e face flat si de) of

the slip is use d. I

sit on.a

stool at

the

wcrkbench w ith the hand le's butt nestled

in my lap and the steel shank .of the gouge

pressedagainst th e front edge of the work-

ben ch . This way the tool is s ta tio na ry , y et

it

C \l

be

ro lled as W s sharpened,

AS the goug e ishoned, I sl ide th e slip in .

bae k-and-fonth motion (in line w ith the

cu tt1llg edge) al ong a small section or the

bevel, keepin g it pressed again st both the

tip and heel of the bevel.