What's New in Process Technology Dec 11/Jan 12

-

Upload

westwick-farrow-media -

Category

Documents

-

view

224 -

download

5

description

Transcript of What's New in Process Technology Dec 11/Jan 12

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 3

INDUSTRYLEADERS 2012

of

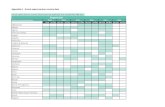

4 _____ AMS Instrumentation & Calibration 6 _____ Omron 8 _____ Bürkert10 ____ Weidmüller12 ____ Pilz Australia14 ____ ifm efector

16 ____ Crystal Ball Gazing

18 ____ Endress + Hauser20 ____ insignia

22 ____ Hot Products 2011 28 ____ MSA Australia 30 ____ Point to Point Group 32 ____ PAFtec 34 ____ Worksense 36 ____ Microsite Partners

Welcome …

This special Leaders of Industry edition of What’s New in Process Technology is one of two Westwick-Farrow Media magazines that will feature profiles of leading suppliers to the industrial, government and manufacturing sectors across Australia and New Zealand. These spreads are sponsored, and they include content on new products and developments planned for the year ahead, as well as details of each company’s special areas of expertise.

The CEOs of some of these companies share their thoughts about what challenges and opportunities lie ahead for 2012 in the Crystal Ball section.

This special issue also features some of the hottest products of 2011 and details of our online Microsite partners who feature on your industry website www.ProcessOnline.com.au. The site also includes a comprehensive industry directory and a showcase of new products, case studies and technical articles to help you keep up to date and do your job more efficiently.

The companies featured in the Leaders of Industry program will also join the WF Media editorial and management teams in late February for a Leaders Roundtable event to discuss issues, share ideas and look at collaborative opportunities across different industry sectors.

We hope you enjoy this special edition and would be happy to hear your feedback.

Geoff Hird Publisher Westwick-Farrow Media [email protected]

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 5

OUR TEAM

PRODUCT

AMS Instrumentation & Calibration, a family owned and operated

business, is now operating in all states of Australia due to its managed

growth. Since changing ownership, the company has grown from

four people to 25 people and turnover has more than quadrupled.

With its expanded headquarters based in Melbourne (close to

doubling in size) with a total staff of 15 people (mainly technical),

the company provides a high level of technical competence for our

customers to ensure that the right equipment is provided. Additional

staff at head office includes clerical, financial and stores personnel.

In addition to the normal services, AMS has moved into other

directions, where it sees future growth. With the formation of an

analytical area, AMS sees a bright future ahead. Offices are also

located in Brisbane, Sydney, Adelaide and Perth. All have very

competent sales engineers with many years of experience in the

instrumentation and calibration field. Several of

our technical staff have been trained overseas

by our principal suppliers, ensuring that they

are kept up to date with the latest technologies.

There is also regular training for all staff at

head office.

With a very low staff turnover and a combined

staff experience of more than 200 years, AMS

is confident it can offer solutions to best suit its

customers’ needs.

AMS Instrumentation & Calibration is

proud to service the industry with its highly

specialised equipment in the various areas of

instrumentation and calibration, and we are

looking forward to an exciting future.

Clamp-on ultrasonic flow meter

The KATflow clamp-on ultrasonic flow meters work on the transit-time method. This is based

on the principle that sound waves travelling with the flow will move faster than those travelling

against it. The resulting difference in transit time is directly proportional to the flow velocity of the

liquid and consequently to the volumetric flow rate.

The ultrasonic transducers (sensors) of the flow meter are mounted on the external surface of

the pipe and are used to generate and receive pulses. The flowing liquid within the pipe causes

time differences in the ultrasonic signals, which are evaluated by the flow meter to produce an

accurate flow measurement. The advanced electronics of the flow meter compensates for and

adapts to changes in the flow profile and medium temperature to deliver reliable measurements.

The KATflow 200 is a handheld ultrasonic flow meter for non-invasive and non-intrusive flow

measurement of liquids and liquefied gases in fully filled pipes. The flow meter is equipped with

one measurement channel to monitor the flow in one single pipe at a time. The instrument is

supplied with an internal data logger and software for the recording and download of measured

values. Additionally, the KATflow 200 can be equipped with an integrated wall thickness gauge

to provide further information about the application parameters. Thanks to its intuitive instrument

menu, Setup Wizard, and Audible Sensor Positioning Assistant, the flow meter can be set up

and its sensors correctly installed in a matter of minutes.

THE RIGHT PRODUCTS FOR DIFFICULT APPLICATIONSAMS Instrumentation & Calibration supplies a range of equipment

suitable for a wide variety of industries, including the mining, gas,

petroleum, petrochemical, pulp and paper, water and wastewater

industries. Following a major review of its operations, AMS now

provides a range of flow metering devices and other equipment

including various measuring transmitters and devices from FCI,

Yamatake, EMCO Controls, Katronic and Trimec, as well as Beamex

calibration equipment, Bellofram transducers and Noshok pressure-

sensing equipment. The newly formed analytical division supplies

a range of analysers for cloud point, vapour pressure, flash point,

relative humidity, moisture and oxygen from Michell and PAC.

Phone: 03 9017 8225 Fax: 03 9729 9604Email: [email protected]: www.ams-ic.com.au

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 7

Omron is known to most major enterprises as a superior technological developer and

innovator, with extensive application expertise and worldwide resources to support

ventures. We combine quality products and services with extensive knowledge and

experience to deliver maximum customer value.

As a leading global company, we rely on our safety, automation, and sensing and control

technologies to produce innovative products and solutions for various industries.

Omron has a global network that encompasses North America, Europe, Asia-Pacific,

China and Japan, along with localised service systems to provide customers with the

products they need, when they need them. These complete systems allow Omron to

provide full support of clients’ product lifecycles, including development, production,

distribution, sales and maintenance. This is why we can provide the most dependable

support wherever customers and associates are located.

As Managing Director for Omron Electronics Oceania region, Greg Field brings

a wealth of experience and knowledge of the market. He has been with Omron

Electronics for almost 20 years, beginning his career in

sales, and has more than 10 years of senior management

experience. Omron functions as a partner to help innovate

manufacturing for its clients. Through our expertise in safety,

automation, and sensing and control technologies, we

enable manufacturers to operate with greater productivity

and streamlined efficiency. Our application experts strive

to be on the top of the technological development of

clients’ manufacturing processes to provide valuable

expertise to further improve their processes. They can also

draw on resources from our extensive global network and

development centre.

Omron partners with its clients to continuously increase

efficiency and productivity, as well as improve quality

that is crucial to them remaining competitive with their

production processes.

OUR TEAM

PRODUCT

COMPANY PROFILE

Established in 1933, Omron now has over 35,000

employees in over 35 countries. Omron founded its

Asia-Pacific operations over a quarter of a century ago

to meet the needs of the region’s rapidly expanding

industrial markets. Our Asia-Pacific network now

consists of over 4000 strategically located employees

involved in sales, manufacturing and technical support

as well as research and development activities.

Phone: 1300 766 766Fax: 1300 434 682 Email: [email protected]: www.omron.com.au

Unified motion and automation for next-generation machines

The NJ Machine Automation Controller from Omron seamlessly integrates motion control,

automation, vision inspection and communications. Its architecture offers performance

and reliability advantages over many controllers. Based on Intel Multicore Processing Unit

technology and QNX OS, it achieves high-performance and industrial reliability. Performance

surpasses PLC-based motion automation, matching industrial PC (IPC) levels, giving a

minimum motion automation cycle of 500 µs. Using QNX, NJ’s reliability betters Omron’s CJ

PLC benchmark, aiming to surpass the reliability of IPCs, which mostly run variants of the

Microsoft Windows operating system. NJ also boots in only eight seconds.

Advanced motion and synchronisation of servos is possible, via an EtherCAT machine

network and distributed clocks. EtherCAT’s refresh rate is 100 µs with less than 1 µs of jitter.

Topologies are flexible, suiting remote I/O like Omron’s GRT1 I/O slices. Motion functions

include linear and circular interpolation, electronic gearing and CAMS, as well as virtual

axes. Automation is equally impressive, supporting a maximum of 2560 rack I/O (40 CJ1W series I/O units).

USB, EtherCAT and EtherNet/IP ports are built in, plus CJ1W communications unit support.

NJ creates opportunities for machine builders. Its programming software, Sysmac Studio, is designed to cut

development costs. Featuring IEC61131-3 compliance, PLCopen motion function blocks, automation and 3D

motion simulation, CAM editor and user-defined function blocks, advanced solutions are made quicker and easier.

Mr. Clean!With our control head 8681 a new star is born! Not only because of its super-bright LED status display visible across the process floor, but because its talent in decentralised automation systems shines.

Universally adaptable for all valve types, it takes on complete pneumatic control, feedback, diagnosis and even fieldbus communication. And since it is made of chemically stable materials, has a high IP rating, a smooth housing and is easy to clean, the 8681 is perfectly suited for hygienic applications.

We make ideas flowwww.burkert.com.au | 1300 888 868www.burkert.co.nz | 0800 BURKERT (0800 287 537)

Innovative valve automation

WNIPT Ad 201201.indd 3 7/12/2011 2:17:52 PM

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 9

OUR TEAM

PRODUCT

Bürkert Australia has a single focus - delivering smart solutions

to Australian manufacturing and industry. To this end, our team

is centred around the technical and engineering disciplines.

Our sales team is experienced in Australian industry, each person

coming from an engineering background. As a consultant to

your own engineering team, Bürkert sales managers have the

experience to understand your process and to support you in

areas including system design, optimisation and maintenance,

or in OEM development. Around the country in each state and

regional processing centre, our sales managers are where you

need them to give expert counsel when and where you need it.

With product experts and industry sector specialists who speak

your language, we are relied upon for straightforward advice by

our key customers.

An engineer himself, Managing Director Chris

Hoey has 25 years’ experience in thinking

outside the square to deliver innovative

process solutions and concepts. With a

hands-on approach to leadership, Chris is

active with key accounts and system design.

As a long-standing member of the board of

the Institute of Instrumentation, Control and

Automation, Chris is active in the industry and

continuously campaigns for more efficient,

ingenious and smarter systems.

Bürkert is an engineering partner with our

own manufactured range of technologies

and products, and with the single goal of

supporting our partners in Australian industry

with smarter solutions and possibilities.

Type 8681 hygienic process control head

The 8681 control head has been specially developed for automation of hygienic seat valves, butterfly

valves and ball valves from any manufacturer. It supplements Bürkert’s ELEMENT series of control heads,

digital positioners and process controllers for diaphragm, angle seat and globe valves and rounds out the

automation portfolio for the food and beverage, and pharmaceutical industries.

The Type 8691 Control Head is universally adaptable and can be combined with all commercially available

valve types, such as butterfly valves, ball valves and single- and double-seat valves. Since the control

head is very easy to clean, features time-tested ingress protection and is made of chemical-resistant

materials, it is ideal for use in hygienic applications including washdown areas. Within the framework

of decentralised automation, the Type 8681 performs all pneumatic actuation, feedback and diagnostic

functions, plus fieldbus communication. Depending on the process valve, as many as three pneumatic

actuator chambers can be separately controlled.

The respective switching positions of the process valve are measured by the Control Head via an

inductive analog position sensor and transmitted to a PLC. The Type 8681 is fieldbus ready, for ASi,

Profibus and DeviceNet. The Type 8681 supports deployment of a single operational control platform for

all pneumatic devices.

COMPANY PROFILEBürkert Fluid Control Systems is a global organisation that has had

a presence in Australia and New Zealand for more than 30 years.

Building on our range of German-manufactured fluid control

products, we design, build and commission complete process

automation solutions at our Systemhaus in Sydney.

Bürkert works across Australia’s manufacturing, processing,

civil and industrial sectors providing services in product

specification, design consultancy, process development and

turnkey system production.

Phone: 1300 888 868 Fax: 1300 888 076Email: [email protected]: www.burkert.com.au

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 11

DEVELOPMENTS AND INNOVATIONS

PRODUCT

Innovation and development are key components of

Weidmüller’s global success and are areas that the company

remains fully committed to pursuing.

Our ongoing commitment to research and development has

seen many innovations come to fruition. Among them of late

is the incorporation of W-Ring technology into redundant

ring networks to simplify ethernet network design. W-Ring

technology also meets the new IEC standard 62439 for high-

availability automation networks.

W-Ring technology eliminates the need for master and slave

settings in a redundant ring and therefore eradicates a single

point of failure, while providing network re-instatement in less

than 20 ms.

All participants on a W-Ring determine who the master and

slaves are at system start-up. The master blocks one port and

manages the ring. If there is a break in the cable or CRC errors

are received at a port, this will alter the rules and initiate a

change of master to manage the port where the error occurs.

The implementation of W-Ring technology also eliminates the

need to refresh MAC address tables at each switch location,

helping to improve network reaction time. Add to this W-Ring+

which allows redundant connections between two rings and

you have a much improved and robust ethernet network. In

essence, W-Ring technology helps deliver a far more secure

and simplified ethernet network with prolonged uptime.

Weidmüller will continue to develop technology and further

improve its implementation to build product capability and

better efficiency.

Weidmüller is a world-leading provider of solutions for electrical

connectivity, and for the transmission, conditioning and processing

of power, signals and data in industrial environments. Weidmüller

has a long history of developing innovative products in electrical

connectivity and electronics that exceed market expectations.

The Australian operation has become a strategic centre for the

design, development and manufacture of the Group’s electronics

products, which deliver undisputed quality and reliability.

Phone: 02 9671 9999 Fax: 02 9671 9900Email: [email protected]: www.weidmuller.com.au

Rack-mounted managed switches for high-temperature operation

The IE series of 19″ 1U rack-mounted ethernet switches delivers optimum performance in

demanding, high-temperature environments. Suitable for the mining and heavy manufacturing

industries, and substation automation plants, the switches are housed in robust metal casings

that require neither air conditioning nor cooling fans.

Delivering real choice, users can choose from the entry-level IEMS1000 fixed rack

or the modular IEMS2000 and IEMS3000 options. All the switches offer low- and

high-voltage power supply options.

The IEMS1000 provides up to 26 ports of 10/100 Fast Ethernet connections.

It delivers all the network features you would expect, including IGMP snooping,

256 VLANs, support for SNMP V1, 2 and 3, QoS, TOS plus more.

The modular IEMS2000 and IEMS3000 switches provide complete flexibility.

Users can mix and match the components required.

The IEMS2000 delivers advanced Layer 2 control functionality with either a 24-port

10/100 Fast Ethernet with four gigabit ports for redundancy to a 28-port gigabit switch.

The IEMS3000 is an advanced Layer 3 option with selectable port combinations. It features

all layer 3 requirements including RIP v1/v2, OSPF v2, BGP v4, up to 4096 VLAN IDs, SNMP

v3, TACAS+, Radius and other benefits.

Both the IES2000 and IES3000 take up to six 0.5U 4-port combination cards plus a 1U

4-port gigabit slot and encompass PTP. All the ports are available in combinations of copper,

fibre or both.

COMPANY PROFILE

Modular Ports to suit your data connection requirements

You‘re in safe hands with Pilz.

One StopSafety

Solutions

Melbourne • Sydney • Brisbane • Auckland

Ph: 03 9544 6300 Fax: 03 9544 6311www.pilz.com.au [email protected] the spirit of safety

LeadersIndustryAdNov.indd 1 28/11/11 12:41 PM

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 13

PRODUCT

THE COMPANYCurrently employing more than 1600 staff worldwide, Pilz

operates internationally as technology leader in safe automation

technology. Headquartered in Stuttgart, Germany, Pilz is

represented globally by its 26 subsidiaries operating across all

of the inhabited continents as well as numerous supporting trade

partners worldwide.

Phone: 03 9544 6300 Fax: 03 9544 6311Email: [email protected]: www.pilz.com.au

Pilz Australia was started in Melbourne during 1998 to build

on Pilz’s growing customer base in the region and increase

the local level of technical knowledge in machine safety and

its safety products. Today, Pilz has grown to having offices in

Sydney, Brisbane and Auckland as well as a strong network

of sales partners and systems integrators across the country.

Based on our industry experience, Pilz is a trusted provider

of safety products and services to leading national and

international industrial companies. We provide viable solutions

to the most complex safety issues in a wide range of industry

domains. With our local team of passionate people, coupled

with the backup and support of a global footprint, we help

companies apply best manufacturing practice to safely optimise

the availability and productivity of their plants worldwide.

Pilz is active in a wide variety of industries and we are

especially focused on industries like OEM machine builders,

FMCG, automotive, food and beverage, packaging, materials

handling and mining. However, our products and services

are also starting to penetrate into the rail, ports, oil and gas,

and energy industries which have demonstrated a very high

demand to improve safety outcomes recently.

Machine safety can often be a complex and a forever-changing

environment and our team is well placed to support your

business from simply training your staff on the fundamentals

of machine safety and the interpreting of local legislation and

standards such as AS4024 or ISO13849, all the way through

to completely custom-engineered solutions that reduce overall

plant risk and improve the working environment in which your

company operates.

PSS 4000 - One system for all automation functions

PSS 4000 from Pilz brings a solution for all your machine automation control and safety functions

together in one place. The primary aim of the PSS 4000 is to simplify the decentralisation of

control functions and reduce engineering work through the Pilz Automation Suite software

platform, PAS4000, which plays a key role in the system. It enables users to retain a centralised

perspective of decentralised, distributed control structures.

Pilz has taken into account customers’ requirements for complete solutions, comprising

safety and standard control technology. The PSS 4000 is designed as an automation system

for all industries and comes out of the box with a wide variety of customised function blocks

applicable to your specific application. It’s a system that’s easy to operate and considers the

requirements for safety of man and machine from the outset.

Because of its versatility, the PSS 4000 automation system can be used across a whole

range of industries, for applications of any size. The software tool PAS4000 gives you a local

perspective on even the largest networked system, reducing complexity in your project. The

tool also allows you the freedom of writing your project in familiar PLC languages, a unique

graphical editor, called PASmulti, or a combination of the two. This in turn allows for a modular

structure, so that identical components can be re-used with minimum effort. The benefits can

be seen in greater availability due to local error reactions and higher productivity as a result of

shorter reaction times across the whole system. All these features add up for you to ‘Simplify

Your Automation’.

THE TEAM

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 15

OUR TEAM

PRODUCT

COMPANY PROFILEifm provides German engineered and manufactured sensor and

control solutions for automation, including position sensors and object

recognition, fluid sensors and diagnostic systems, bus systems and

identification systems, control systems and connection technology.

ifm provides the right combination of German engineering and

local service and support. For 40 years the company has been

researching, developing and producing products and technology

with the aim of optimising technical processes. It started in Germany

with the inductive sensor in 1969, based on innovative flexible film

technology. Today, the ifm group of companies has a presence in over

70 countries, with more than 4300 employees looking after more than

90,000 customers around the world.

Our people and our products are committed to helping you succeed in

your business. You can count on ifm efector to be a reliable partner for

your automation and control solutions. That means solutions for your

application challenges, knowledgeable technical support and easy

order placement. Our customer service team is available to provide

phone-based support and our network of sales engineers is available

around Australia and New Zealand to visit you on-site. Through our

website you are also able to check price and availability, track orders,

view order history and purchase ifm products using our e-shop

(www.ifmefector.com.au/eshop).

We hold extensive stock at our warehouse facilities in Australia and

New Zealand, and our products can be delivered to you overnight in

over 97% of instances. Our customers have continuously trusted us

to reliably supply product on time, when they need it most. In order to

improve even further, we have recently undergone a major warehouse

upgrade at our Melbourne head office, which will mean even better

service.

From inductive and flow sensors to

pressure and temperature sensors

- from individual sensors to a

complete system solution - you will

find sensor and control products to

suit your requirements.

Vision sensor

ifm has applied practical innovation to simplify complex vision technology.

The result: a product family that offers robust housing, simple set-up, and reliable

performance and cost-effectiveness. With the power of a vision system and the

simplicity of a sensor, the efector dualis vision sensor has proven success in

solving a broad range of error-proofing and inspection applications. These include

verification, orientation, sortation, part/no part detection, recipe, object character

verification and measurement. Features include a diecast metal housing rated

IP67, high performance, durability with no moving parts, fast image capture,

integrated lighting, high speed, flexible connection and easy set-up.

This vision technology provides the power of a vision system with the simplicity

of a sensor. Reliable functionality with a new benchmark for performance

and value.

Phone: 1300 365 088 Fax: 1300 365 070Email: [email protected]: www.ifm.com/au

Chris Hoey, Managing Director, Bürkert Fluid Control SystemsProcessing and manufacturing companies will capitalise on a rapidly advancing technological landscape in

2012. Continued international and domestic pressures will fuse with process technology investment for a fresh look at complete system design. Successful companies will take these challenges as opportunities to grow and develop. Trends to more sophisticated automation will continue to realise maximum produc-tion capacity and efficiency. The next evolution will be in mobile and cloud-based technologies, with 24/7 operation and unmanned remote sites more common. While commercial pressures will remain a strong factor, the elevated importance of plant availability will cause operators to mitigate high unplanned downtime costs with reliable partners and quality equipment. Companies will need partners that take responsibility for

understanding new technologies and how they best merge with the industrial environment. Partners with the resources to deliver complete system, support and training packages will fit this streamlined operative

model. Progressive specialisation will follow technology advances and extend the trend of outsourcing func-tions traditionally undertaken in-house.

Bürkert’s Sydney Systemhaus has grown further to accommodate new technologies and expanding activity; particularly in the water and wastewater, resources and hygienic processing sectors. A national network of industry specialists

has ensured the right partners are on the spot in each region, supporting adoption of innovative processing technologies.

Andrew Finch, Managing Director, Weidmüller Pty LtdClearly from an international economic perspective we are in unchartered waters. The investments swings we are witnessing have been massive since 2009 and very unpredictable. For Weidmüller, one of the key challenges will be successfully managing our industrial electronics manufacturing and solutions capability during such volatility. Product development, by its very nature, is an expensive and lengthy process and successfully balancing investment in technological development with economic fluctuations will be paramount.

Undertaking an effective risk assessment process for 2012 and beyond will also prove challenging for industrial electronic manufacturers. No doubt, a clear development and design strategy that uses modular and slice technology with multifunctional platforms, and a flexible, fast response manufacturing process will go some way to eliminating risk.

We expect that in 2012 our ability to fast track the development of unique, application-specific products will present some very exciting possibilities for Weidmüller. We can design and tailor-make solutions that meet the specific needs of customers, while maintaining a platform of consistency in line with standard products. This not only brings us closer to our customer, it clearly helps differentiate us because we are willing to solve problems. With the continuing rise of ‘smart’ technology in 2012, the industry in general will continue to focus on incorporating smart communication and automation technology in the industrial process.

David Delany, Managing Director, ifm efector pty ltdI believe that the carbon tax situation and the high Australian dollar mean that companies will need to

make efficiency gains and to put processes in place to deal with them, without adding significant costs to their business. For example, engaging in lean manufacturing and innovation, and providing new

products to market, or seeking out and entering new markets.There is also a shortage in skilled workers. This creates challenges in industry with employers

facing the pressure of not being able to fill positions and jobs being left vacant, often for long periods of time.

I believe that in terms of the economy there may be a bit more pain for industry to go through in 2012 before the situation begins to improve. However, the past has shown that Australian industry

is quite resilient and has handled many challenges over the years. It has survived, and in some cases flourished, despite these challenges. ifm invests significantly in research and design, and in

2012 this will create new opportunities in the market for us. For 40 years the company has been researching, developing and producing products and technology with the aim of optimising technical

processes. As a company focused on innovation and increasing the efficiency of your applications, we are constantly releasing new products to market and 2012 will be no exception.

Crystal Ball Gazing

2012

16 What's New in Process Technology - LEADERS OF INDUSTRY 2012

Dirk Kuiper, General Manager, AMS Instrumentation & Calibration Pty LtdIn my view, the next two to five years will see good growth in the instrumentation, process control and automation industry. This industry growth will be largely on the back of large projects in the mining industry and the oil and gas industry in Queensland, Western Australia and (to a lesser degree) South Australia and the Northern Territory. This will open up great opportunities for AMS, due to its product area of calibration, pressure, level and flow, and now the analytical range.

With these opportunities there will also come challenges, however. We see the key challenge lies in being able to maintain equipment supply to a broad range of geographically dispersed projects that are running concurrently or within a short time of each other. The companies that will succeed will be those that can deliver the right equipment on time, no matter where.

Competition will be fierce among the various instrumentation and automation companies, but with the AMS niche product range we are hopeful of seeing an increased market share in 2012. It was the intention of AMS to further its brand recognition and increase its range of suppliers to ensure further growth, and this has now been accomplished with a rationalisation of product ranges.

Scott Moffat, Managing Director, Pilz Australia Industrial AutomationImplementing the national harmonisation of the Australian OH&S laws in 2012 will be a large challenge for the safety industry next year. Mainly on two fronts: the bodies and regulators who are required to enact the new laws on a state-by-state basis, as well as the various companies spanning all local industries that are required to implement these changes. With the states still bickering over whether they will be included or not in the harmonisation as of 1 January 2012, and various industry bodies lobbying to have their interests included at the expense of harmonisation, I see little chance of the harmonisation happening before the deadline.

A key focus for us at Pilz Australia is educating the industry that safety is more than an add-on or necessary evil and should be an integral part of your overall control system - just like reliability, quality, throughput and accuracy. Too many people have the perception that safety systems are a hindrance to production and safety outcomes, and are only achieved at the expense business productivity. With this in mind we are planning on working closer with our end-user customers and increasing the level of integration, engineering support and expertise. In the end, highly technical products are only as good as the level of system design and implementation.

Greg Field, General Manager, Omron Electronic Pty LtdIn 2012, global business uncertainty and factors such as the carbon tax, the high Australian dollar and the

mining resource boom are expected to have a continuing impact on the Australian manufacturing market.Australian manufacturing provides employment opportunities in a variety of industries and, as a

backbone of employment in this country, we need to ensure its survival. To do this, the local industry needs to embrace technology, and the changes associated with it, to ensure its future. Companies need to recognise that investment in today’s and tomorrow’s technology can help them not only to survive, but to compete in the global markets of the future.

Omron Electronics is a world leader in factory automation products. We are accelerating our efforts to quickly produce and deliver to our customers value-added products and services embedded with the latest technologies and standards - so they can control their equipment with high speed, high precision and safety in a stress-free situation and with peace of mind.

It is often said that when one door closes another one opens, and while the debate continues about the carbon tax and whether it will be detrimental to current manufacturing, it may open up

new industries which will create new opportunities in the future.Energy conservation devices will be a means of adding further value to products besides productivity,

quality and safety in the field of machine automation. In order to do this we will make visible the state of power consumption and operation of machines and production lines. Based on the correlation there we

will be able to offer products developed on our core competencies of sensing and control that cut unneces-sary electricity consumption and help factories achieve their goals of meeting today’s environmental requirements.

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 17

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 19

INNOVATIONS WITH THE WORLD’S FIRST 14 " DIAMETER, 4-TUBE CORIOLIS FLOW METER

PRODUCT

When measuring flow rates up to 4100 tonnes per hour or

720,000 barrels per day of a valuable commodity like crude

oil in a big pipeline, accuracy is very important. An error of 1%

in the flow rate represents 300 barrels of crude oil per hour, or

about $30,000 per hour at the current price of $100 per barrel.

It has always been difficult to measure flow with accuracy in

large pipelines.

The Promass X, with its 0.05% accuracy, provides the best

accuracy of any flow meter for custody transfer on oil and gas

lines up to 16″ in diameter, ensuring that both the buyer and

the seller know exactly how much is changing hands. The 83X

model comes standard with fully traceable 0.1% flow accuracy

and optionally with a flow accuracy of 0.05%. For custody

transfer applications the 84X model features MID (OIML R117) and

PTB approvals.

The Promass X is the first commercially available four-tube Coriolis

mass flow meter. Its all 316L stainless steel construction makes it

ideal for onshore or offshore applications. Available with 12, 14 and

16-inch flanges, it replaces conventional flow measurement devices

in pipelines with a flow meter that’s more stable and has a lower

pressure drop.

This four-tube flowmeter has no moving parts, so maintenance is

exceptionally low when compared with other, more traditional types

of meter. Operating at temperatures of -50 to 180°C and process

pressures up to 100 bar with 316L secondary containment for increased

process safety, it is ideal for applications involving toxic or hazardous

liquids or gases.

New trend in slurry density measurement

Historically, nucleonic and differential pressure systems have been the norm for density

measurement of slurries. The density measurement is used for the calculation of process

variables like specific gravity, dry tones and concentration.

A new and increasingly popular solution using two flush-mounted ceramic pressure

transmitters offers a simple, cost-effective measurement of slurries. Compared to a nucleonic

system, it is half the price and avoids the radioactive licensing requirements. Traditional

differential pressure systems consist of metal diaphragms connected with metal capillaries.

The metal diaphragms are susceptible to abrasion, mechanical stress and impact damage,

while the capillaries incur significant inaccuracies due to ambient temperature variations.

Ceramic sensors are immune to all of these effects, and additionally are easily adapted for

‘hot-swap’ maintenance or change-out.

How it works

Two ceramic diaphragm Cerabar PMC71 pressure transmitters are flush mounted at a known

distance on a rising main pipe and the pressure at each point is fed to an intelligent field indicator.

As the pressure difference between the two transmitters is directly proportional to the density, the

field indicator can calculate the density of the medium inside the pipe. In addition to the density

of the medium, the pressure in the pipe or vessel is also provided. Measuring ranges are almost

infinite and are limited only by the possible distance between sensors, offering accuracies as

good as 0.05% and withstanding process temperatures up to 150°C.

COMPANY PROFILE

Endress+Hauser Australia Pty Ltd offers a complete range of

process measurement and instrumentation solutions.

The Endress+Hauser product range includes liquid analysis,

switch point detection and continuous measurement of level, flow,

pressure and temperature, as well as data recorders, displays,

power supplies and fieldbus technologies.

Service and sales offices are based in Sydney, Brisbane,

Melbourne and Perth, with additional sales offices in Adelaide,

Gladstone and Newcastle.

Phone: 02 8877 7000 Fax: 02 8877 7099Email: [email protected]: www.au.endress.com

Providing tried&true label print and apply solutions for over 25 years.

Featuring quality modular design for simple operation and maintenance, the M-Series is hard to beat. With the flexibility of 80 tamp arm options and built in bar-code scanners, the M-Series is packaged into durable cabinets for OH&S and environmental protection considerations.

Simple integration allows for easy management and setup, including IO and Ethernet capabilities, with an intelligent controller taking the complexity out of integration. Add to that insignia’s tailored agreements for technical support options and over 25 years experience - it’s no coincidence that the Domino M-Series is world class.

The Domino M-Series printer applicator range is reliable, adaptable, and has proven 99% up time.

Contact us to find out more about the Domino range.

Phone: 1300 467 446 | Email: [email protected] | Web: www.insignia.com.au

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 21

COMPANY PROFILEThe Winson Group, incorporating insignia and Signet, has

operated for over 40 years and is an Australian owned and

operated company. insignia provides a wide range of labelling,

coding and service packaging solutions to customers. The Winson

Group is a $90m business with 260 staff and offices located in

Darwin, Townsville, Mt Isa, Brisbane, Sydney and Melbourne.

Warehouses are strategically located in these regions to ensure

the most efficient supply chain handling and include multiple

production sites across Australia.

Phone: 1300 467 446 Fax: 1300 780 049Email: [email protected]: www.insignia.com.au

A UNIQUE OPTION FOR AUSTRALIAN MANUFACTURERS

PRODUCT

insignia offers a unique option to Australian companies who

have requirements for a labelling and coding partner. With over

40 years’ experience, insignia distributes leading labelling and

coding hardware brands such as Datamax O’Neil, Domino,

Zebra and Bixolon. They are also an award-winning label

manufacturer and national technical service supplier. Providing

all of these products and services means insignia customers

enjoy the complete confidence of their ‘one stop shop’ -

supplier to take ownership over the entire labelling and coding

solution from hardware, to consumables and maintenance.

Because insignia’s product range is technical and diverse,

the majority of their sales team are technical engineers with

years of industry knowledge and specified product expertise.

The strategy to recruit engineers is critical to ensuring seamless

integration of their products into customers’ production lines.

Likewise, insignia’s label manufacturing operation is based

on a foundation of trade-qualified printers operating state-

of-the-art printing presses and finishing equipment to ensure

consistent quality.

insignia’s sales team possesses an advanced knowledge

of GS1 (Global Barcode Standards Association), reassuring

customers with the latest knowledge of barcoding and supply

chain standards. Employees are required to attend GS1

certified training programs, ensuring they have the ability to

assist customers with SSCC pallet labelling and GTIN labelling

requirements. insignia is also GS1 ‘Print Accredited’, which

means all barcodes printed on press are verified as part of

standard quality procedures, an unmatched process in the

Australian marketplace.

Domino M-Series label printer applicator

The Domino M-Series automated carton and pallet labellers have recently been released and deployed

into GS1 standard carton and pallet labelling requirements, providing for greater reliability and quality

in critical labelling applications. Ensuring cartons and pallets meet GS1 standards is made easier with

built-in barcode check scanners to ensure accuracy and quality.

The modular design of the unit coupled with over 80 tamp arm options allows the M-Series to be

tailored for various applications and delivers simplistic operation and maintenance. Swedish built,

the M-Series features quality cabinets catering to OH&S and environmental protection standards.

The system’s height adjustment feature ensures labelling occurs at the correct heights for part and

full pallets.

The M-Series has the capability of hitting high speeds required on production lines, including new

even higher speed labelling capabilities for cartons. The Domino M-Series is simple to integrate,

featuring ethernet capabilities and eight I/O ports providing a wide range of feedback. Storing label

designs, formats, graphics and fonts is easy with the controllers’ intelligent in-built logic. This enables

the flow of communication via software to the system, enhancing operation speeds, ultimately reducing

network traffic.

The M-Series can be linked into existing software systems or coupled with insignia’s Factory Plus

software. Factory Plus caters to production changes, consistently checking that the correct label is set

to be applied on the correct product.

22 What's New in Process Technology - LEADERS OF INDUSTRY 2012

Code-reading vision sensorBalluff’s line of Sharpshooter vision sensors includes an ID version designed to read a large range of linear

barcodes and 2D data matrix codes, as well as optical character verification (OCV).

The vision sensor can read more than 10 types of linear barcodes, including PDF417 and 2D Data Matrix

codes. The Data Matrix code reader is designed to read both printed and direct part mark (DPM) based

marks. The ID version also has an OCV tool that can verify alphanumeric characters like date codes or

expiration codes that can typically coexist with barcodes. The vision sensor incorporates Balluff’s higher

resolution algorithm, providing the highest accuracy for code reading at a standard vision resolution of

640 x 480 pixels. The ID code reader is also ECC 200 compliant and includes an ethernet and serial

communication port as well as pass/fail I/O.

The vision sensor uses ConVis, the three-step Windows-based configuration software. Because the

software uses an ethernet network connection, multiple vision sensors can be monitored and configured

by a single PC. The vision sensor has a storage capacity of 20 configurations/jobs, remote job switching

via I/O, external lighting trigger and internal image storage.

Balluff-Leuze Pty Ltd

Contact info and more items like this at wf.net.au/K030

Integrated chassis and controllerThe NI cRIO-9075 and cRIO-9076 integrated chassis and controllers are

designed to lower the cost of the NI CompactRIO platform for embedded

control and monitoring applications.

The integrated systems combine an industrial 400 MHz Freescale real-time

processor and four-slot chassis with an embedded, reconfigurable Xilinx

Spartan-6 field-programmable gate array (FPGA) for custom timing, control

and signal processing capabilities. These RIO systems are programmable

with LabVIEW graphical system design tools and combine the ease of use

of commercial off-the-shelf (COTS) systems with the performance of custom

hardware. They are suitable for embedded control and monitoring applications within

industries such as energy, medical and robotics that require a short time to market, advanced control

algorithms and high-speed analog and digital I/O.

In addition to the 4-slot chassis and 400 MHz CPU, the cRIO-9075 offers 128 MB of DRAM and 256

MB of non-volatile storage, a 10/100 Mbps ethernet port and a RS232 serial port.

The cRIO-9076 offers the same as the cRIO-9075, but with increased DRAM and non-volatile memory

of 156 MB and 512 MB respectively, and a USB port.

Both operate from a single 9-30 VDC supply, have an operating temperature range of -20 to 55°C,

and can withstand 50 g shock or 5 g vibration.

National Instruments Australia

Contact info and more items like this at wf.net.au/K163

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 23

Introducing a smarter way to calibrate temperatureBeamex introduces a smarter, more effi cient and accurate solution for calibrating temperature. Beamex® has two different dry block series: the Beamex® FB Series Field Temperature Blocks and the Beamex® MB Series Temperature Metrology Blocks. The dry blocks in the FB Series are lightweight, high-accuracy temperature dry blocks for industrial fi eld use. The dry blocks in the MB Series deliver bath-level accuracy for industrial applications.

Beamex® FB Field Temperature BlockBeamex® MB Metrology Temperature Block

NEW!

Data loggerThe CAS DataLoggers dataTaker DT80M intelligent data logger

is a stand-alone data logger featuring extensive communications

capabilities. The unit can be used for a wide range of applications from

agriculture, weather station, hydropower and other outdoor projects.

The in-built 2G/3G modem emails data directly to an inbox

with automatic settings and alarms. Users can view real-time

measurements or logged data on the in-built web interface and

connect to sensors which support measurement of temperature,

voltage, current, 4-20 mA loops, resistance, bridges, strain gauges,

frequency, digital and SDI-12.

Features include: 18-bit resolution; simple set-up with dEX operator

interface; internal FTP server; analog and digital channels.

TechRentals

Contact info and more items like this at wf.net.au/K924

HART loop isolatorThe HIX HART loop isolator provides loop isolation while

allowing the HART signal to pass through uninterrupted.

It provides economical solutions to three common

and costly problems that plague many of today’s smart

HART loops. It can be used for splitting the HART

output of one transmitter safely between a DCS and

safety system without further burden on, or risk to, the

primary safety loop. It can also be used for surge, spike

and transient safeguarding to protect I/O cards - the

1500 VRMS isolating capability of the HIX breaks the

galvanic path that can pass dangerous overloads from

DCS to transmitter to PLC or vice versa, even when

equipment is supposedly isolated already. It also enables

area isolation to allow for equipment maintenance without

loop downtime, and allows HART devices on isolated

legs of a loop to be removed from the circuit without

affecting other equipment.

Moore Industries Pacific Inc

Contact info and more items like this at wf.net.au/L318

24 What's New in Process Technology - LEADERS OF INDUSTRY 2012

Tank gauging systemThe Raptor tank gauging system from Emerson Process Management

is based on open technology and is fully scalable. As a result, it is

easy to install exactly the devices needed today as well as adding or

replacing units tomorrow.

The system includes safety technologies to help protect plant assets,

the environment and human lives. One example is 2-in-1 functionality

- with two independent gauges in one single enclosure - providing

SIL3 safety for overfill prevention. There are also a number of other

dual-redundant configurations available to suit individual tank safety requirements.

Raptor is built around a line of 0.5 mm precision radar level gauges, plus

u l t r a - s t a b l e temperature transmitters with 3- or 4-wire multiple spot sensors. This results in high available

precision in net volume calculations for custody transfer and inventory management. Equipment such as

pressure and water bottom measurement sensors can also be added as well as operator interface software.

The system reduces installation costs by using the bus-powered 2-wire Tankbus that is based on self-

configuring Foundation fieldbus technology, allowing easy start-up and integration of all system units. The

tank units are intrinsically safe, which means no expensive cable conduits are required. Communication to

the control room can be made using Modbus over most existing cabling, or using other fieldbus standards.

The system can also emulate gauges from other manufacturers so that users can add Raptor units to their

existing system using the same cabling and control room infrastructure. The system can also include Emerson’s

Smart Wireless functionality.

Emerson Process Management

Contact info and more items like this at wf.net.au/H423

Real-time thermal imagerThe thermoIMAGER TIM from Micro-Epsilon is a miniature real-time

thermal imager with USB interface. It can measure temperatures

from -20 to 900°C with a thermal sensitivity of 0.1 K. The system has

exchangeable lenses with 9° FOV (field of view), 31° FOV and 64° FOV

- allowing temperature to be measured in a variety of object distances,

from close focus to far field focus. Optical resolution is 160x120 pixels.

Power supply and operation is via the USB 2.0 interface, so no

external power supply is required. Real-time video recording at 100 Hz frame rate is also possible. The software will

store the data to a file, which allows playback at user-defined speeds, such as in slow motion or frame-by-frame

if required. This means that the thermoIMAGER TIM is a suitable tool for R&D applications, failure diagnostics or

process monitoring.

Additionally the software can be used as a runtime application where the user is able to program and configure

a custom environment (multiple monitoring windows, alarms, hot spot localisation, line profile, etc). A programmable

process interface, hard-wired input and output (PIF in) enables external control and communication for the emissivity

of the target material, trigger functions, shutter control or alarm outputs.

The thermal imager also has analog outputs, and cable lengths of up to 100 m are available. The unit is compact

and lightweight at 250 g and has an environmental rating of IP67.

Bestech Australia Pty Ltd

Contact info and more items like this at wf.net.au/H166

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 25

Portable multifunction calibratorDespite its compact design and robust construction, the CEP6000

offers the functionality, accuracy and reliability of fixed installation

laboratory equipment and is ideally suited for on-site use.

The calibration instrument can be used to measure and

simulate thermocouples, resistance thermometers, current,

voltage and frequency, to source pulse trains and to measure

pressure. The insulated mA/V measuring channel also permits

complete transmitter calibration using a single instrument.

An accuracy of up to ±0.015% of the measured value makes

the CEP6000 suitable for virtually all calibration tasks.

The multifunction calibrator is protected by a rubber boot

and is both easy and quick to use. This is achieved via direct

entry on a numeric keypad, the three software-driven function

keys and the large, illuminated display.

The calibrator is suitable for a number of applications in

industry (laboratory, production, workshop), in calibration service

companies and service industries as well as for quality assurance.

WIKA Australia

Contact info and more items like this at wf.net.au/H564

Encoder signal converterThe Motrona IV251 SSI signal converter is suitable for use with all

SSI-type sensors and absolute encoders from 9 to 25 bits, either with

master mode or slave mode analog outputs of ±10 V, 0-20 mA or

4-20 mA, proportional to the encoder position.

RS232 and RS485 serial interfaces also provide for readout of the

actual encoder position. It is easy to set up by a simple teaching

procedure, or by PC operator software that also provides features

such as scaling, programmable linearisation curves and bit blanking

functions. The unit is powered from a 115/230 VAC supply.

Plant Control & Automation

Contact info and more items like this at wf.net.au/J970

26 What's New in Process Technology - LEADERS OF INDUSTRY 2012

RFID-based safety switchesThe Allen-Bradley Guardmaster SensaGuard range

is designed to provide secure safety switching,

diagnostics and monitoring in one package. Combining

RFID coding with an M23 Safety Distribution block,

SensaGuard is designed to simplify the integration of

multiple sensors.

RFID coding provides an additional level of security,

allowing a SensaGuard switch and actuator to be

paired with a specific code. This enhances safety

by reducing the possibility of other actuators being

used to bypass the switch.

The switch is paired with an actuator on initial

power-up and can be locked to this unit immediately.

If some flexibility is required, the switch can be

re-paired to another actuator up to eight times. After

the eighth time, it is locked to the last-paired actuator.

At any time during the pairing process, the switch

can be locked to a specific actuator permanently.

When multiple sensors are installed, the use of

the Allen-Bradley M23 Safety Distribution block helps

simplify integration. Available with either four or eight

ports, the Safety Distribution block provides the ability

to connect up to eight SensaGuards to meet Cat4/

SIL3/PLe, with an individual auxiliary contact from

each device going back to the control panel. This

provides specific diagnostic information for each door

or device to the control system. The LEDs on the

distribution block provide additional local diagnostic

information for troubleshooting. Shorting plugs for

unused ports, variable length 19-pin patchcords and

8-pin cordsets are available to provide full connectivity

and circuit safety.

Rockwell Automation Australia

Contact info and more items like this at wf.net.au/K542

Servo packageSEW-Eurodrive’s Smart Servo

Package is designed to make a

servomotor drive automation task

simpler and faster to implement and

contains all necessary components

for a complete automation solution in

a coordinated package.

The package is comprised

of programmable company

controllers, servo universal inverters,

servomotors close coupled to optional compact servo gear units and

ready-to-use accessories. It has been specifically optimised to suit

most applications in the power range up to 1.5 kW and at 230 VAC.

The use of a graphic configuration wizard to enter all axis-to-axis

relationships and preconfigure application properties is designed to

remove the need for time-consuming programming.

The package also introduced the Movitrac LTX single-phase universal

servo inverter. An integrated operator keypad provides easy access

to all parameters and commissioning data, while onboard digital and

analog I/Os, fieldbus gateway and encoder connections can all be

easily accessed from the front of the unit. High-level control solutions

for more demanding automation tasks are possible via a MoviPLC

position controller, while the analog interface can be used for simple

speed control or speed setpoint from an external position controller.

The standard package includes the company’s CMP servomotors

combined with the Movitrac LTX and prefabricated cables. Extensions to

the package can include a MoviPLC, CCU, gateway or the company’s

range of servo or 7 Series gear units. The system supports connection

to industrial fieldbus-based communications systems via the company’s

range of gateways or programmable controllers.

SEW-Eurodrive Pty Ltd

Contact info and more items like this at wf.net.au/J980

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 27

Flow switchThe Gems FS-600 Series flow switch has a robust,

‘no moving parts’ design that works with both

conductive and non-conductive fluids.

The FS-600 uses the cooling effect of a flowing

fluid or gas (calorimetric principle) to monitor

the flow rate. This temperature-based operating

principle can reliably sense the flow of virtually

any liquid or gas without using any moving parts.

It is also immune to changes in viscosity and is

suitable for clean fluids and some slurries, and

maintains reliability without filtration.

The FS-600 is made from durable stainless steel

and is available in various housings to suit a wide

variety of pipe sizes for flow rates from 0.5 to 41

L/min. All models have an IP65 M12 electrical

termination and include a 1 m cable assembly.

Longer cable assemblies are available. The port

sizes range from ½″ to 1½″ and the switch can

be mounted in any orientation. The FS-600 can

also be customised for volume OEMs with any

setpoint based on specific customer applications.

Control Components Pty Ltd

Contact info and more items like this at wf.net.au/K215

PAC power supply modulesThe 72 W APAX-5343 and -5343E

PAC power supply modules from

Advantech have passed Energy Star

compliance and provide a power

transmission efficiency of over 88%

from AC input to DC output, providing

power for more APAX modules.

The APAX-5343 and -5343E have

also passed UL 508 certification showing

that they are suitable for safe operation in industrial environments.

In order to protect the devices from overloading, voltage spikes and

short-circuits, they include an auto-recovery mode which ensures that

the APAX power supply will continue to work normally. The APAX-5343

is designed for APAX-5570 controller series, and the APAX-5343E is

for APAX expansion modules, such as APAX-5520 compact controllers,

APAX-5070 coupler series and relative APAX I/O series.

Advantech Australia Pty Ltd

Contact info and more items like this at wf.net.au/L012

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 29

OUR TEAM

PRODUCT

OUR COMPANYThis year, MSA Australia celebrates 50 years in

delivering safety products in Australia and New

Zealand. With Australian and global manufacturing

capability, MSA leads in the provision of sophisticated

safety products. MSA provides integrated solutions for

respiratory protection, gas detection, fall protection,

head, eye, face and ear protection. MSA has global

offices as well as offices and staff throughout Australia

and New Zealand. We are always close by to assist.

Why have we led for so long? We listen, we learn, we

act and we care.

Phone: 1300 728 672Website: www.msa.net.au

The MSA team is Australia’s leading safety solutions provider with hundreds of

years in combined safety experience locally and internationally. Our experience

and innovative products set us aside and help ensure our customers come

home safely every day.

MSA is a truly global organisation with offices and representatives around the

world. We have been protecting people in all walks of life, in many countries

and in many occupations for nearly 100 years. In Australia, MSA reaches

50 years of committed service this year.

Our executive team brims with technical safety experience supporting our

acclaimed ‘feet on the street’ sales and customer support team. It’s where

the ‘tyre hits the tarmac’ and real experience counts. MSA Australia delivers

over 100 years’ combined experience with a nationwide network of Account

Managers, Product Managers and Segment Managers.

Knowledge is the key to innovation and MSA excels in capturing real needs

and issues in the workplace and transforms safety through innovation. Driven

by our Global Steering Teams and our unique ‘Voice of Customer’ approach,

MSA is always in touch with the real issues related to safety. MSA’s goal is

to ensure its products not only improve worker safety but also make the task

easier.

Our approach is to capture real industry

wisdom through participation and

observation in the workplace. This,

combined with our technical knowledge,

leads to functional breakthroughs and

industry-driven advancements. The process

of assimilation of knowledge and real-world

development drives our engineers and

supports our mission “that men and women

may work in safety and that they, their

families and their communities may live in

health throughout the world”. This mission

drives our team.

With the Altair® single-gas detector, MSA sets a new market standard by offering over two

years of maintenance-free performance (depending on alarm minutes used). These long-life

cost-effective single-gas detectors offer dust and water protection and feature a distinct triple

alarm system.

The Altair® Pro single-gas detector is based on the design of the standard single-gas detector,

but with added features and functionality. It accurately measures the gas concentration or

percent oxygen and displays information on a large, clear, backlit LCD screen.

The Altair® 4X multigas detector comes from new sensor technology. The MSA XCell™ sensors

have a life of more than four years, double the industry average, and are engineered using

MSA’s proprietary application specific integrated circuit (ASIC) design. MSA XCell™ sensors are

a breakthrough in chemical and mechanical sensor design, enabling faster response and span

calibration times. The Altair® 4X is now NSW Underground Mines Registered.

MSA is proud to present the pinnacle of their portable gas detection range: the Altair® 5X multi-

gas detector with MSA XCell™ sensor technology. The Altair® 5X detector can measure up to six

gases simultaneously and can be fitted with a wide range of both toxic and infra-red sensors,

providing the flexibility required for meeting most applications.

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 31

OUR TEAM

PRODUCT

The Point to Point Group is a well-established, hands-free communication

specialist with a global presence. The group is the sole importer and

distributor for Bury Technologies hands-free products. It has recently

expanded its product portfolio to include the Midland 2 Way Radio range

of products and DryCase products, for Australia and New Zealand. Since

2003, the group has been a major wholesaler and distributor of hands-free

products and accessories in Australia and New Zealand.

Point to Point operates registered and trading companies across the world.

Its major hub offices are located in Melbourne - Australia, Delaware - United

States, and Auckland - New Zealand.

The group supplies a complete range of in-car, hands-free solutions and

accessories for cellular phones. The Bury brand is well

known throughout the world and is recognised as a leader

in the occupational health and safety (OHS) industry.

Point to Point Technology has exclusive distribution

rights for the Bury product range within Australia and

New Zealand, allowing the group to provide a two-year

nationwide advance warranty replacement on the car

kits and cradles, ongoing technical support for the life

of the product and a help desk facility that is operated

by PTP.

The Point to Point Group prides itself on working with

companies - with high-quality products - that continue

to push the boundaries in terms of creativity and

product features. For this reason, the group works very

closely with its manufacturers. Whether this is to meet

regulations, road rules, feature requirements or just the

product look and feel, we are active in the development.

Phone: 1300 550 720Fax: +61 3 9709 0999Email: [email protected]: http://www.ptp-group.net/

Bluetooth hard-wired car kit

The Bury CC9060IQ Bluetooth hard-wired car kit eliminates the need for users to touch a

handset or car kit while driving.

Its Magic Word feature continuously listens for the command “activate voice dial”.

On command, users receive a response via a menu and voice request awaiting instructions.

From this point on, the user is offered a wide range of menu-driven options including name

dial, number dial, access phonebook, view missed/received/dialled calls, multipoint, vocal

email read from a Blackberry handset, and two types of memo.

The Sync feature allows the pairing of 10 separate handsets. Without prompting, the kit will

read the phonebook entries.

The transfer rate is fast regardless of whether the user has 10 or 1000 contacts. For contacts

with three or more phone numbers, the unit prompts for the location required, such as home,

mobile or office. Alternatively, users can say “dial (John) mobile”.

Other features include: email read out loud from Blackberry handset and, if the handset

supports it, SMS messages can also be read out loud.

Combined with the company’s system 9, continuous charge of the handset and access to an

external antenna is allowed. It complies with current Australian legislation governing the use

of mobile phones in vehicles.

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 33

OUR TEAM

PRODUCT

PAFtec Australia is a company specialising in respirator design, manufacture

and global marketing. The company’s leading technology PAFtec CleanSpace®

is a state-of-the-art, low-profile, lightweight, powered respirator.

PAFtec was founded by engineers who understand that respiratory protection

should be comfortable, safe and user-friendly. Innovation and passion to

provide the highest quality products is at the heart of everything they do.

PAFtec CleanSpace® builds on a combination of technologies found in today’s

industrial respirators, medical respiratory devices and consumer electronics.

At the core of the technology is the company’s patented AirSensit Responsive

Flow Control System™ which responds to airflow demand breath by breath,

making it pleasant and easy to breathe, even in the most challenging

environments.

The PAFtec team has previously designed medical devices from concept to

manufacturing that are currently being used by millions of people around the

world. Over their professional careers they collectively hold 30 international

patents, three Australian design awards and an Engineering Excellence Award.

Their expertise is the reason our products are safe, robust

and high-performing even in the harshest environments. The

team is expert in every area of product development: design

of small and quiet motors, comfortable masks and control

algorithms; as well as an understanding of computational

flow dynamics to optimise filtered air needed breath by

breath. Above all, this team always has the wearer’s comfort

and protection at the heart of everything they do.

As a part of PAFtec's dedication to quality and reliability, the

company’s quality management system (QMS) is accredited

to the globally recognised ISO 9001 standard. In October

2010, PAFtec gained the Australian Standard AS/NZS 1716

certification for the PAFtec CleanSpace® . Following the

ISO 9001 certification in September, PAFtec anticipate that

the PAFtec CleanSpace® will achieve CE Mark (European

Certification) later this year, paving the way for European

sales early in 2012.

PAFtec CleanSpace® is the first Powered Air Purifying Respirator (PAPR) that offers all the benefits of a powered

respirator and the convenience and mobility of a high-profile air purifying respirator. Innovative features include:

world’s first neck-mounted respirator with no cables or hoses for revolutionary mobility; fits with existing safety

equipment - helmets, earmuffs or eyewear; a patented micro turbine that is responsive, tough and quiet; a

patented cushion system means the motor is very robust and able to withstand high impacts time and time

again (see the impact test video on the company website); soft, hygienic, non-allergenic,

medical-grade, silicone mask that is compliant and seals comfortably to the face and

is low profile; a simple clip means it can be easily changed between wearers or

removed for washing; AirSensit Responsive Flow Control System™ provides filtered

air breath by breath. The system detects the user’s breathing effort and adjusts the

flow to maintain a positive pressure within the mask at all times; PAFtec CleanSpace®

P2 accredited filter offers 99% filtration efficiency of particles 0.3 µm or above. It is

easy and intuitive to fit and it can be replaced in seconds.

PAFtec CleanSpace® is currently accredited in Australia and New Zealand. Although the

company has sales around the world from Canada to Taiwan, the product is currently undergoing

the European testing for CE Mark and Japanese testing for JIS to shortly enter Europe and Japan markets.

Phone: Jon Imms, sales representative (m) +61 437 446 453Email: [email protected]: www.paftec.com.au

PAFtec Australia Pty Ltd is an Australian company that

believes that comfort, mobility and performance are critical

to highly effective respiratory protection. Employers,

hygienists and workers who work with safety equipment in

their day to day jobs shouldn’t have to compromise – ever.

The company is targeting core markets where respiratory

protection is critical to workers across different industries

such as mining, resources, manufacturing, welding,

woodworking and agriculture.

COMPANY PROFILE

INTENSE PRESSUREAND TRYING NOT TO

BUST MY NUTS.

BUILT FOR THE TOUGHEST COUNTRY

LEADERS OF INDUSTRY 2012 - What's New in Process Technology 35

EVERY TRADIE NEEDS A MATEThe newest addition to the toughest range of workwear is here. Made for the

Aussie tradesman, ‘TradiesMate’ trousers have all the room needed for tools with extra comfort and protection for your knees. All of the pockets on these 100% Cotton canvas trousers are reinforced with Cordura fabric at the toughest wearing points. The rear pockets have a gusset so you can get your tools in and out with ease. The kneepads used along with the ‘TradiesMate’ trouser are lightweight and give a great amount of comfort and protection to the knees. Made from moulded rubber, they return to their usual shape after each use. Load up your tools and get started working with your new best mate - the ‘TradiesMate’.

OUR TEAMAt Worksense, we are continually committed to

maintaining product quality and providing service to our customers. Our Workwear Experts can visit your site and discuss garment requirements to cover and protect all employees (and site visitors) for both men and women.

Our fabrics are tested to Australian Standards to ensure consistency across the product range so we can provide high-quality apparel that you can rely on. Predefined QA procedures and regular monitoring from fabric to finished garments makes Worksense one of the leading providers of protective workwear in Australia.

We have identified and developed various types of fabrics and garments to cater for different levels of requirements within most industries. Some of these include:

• 100% cotton fabric in minimum weight of 160 gsm and up to a maximum of 320 gsm.

• High standard of colour fastness, meaning your colour stays bright and keeps you safer for longer (our yellow fabric surpasses the Australian Standard test for daytime visibility).

• Fire-retardant cotton fabrics treated with Pyrovatex from Huntsman offering superior fire protection.

• Permanant Fire Resistant Fabric - Firesistex for fire and arc flash advanced fire protection.

• Cordura incorporated into garment designs for extra abrasion resistance and garment longevity.

COMPANY PROFILEFor anyone working in industries such as mining, resources,

manufacturing or construction, protective clothing and equipment is not only highly regarded, it’s a non negotiable requirement.

Worksense is one of twelve companies within the Jeminex group. 100% Australian owned, Worksense specialises in workwear, clothing and personal protective equipment. We are a national company that has branches in every state, with 15 locations Australia wide. We take pride in the fact that as the manufacturer of our Workwear range, we control everything from the quality and quantities of production right through to the supply chain within our retail stores, distributors and customer direct.

Although it’s apparent that Worksense specialises in Workwear and PPE, one of our real strengths is our purchasing power through our network of Jeminex companies: Beaver Brands, Robertsons Lifting & Rigging, A & D Lifting, Heatleys Industrial and Safety, Addrill Drill & Blast, Impact Drilling, Pacific Drilling and Blasting, MDL Australia, Network Packaging, Bri-Tech and ECO.