WHIPPLETREE PRODUCT INFORMATION ... - English Oak …...produce splintered corners on the two new...

Transcript of WHIPPLETREE PRODUCT INFORMATION ... - English Oak …...produce splintered corners on the two new...

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

C o n s t r u c t i o n O a k A I R D R I E D B E A M S – E X S T O C K E U R O P E A N

Please see next sheet for Ex Mill DESCRIPTION For collection within a few days. Price is based on a minimum of 2 to 3 year

guaranteed age stock sections that have been graded by us prior to drying.

Technical Specif icat ions – AIR DRIED BEAMS – Ex Stock EUROPEAN

Lengths 2.4, 3.0., 3.6, 4.3, 4.8, 5.4, 6.0, 7.0

Sect ions (MM) 150 x 150, 175 x 175, 200 x 200, 225 x 225, 250 x 250, 300 x 300, 350 x 350, 225 x 150, 300 x150, 300 x 225 (all subject to availability)

Colour Can be very ‘weathered’ silver or dark grey with ‘water’ marks, dark brown tide marks – re-sawn faces will be new and light coloured

Grade Grade One (the usual grade for construction). Can be Graded to BS5756 D30 and D40 strength class

Knot s ize Live knots up to 50% of the sectional face width. Dead knots that are sound (i.e. without holes) are acceptable

Sap Not regarded as a defect and may have worm holes showing that could be active (see recommendations for treatment)

Wane A small amount allowance on two edges Availabi l i ty Next day to 5 days (dependant on order size)

Cracks & Spli ts Provided that they are not going to structurally affect the piece they are acceptable

Tolerances Due to shrinkage and general movement tolerances can be up to + or -15mm

Moisture Content Depends on section size – 18% - 35% Weight 1.1m³ per Tonne Surface Finish Generally fine sawn (can be planed – special order)

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

C o n s t r u c t i o n O a k A I R D R I E D B E A M S E U R O P E A N – E X M I L L

Please see last sheet for Ex Stock DESCRIPTION Available within three to four weeks, although on larger enquiries or orders,

we can quote a more competit ive price than on our own dried stock,

however, we cannot guarantee the age or quality.

Technical specifications – Air Dried Beams = Ex Stock

Lengths Up to 8m (longer subject to availability) Sect ions (MM) Any section up to 400 x 400 (subject to availability)

Colour Can be very ‘weathered’ silver or dark grey with ‘water’ marks, dark brown tide marks – re-sawn faces will be new and light coloured

Grade Grade One (the usual grade for construction) Can be Graded to BS5756 D30 and D40 strength class

Knot s ize Live knots up to 50% of the sectional face width. Dead knots that are sound (i.e. without holes) are acceptable

Sap Not regarded as a defect and may have worm holes showing that could be active (see recommendations for treatment)

Wane A small amount allowance on two edges Availabi l i ty 3 – 4 weeks (dependant on order size)

Cracks & Spli ts Provided that they are not going to structurally affect the piece they are acceptable

Tolerances Due to shrinkage and general movement tolerances can be up to + or -15mm

Moisture Content Depends on section size – 18% - 35% Weight 1.1m³ per Tonne Surface Finish Generally fine sawn (can be planed – special order)

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

Warnings/Cautions/Recommendations

Due to the drying process some of the init ial sectional size wil l be lost. As

an example, an original 200x200mm beam when Air Dried for a number of

years may dry down to 190x190mm. The sections could have twist along

their length, wil l not be particularly square and some of their straightness

can be lost. This is the character of Air Dried Oak. The solution is to re-saw

the timbers if they are required to provide a true square section f inish.

We can also supply Grade A with knots up to 33% of the sectional face

(subject to availabil i ty) i f you have a specif ic request for this.

Air Dried Oak can be supplied free from sap on request although this is

more expensive and subject to stock availabil i ty.

If ordering Air Dried Construction Oak Ex-Europe, be aware that some

sections can be ten years Air Dried and have a very weathered look, where

others may only be one-year Air Dried and sti l l be quite green inside.

Although we CAN specify two to three years of air drying ON OUR English

Oak, in Europe they do not record when stock was sawn they just go by

looks!

Also remember that if you were to buy English Oak, that it is al l tagged and

logged with a complete record of i ts history from stump to site and

certif ication is available on request.

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

Warnings/Cautions/Recommendations (CONTINUED)

As Air Dried Oak has been outside for a number of years, the sapwood wil l

often show signs of ‘going soft ’ and may have signs of beetle holes. This

can often be removed by chamfering the long edges of the piece, but wil l

st i l l need treating with an approved preservative.

With ALL timber products, treatment in advance is always the best advice.

Although Air Dried Construction Oak has a relatively low moisture content it

can sti l l move or sett le a l i t t le once installed particularly with regard to the

larger sections. Always be mindful of this and allow to ‘make good’ any

finishes 6-12 months later.

If you ask us to re-saw a large section down the middle, for example a

200x200mm section beam cut to two 200x100mm section beams, it may bow

both of the re sawn pieces and wil l also cut along the heart shakes and may

produce splintered corners on the two new edges of each piece. To make a

good sound beam, although it costs a l i t t le more, i t is better to cut the

required piece from the centre of the larger beam.

Commonly Asked Questions

ISGREENOAKMUCHCHEAPERTHANAIRDRIED?

Yes it is, however, remember the shrinkage and movement aspect. Generally, if it is a

complete structure that is being built and there is not any glass included in the design, then

Green Oak is okay. If repairing an existing frame or if glass is included in the design, then

Air Dried is better.

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

Commonly Asked Questions (CONTINUED)

CANWERETAINTHEWEATHEREDLOOK?

Yes of course, as long as we can provide you with the exact section you require without re-

sawing. If you re-saw or chamfer the beam, then the sawn faces will look new and bright

and you cannot easily weather the new face.

CANWEHAVEWANEONTHEEDGESLIKEALOTOFOLDERBEAMS

HAVE?

Generally, no. Very few customers want this and so we do not produce it as a standard

although we do keep smaller section studs with a little wane (subject to availability).

Customer Ordering Advise

From a pricing perspective, it will help if you can be a little flexible with the size of the

section required. We can then match your order to our stock and keep the wastage to a

minimum to save you money.

Whilst on the subject of saving money, it is always more cost effective to order your full

requirements in one order rather than ordering a few lengths as and when you need them.

Always order the length you will be using, do not add lengths together and order the longer

lengths as longer lengths are more expensive per metre. In other words, you will save

money if you order two 3.00 metre lengths rather than one 6.00 metre length which you

then cross cut to two 3.00 lengths. Always try to give us the cutting list you actually need to

do the job and we will find the most cost effective way to supply it to you.

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

Architects Specifications: (Please copy and paste into your specifications)

European Green Sawn Oak construction beams to be used will be of structural quality with

minimum sapwood and have heartwood that is free from decay and live worm holes.

Sections above 150x150mm will be ‘Boxed Heart’. No live insect attack or decay allowed.

Tel: Whippletree on 01763 208966

WHIPPLETREE PRODUCT INFORMATION &

SPECIFICATION SHEET

W www.whippletree.co.uk | T 01763 208966 | F 01763 208977 | E [email protected]

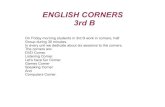

Above: Air Dried Beams showing the existing ‘weathered and aged’ finish and out of

‘square’ sections caused by shrinkage in the air drying process

Above: Air Dried Beams ‘re-sawn’ to give a fresh finish

and bringing back to ‘square’ sections