What is Sampling ?

Transcript of What is Sampling ?

TAKAHIRO WATANABE, Dr

National Institute of Health Sciences, Japan

What is Sampling ?

General aspects of sampling and

the specified plan and procedure for aflatoxin testing

Regional Training Course “Strengthening Capacity in Data Collection and Generation for Food Safety Risk Analysis”

June 2013

Today’s topics

・General aspect of sampling

・The specified procedure of sampling for aflatoxin testing

・New Codex guidelines that is useful for understanding of sampling and testing

Sampling Characteristics of a lot are important in the fair trade of food. Knowledge of various characteristics helps marketers determine quality and negotiate prices for the lots. In the point of view of risk control, the amount of the specified contaminants is the important characteristics of a lot. For example, some of the characteristics that may be of interest are damaged kernels, moisture, protein, foreign material, and aflatoxin level for a grain lot. Knowing exactly what the lot contains is the desired outcome of inspection. The only way to know exactly what a lot contains is to inspect the entire lot. Inspecting the entire lot is usually cost-prohibitive and far more time consuming than the food market will tolerate. A representative sample, a small subset of the lot, can be inspected in a timely manner and at a reasonable cost.

Sampling

Sampling is the process of selecting food items (e.g., an apple, a packed confectionary, grain…) from a population of interest (e.g., lot, consignment) and preparing a sample which is representative of a lot. By analyzing a representative sample, we may fairly estimate mean of the population or number of defective items in the population. We can not obtain estimates of population mean or number of defective items in the population, which are scientific evidence required for relevant decision, without sampling and analysis (or examination). To prepare the representative sample, it is important to know the characteristics of a lot.

The worlds surround sampling

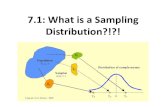

To understand “what is sampling?”, it is most important to recognaize the three worlds surround sampling clearly.

The worlds surround sampling are “population”, “ sampling”, and “ sample”.

Particulaly, It may be difficult to understand difference between

“the world of sampling” and

“the world of sample”.

The worlds surround sampling Population

Depth of the colre: concentration of an interest in a item

The total number of items of a definite population is the size of the population and is denoted by N. Item

𝜇 =1

𝑁 𝑦𝑖

𝑁

i=1

𝜎2 =1

𝑁 − 1 𝑦i

2

𝑁

i=1

−1

𝑁 yi

𝑁

i=1

2

µ:population mean

σ2:population variance

We want to know the value for the charactersitics of the population, that is µ and/or σ, but we can not do it.

y1

yi

y2 y3 y6 y7 y8 y9 y10 y5 y4

Population

y1

yi

y2 y3 y6 y7 y8 y9 y10y5y4

N = 10000

n=6

1.38681E+21 The number of the combination of 6 items

y2 y6 y8

yi

y1 y2 y3 y1 y6 y10

Sampling

Samples The total number of items of a sample is sample size and is denoted by n.

The worlds surround sampling

y2 y6 y8

yi

y1 y2 y3y1 y6 y10

Population

y1

yi

y2 y3 y6 y7 y8 y9 y10y5y4

Samping

Samples

yi

y1 y2 y3

One of all possible sample (1.38681E+21 samples)

𝑦 =1

n 𝑦i

n

i=1

𝑆2 =1

n − 1 𝑦i − 𝑦 2

n

i=1

μ s1, μ s2

, μ s3 , …… . μ si

The number of estimate of population mean: the number of samples

μ si= 𝑦 :sample mean

s2: sample variance

We can obtain only a limited number of sample mean. ( one of estimates of population mean.)

The worlds surround sampling

1) Statistical consideration let we know the number of all possible samples which are prepared by taking a definite number of items from a population is enormous.

2) Actually, one or a limited number of samples are analyzed to obtain the value of sample mean by taking the cost, time etc. into consideration.

3) Sample means are not always equal to the population mean. Though sample means are not equal to the population mean, they distribute around the population mean.

In food testing, we should accept the probability of wrongly decision (the probability of wrongly accepting or wrongly rejecting a lot or consignment).

We can never entirely eliminate inccorect decision

We make a decision basing on estimates (sample mean).

Making or choosing a relevant

・Sampling plan

The sampling comprises several stages

Defining the population of interest

・Sampling procedure Specifying a sampling procedure for selecting items, taking series of items from the population, and preparing the samples for anlysis

Determining the sample size

Defining the characteristics of population you want to know (Is the characteristics variables or attributes?)

The sampling in an actual inspection

Case. 1 Dressed Carcasses

Various lots and food items in the lot

One carcass is a item

Number of the item in the lot (lot size) is very small.

We can not take large number of item from the lot.

We should cut off a part of the item to prepare the test portion(s) for analysis.

Sampling plan Sampling procedure

Various lot and food items in the lot

Case. 2 Apples An apple is a item

Number of the item in the lot (lot size) is greater than as dressed carcass.

We can take relevant number of apples from the lot.

We prepare the test portion(s) for analysis.

Sampling plan Sampling procedure

Homogeneous paste prepared with defined number of apples

Various lot and food items in the lot

Case. 3 corn grain Defined number or weight of grains taken with a sampling equipment at one time is increment

Number of grain in the lot (lot size) is huge.

We can take relevant number of increment from the lot.

We should prepare the test portion(s) for analysis.

Sampling plan Sampling procedure

Homogeneous ground powder prepared with defined weight or number of kernel.

The number of kernel in the

increment or the increment weight is defined by sampling

equipment we used.

Is the lot dynamic or static ? Silo

Trailer or ship

Conveyor, etc.

Sampling procedure will be changed.

dynamic

static

How is the analyte distributed in the lot ?

Sampling plan (sample size: number of items taken from the lot ) are changed depending on the distribution pattern of analyte in the lot.

Nominal distribution

Log nominal distribution

Negative binominal distribution

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0.045

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

µ = 0

σ = 1 µ = 1

σ = 1

p = 0.1

k = 2 (red),

k = 5 (blue)

Example for distribution pattern

General aspects of the sampling

Basically, sampling plan are changed according to the characteristics of the lot (population) of interest, the distribution pattern of analyte in the lot and the purpose of the testing (conformity assessment, control of process, etc.). Therefore, we should select the most appropriate sampling plan, by taking cost, practicability and international harmonization etc. into consideration. It is necessary to know the general characteristics of sampling to perform the specific sampling for food testing.

Definitions of important terms relating sampling (from CAC/GL50) ・Lot A lot is a definite quantity of some commodity manufactured or

produced under conditions, which are presumed uniform for the purpose of these Guidelines.

Note: A continuous series of lots is a series of lots produced, manufactured or commercialized on a continuous manner, under conditions presumed uniform. The inspection of a continuous lots can only be achieved at the production or processing stage.

・Consignment A consignment is a quantity of some commodity delivered at one time.

It may consist in either a portion of a lot, either a set of several lot. However, in the case of statistical inspection, the consignment shall be

considered as a new lot for the interpretation of the lot. ・ If the consignment is a portion of a lot, each portion is considered as

a lot for the inspection. ・If the consignment is a set of several lots, before any inspection, care

shall be given to the homogeneity of the consignment.

Definitions of important terms relating sampling (from CAC/GL50)

・Sample (representative sample) Set composed of one or several items selected by different means in

a population. It is intended to provide information on a given characteristic of the studied population, and to form a basis for a decision concerning the population.

A representative sample is a sample in which the characteristics of the lot from which it is drawn are maintained. It is in particular the case of a simple random sample where each of the items or increments of the lot has been given the same probability of entering the sample.

・Sampling plan Planned procedure which enables one to choose, or draw separate

samples from a lot, in order to get the information needed, such as a decision on compliance status of the lot.

More precisely, a sampling plan is a scheme defining the number of items to collect and the number of non-conforming items required in a sample to evaluate the compliance status of a lot.

・The characteristic A characteristic is a property, which helps to identify, or differentiate

between, items within a given lot. The characteristic may be either quantitative (a specific measured amount, plan by variable), or qualitative (meets or does not meet a specification, plan by attributes).

・Operating characteristic curve For a given sampling plan, an Operating Characteristic (OC) curve describes the probability of acceptance of a lot as a function of its actual quality. It relates the rate of defective items in lot (x-axis) with the probability of accepting these lots at control (y-axis).

・Producer’s risk On the OC curve of a sampling plan, the producers’ risk is the probability to wrongly reject a lot.

・Consumer’s risk On the OC curve of a sampling plan, the consumers’ risk is the probability to wrongly accept a lot.

Definitions of important terms relating sampling (from CAC/GL50)

・Acceptable quality level (AQL) The AQL for a given sampling plan is the rate of non-conforming items

at which a lot will be rejected with a low probability. The AQL is used as an indexing criterion applied to a continuous series

of lots which corresponds to a maximum rate of acceptable defective items in lots.

For any given sample size, the lower the AQL, the greater the protection for the consumer against accepting lots with high defective rates, and the greater the requirement for the producer to confirm with sufficiently high quality requirements. Any value for AQL should be realistic in practice and be economically viable. If necessary, the value of AQL should take into account safety aspects.

It should be recognized that the selection of a value for the AQL depends on the specific characteristic considered and of its relevance (economic or other) for the standard in its whole. A risk analysis may be undertaken to assess the possibility and severity of negative impacts on public health caused.

Definitions of important terms relating sampling (from CAC/GL50)

・Limiting Quality (LQ) The LQ for a given sampling plan is the rate of non-conforming items

at which a lot will be accepted with a low probability. The LQ is applied when a lot is considered in isolation. It is a quality

level which corresponds to a specified and relatively low probability of acceptance of a lot having a rate of defective items of LQ. Generally, the LQ corresponds to the rate of defective items of accepted after control in 10% of the case.

The LQ is generally very low when the plans aim at the control of food safety criteria.

The users of sampling plans shall mandatory agree on the choice on

the AQL or LQ of the plan used for the quality control of the lots.

Definitions of important terms relating sampling (from CAC/GL50)

・A single sampling plan by attributes of AQL=2.5% ・The lot is accepted if there is nonconforming increment (c=0) in a sample of 5 increments (n=5), a nonconforming increment being one whose the analyte content is higher than the specification.

One example for performance evaluation of a sampling plan by OC curve.

In 50% of the case, lots having 13%of defective items are accepted at inspection.

In 10% of the case, lots having 36.5 %of defective items are accepted at inspection.

・Lot size and Sample size There is no mathematical relationship between sample size (n) and

lot size (N). Therefore, mathematically, there is no objection to take a sample of small size to inspection an homogeneous lot of large size. However, the designers of the plan in the ISO and other reference documents have deliberately introduced a relationships to reduce the risk of making an incorrect decision for larger lots. The ratio f = n/N influences the sampling error only when the lot size is small.

When the ratio f=n/N is less than or equal to 10%, and when the lots are assumed to be homogenous, it is absolute sample size is more important rather than its relationship to the size of the lot.

However, in order to reduce the risk of accepting large numbers of defective items, it is usual to increase the sample size as the lot size increases, especially when it is assumed that the lot is not homogenous.

Definitions of important terms relating sampling (from CAC/GL50)

・Representative sampling The representative sampling is a procedure used for drawing or

forming a representative sample. Random sampling involves the collection of n items from a lot of N

items in such a way that all possible combination of n items have the same probability of being collected. The randomness can be obtained by used of table of random number which can be generated by using computer software.

In order to avoid any dispute over the representativeness of the sample, a random sampling procedure should be chosen, whenever possible, alone, or in combination with other sampling techniques.

Definitions of important terms relating sampling (from CAC/GL50)

・Representative sampling (continued) Assuming the item can be numbered or ordered, even virtually

when it is not possible to have individual items (e.g., a silo of grain), the choice of the items or of the increments entering into the sample should be done as follows;

1. To number all the items or increment of the lot (true or virtual) 2. The numbers of the items or increments to be sampled are

determined randomly. The collection of samples is to be performed in a random manner,

whenever possible during the loading or unloading of the lot. If the lot is heterogeneous, a random sample may not be

representative of the lot. In such cases, stratified sampling may be a solution. Stratified sampling consist of dividing the lot into different strata or zones, each stratum being more homogenous than the original lot. Then a random sample is drawn from each of these strata.

Definitions of important terms relating sampling and notification (from CAC/GL50)

・Representative sampling (continued) When it is not possible to sample at random, for example in a very

large store where the goods are badly tidied or when the production process includes a periodic phenomenon (e.g. a contaminant which is specifically located in a particular area of the silo or a regulator detuned every each k seconds, such as every k seconds the products packaged by this regulator have defaults), it is mandatory:

1. To avoid preferentially choosing items which are more easily

accessible or which can be differentiated by a visible characteristic. 2. In the case of periodic phenomena, to avoid sampling every k

seconds or every Kth package, or every Kth centimetres, to take an unit from every nth palette, pre-package………

Definitions of important terms relating sampling and notification (from CAC/GL50)

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

Preamble Codex Food Standards are aimed at protecting consumers’ health and ensuring fair practices in the food trade. Codex Methods of Sampling are designed to ensure that fair and valid sampling procedures are used when food is being tested for compliance with a particular Codex commodity standard. The sampling methods are intended for use as international methods designed to avoid or remove difficulties which may be created by diverging legal, administrative and technical approaches to sampling and by diverging interpretation of results of analysis in relation to lots or consignments of foods, in light of the relevant provision(s) of the applicable Codex standard.

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

Basic recommendation for the selection of Codex sampling plans The following enumerates the essential points that the Codex commodity committees, governments and other users should address for the selection of appropriate sampling plans, when setting-up specifications.

1) Existence (or not) of international reference documents on sampling of the considered products.

One of the important international reference related to sampling is ISO standards. The standards are provided in the following. ・ISO 2854:1976(E): Statistical interpretation of data-Techniques of estimation and tests relating to means and variance. ・ISO 2859-0:1995(E): Sampling procedures for inspection by attributes-Part 0: Introduction to the ISO 2859 attribute sampling system. ・ISO 2859-1: 1999(E): Sampling procedures for inspection by attributes-Part 1: Sampling plans indexed by acceptable quality level (AQL) for lot-by-lot inspection. ・ ISO 2859-2: 1985(E): Sampling procedures for inspection by attributes-Part 2: Sampling plans indexed by limit quality (LQ) for isolated lot inspection.

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

ISO standards related to sampling plan and interpretation of test results(continued)

・ISO 3494:1976: Statistical interpretation of data- Power of test relating to means and variances. ・ISO 3951:1989: Sampling procedures and charts for inspection by variables for percent nonconforming. ・ISO 5725-1: 1994: Application of statistics-Accuracy (trueness and precision) of measurement methods and results-Part 1: General principles and definitions. ・ ISO 7002: 1986: Agricultural food products-Layout for a standard methods of sampling a lot. ・ ISO 8423: 1991: Sequential sampling plans for inspection by variables for percent nonconforming (known standard deviation) ・ ISO 8422: 1991: Sequential sampling plans for inspection by attributes. ・ ISO/TR 8550: 1994: Guide for the selection of an acceptance sampling system, scheme or plan for inspection of discrete items in lots. ・ ISO 10725: 2000: Acceptance sampling plans and procedures for the inspection of bulk material. ・ ISO 11648-1: 2003: Statistical aspects of sampling from bulk materials-Part 1: General principles ・ ISO 14560 : 2004: Acceptance sampling procedures by attributes-Specified quality levels in nonconforming items per million.

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

2) Nature of the control ・Characteristic applicable to each individual item of the lot ・Characteristic applicable to the whole lot (statistical approach) 3) Nature of the characteristic to control ・Qualitative characteristic (characteristic measured on a pass/failed or similar basis, i.e. presence of pathogen micro-organism) ・Quantitative characteristics (characteristic measured on a continuous scale, for example a compositional characteristics) 4) Choice of the quality level (AQL or LQ) ・In accordance with the principle laid down in the Codex Manual of Procedures and with the type of risk: critical/non-critical non-conformities. 5) Nature of the lot ・Bulk or pre-packed commodities ・Size, homogeneity and distribution concerning the characteristics to control

Basic recommendation(continued)

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

6) Composition of the sample ・Sample composed of a single sampling unit ・Sample composed of more than one unit (including the composite sample) 7) Choice of the type of sampling plan ・acceptance sampling plan for statistical quality control ・for control of average of the characteristic ・for the control for per-cent non-conforming items in the lot -Definition and enumeration of non-conforming items in the sample (attribute plans) -Comparison of the mean value of the items forming thesample with regards to an algebraic formula (variable plans) ・Convenience (or pragmatic, empirical) sampling plan

Basic recommendation(continued)

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

1.1 Purpose Sampling plans are required which ensure that fair and valid procedures are used when food is being controlled for compliance with a particular Codex commodity standard. Since numerous, yet often complex, sampling plans are available it is the purpose of these guidelines to help those responsible for sampling to select sampling plans that are appropriate for statistical inspections under specifications laid down by Codex standards. No sampling plan can ensure that every item in a lot conforms. These sampling plans are nevertheless useful for guaranteeing an acceptable quality level. These guidelines contain the elementary principles of statistical control at reception, which complete the basic recommendations laid down in the Preamble.

Section I. PURPOSE OF CODEX GUIDELINES ON SAMPLING

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

1.2 Target audience of the guidelines These Guidelines are above all aimed at Codex Commodity Committees which select from the plans recommended in sections 3, 4, and 5 those which at the time of the drafting of a commodity standard appear to them best suited for the inspection to be made. These Guidelines can also be used, if applicable, by governments in case of international trade disputes. The Codex commodity committees, Governments and other users should be provided with the competent technical experts needed for good use of these guidelines, including the selection of appropriate sampling plans.

Section I. PURPOSE OF CODEX GUIDELINES ON SAMPLING

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

1.3 Users of sampling plans recommended by the guidelines The sampling plans described in these Guidelines may be implemented either by Governmental food control authorities, or by professionals themselves (self-inspection performed by producers and/or traders). In the latter case, these Guidelines enable the governmental authorities to check the appropriateness of the sampling plans implemented by the professionals. It is recommended that the different parties concerned with sampling come to an agreement on the implementation of the same sampling plan for the respective controls.

Section I. PURPOSE OF CODEX GUIDELINES ON SAMPLING

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

1.4 Scope of the guidelines The following sampling situations are covered: ・for the control of only homogeneous goods These guidelines do not cover the control of ・non-homogenous goods

Section I. PURPOSE OF CODEX GUIDELINES ON SAMPLING

?

Homogeneous Non-homogeneous lot lot

Homogeneous: single distribution pattern exist in a lot.

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

1.4 Scope of the guidelines (continued) Section I. PURPOSE OF CODEX GUIDELINES ON SAMPLING

The following sampling situations are covered: for the control of only homogeneous goods: ・ control of percentage of defective items by attributes or by

variable, for goods in bulk or in individual items, ・ control of a mean content. These Guidelines do not cover the control of ・ non-homogeneous goods; ・ for homogeneous goods, the case where measurement error is

not negligible compared to sampling error, as well as the control of a qualitative characteristic in a bulk material and;

・ they do not deal with double, multiple and sequential sampling plan, deemed too complex in the frame of these Guidelines.

Supplement

Only simple random sampling is deal with CAC/GL 50.

Simple random sampling is simplest and most popular type of random sampling. In this sampling, items are chosen from a lot at random to prepare a sample. Every set of items making a sample, has an equal chance to be selected. There are other types of sampling including ‘Stratified sampling’, ‘Cluster sampling’, ‘Two-stage sampling’, ‘systematic sampling’, etc. other than simple random sampling. They are complex and will not be useful for food testing.

Simple random sampling

Sampling A sample Population

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

Table 1. Guide to selection of sampling plans for homogeneous lots

Lots consisting of

individualisable bulk material

Quantitative measurements Qualitative measurements

Inspection by variables of

bulk materials for percentage

non-conforming

Inspection by attributes for percentage

non-conforming

Microbiological inspection of product

Inspection by variables for

percentage non-conformingAverage content

Exm. Chek tank of milk for

added water

Exm1. inspection of pieces of fruit fo

defects

Exm2. Testing uncooked vegetables for

mesophilic aerobic micro-organisms

Exm. To check whether fat

content of a skimmed milk

powder complies with Codex

lilmit

Exm. To check that average

weight of items in a lot

complies with label

declaration (ISO 2854-1976,

3494-1976)

Inspection by variables of

bulk materials for percentage

non-conforming

Inspection by attributes for percentage

non-conforming

Microbiological inspection of product

Inspection by variables for

percentage non-conformingAverage content

Exm. Chek tank of milk for

added water

Exm1. inspection of pieces of fruit fo

defects

Exm2. Testing uncooked vegetables for

mesophilic aerobic micro-organisms

Exm. To check whether fat

content of a skimmed milk

powder complies with Codex

lilmit

Exm. To check that average

weight of items in a lot

complies with label

declaration (ISO 2854-1976,

3494-1976)

Quantitative measurements

Lots consisiting of individual items

Isolated lots

Continuous

series of lots

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

Two flow charts are shown as a systematic approach for the selection of a sampling plan.

Qualitative characteristics

Quantitative characteristics

Isolated los A continuous series of lots

Isolated los

To be sampled by attribute sampling plan for isolated lots

A continuous series of lots

To be sampled by attribute sampling plan for continuous lots

Bulk (e.g. fat content of

milk in tank)

To be sampled by variable sampling plan for a isolated lots

item (e.g. sodium content of

a dietary cheese)

Sampling by attributes

Bulk (e.g. fat content of

milk in tank)

To be sampled by variable sampling plan for a continuous series of lots

item (e.g. sodium content of

a dietary cheese)

To be sampled by attribute sampling plan for a continuous series of lots

Other definition (information) will be required for the setting or selection of an acceptance sampling plan and procedure is

・Lot size ・The limiting quality (LQ) level, or Acceptable quality level (AQL) ・The level of inspection ・The size of the sample ・The criteria for acceptance or rejection of the lot ・The procedure to be adopted in case of dispute

GENERAL GUIDELINES ON SAMPLING (CAC/GL 50-2004)

Characteristics of the sampling plan and procedure defined in CODEX STAN 193-1995 for testing of aflatoxin

・Isolated or continuous: Isolated lots ・ Bulk or item: Bulk

The characteristics of lots

・ Quantitative or Qualitative: Quantitative measure

The characteristics to be measurand

・ Variable or attribute: Variable ・ Distribution pattern: negative-binominal

Statistic characteristics of lots

CODEX STAN 193-1995 CODEX GENERAL STANDARD FOR CONTAMINANTS AND TOXINS IN FOOD AND FEED

1.1 SCOPE This Standard contains the main principles which are recommended by the Codex Alimentarius in dealing with contaminants and toxins in food and feed, and lists the maximum levels and associated sampling plans of contaminants and natural toxicants in food and feed which are recommended by the CAC to be applied to commodities moving in international trade.

Maximum level: Codex maximum levels (MLs) for a contaminant in a food or feed commodity is the maximum concentration of that substance recommended by CAC to be legally permitted in that commodity.

1.2.3 Natural toxins included in this standard The Codex definition of a contaminant implicitly include naturally occurring toxicants including metabolites of certain microfungi that are not intentionally added to food and feed (mycotoxins)

CODEX STAN 193-1995 CODEX GENERAL STANDARD FOR CONTAMINANTS AND TOXINS IN FOOD AND FEED

Toxins that are produced by algae and that may be accumulated in edible aquatic organisms such as shellfish (phycotoxins) are also included in this standard. Mycotoxins and phycotoxins are both subclasses of contaminants.

1.3.3 Specific criteria (for establishing MLs) The criteria should be considered when developing MLs and/or other measures in connection with the Codex General Standard for Contaminants and Toxins in Food and Feed. In this standard, the specific criteria are listed for

CODEX STAN 193-1995 CODEX GENERAL STANDARD FOR CONTAMINANTS AND TOXINS IN FOOD AND FEED

・Toxicological information ・Analytical data ・Intake data ・Technological considerations ・Risk assessment and risk management considerations

1.3.3 Specific criteria (continued)

CODEX STAN 193-1995 CODEX GENERAL STANDARD FOR CONTAMINANTS AND TOXINS IN FOOD AND FEED

Analytical data - validated qualitative and quantative data on representative samples; and - appropriate sampling procedures.

Specific criteria for

For the establishment of maximum levels (MLs) of contaminants in food and feed, several criteria should be considered. Sampling is one of these criteria. The data obtained following inappropriate sampling could not be scientific evidence to establish the MLs.

(CODEX STAN 193-1995) SCHEDULE I – total aflatoxins

AFLATOXINS, TOTAL

Toxicological guidance: Carcinogenic potency estimates for aflatoxins B, G, M (1997, Intake should be reduced to levels as low as reasonably possible) Residue definition: Aflatoxins total (B1 + B2 + G1 + G2) Synonyms: Abbreviations, AFB, AFG, with numbers, to designate specific compounds Related Code of Practice: ・Code of Practice for the Prevention and Reduction of Aflatoxin Contamination

in Peanuts (CAC/RCP 55-2004) ・ Code of Practice for the Prevention and Reduction of Aflatoxin Contamination

in Tree Nuts (CAC/RCP 59-2005) ・Code of Practice for Reduction of Aflatoxin B1 in Raw Materials and

Supplemental Feedingstuffs for Milk Producing Animals (CAC/RCP 45-1997) ・Code of Practice for the Prevention and Reduction of Aflatoxin Contamination

in Dried Figs(CAC/RCP 65-2008)

AFLATOXINS, TOTAL

Commodity

Code

Product

name

Level

(µg/kg)Type Reference Notes/Remarks for Codex Alimentarius

SO 0697 Peanut 15 MLThe ML applies to peanuts intended for further processing.

For sampling plan, see Annex 1 below.

TN 0660 Almonds 15 MLThe ML applies to almonds intended for further processing.

For sampling plan, see Annex 2 below.

Brazil nuts 10 MLThe ML applies to shelled ready-to-eat Brazil nuts.

For sampling plan, see Annex 1 below.

Brazil nuts 15 MLThe ML applies to shelled Brazil nuts destinated for further

processing. For sampling plan, see Annex 2 below.

TN 0666 Hazelnuts 15 MLThe ML applies to hazelnuts intended for further processing.

For sampling plan, see Annex 2 below.

TN 0675 Pistachios 15 MLThe ML applies to pistachios intended for further processing.

For sampling plan, see Annex 2 below.

TN 0660 Almonds 10 MLThe ML applies to almonds 'ready-to-eat'.

For sampling plan, see Annex 2 below.

TN 0666 Hazelnuts 10 MLThe ML applies to hazelnuts 'ready-to-eat'.

For sampling plan, see Annex 2 below.

TN 0675 Pistachios 10 MLThe ML applies to pistachios 'ready-to-eat'.

For sampling plan, see Annex 2 below.

(CODEX STAN 193-1995) SCHEDULE I – total aflatoxins

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

(CODEX STAN 193-1995, Annex 1)

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

INTRODUCTION 1. The sampling plan calls for a single 20 kg laboratory sample of

shelled peanuts (27 kg of unshelled peanuts) to be taken from a peanut lot (sub-lot) and tested against a maximum level of 15 μg/kg total aflatoxins.

2. This sampling plan has been designed for enforcement and

controls concerning total aflatoxins in bulk consignments of peanuts traded in the export market. To assist member countries in implementing the Codex sampling plan, sample selection methods, sample preparation methods and analytical methods required to quantify aflatoxins in bulk peanut lots are described in this document.

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

A. Definition Lot: an identifiable quantity of a food commodity delivered at

one time and determined by the official to have common characteristics, such as origin, variety, type of packing, packer, consignor or markings.

Sublot: designated part of a large lot in order to apply

the sampling method on the designated part. Each sublot must be physically separate and identifiable.

Sampling plan: is defined by an aflatoxin test procedure and

an accept/reject limit. An aflatoxin test procedure consist of three steps: sample selection, sample preparation and aflatoxin quantification. The accept/reject limit is a tolerance usually equal to the Codex maximum limit.

A. Definition (continued) Incremental sample: a quantity of material taken from a single random place in

the lot or sublot. Aggregate sample: the combined total of all the incremental samples taken

from the lot or sublot. The aggregate sample has to be at least as large as the 20 kg laboratory sample.

Laboratory sample: smallest quantity of peanuts comminuted in a mill.

The laboratory sample may be a portion of or the entire aggregate sample. If the aggregate sample is larger than 20 kg, a 20 kg laboratory sample should be removed in a random manner from the aggregate sample. The sample should be finely ground and mixed thoroughly using a process that approaches as complete a homogenisation as possible.

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

A. Definition (continued) Test portion: portion of the comminuted laboratory sample. The entire

20 kg laboratory sample should be comminuted in a mill. A portion of the comminuted 20 kg sample is randomly removed for the extraction of the aflatoxin for chemical analysis.

Based upon grinder capacity, the 20 kg aggregate sample can be divided into several equal sized samples, if all results are averaged.

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

Lot consisting of 9 sublot

Defined number of increment sample should be taken from the lot randomly. (quantity of increment sample was defined . (e.g. by size of sampling device )

Aggregate sample is the sample combined total of all increment samples. (The aggregate sample has to be larger than 20 kg)

Example 1

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

A portion of or the entire aggregate sample is comminuted in a mill. (The sample should be finely ground and mixed to homogenize)

Laboratory sample Test portion

The 20 kg aggregate sample can be divided into several equal sized samples, if all results are averaged.

A portion of the comminuted sample is randomly removed for analysis

SAMPLING PLAN FOR TOTAL AFLATOXINS IN PEANUTS INTENDED FOR FURTHER PROCESSING

B. Sampling

Material to be Sampled 3. Each lot which is to be examined must be sampled separately.

Large lots should be subdivided into sublots to be sampled separately. The subdivision can be done following provisions laid down in Table 1 below.

4. Taking into account that the weight of the lot is not always

an exact multiple of the weight of the sublots, the weight of the sublot may exceed the mentioned weight by a maximum of 20 %.

Table 1 Subdivision of Large Lots into Sublots for Sampling

5. The number of incremental samples to be taken depends on the weight of the lot, with a minimum of 10 and a maximum of 100.

Table 2 Number of Incremental Samples to be Taken Depending on the Weight of the lot

CommodityLot weight-tonne

(T)

Weight or number of

sublots

Number of

incremental samples

Laboratory sample

weight (kg)

≥500 100 tonnes 100 20

>100 and <500 5 sublots 100 20

≥25 and ≤100 25 tonnes 100 20

>15 and <=25 1 sublot 100 20

Peanuts

Lot weight

tonnes (T)

Number of incremental

samples

T≤1 10

1<T≤5 40

5<T≤10 60

10<T<15 80

When low weight is 500 tonnes

The lot should be subdivided into 5 sublots

Lot

sublots sublots

sublots

sublots sublots

Weight of sublot is 100 tonne

sublots sublots sublots sublots sublots

Number of incremental samples is 100

Weight of laboratory sample is 20 kg

6. Procedure used to take incremental samples from a peanut lot are extremely important. Every individual peanut in the lot should have an equal chance of being chosen. Biases will be introduced by the sample selection methods if equipment and procedures used to select the incremental samples prohibit or reduce the chances of any item in the lot from being chosen.

7. Since there is no way to know if the contaminated peanut

kernels are uniformly dispersed through out the lot, it is essential that the aggregate sample be the accumulation of many small portion or increments of the product selected from different locations throughout the lot. If the aggregate sample is larger than desired, it should be blended and subdivided until the desired laboratory sample size is achieved.

Incremental Sample selection

Procedure of random sampling should be completely done.

8. A static lot can be defined as a large mass of peanuts contained either in a single large container such as a wagon, truck, or railcar or in many small containers such as sacks or boxes and the peanuts are stationary at the time. Selecting a truly random sample from a static lot can be difficult because the container may not allow access to all peanut.

Static Lots

9. Taking a aggregate sample from a static lot usually requires the use of probing devices to select product from the lot. The probing devices used should be specially designed for the type of container. The probe should be long enough to reach all product, not restrict any item in the lot from being selected, and not alter the items in the lots. As mentioned above, the aggregate sample should be a composite from many small increments if product taken from many different locations throughout the lot.

Static Lots

Implements for manual sampling (Referred from ISO 11648-2 Statistical aspects of sampling from bulk material-Part 2:

Sampling of particulate materials)

A recommended design for a scoop as a sampling implement

7.4 Mass of increment for manual sampling implement designed to avoid bias

mI = 27 ρ・d3・10-6

mI ; is the mass (kg) of the increment

ρ ; is bulk density of the material (tonnes/m3)

mI ; is the nominal top size of the particles of the material (mm)

10. For lots traded in individual packages, the sampling frequency (SF), or number of packages that incremental samples are taken from, is a function of the lot weight (LT), incremental sample weight (IS), aggregate sample weight (AS) and the individual packing weight (IP), as follows

Equation 1: SF=(LT x IS)/(AS x IP). The sampling frequency (SF) is the number of packages sampled.

All weights should be in the same mass unit such as kg.

The lot weight; 500000 kg (500 t), Incremental sample weight ; 0.2 kg (number of increment is 100),

Aggregate sample weight; 20 kg, Ex. 1) when the individual packing weight is 1000 kg, SF is 5. Ex. 2) when the individual packing weight is 20 kg, SF is 25.

Static Lots

11. True random sampling can be more nearly achieved when selecting an aggregate sample from moving stream of peanuts as the lot is transferred, for example, by a conveyor belt from one location to another.

When sampling from moving stream, take small increments of product from the entire length of the moving stream; composite the peanuts to obtain an aggregate sample; if the aggregate sample is larger than the required laboratory sample, then blend and subdivide the aggregate sample to obtain the desired size of laboratory sample.

Dynamic lots

12. Automatic sampling equipment such as cross-cut sampler are commercially available with timers that automatically pass a diverter cup through the moving stream at predetermined and uniform intervals. When automatic equipment is not available, a person can be assigned to manually pass a cup though the stream at periodic intervals to collect incremental samples. Whether using automatic or manual methods, small increments of peanuts should be collected and composited at frequent and uniform interval throughout the entire time peanuts flow past the sampling point.

Dynamic lots

13. Cross-cut samplers should be installed in the following manner: (1) the plane of the opening diverter cup should be perpendicular to the direction of flow: (2) the diverter cup should pass through the entire cross sectional area of the stream; and (3)the opening of the diverter cup should be wide enough to accept all items of interest in the lot.

14. The size of the aggregate sample (S) in kg, taken from a lot by cross cut sampler is:

Dynamic lots

Equation 2: S=(D x LT)/(T x V). D; the width of the diverter cup opening (in cm), LT; the lot size

(in kg), T; interval or time between cup movement through the stream (in second), and V; cup velocity (in cm/sec)

15. If the mass flow rate of the moving stream, MR (kg/sec), is known, then the sampling frequency (SF), or number of cuts made by the automatic sampler cup is:

Equation 3: SF=(S x V)/(D x MR).

Dynamic lots

Automatic sampling equipment :cross-cut sampler

aggregate sample

increment

・weight of aggregate sample ・the width of the diverter cup opening ・the lot size ・interval or time between cup movement ・cup velocity

Combine and mix well

Dynamic lots

Automatic sampling equipment :cross-cut sampler

aggregate sample

increment

・weight of aggregate sample ・the width of the diverter cup opening ・the lot size ・interval or time between cup movement ・cup velocity

Combine and mix well

a

Cup opening width

Cup velocity

Cross-cut bucket

18. The weight of the incremental sample should be approximately 200 g or greater, depending on the total number of increments, to obtain an aggregate sample of 20 kg.

Weight of the Incremental sample

5. The number of incremental samples to be taken depends on the weight of the lot, with a minimum of 10 and a maximum of 100.

The weight of the incremental sample to be taken depends on the weight of the lot, with a minimum of 200 g and a maximum of 2 kg. The weight of aggregate sample of 20 kg does not depend on the weight of lot.

19. Each laboratory sample shall be placed in a clean, inert container offering adequate protection from contamination and against damage in transit. All necessary precautions shall be taken to avoid any change in composition of the laboratory sample which might arise during transportation or storage.

Packaging and transmission of samples

20. Each laboratory sample taken for official use shall be sealed at the place of sampling and identified. A record must be kept of each sampling, permitting each lot to be identified unambiguously and giving the date and place of sampling together with any additional information likely to be of assistance to the analyst.

Sealing and labeling of samples

C. Sample preparation

Precautions 21. Daylight should be excluded as much as possible during

the procedure, since aflatoxin gradually breaks down under the influence of ultra-violet light.

Homogenisation-Grinding 22. As the distribution of aflatoxin in extremely non-homogeneous,

samples should be prepared and especially homogenised with extreme care.

All laboratory sample obtained from aggregate sample is to be used for the homogenisation/grinding of the sample.

Homogenisation-Grinding (continued) 23. The sample should be finely ground and mixed thoroughly using

a process that approaches as complete a homogenisation as possible.

24. The use of a hammer mill with a #14 screen (3.1 mm diameter hole in the screen) has been proven to represent a compromise in terms of cost and precision. A better homogenisation (finer grind- slurry) can be obtained by more sophisticated equipment, resulting in a lower sample preparation variance.

Test portion 25. A minimum test portion size of 100 g taken from the laboratory

sample.

Aggregate sample: The aggregate sample has to be at least as large as the 20 kg laboratory sample.

Laboratory sample: The smallest quantity of peanuts comminuted in a mill. The laboratory sample may be a portion of or the entire aggregate sample. If the aggregate sample is larger than 20 kg, a 20 kg laboratory sample should be removed in a random manner from the aggregate sample.

How to prepare the test potion from a aggregate sample

Is weight of aggregate sample larger than 20 kg or not?

Can 20 kg of sample grind in a mill?

All result are averaged.

The 20 kg aggregate sample can be divided into several equal sized samples

20 kg Larger than 20 kg

20 kg

100 g of test portion

20 kg 20 kg

Equipments need to prepare a test portion (for example)

Larger than 20 kg

20 kg

20 kg

For taking 20 kg of laboratory sample from the aggregate sample which is larger than 20 kg in random manner

For homogenisation (grinding and mixing) of 20 kg of laboratory sample.

Open riffle Closed riffle

Hammer mill

D. Analytical methods

Background 26. A criteria-based approach, whereby a set of performance criteria is

established with which the analytical method used should comply, is appropriate. The criteria-based approach has the advantage that, by avoiding setting down specific details of the method used, developments in methodology can be exploited without having to reconsider or modify the specified method. The performance criteria established for methods should include all the parameters that need to be addressed by each laboratory such as the detection limit, repeatability coefficient of variation, reproducibility coefficient of variation, and the percent recovery necessary for various statutory limits.

Utilising this approach, laboratories would be free to use the analytical method most appropriate for their facilities. Analytical methods that are accepted by chemists internationally (such as AOAC) may be used. These methods are regularly monitored and improved depending upon technology.

Performance Criteria for Methods of Analysis ・ The detection limits of the methods used are not stated as

the precision values are given at the concentrations of interest; ・ The precision values are calculated from the Horowitz equation.

Criteiron Concentration Range Recommended ValueMaximum Permitted

Value

Blank All Negligible

1-15 µg/kg 70 to 110%

˃ 15 µg/kg 80 to 110%

Precision RSDR AllAs derived from Horowitz

Equation

2 x value derived from

Horwitz Equation

Precision RSDr may be calculated as 0.66 times Precision RSDR at the concentration of interest

Recovery-Aflatoxins

Total

Table 3: Specific Requirements with which Methods of Analysis should Comply

Horwitz equation

PRSDR = 2C-0.1505

Predicted relative standard deviation (PRSDR) is established as criterion for precision. PRSDR calculated from the Horwitz equation, i.e.;

Where: ・ RSDR is the relative standard deviation calculated from results generated

under reproducibility conditions. ・C is the concentration expressed as a mass fraction (both numerator and

denominator expressed in the same unit; i.e. 1=100 g/100 g)

Ex.) Calculation of PRSDR When the targeted concentration is 15 ppb

PRSDR = 2(0.000000015) -0.1505 = 43 (%)

27. This is a generalised precision equation which has been found to be independent of analyte and matrix but solely dependent on concentration for most routine methods of analysis.

SAMPLING PLAN FOR TOTAL AFLATOXINS IN READY-TO-EAT TREENUTS AND TREENUTS

DESTINED FOR FURTHER PROCESSING: ALOMONDS,HAZERNAUTS, PISTACHOS AND

SHELLED BRAZIL NUTS (CODEX STAN 193-1995, Annex 2)

SAMPLING PLAN DESIGN CONSIDERATIONS 1. Importers may commercially classify treenuts as either ʻready-

to-eatʼ (RTE) or ʻdestinated for further processingʼ (DFP). As a result, maximum levels and sampling plans are proposed for both commercially types of treenuts. Maximum levels need to be defined for treenuts destined for further processing and ready-to-eat treenuts before a final decision can be made about a sampling plan design.

2. Treenuts can be marketed either as inshell or shelled nuts. For example, pistachios are predominately marketed as inshell nuts while almonds are predominately marketed as shelled nuts.

SAMPLING PLAN DESIGN CONSIDERATIONS (continued)

3. Sampling statistics, shown in Annex I, are based upon the uncertainty and aflatoxin distribution among laboratory samples of shelled nuts. Because the shelled nut count per kg is different for each of the three treenuts, the laboratory sample size is expressed in number of nuts for statistical purpose. However, the shelled nut count per kg for each treenut, shown in Annex I. can be used to convert laboratory sample size from number of nuts to mass and vice versa.

SAMPLING PLAN DESIGN CONSIDERATIONS (continued) 4. Uncertainty estimates associated with sampling, sample preparation, and

analysis shown in Annex I, and the negative binominal distribution are used to calculate operating characteristic (OC) curves that describe the performance of the proposed aflatoxin-sampling plans (Annex II)

Negative binominal distribution Suppose there is a sequence of independent Bernoulli trials, each trial having two potential outcomes called “success” and “failure”. In each trial the probability of success is p and of failure is 1 − p. We are observing this sequence until a predefined number x of failures has occurred. Then the random number of successes (k) we have seen, will have the negative binomial distribution. The probability mass function of the negative binomial distribution is

f(x) = ( )(1-p)k px x

x+k-1

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

P = 0.1 K =2(blue) or 5(red)

CONSIDERATIONS FOR ANALYTICAL METHODS In Annex I, the analytical variance reflects a reproducibility relative standard

deviation of 22%, which is suggested by Thompson and is based upon Food Analysis Performance Assessment Scheme (FAPAS) data. A relative standard deviation of 22% is considered by FAPAS as an appropriate measure of the best agreement that can be reliably obtained between laboratories. An analytical uncertainty of 22% is larger than the within laboratory variation measured in the sampling studies for the four treenuts.

The issue of correcting the analytical test result for recovery is not addressed in this document. However, Table 2 specifies several performance criteria for analytical methods including suggestions for the range of acceptable rates.

MAXIMUM LEVELS AND PRACTICABILITY OF AFLATOXIN TESTING An aflatoxin-sampling plan is defined by an aflatoxin test procedure and

a maximum level. A value for the proposed maximum level and the aflatoxin test procedure are given below in this section.

The maximum levels for total aflatoxin in treenuts (almonds, hazelnuts, and pistachios and shelled brazil nuts) “ready-to-eat” and “destined for further processing” are 10 and 15 µg/kg, respectively.

Choice of the number and size of the laboratory sample is a compromise

between minimizing risks (false positive and false negatives) and costs

related to sampling and restricting trade. For simplicity, it is recommended

that the proposed aflatoxin sampling plans use a 20 kg aggregate sample for

all four treenuts.

MAXIMUM LEVELS AND TESTING PROCEDURE The two sampling plans (RTE and DFP) have been designed for enforcement

and controls concerning total aflatoxins in bulk consignments (lots) of treenuts traded in the export market.

Treenuts destined for further processing (MLs; 15 µg/kg) Number of laboratory samples 1 Laboratory sample size 20 kg Almonds – shelled nuts Hazelnuts – shelled nuts Pistachios – inshelled nuts (equivalent to about 10 kg shelled

nuts that is calculated on the basis of the actual edible portion in the sample)

Brazil nut – shelled nuts

MAXIMUM LEVELS AND TESTING PROCEDURE (Continued) Sample preparation Sample shall be finely ground and mixed thoroughly using a process, e.g., dry

grind with a vertical cutter mixer type mill, that has been demonstrated to provide the lowest sample preparation variance.

Analytical method Performance based (see Table 2) Decision rule If the aflatoxin test result is less than or equal to 15 µg/kg total aflatoxins,

then accept the lot. Otherwise, reject the lot.

The operating characteristic curve describing the performance of the sampling plan for the four treenuts destined for further processing is shown in Annex II.

Ready-to-eat treenuts (MLs; 10 µg/kg) Number of laboratory samples 2 Laboratory sample size 10kg Almonds – shelled nuts Hazelnuts – shelled nuts Pistachios – inshelled nuts (equivalent to about 5 kg shelled

nuts per test sample that is calculated on the basis on the actual edible portion in the sample)

Brazil nuts– shelled nuts Sample preparation Sample shall be finely ground and mixed thoroughly using a process, e.g., dry

grind with a vertical cutter mixer type mill, that has been demonstrated to provide the lowest sample preparation variance. Preferably, Brazil nuts should be ground as slurry.

Analytical method Performance based (see Table 2) Decision rule If the aflatoxin test result is less than or equal to 10 µg/kg total aflatoxins in

both test samples, then accept the lot. Otherwise, reject the lot.

The operating characteristic curve describing the performance of the sampling plan for the four ready-to-eat treenuts is shown in Annex II.

MAXIMUM LEVELS AND TESTING PROCEDURE (Continued)

SAMPLE SELECTION Material to be sampled Each lot, which is to be examined for aflatoxin, must be sampled separately. Lots

larger than 25 tonnes should be subdivided into sublots to be sampled separately. If a lot is greater than 25 tonnes, the number of sublots is equal to the lot weight in tonnes divided by 25 tonnes. It is recommended that a lot or a sublot should not exceed 25 tonnes.

The minimum lot weight should be 500 kg. Taking into account that the weight of the lot is not always an exact multiple

25 tonne sublots, the weight of the sublot may exceed the mentioned weight by a maximum of 25 %.

Sample should be taken from the same lot, i.e. they should have the same batch

code or at the very least the same best before date. Any changes which would affect the mycotoxin content, the analytical determination or make the aggregate samples collected unrepresentative should be avoided. For example do not open packaging in adverse weather conditions or exposure samples to excessive moisture or sunlight.

Avoid cross-contamination from other potentially contaminated consignments nearby.

SAMPLE SELECTION Material to be sampled

The lot should be subdivided into 5 sublots

Larger than 25 tonnes (Case 1, 125 tonnes)

sublots

sublots

sublots sublots

Sublots (25 t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

Case 2, when the weight of lot is 130 tonnes (not multiple of 25 tonnes)

Sample must be taken from each sublot

Sublots (25t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

Sublots (30t)

Maximum of 25% excess (31.25 tonnes) may be accepted Do not open packaging in adverse weather conditions

or exposure sample to excessive moisture or sunlight. Cross-contamination should be avoided from other potentially contaminated consignments nearby.

15. In most cased any truck or container will have to be unloaded to allow representative sampling to be carried out.

If you have sampling equipment such as spear, it permits to perform the sampling without loading from truck.

SAMPLE SELECTION Material to be sampled

SAMPLE SELECTION (Incremental Sample Selection)

Procedures used to take incremental samples from a treenut lot are extremely important. Every individual nut in the lot should have an equal chance of being chosen. Biases will be introduced by sample selection methods if equipment and procedures used to select the incremental samples prohibit or reduce the chance of any item in the lot from being chosen.

Since there is no way to know if the contaminated treenut kernels are

uniformly dispersed throughout the lot, it is essential that the aggregate sample be the accumulation of many small incremental samples of product selected from different locations throughout the lot. If the aggregate sample is larger than desired, it should be blended and subdivided until the desired laboratory sample size is achieved.

The important things regarding selection of incremental sample are common in peanut and treenut.

Random sampling should be completely done.

SAMPLE SELECTION Number of Incremental Samples for Lots of varying weight The number and size of the laboratory sample(s) will not vary with lot

(sublot) size. However, the number and size of the incremental samples will vary with lot (sublot) size.

The number of incremental samples to be taken from a lot (sublot) depends on the weight of the lot. Table 1 shall be used to determine the number of incremental samples to be taken from lots or sublots of various sizes below 25 tonnes. The number of incremental samples varies from a minimum of 10 and to a maximum of 100.

a: minimum aggregate sample size = laboratory sample size of 20 kg. b: 1 Tonne = 1000 kg c: minimum incremental sample size = laboratory sample size / minimum number of incremental samples.

Table 1

Lot or Sublot

Weightb

(T in Tonnes)

Minimum Number

of Incremental

Samples

Minimum

incremental Sample

Sizec (g)

Minimum aggregate

Sample Size (kg)

T < 1 10 2000 20

1 ≤ T < 5 25 800 20

5 ≤ T < 10 50 400 20

10 ≤ T < 15 75 267 20

15 ≤ T 100 200 20

SAMPLE SELECTION Weight of the Incremental Sample

The suggested minimum weight of the incremental sample should be approximately 200 g for lots of 25 metric tonnes (25000 kg).

The number and/or size of incremental samples will have to be larger than that suggested in Table 1 for lots size below 25000 kg in order to obtain an aggregate sample greater than or equal to the 20 kg laboratory sample.

SAMPLE SELECTION

Sample must be taken from each sublot

Larger than 25 tonnes(ex. 125 tonnes)

sublots

sublots

sublotssublots

Sublots(25 t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

Sublots (25t)

25 tonnes

200 g of incremental sample (number of incremental sample is 100)

1 tonnes

2000 g of incremental sample (number of incremental sample is 10)

In any case, the weight of aggregate sample is same

Case 1

Case 2

Case 3

20 kg

SAMPLE SELECTION Static lot 21. A static lot can be defined as a large mass of treenuts contained

either in a large single container such as a wagon, truck or railcar or in many small containers such as sacks or boxes and the nuts are stationary at the time a sample is selected. Selecting a truly random sample from a static lot can be difficult because all containers in the lot or sublot may not be accessible.

22. Taking incremental samples from a static lot usually requires the use

of probing devices to select product from the lot. The probing devices should be specifically designed for the commodity and type of container. The probe should be long enough to reach all products, not restrict any item in the lot from being selected, and not alter the items in the lot. As mentioned above, the aggregate sample should be a composite from many small increment samples of product taken from many different locations throughout the lot.

These considerations are the same as that forpeanut.

SAMPLE SELECTION Static lot (continued) 23. For lots traded in individual packages, the sampling frequency (SF),

or number of packages that incremental samples are taken from, is a function of the lot weight (LT), incremental sample weight (IS), aggregate sample weight (AS) and the individual packing weight (IP), as follows:

Equation 1: SF=(LT x IS)/(AS x IP). 24. The sampling frequency (SF) is the number of packages sampled.

All weight should be in the same mass units such as kg.

These considerations are the same as that forpeanut.

SAMPLE SELECTION Dynamic lot 25. Representative aggregate samples can be more easily produced when selecting

incremental samples from a moving stream of treenuts as the lot is transferred from one location to another. When sampling from a moving stream, take small incremental samples of product from the entire length of the moving stream; composite the incremental samples to obtain an aggregate sample; if the aggregate sample is larger than the required laboratory sample(s), then blend and subdivide the aggregate sample to obtain the desired size laboratory sample(s).

26. Automatic sampling equipment such as cross-cut sampler are commercially available with timers that automatically pass a diverter cup through the moving stream at predetermined and uniform intervals. When automatic equipment is not available, a person can be assigned to manually pass a cup though the stream at periodic intervals to collect incremental samples. Whether using automatic or manual methods, incremental samples should be collected and composited at frequent and uniform intervals throughout the entire time the nuts flow past the sampling point.

27. Cross-cut samplers should be installed in the following manner: (1)the plane of the opening of the diverter cup should be perpendicular to the direction of flow: (2) the diverter cup should pass through the entire cross sectional area of the stream; and (3)the opening of the diverter cup should be wide enough to accept all items of interest in the lot. As a general rule, the width of the diverter cup opening should be about two to three times the largest dimensions of items in the lot.

These considerations are the same as that forpeanut.

SAMPLE SELECTION Dynamic lot

28. The size of the aggregate sample (S) in kg, taken from a lot by a cross cut sampler is:

Equation 2: S=(D x LT)/(T x V). D; the width of the diverter cup opening (in cm), LT; the lot size

(in kg), T; interval or time between cup movement through the stream (in second), and V; cup velocity (in cm/sec)

29. If the mass flow rate of the moving stream, MR (kg/sec), is known, then the sampling frequency (SF), or number of cuts made by the automatic sampler cup can be computed from Equation 3 as a function of S, V, D, and MR.

Equation 3: SF=(S x V)/(D x MR).

These considerations are the same as that forpeanut.

SAMPLE SELECTION Dynamic lot

29. Equation 2 and 3 can also be used to compute other terms of interest such as the time between cut (T). For example, the time (T) required between cuts of the divert cup to obtain a 20 kg aggregate sample from a 20000 kg lot where the divert cup width is 5.0 cm and the cup velocity through the stream 30 cm/sec. Solving for T in Equation 2,

T = (5.0 cm x 20000 kg)/ (20 kg x 20 cm/sec) = 250 sec

30. If the lot is moving at 500 kg per minute, the entire lot will pass through the sampler in 40 minutes (2400 sec) and only 9.6 cuts (9 incremental samples) will be made by the cup through the lot (Equation 3). This may be considered too infrequent, in that too much product (2083.3 kg)passes through the sampler between the time the cup cuts through the stream.

These considerations are the same as that forpeanut.

32. Each laboratory sample shall be placed in a clean, inert container offering adequate protection from contamination, sunlight, and against damage in transit. All necessary precautions shall be taken to avoid any change in composition of the laboratory sample which might arise during transportation or storage. Samples should be stored in a cool dark place.

Packaging and transmission of samples

33. Each laboratory sample taken for official use shall be sealed at the place of sampling and identified. A record must be kept of each sampling, permitting each lot to be identified unambiguously and giving the date and place of sampling together with any additional information likely to be of assistance to the analyst.

Sealing and labeling of samples

These considerations are the same as that forpeanut.

Sample preparation

Precautions Sunlight should be excluded as much as possible during the procedure, since

aflatoxin gradually breaks down under the influence of ultra-violet light. Also, environmental temperature and relative humidity should be controlled and not favor mold growth and aflatoxin formation.

Homogenisation-Grinding As the distribution of aflatoxin in extremely non-homogeneous, laboratory

samples should be homogenized by grinding the entire laboratory sample received by the laboratory. Homogenization is a procedure that reduces particle size and disperses the contaminated particles evenly throughout the comminuted laboratory sample.

The laboratory sample should be finely ground and mixed thoroughly using a process that approaches as complete a homogenisation as possible. Complete homogenization implies that particle size is extremely small and the variability associated with sample preparation (Annex I) approaches Zero. After grinding, the grinder should be cleaned to prevent aflatoxin cross-contamination.

Sample preparation

Homogenisation-Grinding (continued) The uses of vertical cutter mixer type grinders that mix and

comminute the laboratory sample into a paste represent a compromise in terms of cost and fineness of grind or particle size reduction. A better homogenization (finer grind), such as a liquid slurry, can be obtained by more sophisticated and should provide the lowest sample preparation variance.

One example of vertical cutter mixer

SAMPLE SELECTION Test portion

The suggested weight of the test portion taken from the comminuted laboratory sample should be approximately 50 g. If the laboratory sample is prepared using a liquid-slurry, the slurry should contain 50 g of nut mass.

Procedures for selecting the 50 g test portion from the comminuted

laboratory sample should be random process. If mixing occurred during or after the comminution process, the 50 g test portion can be selected from any location throughout the comminuted laboratory sample. Otherwise, the 50 g test portion should be the accumulation of several small portions selected throughout the laboratory sample.

It is suggested that three test portions be selected from each

comminuted laboratory sample. The three test portions will be used for enforcement, appeal, and confirmation if needed.

ANALYTICAL METHODS Background

41. A criteria-based approach, whereby a set of performance criteria

is established with which the analytical method used should comply, is appropriate. The criteria-based approach has the advantage that, by avoiding setting down specific details of the method used, developments in methodology can be exploited without having to reconsider or modify the specific method. The performance criteria established for methods should include all the parameters that need to be addressed by each laboratory such as the detection limit, repeatability coefficient of variation (within laboratory), reproducibility coefficient of variation (among laboratory), and the percent recovery necessary for various statutory limits. Analytical methods that are accepted by chemists internationally (such as AOAC) may be used. These methods are regularly monitored and improved depending upon technology.

These descriptions are almost the same as the descriptions for the case of peanut.

ANALYTICAL METHODS Performance Criteria for Methods of Analysis

A list of criteria and performance levels are shown in Table 2. Utilizing this approach, laboratories would be free to use the analytical method most appropriate for their facilities.

Table 2: Specific Requirements with which Methods of Analysis Should Comply

CriteironConcentration

Range (ng/ g)

Recommended

Value

Maximum

Permitted Value

Blank All Negligible n/a

1 to 15 70 to 110% n/a

˃ 15 80 to 110% n/a

1 to 120Equation 4 by

Thompson

2 x value derived from

Equation 4

˃ 120 Equation 5 by Horwiz2 x value derived from

Equation 5

1 to 120Calculated as 0.66

times Precsion RSDR

n/a

˃ 120Calculated as 0.66

times Precsion RSDrn/a

Recovery

Precision or Relative

Standard Deviation

RSDR (Reproducibility)

Precision or Relative

Standard Deviation

RSDr (Repeatability)

ANALYTICAL METHODS Performance Criteria for Methods of Analysis

The detection limits of the methods used are not stated. Only the precision values are given at the concentrations of interest. The precision values are calculated from equation 4 and 5 developed by Thompson and Horwitz and Albert, respectively.

Equation 4: RSDR= 22.0 (%) (for C ≤ 120 µg/kg or c ≤ 120 x 10-9) Equation 5: RSDR= 2(1-0.5log C) = 2 C -0.1505 (for C ˃ 120 µg/kg or c ˃ 120 x 10-9) ・ RSDR = the relative standard deviation calculated from results generated under reproducibility

conditions ・ RSDr = the relative standard deviation calculated from results generated under repeatability

conditions = 0.66 RSDR ・ c = the aflatoxin concentration ratio (i.e. 1 = 100 g/ 100 g, 0.001 = 1000 mg/kg) ・C = aflatoxin concentration or mass of aflatoxin to mass of treenuts (i.e. ng/g)

ANALYTICAL METHODS Performance Criteria for Methods of Analysis

Equation 4 and 5 are generalized precision equations, which have been found to be independent of analyte and matrix but solely dependent on concentration for most routine methods of analysis

Horwitz, W., Kamps, R.L., Boyer, K.W.: Quality assurance in the analysis of foods for trace constituents, J. Assoc. Off. Anal. Chem. 63, 1344-1354 (1980) Thompson, M.: Recent trends in inter ̶ laboratory precision at ppb and sub ̶ ppb concentrations in relation to fitness for purpose criteria in proficiency testing, Analyst. 125, 385-386 (2000)

Results should be reported on the edible portion of the sample.

REPORT OF ANALYTICAL RESULTS

Annex 2 SAMPLING PLAN FOR TOTAL AFLATOXINS IN READY-TO-EAT TREENUTS AND TREENUTS DESTINED FOR FURTHER PROCESSING: ALMONDS, HAZERNAUTS AND PISTACHOS

Annex I Uncertainty, as measured by the variance, associated with sampling, sample preparation, and analytical steps of the aflatoxin test procedure used to estimate aflatoxin in almonds, hazelnuts, pistachios and shelled Brazil nuts. Sampling, sample preparation, and analytical variance associated with testing almonds, hazelnuts, pistachios and shelled Brazil nuts was estimated.

And these variance estimates and the negative binominal distribution were used to compute operating characteristic curves for each treenut.

Measurement uncertainty (terms of definition; CAC/GL72) Non-negative parameter characterizing the dispersion of the values being attributed to a measurand, based on the information used.

Uncertainty Most quantitative analytical results take the form of “a ± 2u or a ± U” where “a” is the best estimate of the true value of the concentration of the measurand (the analytical result) and “u” is the standard uncertainty and “U“(equal to 2u) is the expanded uncertainty. The range “a ± 2u” represents a 95% level of confidence (K=2) within which the true value would be found (in other cases can be increased as K=3 (99%)). The value of “U“ or “2u”is the value which is normally used and reported by analysts and is referred to as “measurement uncertainty” and may be estimated in a number of different ways.

Uncertainty arising from sampling Uncertainty arising from sampling have not been clearly defined yet.

An example of use of measurement uncertainty CAC/GL 70 (GUIDELINES FOR SETTLING DISPUTES OVER ANALYTICAL (TEST) RESULTS )

Scope These guidelines provide guidance to governments on the procedures to resolve disputes which arise between food control authorities about the status of a food consignment, when the assessment based on test results made in the importing country disagrees with the assessment made by the exporting country on the same lot. These guidelines only address disputes related to methods of analysis or laboratory performance and do not address questions of sampling. The procedure examines only the validity of the importing country’s results on which non-compliance is alleged.

・validation status of the methods of analysis used ・raw data ・results of repeat analysis ・internal quality assurance/control ・performance in relevant proficiency testing ・official accreditation status of the laboratories

An example of use of measurement uncertainty

CAC/GL 70 (GUIDELINES FOR SETTLING DISPUTES OVER ANALYTICAL (TEST) RESULTS )

For settling disputes

Step 1: The analytical results and procedure of the laboratory of the exporting country and its counterpart in the importing country are compared.

The dispute is not solved

Step 2:Reserve sample analyzed

An example of use of measurement uncertainty

CAC/GL 70 (GUIDELINES FOR SETTLING DISPUTES OVER ANALYTICAL (TEST) RESULTS )

For settling disputes

Step 2:Reserve sample analyzed

The procedure to settle the dispute basing on quality of analytical results (measurement uncertainty)

If the original test result of the importing country and the result of the reserve sample differ by less than the critical difference Δ that would be expected from measurement uncertainty of the results (see Annex), the importing country’s original assessment of the lot shall stand, and the dispute is thus resolved.

Δ=(U12 + U2

2)1/2 U1: expanded uncertainty associated to the results from exporting country U2: expanded uncertainty associated to the results from importing country

Annex I Uncertainty, as measured by the variance, associated with sampling, sample preparation, and analytical steps of

the aflatoxin test procedure used to estimate aflatoxin in almonds, hazelnuts, and pistachios.

Table 1. Variancesa associated with the aflatoxin test procedure for each treenut.

a: Variance S2 (s, sp, and a denote sampling, sample preparation, and analytical steps, respectively, of aflatoxin test procedure)

b: ns = laboratory sample size in number of shelled nuts, nss = test portion size in gram, na = number of aliquots quantified by HPLC, and C = aflatoxin concentration in µg/kg total aflatoxin.

c: Shelled nut count/kg for almonds, hazelnuts, pistachios and Brazil nuts is 773, 1000, 1600, 185 respectively. d: Sample preparation for almonds, hazelnuts, and pistachios reflect Hobart, Robot Coupe and Marjaan Khatman

type mill, respectively. Laboratory samples were dry ground into a paste for each treenut except for Brazil nut that were prepared as slurry Brazil nut/water 1/1 w/w.

e: Analytical variances reflect FAPAS recommendation for upper limit of analytical reproducibility uncertainty. A relative standard deviation of 22% is considered by Thompson as an appropriate measure of the best agreement that can be obtained between laboratory. An analytical uncertainty of 22% is larger than the within laboratory uncertainty measured in the sampling studies for the four treenuts

Test Procedure Almonds Hazelnuts Pistachios Shelled Brazil nuts

Samplingb,c

S2

s = (7730/ns)5.759C1.561

S2s = (10000/ns)4.291C

1.609S

2s = (8000/ns)7.913C

1.475S

2s = (1850/ns)4.8616C

1.889

Sample Prepd

S2

sp = (100/nss)0.170C1.646

S2sp = (50/nss)0.021C

1.545S

2sp = (25/nss)2.334C