Williams Products, Inc.williamsproducts.net/s/Williams Products Catalog.pdf · Williams Products,...

Click here to load reader

Transcript of Williams Products, Inc.williamsproducts.net/s/Williams Products Catalog.pdf · Williams Products,...

Williams Products, Inc. 1750 Maplelawn Drive

Troy, MI 48084 Phone: 248-643-6400

Fax: 248-643-7117

A Worldwide supplier of Construction Seal and Gasket Material

The Williams Product line, Everlastic®, covers a wide variety of "Job Tested" products specifically designed and manufactured to fulfill a required function. They are widely specified by the

Architect/Engineer and used by the concerned contractor. Williams Products are listed with the Construction Specification Institute.

Comprehensive stocks of all items are carried at all times. Assuring you, in most cases, shipment within 24 hours of the receipt of an order.

This catalogue offers technical information for our products and addresses applications based on the needs of the architect. Please feel free to contact us for any additional information you may need,

catalogues, copies of technical data or material samples.

To the best of our knowledge this published information is accurate, however, to determine suitability of material/product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any

loss or damage resulting from inappropriate usage.

Contents

1. DIVISION 3 CONCRETE A. Bearing Pads

a. AASHTO Grade Neoprene ‐ Conforms to AASHTO requirements, 2500 PSI tensile strength b. 1200 Series ‐ Commercial Grade Dense Neoprene c. Bear‐Pad 200 ‐ Cross Laminated with oriented fibers d. Fab‐Pad 300 ‐ Multiple layers of high quality, cotton polyester duck fabric, MIL C 882 E e. Everlastic® Post Pads ‐ For isolation, vibration dampening and sealing under mounting posts or base plate f. Everlastic® Iso/Vib 2300 Series Foam ‐ Vibration and shock absorbency, resists creep under load

B. Rubber Waterstop a. SBR/Neoprene Waterstop b. Waterstop Fittings c. Waterstop Installation d. Waterstop Splicing Instructions e. Williams #37 A Adhesive

C. Column Isolation a. Column Boxboard ‐ Coated Corrugated b. Econ‐O‐Foam ‐ CCPE c. EJ‐2000 ‐ XL Polyolifin

D. Rubber "J" Gate Seals a. Hi Tensile Neoprene Williams Compound # 1025. Also available in other rubber compounds to meet custom specifications

E. Expansion Joints a. Econ‐O‐Foam ‐ CCPE b. EJ‐2000 ‐ XL Polyolefin c. 1040 to 1080 Series ‐ Closed Cell Neoprene d. NN‐1 ‐ Soft, Expanded, Closed Cell, Sponge Rubber e. NN‐5‐2C5 ‐ Closed Cell Expanded Neoprene Foam f. 1056 Joint Filler g. NN‐1, NN‐3, NN‐5 h. Everlastic® 1752 Rebonded Rubber Type IV i. 1300 Series ‐ Concrete Gray Sponge Rubber j. 1400 Series ‐ Open Cell Neoprene (Vibration Isolation) k. Everlastic® 1752 Highway Modified ‐ Isomeric Polyolefin Resilient Flexible Gray Foam l. Everlastic® Expand‐O‐Foam – 900 ‐ Closed Cell Polyethylene Foam, ASTM D‐3575 & ASTM D‐1056 (Modified) m. Vinyl “U” 1000 Series n. Concrete Panel Seals

2. DIVISION 4 MASONRY A. Masonry Control Joints

a. Masonry Control Joints : Slot Seal Standard, Wide Flange, Block Seal ‐ Hard rubber cross shape, shear keys in sash blocks, Weathertite‐R, Everlastic® M‐CJ ‐ Compressible Filler to seal Michigan Control Joints

B. CMU Expansion Joint (Horizontal) ‐ Fill gap at top of wall a. Expand‐O‐Foam b. EVA 200G ‐ Air Seal Gasket c. 1056 Joint Filler d. NN‐1 1040 Series

C. Cavity Wall Baffle a. Everlastic® Cavity Wall Baffle using EVA 200 ‐ Compartmentalization of the cavity wall system will equalize the negative pressure within the

wall cavity to the exterior positive pressure more quickly and efficiently when using PVC brick vents, cell vents or open head joints b. Williams‐Goodco Brick Vents ‐ Ventilates and equalizes pressure within cavity. Sizes, 2 ‐ 1/4", 2 ‐ 3/4", 3 ‐ 5/8". Colors, Standard Gray. We can

dye to match mortar color c. Williams‐Goodco CMU Vents

D. Closures: Close off gap between wall and deck (flat or fluted) a. Metal Deck Closure b. Partition Closure c. Typical Partition/Deck Closure Installation Details

E. Fire Rated a. Dyna Shield Ceramic Fiber Joint Filler

F. Fire Classified a. Everlastic® Fire Classified Closures 1715 ‐ Fire Classified Closure manufactured of Compressible Open Cell Sponge. Used for Partition

closure or plug for Metal Decking

G. Anchor Gaskets a. Self‐stick, CC Neoprene ‐ Thermal and moisture break behind anchors

H. Brick Expansion Joints a. Neo Seal IV ‐ Neoprene profile allows maximum movement b. Column Boxboard c. Econ‐O‐Foam ‐ Filler is inherent bond breaker for most sealants

I. Adhesives a. Williams #37 A Contact Adhesive b. Williams #37 B c. Williams #37 C – Low VOC

3. DIVISION 7 THERMAL AND MOISTURE PROTECTION CUSTOM DESIGNS A. 2nd Seal B. Wide Joint Seal C. Closure / Partition Wall D. Closure / Metal Deck Flutes E. Closure / Everlastic® 1715 Fire Classified F. Backer Rod and Joint Fillers

a. Neoprene Backer Rods b. Standard Closed Cell Polyethylene Backer Rod (CCPE) c. Hot Rod d. Tundra Foam e. Soft Type

G. Roof Expansion Joint: NN‐1 1040 Series H. Everlastic® Cavity Wall Baffle using EVA 200 I. EVA 400 J. Dust Shield 1350 Series

4. SEALANTS A. Sealant Color Chart

DIVISION 3 CONCRETE

Bearing Pads

Rubber Waterstop Rubber “J” Gate Seal

Expansion Joints

Bearing Pads

AASHTO Grade Neoprene 1200 Series Commercial Grade

Bear-Pad BP-200 Fab-Pad FP-300

Post Pads Iso/Vib 2300 Series

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 REV 1/02 www.williamsproducts.net

TECH DATA Description: Bridge Bearing contain only virgin crystallization resistance Polychloroprene (Neoprene) raw polymer Use: As economical efficient bearing plates for pre-cast, pre-stressed concrete or steel beams in bridges and buildings. Neoprene Pads permit a smooth and uniform transfer of load from the beam to the substructure, allow beam rotation at the bearing due to deflection of the beam under load. They further allow lateral and longitudinal movement of the beam caused by thermal forces. Neoprene Pads have no moveable parts and thermal expansion and contraction are absorbed by the pad’s ability to give and take in shear. There is no sliding between pad and beam or between pad and abutment.

Material Property

ASTM Standard

Test Requirements

Polychoroprene 50 Duro 60 Duro 70 Duro Units

Physical Properties

D2240 Hardness Min Tensile Strength Min Ultimate Elongation

50 ±5 2250* 400

60 ±5 2250* 350

70 ±5 2250* 300

ShoreA Pt psi (Mpa) %

Heat Resistence

D573 at spec. temp

Specified Temp of Test Aging Time Max Change in Duro Hardness Max Change in Tensile Strength Max Change in Ultimate Elongation

212 (100) 70 +15 -15 -40

212 (100) 70 +15 -15 -40

212 (100) 70 +15 -15 -40

°F (°C) Hours *Shore Pt % %

Compression Set

D395 Method B at Spec. Temp

Specified Temp of Test Degrees Max Permissible Test (after 22 Hours)

212 (100) 35

212 (100) 35

212 (100) 35

°F (°C) %

Bar Resistance D624 Min Pounds Per Inch (Die C) 180 180 180 Pounds/In

Brittleness Ozone Resistance

D2137 D1149

Low Temp Brittleness at -40°F (-40°C) Partial Presser of Ozone During Test Duration of Test Tested at 20% Strain 100°F ±2°F (37.7°C ±1°C) Mounting Pressure

Pass 50 100 No Cracks

Pass 50 100 No Cracks

Pass 50 100 No Cracks

Mpa Hours

Shear Modulous

At 23°C .62-.90 89.90-135

.90-1.40 135-203

1.40-2.05 203-297.25

Mpa PSI

Note: Williams Bearing Pads conforms to grade 3 as follows: LOW TEMPERATURE BRITTLENESS: D-746, procedure B, @ -40°F, resulting in no failures, 50, 60, and 70 ±5% Shore A Durometer. INSTANTANEOUS THERMAL STIFFENING: D-1043, grade 3, tested @ -40°F. LOW TEMPERATURE CRYSTALLIZATION: Grade 3, 14 days, @ -15°F. Stiffness at test temperature shall not exceed 4 times the stiffness measured at 73°F. * Higher tensile strength available upon request

WILLIAMS AASHTO GRADE NEOPRENE BEARING PADS

SPECIFICATION M251-06

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Dense Rubber • Color: Black

• Meets ASTM-D 2000 Available Sizes • Cut Parts, Rolls & Sheets - CUT TO SIZE • Cut to Thickness, Width & Length • Sheet & Roll Sizes vary – call for specific limits • Available in variable hardness Applications • Bearing Pads • Vibration Isolation Pads • Rustification & Chamfer Strips • Setting Blocks • Spacers

Typical Physical Properties

Property Test Method Typical Values Durometer Hardness ASTM D - 2240 60 ± 5, Shore A Ultimate Tensile ASTM D - 412 1000 psi., min. Ultimate Elongation ASTM D - 412 300% min. Ozone Resistance (20% Strain 100 hours @ 104° F)

ASTM D - 1149 No Cracks

Low Temperature Flexibility (5 hours @ -40°F)

ASTM D - 2137 Pass

Aged in Air (70 hrs @ 158°F) Change in Hardness Change in Tensile Change in Elongation

ASTM D – 573

± 15 pts. max. ± 30% max. -50% max. change (not less than 300%)

Compression Set (22 hrs. @ 158° F)

ASTM D -395 Method B 20% max.

Williams Everlastic® 1200 Series

Commercial Grade Dense Neoprene

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Durable Rubber Compound integrated with cross-ply high strength synthetic fibers, resulting in an

R.O.F Integral Bearing Pad with excellent physical properties and weather resistance. Features • Durable dense rubber with excellent compressive strength, hardness, tear resistance and cold weather

flexibility. “Green Product” molded from masticated rubber using discarded tires. Available Sizes • Thickness from ¼” to 1” • Width and Length up to 48” • Available in cut parts and profiles Applications • Bearing Pads, Shims, Bumpers, Vibration Isolation

Typical Physical Properties Property Test Method Typical Values

Hardness (Shore A) ASTM D - 2240 75 ± 5 duro Tensile Strength – Mpa (psi) Min – With Grain Min – Cross Grain

ASTM D - 412, Die C 7.0 (1015) 3.0 (435)

Compression Maximum Strength Initial Cracking Strain

10,000 psi 40%

Elongation - % Min – With Grain Min – Cross Grain

ASTM D - 412, Die C 15 45

Tear Strength – kN/m (pi) Min –With Grain Min – Cross Grain

ASTM D - 624, Die B 35 (200) 70 (400)

Heat Aging change in tensile - % Max change in elongation - % Max change in hardness – Shore A

ASTM D – 573 After Exposure for 70 Hours @ 70ºC

+/- 25 +/- 25 +/- 10

Oil Swell (increase in volume) ASTM D - 471 120% max. Ozone Resistance kN/m (pi) Min Cross-Grain Tear Strength

ASTM D - 518 After Exposure to 80pphm for 50 hours @ 38ºC

53 (300)

Low Temperature Brittleness Not Brittle at -40ºC

ASTM D - 2137 Pass

Everlastic® Bear Pad BP - 200

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 REV 1/02 www.williamsproducts.net

TECH DATA Description • Bearing pads constructed of multiple layers of cotton duck fabric saturated with Neoprene. Specifications • AASHTO 18.10.2

• MIL - C - 882-E Features • Outstanding Compression Strength. Superior resistance to Oil, Ozone, Sunlight, Heat, Water,

Steam and Fungus. Applications • Bearing Pads under extreme loads to reduce shock and vibration and to disperse the load.

Typical Physical Properties

Property Typical Values

Density 67 lbs./cu.ft min. Hardness (Shore A) 90 ± 5 Plies per inch 64

Typical Load Deflection - ½” Thick (32 ply)

50 PSI - 0.005 400 PSI - 0.020 800 PSI - 0.032 1400 PSI - 0.047 100 PSI - 0.008 500 PSI - 0.023 900 PSI - 0.034 1600 PSI - 0.052 200 PSI - 0.013 600 PSI - 0.026 1000 PSI - 0.037 1800 PSI - 0.057 300 PSI - 0.017 700 PSI - 0.029 1200 PSI - 0.042 2000 PSI - 0.062

Typical Permanent Set

Compressive Stress Permanent Set %

500 0.85 % 1000 1.6 % 3000 3.5 % 5000 5.1 %

10,000 8.9 %

Everlastic® Fab-Pad FP - 300

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Blvd. • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Applications: For isolation, vibration dampening, and sealing under mounting posts or base. Available in the following load bearing pads: Bear Pad BP-200 Masticated Rubber with synthetic fabric (green product)

Commercial Grade Dense Neoprene ASTM D-2000, BC 610

AASHTO Grade Dense Neoprene 50. 60, and 70 Durometer M-251-06

Everlastic Fab Pad AASHTO 18.10.2, MIL-C-882-E

Also available in Closed Cell Foam

Williams Everlastic® Post Pads

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Blvd. • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description: Everlsatic Iso/Vib (isolation vibration) 2300 Series is a closed cell polyethylene foam that is a flexible, lightweight, durable, solid extruded plank. Ideally suited as a shock absorbing, vibration dampening, isolating and cushioning material. Features: Offers excellent strength, vibration, and shock absorbency, resistance to creep under load, and water resistance characteristics. Everlastic 2300 Series is impervious to most chemicals, non-abrasive, and preforms consistently over a wide range of temperatures. Uses: Where equipment foundations require vibration containment, foundations for press pits, or any concrete slab that requires isolation or vibration dampening (see detail below). Color: Black Available Sizes: • Standard thickness ½” to 4” thick, 48” wide, and 108” long. • Available with self-stick, pressure sensitive adhesive (PSA) on one or two sides. Typical Physical Properties Unit Test Method Typical Results Density ln/ft3 ASTM D-3575 2 to 2.4 Tear Strength lb/in ASTM D-3575 13 Compression Creep psi ASTM D-3575 <5% @ 3.0 Compression Strength 25% Deflection psi ASTM D-3575 10.5 50% deflection psi ASTM D-3575 19

Compression Set (loaded @ 1.5 psi 1000hrs @ 50%)

% ASTM D-3575 18 Tensile Strength (@1/2" thickness) psi ASTM D-3575 42 Water Absorption (lbs SF of cut surface) ASTM D-1056 <0.2 Thermal Conductivity (BTU-in/hr/sf°F) at 75°F ASTM C518 0.4 - 0.18 Thermal Stability (change after 24hrs at 165°F) % ASTM D-3575 <5

Everlastic Iso/Vib 2300 Series Foam

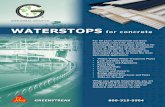

Rubber Waterstop

SBR/Neoprene Waterstop

Waterstop Fittings Waterstop Installation

Waterstop Splicing Instructions 37 “A” Adhesive

TECH DATA Everlastic® SBR /Neoprene Rubber Waterstop

3/8" 1. PRODUCT NAME: 3/4" Williams SBR Hi-Tensile Rubber Waterstop,

6" Williams Neoprene Hi-Tensile Waterstop.

3/8" 2. MANUFACTURER: 3/4" Williams Products, Inc.

9" 1750 Maplelawn Troy, Mi. 48084

3/8" ph. (248) 643-64003/4" Toll Free (800) 521-9594

12" Fax. (248) 643-7117

Centerbulb (CB) 3. PRODUCT DESCRIPTION:1-1/8" O.D. 3/4" I.D. 1-1/2" O.D. 3/4" I.D. Basic Use: " A Waterstop is usually a section of flexible waterproof

1/4" 3/8" material placed at any joint in concrete to prevent the passage of water".5/8" Williams Products, Inc. has been a pioneer supplier to constructors

1" with the Williams Everlastic® Waterstop System since 1954. 6" 9" Joints in concrete structure, on one side of which is subject to

hydrostatic load, are generally Williams Spec. Williams provided with waterstops bridging2010 Hi-Tensile Specification joints and embedded in concrete

(SBR) 1025 on either side. In concrete joints Styrene Hi-Tensile where expansion and contraction

Physical Property ASTM test Method Butadiene Neoprene cause the joints to close and open,Tensile Strength, min (PSI) ASTM D412 2500* 2500* the waterstop must be designed to Ultimate Elongation, Min (%) ASTM D412 450 450 accommodate itself to movement.Hardness, Shore A durometer ASTM D2240 65 +/- 5% 65 +/- 5% The primary reason for specifyingTensile Stress min PSI to Rubber Waterstops rather thanproduce 300% elongation ASTM D412 1150 1150 metal or PVC is their superior per-Water Absorption, max % by formance in withstanding shear weight after immersion 7 days ASTM D471 5 5 movements and to resisting hydrostaticat 73.4 degrees F +/- 2 F pressure. Compression Set, Max % after ASTM D395 Rubber Waterstops will elongate22 hours at 158 digress F Method B 30 30 over four times original size Tensile Strength after aging, Min (ASTM D 412) and will continue% of original after 7 days in air returning to near original shape afterat 158 degrees +/- 2 degrees F, ASTM D572 80 80 repeated movement. They have veryand 300 PSI low compression set and perform Specific Gravity ASTM D1817 1.17 +/- .03 1.17 +/- .03 well at low temperatures.Ozone cracking resistance after The Williams System features20% elongation for 7 days 0.5 p/m ASTM D1149 no cracks no cracks sleeve type fittings that provide fastat 38 degrees C (neoprene 3 p/m) positive splicing and precise Water-Tensile set, % max after 200% stop alignment. Fittings are manufac-elongation for 10 min at 23 ASTM D412 5 5 tured form the same elastomers/poly-degrees +/- 1 degree C mers as the waterstop.* 3000 PSI from actual part / Test Sheets.

TYPICAL INSTALLATIONS INCLUDE: Sewer plants, water filtration plants, aqueducts, reservoirs, aqueducts, reservoirs, locks, tanks, channels, swimming pools, culvertstunnels, underpasses, Bridge decks and abutments, roofs, dams, foundations, mine shafts, retaining walls and any concrete structurerequiring watertight joints.LIMITATIONS: The Dumbell Waterstop is adequate for all vertical and horizontal stress across the joint in the same plane as the waterstop. 6"Dumbell Waterstop is adequate for all vertical and horizontal construction joints. 6" Dumbell is also used on expansion joints up to 1". 9" and 12" Dumbell is used in expansion joints of 1" to 2". 6" Centerbulb is used in expansion joints up to 1" where shear movement is expected and 9" Centerbulb is used in expansion joints up to 2" where shear movement is expected. The Centerbulb is hollow so it can deform to absorb shear movements. Split Waterstops are used for short straight runs only. When Split Waterstops are spread against forms, connecting unionscannot be used.

TECH DATA Everlastic® Waterstop Fittings

UNION VERTICAL ELL VERTICAL TEE HORIZONTAL CROSS

FLAT ELL HORIZONTAL TEE REDUCER

FITTINGS SELECTION TABLE STANDARD STOCK ITEMS

SIZE Type 6" DB 9" DB 12" DB 6" CB 9" CB 12" CB Union 6DB-U 9DB-U 12DB-U 6CB-U 9CB-U 12CB-U Vertical Ell 6DB-VE 9DB-VE 12DB-VE 6CB-VE 9CB-VE 12CB-VE Vertical Tee 6DB-VT 9DB-VT 12DB-VT 6CB-VT 9CB-VT 12CB-VT Flat Ell 6DB-FE 9DB-FE 12DB-FE 6CB-FE 9CB-FE 12CB-FE Flat Tee 6DB-FT 9DB-FT 12DB-FT 6CB-FT 9CB-FT 12CB-FT Flat Cross 6DB-FC 9DB-FC 12DB-FC 6CB-FC 9CB-FC 12CB-FC

Williams Everlastic® Waterstop Fittings are a sleeve type design for easy and efficientinstallation. The illustrations shown are commonly used fittings for common waterstop installation. For unusual waterstop transitions, custom fittings are available, contact William Products for availability and price. The fittings are glued to waterstop for waterproof connections using the Williams Everlastic® No. 37 A Adhesive (see installation instructions).All fittings are available for dumbell and centerbulb waterstops and in SBR or Neoprene compounds.

™ To the best of our knowledge this published information is accurate, however, to determine suitability of material/product WILLIAMS for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss or damage PRODUCTS, INC. resulting from inappropriate usage.

WILLIAMS PRODUCTS, INC. - 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - FAX (248) 643-7117

page 3-07 www.williamsproducts.net

TECH DATA WATERSTOP INSTALLATION PAGE 1

Sealing Expansion Joints in Water Reservoir Wall and Base Slabs with Center bulb Waterstop. Pre-Sealing Plane of Sealing Joint Between two

Weakness in Foundation Wall Floor Slab Members with Dumbell Waterstop. with Dumbell Waterstop.

PLACEMENT OF WATESTOP:

Waterstop shall be cut square, then joined with Williams Efficiency Fittings and Williams No. 37 Adhesive per instructions.

Installation of Waterstop shown involves split forms. The Waterstop is placed in position that one bulb will be embedded in each of two adjoining slabs or walls.The Waterstop shall be held firmly in place with a block or other suitable

Sealing Joint between Roof Slab arrangements on the outside of the split form (away from the concrete which is toand wall of Digester in a Sewage be placed). Treatment Plant with DumbellWaterstop. After the concrete has setup, the split form and block may be removed. When

the adjoining placement is made, care should be taken to support the water stop.

Waterstops are not ridged enough to resist the weight of concrete being placed and must be supported to maintain the proper position. It is easy to supply necessary support by using bulb rings and wire to fasten the water stopto steel rerod. After the water stop is positioned in a split form, wooden blocks should be nailed to one side of the form, as shown below. End bulb rings should be clamped into the bulb of the water stop as shown below. Rings should be embedded in the bulb only to avoid puncturing the web. Rings and tie wires should be place12 to 18 inches apart.

wood split form steel re rod or re barend bulb ring pliers

waterstopend bulb ring

back block wire ties

To the best of our knowledge this published information is accurate, however, to determine suitability of material/product ™ for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss or damage WILLIAMS resulting from inappropriate usage. PRODUCTS, INC.

WILLIAMS PRODUCTS, INC. - 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - FAX (248) 643-7117

page 4-07 www.williamsproducts.net

TECH DATA WATERSTOP INSTALLATION PAGE 2

tie wiresend bulb rings

DO'S AND DON'TS FOR INSTALLATION

DO: Sweep all horizontal joints prior to waterstop placement to insure that foreign material

doesn't interfere with the direct contact between waterstop and concrete.

steel re rod DO: Systematically and thoroughly vibrate concrete around waterstop to avoid voids in concrete and insure complete contact with the waterstop.

DO: Hold waterstop in place to prevent VERTICAL WATERSTOP SET UP misalignment during placement of

concrete.

DO: Take care during second placement to insure that the waterstop is not deformed by the impact of concrete placement.

DO NOT: Drive nails through waterstop.

DO NOT: Embed Center Bulb in concrete. It must be centered in the expansion joint. (see page one Expansion Joints)

FIRST PLACEMENT DO NOT: Embed Bulb Rings into the web of the waterstop when tying to steel rerod.

SECOND PLACEMENT

To the best of our knowledge this published information is accurate, however, to determine suitability of material/product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss or damage

™ resulting from inappropriate usage. WILLIAMS

PRODUCTS, INC.

WILLIAMS PRODUCTS, INC. - 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - FAX (248) 643-7117

page 5-07 www.williamsproducts.net

TECH DATA Waterstop Splicing Instructions

MATERIALS REQUIRED Union

Square Stirring SticksSharp razor knife Paint brushesSandpaper or wire brush Blocks of woodSolvent "C" clamps

"C" clamps WaterstopWoodBlock

Waterstop

"C" ClampsWaterstop and Wood

BlocksUnion

Waterstop - Union Clamping Detail

Horizontal TeeDIRECTIONS Horizontal Tee - Waterstop Clamping Detail 1. Cutting Waterstop: Determine proper length. Use square to mark 90° cutting line. Cut waterstop with sharp razor knife.

2. Waterstop and fitting surface preparation: Sand with medium sand paper or wire brush surfaces which will be glued, to remove mold release of other contaminants and to increase surface area. Remove sandy dust by wiping surfaces with MEK (Methyl ethyl ketone) or other suitable solvent.

3. Adhesive Application: Stir No. 37A adhesive well before using. Brush inside fitting and allow to dry (usually about 5 minutes). Brush No. 37A adhesive on water stop then insert into fitting using wet adhesive on waterstop as a lubricant. When inserting waterstop be sure square cut end of waterstop makes full contact with base of fitting sleeve (THIS IS IMPORTANT TO INSURE MAXIMUM ADHESION).

4. Adhesive drying and curing: To obtain maximum adhesion and prevent movement in the splice joint as work progresses, use wood blocks and "C" clamps to hold firmly in place. Drying time will vary with temperature and humidity. Pressure can usually be removed and joint gently handled within 30 minutes at temperature of 65°F or more. Normally 60% to 70% of optimum strength will be obtained within 24 hours. As the temperature goes down, the adhesive becomes progressively higher in viscosity. This is completely reversible with stirring and increasing temperature. At low Temperatures, the drying time and buildup of strength are greatly extended. Depending on temperature, optimum strength may take anywhere from three days to four weeks.

To the best of our knowledge this published information is accurate, however, to determine suitability of material/product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss or damage

WILLIAMS resulting from inappropriate usage. PRODUCTS, INC.

WILLIAMS PRODUCTS, INC. - 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - FAX (248) 643-7117

page 6-07 www.williamsproducts.net

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 REV 1/05 www.williamsproducts.net

TECH DATA Description A high strength, synthetic based adhesive Cream in color Well suited for bonding cellular rubber to its self as well as vinyl, concrete, metal, and wood. Material Specifications ASTM E 84 Packaging Quart and gallon containers. Preparation of Stock Surfaces to be bonded should be free of excess dust, grease, moisture and other contaminants. Metal surfaces should be degreased with a suitable solvent. Application Instructions Thoroughly clean both surfaces to be bonded with recommended cleaner. Surfaces must be free of moisture to insure proper adhesion. Apply one thin, uniform coat of adhesive to both surfaces to be bonded. Allow the adhesive to become tacky to touch. Join with sufficient pressure to insure contact. Best used at room temperature 72°F. Approximate optimum service temperature range 40°F to 90°F. The adhesive should be used directly from storage. Cleaner and Thinner: Thin with Toulene Clean up can be done with Toulene or MEK Precautionary Data: This product is extremely flammable. Vapors may cause flash fires. Vapors may ignite explosively under certain conditions. Keep away from fire, sparks, and sources of heat. Open all doors and windows. Extinguish all flames and pilot lights. Turn off electric motors, stoves, or heaters, or any source of ignition during use and until all vapors have been dispersed. Do not smoke. Close containers after use. Review MSDS Sheet for handling before use. FLASH POINT: Less than 0°F AVOID PROLONGED BREATHING OF VAPORS AVOID PROLONGED AND REPEATED CONTACT WITH SKIN KEEP OUT OF REACH OF CHILDREN STORE AT TEMPERATURES OF 90°F OR BELOW FOR MAXIMUM SHELF LIFE USE WITH ADEQUATE VENTILATION INFORMATION PHONE Out of State: 800-521-9594 In State: 248-643-6400 Chemtel: 1-800-255-3924

Williams Everlastic® #37 “A” Adhesive

Column Isolation

Column Boxboard

Econ-O-Foam EJ-2000

TECH DATA Everlastic® Column Boxboard

COLUMN BOXBOARD IS CONSTRUCTED FROM 100% RECYCLED PAPER.

COLUMN BOXBOARD

column

5002-3 5008-3 5004-3

block

1/4" 1/2" 1/4"

ROLLS SHEETS brick 48" X 250' 48" X 48"

COLUMN BOXBOARD Neo Seal (Nominal sizes)

COLUMN BOXBOARD

The Column Boxboard material is used as a isolation material between the structural column and the masonry wall construction. This separation is necessary to prevent the masonry from coming in contact with the column during loading and prevent mortar from being within the same joint. Thisproduct is a cellulose material coated on the weathering side and can be factory scored or scored in the field for bending or breaking to fit any column shape. The nominal thickness of the roll product 1/4"while the sheet product is available at either 1/4" or 1/2" nominal thickness and each being 48" square.

INSTALLATION:

The Column Boxboard material is installed prior to the erection of the masonry wall to assure isolation between the structural column and the masonry wall.

To the best of our knowledge this published information is accurate, however, to determine suitability of material/ ™ product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss WILLIAMS or damage resulting from inappropriate usage. PRODUCTS, INC.

WILLIAMS PRODUCTS, INC. 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - TOLL FREE (800) 521-9594 - FAX (248) 643-7117

www.williamsproducts.net

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description

♦ Expanded, closed cell, plank, polyethylene foam. Economical, lightweight, flexible, compressible, resilient, non-absorbent, inherent bond breaker.

Typical Properties Test Procedure Results

Properties and Characteristics

Density (PCF) ASTM D 3575 Test C 1.3-1.5 nominal

1. Compressive Strengths: Econ-o-Foam is available in a variety of compressive strengths, and can supports a wide range of loads. 2. Weights: Econ-O-Foam is available in densities ranging from 1.5 to 2.2 lbs/cu ft 3. Chemical Resistance: Econ-O-Foam offers excellant stability when exposed to most acides, hydrocarbons, chlorinated solvents, petroleum products, apints, warnishes, thinners, and alcohols 4. Tempurature Range: Econ-O-Foam polyethylene foam has been used successfully in tempuratures ranging from -40°F tp 160°F without significant effect on many of its properties. 5. Water Absorption: Econ-O-Foam polyethylene is virtually impermeable. The amount of water absorbed is negligible even when used in flotation applications. Econ-O-Foam also offers high resistance to transmission of water vapors, with ratings of less than .1 per inch. It contains no water soluble sonstituents. 6. Availability: Econ-O-Foam is available in cut strips. pads, and trimmed or mill run sheets. Rolls are stocked in 1/4", 3/8", and 1/2" thicknesses by 48" wide and 50'0" long.

Cell Size (MM) ASTM D 3576 Dow Modified 1.3

Compression Strength ASTM D 7576 Test B 5% 10% 25% 50%

3.5 5 8 15

Compression Creep ASTM D 3575 Test BB Loaded @ specified PSI static load for 1000hrs 75°F 160°F

5 @ 1.5 psi 5 @ .25 psi

Tensile Strength (psi) ASTM D 3575 Test E 50 Tensile Elongation (%)

ASTM D 3575 Test E 60

Tear Stength (lb/in) ASTM D 3575 Test D 15 Flexural Modulous (psi)

ASTM D 790 300

Bouyancy (PFC) ASTM D 3575 Test AA 55-60

Thermal Conductivity (B1U-in/hr ft °

ASTM D 3575 Test EE Method B 0.4

Thermal Stability (% shrinkage)

ASTM D 3575 Test F Conditioned @ specified temp. with no load 24hrs 48hrs

-1.0 @ 165°F -2.4 @ 165°F

Everlastic® Econ-O-Foam

1390 Series

TECH DATA Everlastic® EJ - 2000

Everlastic® EJ - 2000 with PSA

Scoredcolumn Tear - Tab

block

Concrete brick Slab

Everlastic® EJ-2000

Neo- Seal IVDescription • Everlastic® EJ-2000 is a cross linked closed cell foam. • Gray in color.

Applications • Expansion joint filler with hot or cold applied sealants, pipe and thermal wrap, acoustica partition closures, corrugated deck closures, column isolation wrap, and other uses.

Available Sizes • Standard thickness 3/8" and 1/2". Other sizes skived or laminated. • Standard rolls are 60" x 50'-0". • Available multi score, standard score and tear tab to allow sealant reservoir. • Available with self-stick, pressure sensitive adhesive (PSA) on one or two sides. • Die cut parts Available.

Typical Physical Properties Test Method Typical ResultsDensity: lb/ft³ ASTM D- 3575 2Tear resistance pi ASTM D- 3575 10Compression Deflection 10% defection ASTM D- 3575 2.6 psi

25% defection 5.6 psi40% defection 9.2 psi50% defection 13.5 psi

Compression Set (22 hrs @50%) ASTM D- 3575 99%Elongation % ASTM D- 3575 135Tensile Strength psi ASTM D- 3575 37 Water Absorption (lb/sf of cut surface) % ASTM D-1056 < 0.07K Factor ASTM C -177 0.25

To the best of our knowledge this published information is accurate, however, to determine suitability of material/ ™ product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss WILLIAMS or damage resulting from inappropriate usage. PRODUCTS, INC.

WILLIAMS PRODUCTS, INC. 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - TOLL FREE (800) 521-9594 - FAX (248) 643-7117

www.williamsproducts.netpage 25-07

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Material Specifications

• Hi Tensile Neoprene Williams Compound # 1025, also available in other rubber compounds Tolerances:

• Width +/- 3/16” • Diameter of bulb +/- 1/16” • Length: 20’0”

Available Sizes: • 1-3/4” dia. Solid bulb or hollow bulb 4” wide • For custom configurations contact Williams Products

Uses: • Low head gate where conditions are favorable to using the water pressure to aid in sealing • Flat, vertical lift gates, bulkheads, stop locks

Typical Physical Properties

Property Typical Values Tensile Strength 2250 min. PSI Ultimate Elongation 400% min. Shore A Durometer 60/70 Specific Gravity 1.4 Compression Set 30% max. Tensile Strength after Oxygen Bomb Aging 80% min. Ozone Resistance Good All “J” Seals set forth in these specifications, and shown on the drawings, shall be of an extruded neoprene rubber with a SOLID or HOLLOW BULB, and typically 4” wide, as manufactured by Williams Products, Inc. For custom profiles, and other rubber compounds of “J” Seals, contact Williams Products.

Everlastic® Rubber “J” (Gate Seals)

1-3/4” O.D. ¾” I.D.

9/16”

Standard Rubber “J” (Gate Seal)

4”

Expansion Joints

Econ-O-Foam EJ-2000

1040 to 1080 Series NN-1 1040 Series

NN-5 2C5 E1 1056 Joint Filler

NN-1/NN-3/NN-5 1752 Rebonded Rubber Type IV

1300 Series Concrete Gray 1400 Series

1752 Highway Modified Expand-O-Foam

Vinyl “U” 1000 Series Panel Seals

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description

♦ Expanded, closed cell, plank, polyethylene foam. Economical, lightweight, flexible, compressible, resilient, non-absorbent, inherent bond breaker.

Typical Properties Test Procedure Results

Properties and Characteristics

Density (PCF) ASTM D 3575 Test C 1.3-1.5 nominal

1. Compressive Strengths: Econ-o-Foam is available in a variety of compressive strengths, and can supports a wide range of loads. 2. Weights: Econ-O-Foam is available in densities ranging from 1.5 to 2.2 lbs/cu ft 3. Chemical Resistance: Econ-O-Foam offers excellant stability when exposed to most acides, hydrocarbons, chlorinated solvents, petroleum products, apints, warnishes, thinners, and alcohols 4. Tempurature Range: Econ-O-Foam polyethylene foam has been used successfully in tempuratures ranging from -40°F tp 160°F without significant effect on many of its properties. 5. Water Absorption: Econ-O-Foam polyethylene is virtually impermeable. The amount of water absorbed is negligible even when used in flotation applications. Econ-O-Foam also offers high resistance to transmission of water vapors, with ratings of less than .1 per inch. It contains no water soluble sonstituents. 6. Availability: Econ-O-Foam is available in cut strips. pads, and trimmed or mill run sheets. Rolls are stocked in 1/4", 3/8", and 1/2" thicknesses by 48" wide and 50'0" long.

Cell Size (MM) ASTM D 3576 Dow Modified 1.3

Compression Strength ASTM D 7576 Test B 5% 10% 25% 50%

3.5 5 8 15

Compression Creep ASTM D 3575 Test BB Loaded @ specified PSI static load for 1000hrs 75°F 160°F

5 @ 1.5 psi 5 @ .25 psi

Tensile Strength (psi) ASTM D 3575 Test E 50 Tensile Elongation (%)

ASTM D 3575 Test E 60

Tear Stength (lb/in) ASTM D 3575 Test D 15 Flexural Modulous (psi)

ASTM D 790 300

Bouyancy (PFC) ASTM D 3575 Test AA 55-60

Thermal Conductivity (B1U-in/hr ft °

ASTM D 3575 Test EE Method B 0.4

Thermal Stability (% shrinkage)

ASTM D 3575 Test F Conditioned @ specified temp. with no load 24hrs 48hrs

-1.0 @ 165°F -2.4 @ 165°F

Everlastic® Econ-O-Foam

1390 Series

TECH DATA Everlastic® EJ - 2000

Everlastic® EJ - 2000 with PSA

Scoredcolumn Tear - Tab

block

Concrete brick Slab

Everlastic® EJ-2000

Neo- Seal IVDescription • Everlastic® EJ-2000 is a cross linked closed cell foam. • Gray in color.

Applications • Expansion joint filler with hot or cold applied sealants, pipe and thermal wrap, acoustica partition closures, corrugated deck closures, column isolation wrap, and other uses.

Available Sizes • Standard thickness 3/8" and 1/2". Other sizes skived or laminated. • Standard rolls are 60" x 50'-0". • Available multi score, standard score and tear tab to allow sealant reservoir. • Available with self-stick, pressure sensitive adhesive (PSA) on one or two sides. • Die cut parts Available.

Typical Physical Properties Test Method Typical ResultsDensity: lb/ft³ ASTM D- 3575 2Tear resistance pi ASTM D- 3575 10Compression Deflection 10% defection ASTM D- 3575 2.6 psi

25% defection 5.6 psi40% defection 9.2 psi50% defection 13.5 psi

Compression Set (22 hrs @50%) ASTM D- 3575 99%Elongation % ASTM D- 3575 135Tensile Strength psi ASTM D- 3575 37 Water Absorption (lb/sf of cut surface) % ASTM D-1056 < 0.07K Factor ASTM C -177 0.25

To the best of our knowledge this published information is accurate, however, to determine suitability of material/ ™ product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss WILLIAMS or damage resulting from inappropriate usage. PRODUCTS, INC.

WILLIAMS PRODUCTS, INC. 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - TOLL FREE (800) 521-9594 - FAX (248) 643-7117

www.williamsproducts.netpage 25-07

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Closed Cell Expanded Neoprene Rubber • Black in color • Excellent physical properties including; abrasion, low temperature, and resistance to petroleum base

fluids. Typical Physical Properties

Product Designation 1040 NN-1

1050 NN-2

1060 NN-3

1070 NN-4

1080 NN-5

ASTM Designation: D 1056 D 1056 D 1056

SCE - 41 RE - 41

2C1

SCE - 42 RE - 42

2C2

SCE - 43 RE - 43

2C3

SCE - 44 RE - 44

2C4

SCE - 45 RE - 45

2C5 MIL R - 6130 C Type / Grade Condition

II - A Soft

II - A Soft -

Medium

II - A Medium

II - A Medium -

Firm

II -A Firm

Physical Properties: Color Black

(Gray) Black (Gray)

Black (Gray)

Black (Gray)

Black

Compression - Deflection 25% defl. (psi.) (kN/m2 )

2 - 5 (14 - 35)

5 - 9 (35 - 63)

9 - 13 (63 - 91)

13 - 17 (91 - 119)

17 - 25 (119 - 168)

Ultimate Tensile Strength 75 psi. 100 psi. 100 psi. 150 psi. 150 psi. Elongation: Typical Properties % 175 % 175 % 200 % 150 % 125 % Density: lb/ft3 6 ± 2

.10 ± 03 7 ± 2

.11 ± 03 10 ± 2

.16 ± 03 20 ± 4

.32 ± 06 24 ± 6

.12 ± 02 Fluid Immersion: 7 days @ 73° F Ref. Fuel B, weight change max. %

5 %

5 %

5 %

5 %

5 %

Accelerated Aging: 7 days @ 73° F Flexibility: 180 ° bend without cracking Change in compression -deflection

Pass ± 20%

Pass ± 20%

Pass ± 20%

Pass ± 20%

Pass ± 20%

Maximum Weight % 5 5 5 5 5 Odor No

objectionable odor

No objectionable

odor

No objectionable

odor

No objectionable

odor

No objectionable

odor Service Temperature Low High Continous High Intermittent

-40°F 200°F 250°F

-40°F 200°F 250°F

-40°F 200°F 250°F

-40°F 200°F 250°F

-40°F 200°F 250°F

This Material is Made in the U.S.A Certified

Resistance To: Acid Excellent Flame Resistance: FMVSS.302, U.L. 94 HF - 1 Alkali Excellent Refers to Suffix Letter “M” Gasoline & Oil Good Mil. R-6130C Aromatic Hydrocarbons Fair MVSS - 305 Self-Extinguishing Ketones Fair Chlorinated Solvents Poor 2C1-2C5 refers to oil resistance (medium swell) Oxidation Excellent Ozone Excellent

Williams Everlastic® Closed Cell Neoprene Types

NN-1, NN-2, NN-3, NN-4, NN-5

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description

• Everlastic® NN-1 is a soft, expanded, closed-cell, sponge rubber. • Blend of Neoprene, EPDM, and SBR.

Material Specifications • ASTM D - 1056 - 2A1/2C1 • ASTM D – 6576 II A/B Condition Soft

Applications • Expansion joint filler in masonry and concrete. • Filler support sealant in traffic bearing joints. • Other applications that require a firm, economical and durable gasket.

Available sizes and packaging • Available in sheets, strips or cut parts. • Standard bun size: 2” x 42” x 72” • Available with self-stick, pressure sensitive adhesive (PSA) one or two sides. • Cut to thickness, width and length. • Larger dimensions factory spliced or bonded as needed.

Typical Physical Properties Property Test Method Typical Values

Polymer Base Na CR/EPDM/SBR Color Na Black Density –LBS per cubic foot ASTM D - 3575 6 ± 2 Compression/Deflection @ 25% Defl. ASTM D - 1056 2 to 5 psi. Elongation (Die A) ASTM D - 412 150 % Ultimate Tensile Strength (Die A) ASTM D - 412 75 psi. Water Absorption maximum increase in weight

ASTM D - 1056 5% max.

Accelerated Aging – 7 days @ 158ºF Flexibility (180º bend without cracking) Change in appearance Change in Compression Deflection

ASTM D - 1056

Pass None ±30%

Service Temperature (F°) Low High Continuous High Intermittent

ASTM D - 746

-40ºF 200ºF 250ºF

K Factor – BTU/hr. (sf) ºF inch Na 0.30

Flame Resistance FM VSS - 302 Pass This Material is Made in the U.S.A Certified

Resistance To: Acid Excellent Flame Resistance: FMVSS.302, U.L. 94 HF - 1 Alkali Excellent Refers to Suffix Letter “M” Gasoline & Oil Good Mil. R-6130C Aromatic Hydrocarbons Fair MVSS – 302 Ketones Fair Self-Extinguishing Chlorinated Solvents Poor 2C1 refers to oil resistance (medium swell) Oxidation Excellent Ozone Excellent

Everlastic® NN -1

1040 Series

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Closed Cell Expanded Neoprene Foam (CR based) • Stable physical properties Material Specifications • ASTM D1056: 2C5 • SAE Designation: 2C5 • ASTM D6576: Type II A Firm Available Sizes • Available in sheets, strips, or cut parts (sheet size: 1” x 40” x 48) • Available with self-stick, pressure sensitive adhesive (PSA) on one or two sides • Cut to thickness, width, and length • Large dimensions factory spliced or bonded as needed Applications • Used above or below grade where good weather and/or resistance to petroleum based fluids (medium

swell). • To isolate dissimilar substrates. • Expansion joint filler.

Typical Physical Properties Property Test Method Typical Values

Density ASTM D1056 24 ± 6 lb./ft³ Hardness Durometer Shore 00 ASTM D2240 70 ± 5 Compression Deflection 25% psi

kPa ASTM D1056 21 ± 4

145 ± 28 Compression Set % ASTM D1056 ?25 % Tear Strength lb/in

kN/m ASTM D624 (Die C) 35

6.1 Tensile Strength psi

kPa ASTM D412 (Die A) 150

1030 Elongation % ASTM D412 (Die A) 175 Resilience ASTM D2632 15 Water Absorption (maximum weight change %) ASTM D - 1056 < 5% Service Temperature (F°) Low

High Continuous High Intermittent

ASTM D746 -40 150 200

Fluid Immersion [7 days @ 23°C (73.4°F)] ASTM Ref Fuel B Weight Change %

ASTM D1056

<150

Accelerated Aging [7 days @ 70°C (158°F)] Flexibility: 180° bend without cracking

Appearance Change Change in Compression Deflection %

ASTM D1056 Pass None ± 30

Combustion Characteristics FMVSS - 302 Pass

Williams Everlastic® NN-5 2C5

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Closed Cell Expanded Rubber Flame-Retarded NBR Nitrile

• Color: Black

• Excellent physical properties including abrasion and low temperature resistance. Poor resistance to petroleum based fluids.

Material Specifications • ASTM D – 1056-2C1 • ASTM D - 1056-RE41E1 • ASTM D - 1056-SCE41 Available Sizes • Rolls, Sheets – Cut to Size: thickness: 1/4" - 1", widths up to 48" • Available with pressure sensitive temporary positioning adhesive. • Use with Williams No. 37 “A” Adhesive for permanent bonding. Shipping Weight • lb. Per 1” x 12” x 12”

Applications • Expansion Joint Filler in Masonry. • Isolation between dislike substrates.

Typical Physical Properties Property Test Method Typical Values

Density ASTM D - 1667 3.5 - 5.0 p.c.f Compression Deflection 25% ASTM D - 1056 1.5 - 3.0 psi. Compression Set 25% ASTM D - 1667 25 max % Compression Set 50% (Sample size 1” x 2” x 2”)

ASTM D - 1056 (ASTM D - 1667*)

50 max % (15 max %*)

Tensile ASTM D - 412 40 min. psi. Elongation ASTM D - 412 100 min % Water Absorption ASTM D - 1056 5 max % Water Absorption ASTM D - 1667 0.1 max lbs/sq.ft. Heat Aging ASTM D - 1056 +/- 30 % Thermal Stability ASTM D - 548

(% change in length after 7 days @ 220F)

10 max wt %

Ozone Resistance ASTM D - 1171 Pass Operating Temperature Range -297°F(-183°C) to 220°F(104°C)

Williams Everlastic® 1056 Joint Filler

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Closed Cell Expanded Neoprene Rubber

• Black in color

• Excellent physical properties including abrasion and low temperature resistance. Fair resistance to petroleum based fluids.

Typical Physical Properties Series 1040 1060 1080

Products Designation NN-1 NN-3 NN-5

Physical Properties Test Method 2A1-2C1 2A3-2C3 2A5-2C5 Density (lb/cu. Ft) ASTM D-1056 6 ±2 9 ± 2 19 ± 4 Hardness (Durometer Shore 00) ASTM D-2240 45 ± 5 60 ± 5 70 ± 5 Compression Deflection: 25% psi kPa

ASTM D-1056 3.5 ±1.5 24 ±10

11 ± 2 76 ± 14

21 ± 4 145 ± 28

Compression Set (%) ASTM D-1056 < 40 < 30 < 25 Tensile Strength psi kPa

ASTM D-412 (Die A) 75

520 100 690

150 1030

Tear Strength lb/in kN/m

ASTM D-624 (Die C) 9.6 1.7 125

12 3.2

35 6.1

Elongation (%) ASTM D-412 (Die A) 125 125 275 Resilience ASTM D-2632 35 25 15 Service Tempurature Low °F High Continuous °F High Intermitttent °F

ASTM D-746 (-)40 200 250

(-)40 200 250

(-)40 200 250

Water Absorption (max. weight change %) ASTM D-1056 < 5 < 5 < 5 Fluid Immersion 7 days @ 23°C (73.4°F) ASTM Ref. Fuel B, weight change max %

ASTM D-1056 Not

Applicable Not

Applicable < 150 Accelerated Aging: 7 days @ 70°C (158°F) 180° bend without craacking Appearance Change Chang in Compression Deflection

ASTM D-1056 Pass None ± 30%

Pass None

± 30 %

Pass None

± 30 % Combustion Charateristics FMVSS-302

UL 94HF-1 Pass Pass

Pass Pass

Pass Pass

This Material is Made in the U.S.A Certified

Resistance To: Acid Excellent Flame Resistance: FMVSS.302, U.L. 94 HF - 1 Alkali Excellent Refers to Suffix Letter “M” Gasoline & Oil Good Mil. R-6130C Aromatic Hydrocarbons Fair MVSS - 305 Self-Extinguishing Ketones Fair Chlorinated Solvents Poor 2C1-2C5 refers to oil resistance (medium swell) Oxidation Excellent Ozone Excellent

Williams Everlastic® Closed Cell Neoprene Types NN-1, NN-3, & NN-5

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Blvd. • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 REV 11/03 www.williamsproducts.net

TECH DATA Description:

Pre-molded sponge rubber made from recycled rubber. Black in color Blend of Neoprene, EPDM, and SBR

Material Specifications: ASTM D 1752 AASHTO M-153

Available Sheet Size: Standard Sheet size is 1" x 42" x 60" Thickness: ¼", 3/8", ½", ¾", and 1" May be laminated to other thicknesses Widths: Cut to order, minimum ½"; maximum 42"

Availability: Typically shipped from shelf stock, cut to order.

Applications: Expansion joint filler material in a variety of construction joints, particularly in concrete cast – in

– place applications.

Physical Properties Chart Density (minimum) ASTM D-1752 30pcf Compression Set ASTM Method: 1/2" samples

compressed 50% for 22 hrs. @ 70 degrees – 24 hr recovery

5% maximum

Recovery ASTM D-1752 95%+ Compression Deflection (50%) ASTM D-1752 50-1500 Temperature Resistance

Low High Continuous High Intermittant

ASTM D-1752 -40 degrees F +180 degrees F +220 degrees F

Accelerated Aging (7 days at 158°F – Lineal shrinkage maximum 2%) 114 Flexibility

ASTM D-1752 Good 180° bend without cracking

Water Absorption by weight ASTM D-1752 Average of closed- celled and open-celled sponge

Tensile Strength ASTM D -1752 25 psi Elongation ASTM D -1752 75%

Williams Everlastic® 1752 Rebonded Rubber

Type IV

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Blvd. • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Preformed, chemically blown, sponge rubber comprised of all virgin polymer and containing no

reclaim rubber or factice. Material Specifications • ASTM D - 1752 - Type 1 Sponge Rubber • Federal: HH - F - 341f Type II, Class A • AASHTO - M - 153 - Type 1 Available Roll Sizes • Thickness: ¼” x 36” x 60 LF; 3/8” x 36” x 60 LF; ½” x 36” x 45 LF; ¾” x 36” x 30 LF; 1” x 36” x

24 LF • May be laminated to other thickness • Widths: Cut to order, Minimum ½”; Maximum 36” Availability • Typically shipped from shelf stock, cut to order.

Applications • Expansion joint filler material in a variety of construction joints, particularly in concrete cast - in -

place applications. • Where concrete is poured on an incline or decline plan or thicker concrete pours where lateral loads

at the base require a firmer joint treatment.

Typical Physical Properties

Property Test Method Typical Values

Density ASTM D - 1564 30 lbs/ cubic foot Compression Deflection 50% ASTM D - 1752 70 psi. Recovery ASTM D - 1752 98 % Weathering ASTM D - 545 Pass Extrusion ASTM D - 1752 .10 %

Williams Everlastic® 1300 Series

Concrete Gray Sponge Rubber Joint Filler

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.williamsproducts.net

TECH DATA Description • Black Neoprene Sponge Rubber with a interlinking cell structure for increased compressibility and

outstanding resiliency. Material Specifications • ASTM D - 1056 Grade SCO - 11 • ASTM D - 1056 Grade 1C1 • SAEJ - 18R Grade SCO - 11 • MIL - C - 3133 - C Grade SCO - 3 • MIL - STD - 670 - B Grade SCO - 3 Available Roll Sizes • ¼” x 36” x 90 LF; 3/8” x 36” x 36 LF; ½” x 36” x 36 LF; 1” x 36” x 30 LF• Material may be slit, die cut or saw to any size needed. Uses • Structural Isolation, Vibration Damping, Press Pit Lining, Sealant Back Up, and many more

Typical Physical Properties Property Typical Values

Density 25 to 40 lbs/cu. Ft. Compression Deflection 25%

2 to 5 psi.

Compression Set 50% (50% deflection 22 hrs @158° F)

50% max

Tensile 60 psi. min (.125” thick specimen) Elongation 300% min (.125”thick specimen) Durometer 2 to 7 Shore “A” Hardness Aged Compression Deflection ± 20% change from original (7 days @ 158°F) Resilience Factor (Bayshore Method)

30 to 40% Rebound (.50 thick at room temperature)

Williams Everlastic® 1400 Series

Open Cell Sponge Neoprene Joint Filler

Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 REV 2/02 www.williamsproducts.net

TECH DATA Description Isomeric Polyolefin Resilient Flexible Foam

Gray in color Applications Everlastic 1752 Highway/Modified Expansion Joint Filler used with hot or cold applied sealants;

Horizontal applications, place Everlastic 1752 Highway/Modified next to forms; all interrupting columns and objects; adjacent to abutting structures prior to concrete placement. Vertical applications include Everlastic 1752 Highway Modified placement between panels, panel to column joints, or in block wall joints prior to sealing. And many other uses.

Available Sizes Standard Thickness: 1/8" – 3” (Other sizes Skived or Laminated). Widths from 1/2" to 60"; Available Multi-Score, Standard-Score, or with tear tab to allow sealant

reservoir (available in rolls only 1/8”-1/2”). Self-Stick Pressure Sensitive Adhesive (PSA) optional. (Will Die Cut Parts) Roll (1/8”-1/2”) lengths: 50 LF Sheet (5/8”-3”) lengths: 9 LF Everlastic1752 Highway/Modified must be held in place by either compression or sealant to reduce

float. Typical Physical Properties

Property Test Method Typical Values Density (Nominal) ASTM D - 3575 2 PCF Tear Resistance CM ASTM D - 3575 11 PI Compression Strength

10% Deflection 25% Deflection

40% Deflection 50% Deflection

2.6 psi 5 psi 9.6 psi 15 psi

Compression Set % of Original Thickness

ASTM D - 3575 25%

Elongation ASTM D - 3575 120% Tensile Strength CM ASTM D - 3575 40 PSI Water Absorption (lb./sf of cut surface)

ASTM D - 3575

<0.07

K Factor ASTM C - 177 0.25 Service Temperature Low High

PPP C - 1752

-65°F +210°F

Thermal Stability (Change after 24 hrs. @ 158°F)

ASTM D - 3575 2%

Williams Everlastic® 1752 Highway/Modified

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description

• Expanded, closed cell, plank, polyethylene foam. Economical, lightweight, flexible, compressible, resilient, non-absorbent, inherent bond breaker.

Material Specifications

• ASTM D 1056 ASTM D 3575

Applications • Concrete expansion joint filler for use with cold applied sealants.

Place Expand-O-Foam against existing formed concrete; place subsequent concrete directly to it. • Pipe isolation, thermal wrap. • Acoustical partition closures. • Corrugated deck closures. • Masonry expansion joints and column isolation. • Many other uses.

Available sizes and packaging

• Standard thickness: 5/8" to 4". • Widths from 1/2" to 48". • Will cut to custom size and/or profile. • Self-stick pressure sensitive adhesive optional.

Typical Physical Properties

Property Test Method Typical Values Density ASTM D 1622 2.0 lb./ft3 (32.04 kg/m3) Compression Strength 10% deflection 80% deflection

ASTM D 3575 ASTM D 3575

10 psi (69 KPa) max 125 psi (862.49 KPa) max

Tensile Strength ASTM D 3575 55 psi (379.50 KPa) Water absorption ASTM D 3575 0.5% vol. max Temperature Stability ( N/A -40° F to 160° F (-40° C to 71° C)

Everlastic® Expand-O-Foam

1380 Series

Concrete Slabs

Williams Everlsatic® 1380 Series Expand-O-Foam

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 REV 1/02 www.williamsproducts.net

TECH DATA Description • Closed Cell Expanded Polyvinyl Chloride

• Off White (Natural) Color

• Good Chemical Resistance & temperature serviceability. • Good tensile Material Specifications • ASTM D - 1667 Grade VE41 • ASTM D - 1056 SBE41 & SCE41 • ASTM D - 1056 RE41E1 Available Sizes • ROLLS, SHEETS - CUT TO SIZE • Available with pressure sensitive temporary adhesive. • Use with Williams No. 37 “A” Adhesive for permanent bonding. Uses • Isolation: Steel from masonry • Metal from metal (curtain walls etc.)

Typical Physical Properties Property Test Method Typical Values

Density ASTM D - 1667 8.0 Compression Resistance 25% ASTM D - 1056 1.5 - 3.0 psi. Comp. Set 25% ASTM D - 1056 24% max. Comp. Set 50% (Sample size 1” x 2” x 2”)

ASTM D - 1056 (ASTM D - 1667*)

50% max.. (15% max*)

Tensile ASTM D - 412 40 min. Elongation ASTM D - 412 100 % min. Water Absorption ASTM D - 1056 10 % max wt. Heat Aging ASTM D - 1056

(22 hrs. @ 158°F +/- 30 %

Thermal Stability ASTM D - 548 (% change in length after 7 days @ 220F)

7 % max wt.

Ozone Resistance ASTM D - 1171 Pass Temperature Use (Lower limit to upper limit)

- 40F to 220F

Williams Everlastic® Vinyl Type U 1000 Series

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Blvd. • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description

• Everlsatic Precast Concrete/Metal Panel Seals provide a permanent pressure contact seal at all time, with a minimum of pressure, when placed between panel joints. This type of design provides the architect complete control over joint system.

• The various panel types are designed, with regard to size and functional characteristics, to provide an effective seal for both vertical and horizontal joints under virtually any condition that might arise in either precast concrete or metal panel construction.

• The unusual flexibility in adaptation provided by the design of Everlastic Seals, whether used singly or in combination, will effectively seal panel joints up to one inch in width; with each type readily able to compensate for variations in joint width, irregular joint surfaces and the inevitable reaction adjustments to overall building dimensions.

Technical Data • All the technical data for each seal satisfies the ASTM material standards. If details are required, contact the

technical staff at Williams Products, Inc. Installation

• The Everlastic Panel Seals should be factory installed by the panel manufacturer while joint faces are clean. These seals should be selected on the basis of the seal being compressed at least 25% and not more than 50% in the joint width specified. The seal should be placed in the joint the proper depth to accommodate sealant placement with baker rod. Horizontal seals should be protected during shipment at the bottom side of the panel to prevent destroying seals. Panel seals should be stored in a dry location in unopened cartons prior to installation. All Everlastic Panel Seals can be furnished with pressure sensitive adhesive on one side which will hold the seal in place during installation.

Everlastic® Concrete Panel Seals

DIVISION 4 MASONRY

Masonry Control Joints

CMU Expansion Joint (Horizontal) Cavity Wall Baffle

Closures Fire Rated

Fire Classified Anchor Gaskets

Brick Expansion Joints Adhesives

TECH DATA Everlastic® Masonry Control Joints

SLOTSEAL STD 2015-3 BLOCK SEAL 2018-3 WEATHERTITE "R" 0318-3 mortar

bond breaker 3/8" 11/16"

2-5/8" 5/8" 1/2" 2-11/16" 1"

1"

1-5/8" 1-5/8" 1/2"

APPLICATIONSEverlastic® Masonry Control materials are designed to prevent destructive cracking in masonry and prevent destructive cracking in masonry (from temperature and drying shrinkage, differential movement ofstructural members and surrounding masonry, settling of foundations, etc.). Williams' materials also seal out moisture and cold air at a reasonable price.

SLOT SEAL STANDARD 2015-3A shear lug to provide shear control and vertical control for expansion/contraction of masonry walls. Manufactured of high grade synthetic rubber compounds.Polymer: Blended EPDM/SBR/CR, AASHTO D-2000, 3BA810-80 Shore A Hardness, 1000 PSI tensile.Exceeds material standards of 2AA805 (80 hardness - 500 PSI tensile).

BLOCK SEAL 2018-3For Sash BlockHollow wings are easily compressed to provide pressure seals on each side of keyway in additionto shear control. Manufactured of high grade synthetic rubber compounds.Polymer: Blended EPDM/SBR/CR, ASTM D-2000, 3BA810-80 Shore A hardness, 1000 PSI tensile.Exceeds material standards of 2AA805 (80 hardness - 500 PSI tensile).

WEATHERTITE "R" 0318-3For Stretcher or Line Block (Michigan Control Joints)A specially shaped, non-absorbent, expanded rubber strip seal. Weathertite "R" provides multiple, continuous, presser sealing surfaces. This closed cell material is impervious to water and possess high acoustical insulatingproperties.Polymer: Neoprene grade ASTM D-1056, RE 41, SCE-41, 2A1.

™ To the best of our this published information is accurate, however, to determine suitability of material/ Williams product for a specific application is the user's responsibility. Williams Products, Inc. shall not be liable for any loss Products or damage resulting from inappropriate usage.

WILLIAMS PRODUCTS, INC. 1750 MAPLELAWN BOULEVARD - TROY MICHIGAN 48084 - PHONE (248) 643-6400 - TOLL FREE (800) 521-9594 - FAX (248) 643-7117

www.williamsproducts.net38-07

CMU Expansion Joint

Expand-O-Foam

EVA 200G 1056 Joint Filler

NN-1 1040 Series

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.

Williams Products, Inc. • 1750 Maplelawn Drive • Troy, Michigan 48084 • Ph: 800-521-9594 Fax: (248) 643-7117 www.wiilliamsproducts.net

TECH DATA Description

• Expanded, closed cell, plank, polyethylene foam. Economical, lightweight, flexible, compressible, resilient, non-absorbent, inherent bond breaker.

Material Specifications

• ASTM D 1056 ASTM D 3575

Applications • Concrete expansion joint filler for use with cold applied sealants.

Place Expand-O-Foam against existing formed concrete; place subsequent concrete directly to it. • Pipe isolation, thermal wrap. • Acoustical partition closures. • Corrugated deck closures. • Masonry expansion joints and column isolation. • Many other uses.

Available sizes and packaging

• Standard thickness: 5/8" to 4". • Widths from 1/2" to 48". • Will cut to custom size and/or profile. • Self-stick pressure sensitive adhesive optional.

Typical Physical Properties

Property Test Method Typical Values Density ASTM D 3575 2 to 2.4 pcf Tear Resistance (@ 1/2" thickness) ASTM D 3575 13 pi Compressive Creep ASTM D 3575 <5% @ 3.0psi Compression Strength 25% deflection 50% deflection

ASTM D 3575 ASTM D 3575

10.5psi 19psi

Compression set (Loaded @ 1.5psi1000 hrs @ 50%)

ASTM D 3575 18%

Tensile Strength (@ 1/2" thickness) ASTM D 3575 42psi Water absorption (lb/sf of cut surface) ASTM D 3575 <0.2 Thermal Conductivity (BTU-in/hr ft² °F) at 75ºF

ASTM C518 0.4 – 0.48

Thermal stability (change after 24 hrs at 165ºF

ASTM D 3575 <5%

Everlastic® Expand-O-Foam

1380 Series

revised 1-1-12

www.williamsproducts.net

Description:

Plugs and strips for metal decks

WT --- is the width at the top of the closure. WB --- is the width at the bottom of the closure. H --- is the height from top to bottom of the plug. D --- is the thickness or distance into the flute. V --- is distance between closure plugs at the base. T --- is the thickness of the closure strip.

Closure

WBD

H

T - of runner

Strip Closure

WB

V

H

D

WT

WT

We do not guarantee the applicability or accuracy of this information or the suitability of our products for any given situation Users should make their own tests to determine the suitability of any product for their particular purpose. The products discussed are sold without warrantee, either expressed or implied, buyer assumes all responsibility for any loss or damage arising from the handling or use of our products, whether done in accordance with directions or not. Statements concerning the possible use of our products are not intended as recommendations to use our products in the infringement of any patent.