withBermudagrass Greens - USGA Green Section …gsr.lib.msu.edu/1990s/1991/910701.pdf ·...

Transcript of withBermudagrass Greens - USGA Green Section …gsr.lib.msu.edu/1990s/1991/910701.pdf ·...

Severe verticutting is a basic ingredient for maintaining top-quality bermudagrass greens.

Going for the Goldwith Bermudagrass Greensby JOHN H. FOYDirector, State of Florida, USGA Green Section

FORQUITE SOME TIME, bent-grass greens have remained thebenchmark regarding putting

green quality. Compared to bentgrassgreens, bermudagrass greens havealways been considered second rate.Standard complaints have been thatbermudagrass greens are slow andgrainy. In the past, when equipmentlimitations made it impossible to mowgreens below 3/16 inch, the coarser, stifferleaf blades of bermudagrass resultedin significantly slower putting speeds.

Even today, whenever a professionaltournament is played on bermudagrassgreens, television commentators stillmention the need to allow for the grainin the greens. Let's face it, though.When any turf variety is mowed to :Isinch or less, is there really enough leafsurface left for grain to be a factor?

Most golfers still hold the opinionthat bermudagrass greens produce aninferior play surface. As a result of thisperception, efforts persist to establishbentgrass in areas where it simply is not

well adapted. While breeding effortshave modestly increased the stresstolerance of some bentgrasses, theinevitable loss of some pesticides andreductions in water availability make itunrealistic to expect that bentgrassgreens can be maintained in somegeographic locations. The southeasternUnited States and tropical-to-sub-tropical areas of the world are examples.In these areas, high temperatures andrelative humidity limit the health andpersistence of bentgrass turf. Golfers

JULY/AUGUST 1991

should understand that the best adaptedturf for these regions remains bermuda-grass.

As in all aspects of golf course man-agement, great strides have been takenin improving bermudagrass greensduring the past 10 to 15 years. Thefollowing paragraphs review what ittakes to produce consistent champion-ship green conditioning.

The Basic Ingredients

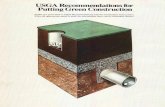

Back in the "good 01' days," when thestandard mowing height of bermuda-grass greens was ~ inch and tourna-ment height was 3/16 inch, the soil usedin green construction was not so critical.The hardy nature of bermudagrassallowed it to survive in very poor qualitysoils. Today, however, low mowingheights place much more stress on theturf, and a poor medium can be alimiting factor to bermudagrass quality.

In Florida, some people mistakenlyquestion the need for USGA specifi-cations when it comes to green con-struction. Besides providing the properphysical characteristics for healthy turfgrowth, though, the moisture conser-vation aspect of USGA greens becomesmore important in Florida due to theprospect of permanent irrigation re-strictions. Quite simply, if healthy turfgrowth and top-quality green condi-tioning is to be provided, proper con-struction is essential.

Other factors that limit the growth ofhealthy turf also must be eliminated.One of the most common obstacles isexcessive shade. Bermudagrass is one ofthe least shade-tolerant turfgrasses andrequires a minimum of six to eighthours of direct sunlight each day tosustain healthy growth. Early morningsun is especially important for reducingthe presence of free moisture, whichincreases the potential for disease out-breaks and surface algae. Winter, spring,summer, and fall shade patterns shouldall be evaluated, and good air circu-lation, while not quite as critical as withbentgrass greens, should not be over-looked when considering the needs ofbermudagrass.

At the present time, two hybridbermudagrass cultivars are available foruse on greens. Tifgreen (Tifton 328),from the research program of Dr. GlennBurton, was released jointly by theUSGA and USDA in 1956. It was atremendous improvement over the ber-mudagrasses available at the time andhas been used extensively. In 1965, Dr.Burton released Tifdwarf, which was

2 USGA GREEN SECTION RECORD

actually a mutant strain taken fromseveral Tifgreen greens. While Tifgreenhas been a very good turfgrass, it is notas well adapted as Tifdwarf for meetingcurrent demands. Primarily, Tifgreendoes not tolerate a mowing heightbelow 3/16 inch for any length of time,especially if other stress factors comeinto play. Tifdwarf, on the other hand,can tolerate a mowing height below3/16 inch on a continuous basis, and itshigher shoot density and finer leaf tex-ture make it the best cultivar availablefor top-quality greens.

That's not to say there are no potentialdrawbacks with the use of Tifdwarf.Concerns have been expressed about itscold temperature sensitivity, reducedwear tolerance, higher incidence ofsurface contamination, and resistanceto winter overseeding establishment.While it's true that Tifdwarf will go off-color more quickly than Tifgreen whentemperatures reach the mid-50s, itactually possesses better winter hardi-ness and starts to recover from winterdormancy 10 to 11 days earlier thanTifgreen. As far as its wear toleranceand overseeding acceptance are con-cerned, proper fertilization and improvedoverseeding methods and materialshave eliminated these issues. "Off-type"strains occur in both Tifgreen- andTifdwarf-based greens, and an annualsummertime program of spot removalmust be practiced to maintain surfacepurity. So comparing one to the other,Tifdwarf is the better bermudagrassfor producing top-quality putting greensurfaces.

The other basic ingredient for successwith bermudagrass greens is a capa-bility and willingness for some work.With proper construction and a Tif-dwarf base turf, maintaining a dense,healthy turf cover is not that difficult.The big difference between bentgrassand bermudagrass greens is the effortthat must be put into grooming thebermudagrass for surface smoothnessand speed.

At courses where the best-qualitybermudagrass greens are maintained,continuous attention is given to surfacegrooming programs. This situationrequires the standard complement ofgreen management equipment, as wellas an array of grooming tools. Amongthe basic items needed are verticuttingunits, brush attachments, and a top-dressing application setup that can becalibrated to apply light rates in a timelyand efficient manner. Also, adequatetime and manpower must be availableto carry out the necessary programs.

Grow the Grass First

Unlike maintaining bentgrass greens,where low fertility has been used tomaintain fast putting speeds,' bermuda-grass greens need to be fed. Bermuda-grass has a high nitrogen requirement,and the old rule of thumb of using 1pound N/1000 sq. ft./month during thegrowing season still applies. When man-aging a high-sand-content rootzone,maintaining adequate potassium levelsis very important. AI: 1 or even 1:2nitrogen-to-potassium fertilization ratiohas been found useful in maintaininghealthy turf.

Controlling thatch is another essentialmanagement practice for maintaininggood bermudagrass greens. Excessivethatch accumulation is a problem in-herent in all of the hybrid bermuda-grasses. Since most bermudagrassgreens are overseeded for the wintermonths, year-round turf growth occurson greens. Core aerification and coreremoval, therefore, are necessary tophysically reduce and control organicmatter accumulation. A minimum ofthree corings each summer is required.When bermudagrass greens becometwo years old, a straight sand top-dressing program is the standardapproach for dealing with thatch.

To the average golfer, a lush green turfis a characteristic of the ideal green. Toprovide this appearance, many superin-tendents feel forced into watering theirgreens too much, resulting in a shallowroot system and overall weak turf. Thebermudagrasses possess good droughttolerance, and less frequent, deeperwatering of bermudagrass greens is thebest strategy for maintaining a healthyturf and optimum surface conditioning.

Surface Grooming

As noted earlier, bermudagrass re-quires very intensive surface groomingprograms to produce a smooth, trueball roll and a medium-to-fast puttingspeed. Some of these practices, unfor-tunately, temporarily disrupt greenplayability and are an inconvenience tothe golfers. When these programs arenot carried out on a regular basis,however, problems eventually occur inmaintaining the desired level of turfhealth and green quality. Many oldersuperintendents will tell you that themore you "beat-up" bermudagrassgreens, the better they perform.

In late spring or early summer, afterthe bermudagrass has exhibited sus-tained active growth, the greens shouldbe severely verticut once or twice. These

severe verticuttings accomplish severalthings. They aid in reducing thatch thathas built up during the fall, winter, andearly spring, and they help complete thetransition from the winter overseedingcover to the dominant bermudagrassturf cover. Most important of all, severeverticutting stimulates dense, upright,juvenile shoot growth and eliminatesgrain that has developed.

A self-propelled verticutting/ de-thatching unit, such as the Ryan Mat-A- Way, is generally considered the bestfor accomplishing these severe opera-tions. However, another verticuttingunit can do a satisfactory job. Theverticutting blades should be adjustedso they only cut into the soil/ thatchlayer of the upper root zone. Typically,this operation is performed twice at 90-degree angles.

The best results occur when twosevere verticuttings are performed inconjunction with the first two corings ofthe greens. If only one severe verti-cutting is scheduled, it should be donebetween the first and second corings ofthe greens. A tremendous amount ofdebris is generated from these verti-cuttings and must be removed.

The typical sequence is to verticut,remove the debris, core aerify, remove

the cores, apply a heavy topdressing,and then work the material into thesurface of the greens. For anyone whohas never observed severe verticuttingof bermudagrass greens, their reactionis that the turf has surely been killed andthe greens destroyed. Granted, the endresult is not a pretty sight, but within 14to 21 days the greens will have fullyrecovered and will provide an excellentputting surface.

In addition to the one or two severeverticuttings, bermudagrass greens re-quire regular, light verticutting throughthe summer growing season. This pro-gram is necessary to maintain uprightshoot growth and help prevent exces-sive thatch accumulation. Duringperiods of active shoot growth, ber-mudagrass greens should be lightlyverticut at least once per month,preferably every 7 to 10 days. A triplexgreensmower with verticutting reelsinstalled is the standard unit foraccomplishing these light verticuttings.The vertical blades should be set sothat they are operating at 1/16 to Y8inch below the base of the bed knife.When done properly, the average golfershould not be able to tell that anythinghas been done to the greens by thenext day.

The groomer attachments that areavailable for most greensmowers arealso quite useful in the management ofbermudagrass greens. Putting greenspeed can be increased from 6 to 12inches with regular use of these attach-ments. A slightly higher mowing heightalso can be practiced, thereby reducingthe amount of mechanical stress on theturf. Groomers are generally used up tothree times per week, and the blades areset to operate at about 1/64 inch belowthe effective mowing height of thegreens. It must be stressed, however,that use of these groomer attachmentsdoes not take the place of a regular lightverticutting program. Bermudagrassgreens still need to be verticut at leastonce a month to control thatch accumu-lation.

Topdressing is another good programfor controlling thatch and improvingsurface smoothness and speed. Inaddition to heavy topdressing appli-cations made after aerification, regularlight applications should be scheduledthroughout the year. These "dustings"of 0.1 to 0.3 cubic yards of material per1,000 sq. f1. help maintain a smooth,true ball roll and good putting speed.Following application, the materialshould be worked into the surface of

Shade and bermudagrass greens just don't mix!

A poor root zone causes shallow-rooted turf thatcan't survive pressures from traffic, low mowingheights, and environmental stresses.

JULY/AUGUST 1991 3

the greens with a dragmat or lightirrigation.

Application frequency should coin-cide with the growth rate of the turf sothat a homogenous soil profile is main-tained. In the summer months, ber-mudagrass greens usually should belightly topdressed every two to fourweeks. Improvement in playabilityusually peaks approximately five toseven days after application, a fact thatshould be kept in mind when planningfor special events or tournaments. Theimportance of using a consistent, high-quality topdressing material with theproper physical characteristics cannotbe overemphasized.

A special note for Tifgreen bermuda-grass greens: Even though warm-seasonturfgrasses require temperatures in themid-80s to 90 degrees for optimumgrowth, Tifgreen greens can suffer fromheat stress. In the mid-to-Iate summer,when temperatures and humidity can beextreme, heat stress can predisposeTifgreen greens to damage from otherstresses such as low cutting height.Under these conditions, Tifgreen greensshould not be mowed below 3/16 inchand should not be verticut intensively.To compensate for the higher cut andthe lack of verticutting, superintendentsat several Florida golf courses have

successfully improved surface play-ability by topdressing more frequently.Biweekly or weekly light topdressingsduring late July, August, and earlySeptember is a common regime, thoughcare must be taken to avoid applyingtoo much material.

When consistently fast greens aredemanded, there are several other prac-tices that should be considered. The useof walk-behind greensmowers on ber-mudagrass greens is becoming a popu-lar way of reducing wear and producinga better-quality cut. For the sake ofconsistency, greens need to be mowedon a daily basis when active growthoccurs. Double cutting of the greensrepresents another excellent strategy forgaining 6 to 12 inches on the Stimp-meter, without reducing the mowingheight. In the past, multiple mowingshave been practiced just prior to andduring the play of special events. Tomeet the demands of the golfers at somecourses, however, double cutting is doneon a more regular basis.

Finally, to obtain the best possiblespeed and smoothness from bermuda-grass greens, surface rolling is becominga more common practice. Both walk-behind and larger rolling units areutilized, offering a few more inches onthe Stimpmeter. Due to the additional

manpower required, though, thisoperation is generally reserved forspecial events or tournaments.

Conclusion

In no way should this article be inter-preted as condoning very fast speeds forall courses with bermudagrass greens.Speed kills! However, television cover-age of professional tournaments hasconvinced golfers that fast greens arethe best, and golf course superinten-dents have to learn to manage thesedemands within reason. In reality, themain objective should be a smooth, trueball roll and a consistent putting speedthrough the course.

There is no denying that bentgrassgreens are probably better suited formeeting present-day player demandsfor green conditioning. However, bent-grass greens cannot be maintained insome areas of the country without theclear risk of failure, environmentalimpacts, and increased cost. In keepingwith sound agronomic practices, ber-mudagrass is the best-adapted turf forgreens in the warm, humid regions ofthe country. With the proper resourcesand good management, bermudagrasscan produce outstanding playing sur-faces for regular play and for cham-pionship events as well.

A tennis court roller can help produce those last few extra inches in putting speed.